If you were to fill a room with the top engine builders in the world, you’d be surprised to hear the various opinions on what part of the engine needs the most focus. Is compression the Holy Grail? Or is it cylinder pressure? Or does none of that really matter because the old adage is true: there’s no replacement for displacement. In truth, all of those key points as well as many other variables play major roles in the engine building process.

The area that all engine builders can agree upon is valve timing and how much a camshaft can affect an engine. To use an analogy, the camshaft’s “profile” is the music sheet to a symphony. Sure all the musicians can read and play the music on the sheet, but if it’s the wrong song, or a different song than what the conductor is leading, then things aren’t going to run that smoothly. The same principal rings true when choosing the right camshaft for an engine.

When choosing a camshaft it’s best to get information on the entire vehicle and not just the engine components. Items such as transmission type, convertor stall and size, differential ratio, and tire size should be recorded to help determine your final decision. When considering what engine components will work with your choice of cam, some of the obvious areas need to be put into consideration as well; items such as engine displacement, compression ratio, fuel delivery type (carb or fuel injection), and cylinder head volume. Some often overlooked variables include what type of driving you will be doing, and in what type of climate and altitude you live in, and how long you typically run the vehicle, as some cam profiles can make huge horsepower numbers at a dragstrip, however the same camshaft can make driving your vehicle on the street close to impossible. Also, will you be adding nitrous, a supercharger, a turbo, or making a cylinder head change? Other items that can help make the camshaft more efficient include an air intake system, a performance manifold, or even a performance exhaust system.

So now that we’ve concluded that changing your engines’ camshaft includes a lot of decision making, let’s focus on the reasons why you want to change your engine’s camshaft in the first place: more horsepower and more torque! As the engine’s sheet music, it plays a crucial role in your engine. The camshaft is paired to the crankshaft by a set of gears tied together by a chain. When the crankshaft makes a revolution the gear on the crank turns the chain that turns the camshaft at an accelerated rate, as many as four times faster depending on how many valves need to be controlled. The camshaft then opens and closes the valves in the cylinder heads in a timed sequence where two roles need to be addressed. The mixed fuel from the intake manifold and cylinder head can enter the combustion chamber and the spent gases from the combustion cycle exiting the engine’s cylinders to the exhaust manifold simultaneously. Again, think of the conductor’s white stick as he directs the musicians to play in harmony. Now try to envision a stick with funny oval shapes moving in perfect harmony as your engine is operating.

| Before we jumped into the swap, we made sure that everything was in place, including our performance camshaft from COMP Cams, plus their Break-In Oil, which will ensure proper molecular mating with the camshaft/roller lifters combo. The existing oil was drained from the engine as well as the engine’s coolant.

Now what are those funny oval shapes and what is the difference between a stock camshaft and a performance camshaft? It has to do with timing, as changing the size and shape of those ovals dictates the way the valves are opened and closed, which, in turn, affects the efficiency of the combustion process. If the intake valves can be held open longer, more air/fuel can enter the combustion chamber. When this happens, and the fuel is ignited, you’ll get a larger explosion, thus pushing the piston down faster and turning the crankshaft over at an accelerated rate. What this means is the bigger the boom, the faster the truck. However, depending on the rest of the components there are limits to a camshaft’s success where again a camshaft’s profile, or how it’s been sized, makes all the difference in the world. So if we know this as truth then why doesn’t the factory just set the specs to make more power in the first place? Well, my friends, there is a give and take to camshaft timing, and when variables are changed from factory specs, things such as how well the engine will start and idle and even its fuel economy fall victim to the gods of horsepower.

Let’s take a look at some of the terminology that one should know to make the right camshaft selection. The first thing to review is camshaft lift and duration. Lift refers to how tall the camshaft’s lobes are and how high they force the pushrods up to operate the rocker arms, which, in turn, open and close the valves. Changing these ratios from stock specs increases the delivery of fresh air/fuel, and spent gases, or exhaust. Duration is how long the camshaft keeps the valves open during operation. This is critical, since there is a lag of how long it takes to open and close valves. During such a time it is possible to have both the intake and exhaust valves open at the same time. This is referred to as “overlap,” and overlap gives the engine a chance at building more efficiency of getting the old gas out, and the new gas in.

Although there are other key points to camshaft timing, we wanted to give you the basics on what a camshaft looks like, and how to change out a stock camshaft for a performance model. We chose to show you a cam swap on a ’14 LT1-equipped GM fullsize, since the LT1 series engines are known to pick up good numbers in horsepower as well as torque over the stock choice. This is a great upgrade to the LT1 truck engine; the Corvette numbers are off the charts and new camshaft combinations are continuing to pop up at a rapid rate. Looking for the right answers, we gave the folks at COMP Cams a call to look into the world of LT1 truck cam swaps and what type of results we would expect to see. COMP was more than cooperative in assisting us by choosing the proper camshaft for the type of driving that we plan to inflict on this ’14 GM truck. This model will remain as a daily driver, but it may also see some local Saturday night dragstrip time, so we want to be able to build some good power while maintaining the convenience of early morning cold starts, smooth idle functions, and decent fuel mileage. Sounds like the best of both worlds to us, so let’s take a look at what it takes to install one. And check back here soon, as we have some more power adders planned for this particular ’14 Chevy.

-

-

Disassembly of the front accessories as well as the cooling fans, air intake box, and just about everything from the front of the engine has to be removed. The lower crank pulley requires the use of a puller to remove, as this component is a press fit.

| Timing Chain Cover Removal

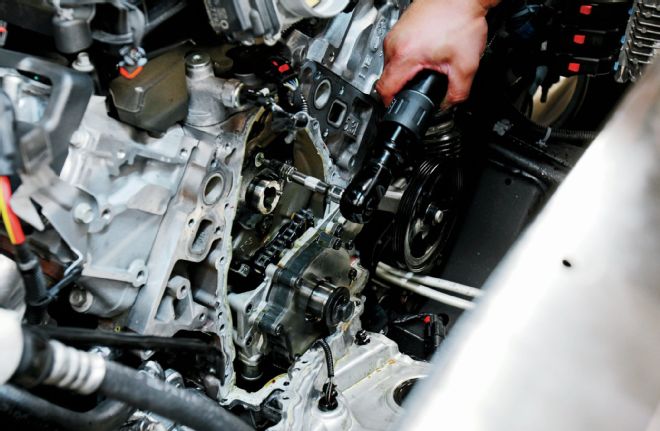

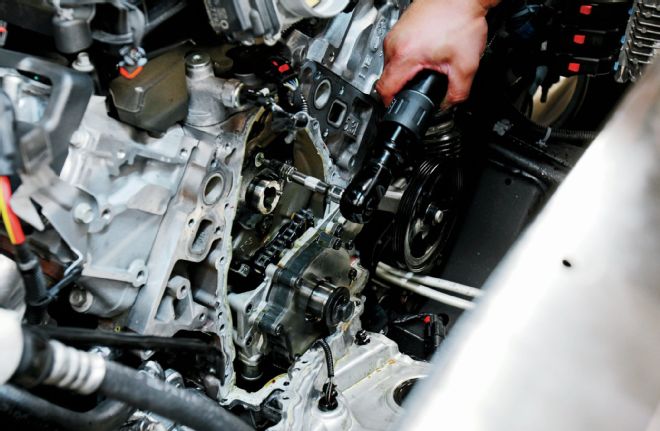

After the lower pulley was removed, the timing chain cover could be removed as well to expose the cam gear, and timing chain and the oil pump.

| Cam Gear Removal

The cam gear was removed after the engine was marked at TDC, or top dead center. This will assist the assembler with reinstalling the camshaft back into the proper timing position. Behind the cam gear sits a retainer plate that will keep the cam from “walking” back and forth while under high rpm situations. This plate will also need to be removed.

Next, the rocker arms and pushrods were removed and laid out in pairs to be reinstalled back to their original location.

The lifters will need to be pulled back off the cam’s lobes, so the intake manifold will need to be removed as well as the lifter valley plate.

Now the stock cam can be removed, only to be replaced by the COMP Cams unit (PN 624-512-13). COMP’s Revolutionary GM Gen V Camshafts (LT1/L83/L86) are designed to work with the direct injection (DI), variable valve timing (VVT) and Active Fuel Management (AFM) lifters featured in GM’s new Gen V V-8 engine. This means that these new XFITM series hydraulic roller cams allow users to leverage the OE technology for performance gains. Having the lifters removed allows us to carefully slide the camshaft back into the block. Be sure to use the provided assembly lube from COMP.

-

-

One of the features that was carried over from the later LS Series engine design introduced in 2010 was the variable timing features on the camshaft. On the front of the camshaft a phaser that uses oil pressure to advance or retard the cam through a range of 62 degrees of engine rotation relies on a signal sent from the engine control module that directs the phaser to advance or retard cam timing, depending on driving demands. A performance camshaft such as the one we’re using from COMP requires a Phaser limiter kit (PN 5456), which limits the range of camshaft movement from 62 to 22 crank degrees, thus requiring VVT program tuning.

The cam gear is realigned back to the timing marks, pairing it once again to the crankshaft gear by the timing chain. Once everything is back in place, the cam gear fastener is torqued to spec.

Now all of the remaining components are set back into place, including the timing cover, pulley, and accessories.

| Comp Cams Break In Oil

It’s common practice that when new valvetrain components are installed a process of “wearing in” the camshaft, lifters, lifter bores, distributor gears, and valveguides is done. It is critical to the longevity of all the components. All surfaces must “mate” each other at a molecular level, since the wear surfaces of the cam lobes, as well as the lifters, and most of the other components see only a microscopic level of oil while under operation. This may sound familiar to some of you who have changed out a flat-faced or solid camshaft before, but studies have shown that even roller lifter–equipped engines benefit from using break-in oil. It’s highly recommended for roller lifters and, of course, mandatory for flat-faced or follower-designed camshafts.

Comp Cams Break-In Oil was poured back into the engine as well as fresh engine coolant before the truck was started back up and ran, so the new camshaft could be bought up to operating speed before sending it on its way down the road.

| Before we jumped into the swap, we made sure that everything was in place, including our performance camshaft from COMP Cams, plus their Break-In Oil, which will ensure proper molecular mating with the camshaft/roller lifters combo. The existing oil was drained from the engine as well as the engine’s coolant.

Now what are those funny oval shapes and what is the difference between a stock camshaft and a performance camshaft? It has to do with timing, as changing the size and shape of those ovals dictates the way the valves are opened and closed, which, in turn, affects the efficiency of the combustion process. If the intake valves can be held open longer, more air/fuel can enter the combustion chamber. When this happens, and the fuel is ignited, you’ll get a larger explosion, thus pushing the piston down faster and turning the crankshaft over at an accelerated rate. What this means is the bigger the boom, the faster the truck. However, depending on the rest of the components there are limits to a camshaft’s success where again a camshaft’s profile, or how it’s been sized, makes all the difference in the world. So if we know this as truth then why doesn’t the factory just set the specs to make more power in the first place? Well, my friends, there is a give and take to camshaft timing, and when variables are changed from factory specs, things such as how well the engine will start and idle and even its fuel economy fall victim to the gods of horsepower.

Let’s take a look at some of the terminology that one should know to make the right camshaft selection. The first thing to review is camshaft lift and duration. Lift refers to how tall the camshaft’s lobes are and how high they force the pushrods up to operate the rocker arms, which, in turn, open and close the valves. Changing these ratios from stock specs increases the delivery of fresh air/fuel, and spent gases, or exhaust. Duration is how long the camshaft keeps the valves open during operation. This is critical, since there is a lag of how long it takes to open and close valves. During such a time it is possible to have both the intake and exhaust valves open at the same time. This is referred to as “overlap,” and overlap gives the engine a chance at building more efficiency of getting the old gas out, and the new gas in.

Although there are other key points to camshaft timing, we wanted to give you the basics on what a camshaft looks like, and how to change out a stock camshaft for a performance model. We chose to show you a cam swap on a ’14 LT1-equipped GM fullsize, since the LT1 series engines are known to pick up good numbers in horsepower as well as torque over the stock choice. This is a great upgrade to the LT1 truck engine; the Corvette numbers are off the charts and new camshaft combinations are continuing to pop up at a rapid rate. Looking for the right answers, we gave the folks at COMP Cams a call to look into the world of LT1 truck cam swaps and what type of results we would expect to see. COMP was more than cooperative in assisting us by choosing the proper camshaft for the type of driving that we plan to inflict on this ’14 GM truck. This model will remain as a daily driver, but it may also see some local Saturday night dragstrip time, so we want to be able to build some good power while maintaining the convenience of early morning cold starts, smooth idle functions, and decent fuel mileage. Sounds like the best of both worlds to us, so let’s take a look at what it takes to install one. And check back here soon, as we have some more power adders planned for this particular ’14 Chevy.

| Before we jumped into the swap, we made sure that everything was in place, including our performance camshaft from COMP Cams, plus their Break-In Oil, which will ensure proper molecular mating with the camshaft/roller lifters combo. The existing oil was drained from the engine as well as the engine’s coolant.

Now what are those funny oval shapes and what is the difference between a stock camshaft and a performance camshaft? It has to do with timing, as changing the size and shape of those ovals dictates the way the valves are opened and closed, which, in turn, affects the efficiency of the combustion process. If the intake valves can be held open longer, more air/fuel can enter the combustion chamber. When this happens, and the fuel is ignited, you’ll get a larger explosion, thus pushing the piston down faster and turning the crankshaft over at an accelerated rate. What this means is the bigger the boom, the faster the truck. However, depending on the rest of the components there are limits to a camshaft’s success where again a camshaft’s profile, or how it’s been sized, makes all the difference in the world. So if we know this as truth then why doesn’t the factory just set the specs to make more power in the first place? Well, my friends, there is a give and take to camshaft timing, and when variables are changed from factory specs, things such as how well the engine will start and idle and even its fuel economy fall victim to the gods of horsepower.

Let’s take a look at some of the terminology that one should know to make the right camshaft selection. The first thing to review is camshaft lift and duration. Lift refers to how tall the camshaft’s lobes are and how high they force the pushrods up to operate the rocker arms, which, in turn, open and close the valves. Changing these ratios from stock specs increases the delivery of fresh air/fuel, and spent gases, or exhaust. Duration is how long the camshaft keeps the valves open during operation. This is critical, since there is a lag of how long it takes to open and close valves. During such a time it is possible to have both the intake and exhaust valves open at the same time. This is referred to as “overlap,” and overlap gives the engine a chance at building more efficiency of getting the old gas out, and the new gas in.

Although there are other key points to camshaft timing, we wanted to give you the basics on what a camshaft looks like, and how to change out a stock camshaft for a performance model. We chose to show you a cam swap on a ’14 LT1-equipped GM fullsize, since the LT1 series engines are known to pick up good numbers in horsepower as well as torque over the stock choice. This is a great upgrade to the LT1 truck engine; the Corvette numbers are off the charts and new camshaft combinations are continuing to pop up at a rapid rate. Looking for the right answers, we gave the folks at COMP Cams a call to look into the world of LT1 truck cam swaps and what type of results we would expect to see. COMP was more than cooperative in assisting us by choosing the proper camshaft for the type of driving that we plan to inflict on this ’14 GM truck. This model will remain as a daily driver, but it may also see some local Saturday night dragstrip time, so we want to be able to build some good power while maintaining the convenience of early morning cold starts, smooth idle functions, and decent fuel mileage. Sounds like the best of both worlds to us, so let’s take a look at what it takes to install one. And check back here soon, as we have some more power adders planned for this particular ’14 Chevy.

| Timing Chain Cover Removal

After the lower pulley was removed, the timing chain cover could be removed as well to expose the cam gear, and timing chain and the oil pump.

| Timing Chain Cover Removal

After the lower pulley was removed, the timing chain cover could be removed as well to expose the cam gear, and timing chain and the oil pump.

| Cam Gear Removal

The cam gear was removed after the engine was marked at TDC, or top dead center. This will assist the assembler with reinstalling the camshaft back into the proper timing position. Behind the cam gear sits a retainer plate that will keep the cam from “walking” back and forth while under high rpm situations. This plate will also need to be removed.

| Cam Gear Removal

The cam gear was removed after the engine was marked at TDC, or top dead center. This will assist the assembler with reinstalling the camshaft back into the proper timing position. Behind the cam gear sits a retainer plate that will keep the cam from “walking” back and forth while under high rpm situations. This plate will also need to be removed.

| Comp Cams Break In Oil

It’s common practice that when new valvetrain components are installed a process of “wearing in” the camshaft, lifters, lifter bores, distributor gears, and valveguides is done. It is critical to the longevity of all the components. All surfaces must “mate” each other at a molecular level, since the wear surfaces of the cam lobes, as well as the lifters, and most of the other components see only a microscopic level of oil while under operation. This may sound familiar to some of you who have changed out a flat-faced or solid camshaft before, but studies have shown that even roller lifter–equipped engines benefit from using break-in oil. It’s highly recommended for roller lifters and, of course, mandatory for flat-faced or follower-designed camshafts.

Comp Cams Break-In Oil was poured back into the engine as well as fresh engine coolant before the truck was started back up and ran, so the new camshaft could be bought up to operating speed before sending it on its way down the road.

| Comp Cams Break In Oil

It’s common practice that when new valvetrain components are installed a process of “wearing in” the camshaft, lifters, lifter bores, distributor gears, and valveguides is done. It is critical to the longevity of all the components. All surfaces must “mate” each other at a molecular level, since the wear surfaces of the cam lobes, as well as the lifters, and most of the other components see only a microscopic level of oil while under operation. This may sound familiar to some of you who have changed out a flat-faced or solid camshaft before, but studies have shown that even roller lifter–equipped engines benefit from using break-in oil. It’s highly recommended for roller lifters and, of course, mandatory for flat-faced or follower-designed camshafts.

Comp Cams Break-In Oil was poured back into the engine as well as fresh engine coolant before the truck was started back up and ran, so the new camshaft could be bought up to operating speed before sending it on its way down the road.