Upgrading The 6.4L Power Strokes Factory Turbochargers

The 6.4L Power Stroke engine in our '08 Super Duty (nicknamed Project Godzilla) has a trick up its sleeve. While GM and Dodge engines are built with single turbos, 6.4L powerplants have a factory compound-turbo system. This twin setup helps produce a favorable boost-to-drive pressure relationship, keeps the turbochargers in their efficiency map, and allows for quicker spooling. While it may seem like an ideal setup, Elite Diesel in Pueblo West, Colorado, saw room for improvement.

| diesel Power 2008 Ford F250 Turbos turbo Setup

It turns out that the factory compound-turbocharger setup cleans up all the smoke pretty well until about 550 hp. Anything beyond that and more airflow is needed. Also, drive pressure can be almost 80 psi when the engine makes 50 psi of boost, which is hard on both the engine and the turbochargers. To address the airflow issue, Elite Diesel has developed larger compressor wheels for both the low-pressure (larger) and high-pressure (smaller) turbochargers.

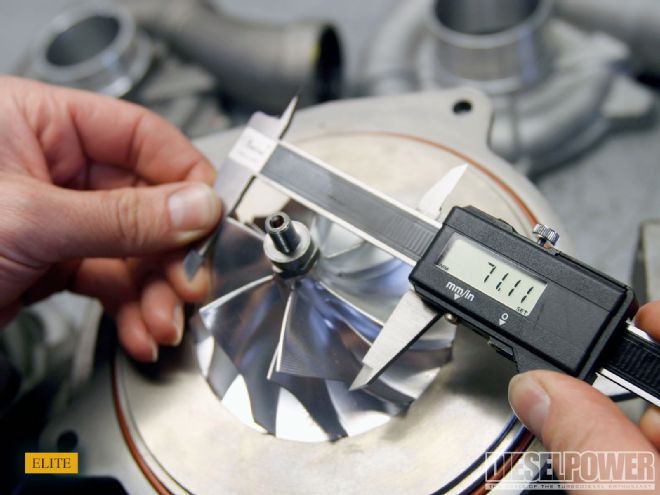

| Here's the high-pressure turbocharger, which is the smaller of the two turbochargers on the 6.4L. It gets an upgraded compressor wheel that flows much more air than the factory piece.

This ensures the turbos remain efficient as engine speed and airflow requirements increase. To address the drive pressure issue, Elite fabricated an up-pipe system incorporating an external wastegate made by Precision Turbo. From the factory, higher amounts of drive pressure are needed to ensure proper spooling at any elevation, but at sea level or in racing applications, less drive pressure makes for a more efficient engine, and consequently, more horsepower. So follow along and see how Elite Diesel took the stock set of turbos off of Project Godzilla and worked its magic on them.

| The low-pressure (larger) turbocharger is upgraded with both a larger billet wheel (arrow), and a modified compressor housing.