| Why is this man smiling? Because he's Charlie Freese, the man behind the new 4.5L Duramax engine. The 4.5L meets the world's strictest emissions requirements and still manages to produce 310 hp and 520 lb-ft of torque.

We recently attended a seminar on the new 4.5L LMK Duramax that will be making an appearance in light-duty trucks for 2010. This potent mill will not only have at least 310 hp and 520 lb-ft of torque (final figures have yet to be released), but it makes these ratings while meeting stricter emissions regulations. How? With a lot of technology. To get the lowdown on this new tech-heavy engine, we're going to have a Q&A session with our new friend Charlie Freese. Who is Charlie? Well, he's one of the guys who spearheaded the 4.5L buildup, as well as the Executive Director of Diesel Engineering over at GM.

Diesel Power:OK, first comes first. We're sure most people are wondering about the switched intake and exhaust arrangement on this engine. Why did you choose to mount the turbo in the middle and have the intakes on either side, rather than just building an engine the "traditional" way?

Charlie Freese:The inboard exhaust configuration is a unique design characteristic. When we started this clean-sheet engine, it was important to think through the design imperatives. As you mentioned, the engine had to deliver high power and torque density while meeting the world's most stringent emissions standards.

| This is the type of vehicle that will receive the new 4.5L engine. We're expecting 14-second quarter-mile times and 20+ mpg right off dealer lots.

Efficiency and capability are key reasons to select diesel powertrains, and exceptional durability is the price of entry for any engine that will carry the Duramax badge. Cost, packaging, and mass are all necessary constraints that determine if the engine can work in a vehicle and be successful in the marketplace. Inboard exhaust supports all these requirements. It helps to take a deeper look at how the exhaust arrangement interacts with the design imperatives.

Let's start with emissions-2010 Tier-2 and LEV2 emission standards are challenging. Exhaust aftertreatment gains additional importance. We will use particulate and NOx aftertreatment, and these devices work best when quickly heated to operating temperatures. Exhaust energy warms aftertreatment components, but exhaust heat represents fuel energy that didn't make power. We want to minimize thermal losses and warm the aftertreatment system efficiently. In Europe, we closely couple aftertreatment hardware to exhaust manifolds. European 4-cylinder engines simplify this situation because exhaust exits from one side of the engine. Things get trickier for V-engines, so using traditional outboard exhaust requires a compromise. Either a separate aftertreatment system would be needed for each bank, or the hardware must be located remotely. That could mean 6 feet away from the engine, so inboard exhaust provides a better solution. By collecting exhaust inboard, we can position the turbocharger and oxidation catalyst in the valley and avoid extra plumbing.

Some traditional designs valley-mount turbochargers, requiring crossover pipes to collect exhaust from outboard manifolds, so we wanted to avoid this if possible. Inboard exhaust removes the crossover pipes adjoining the two banks, but the 4.5L also eliminates exhaust manifolds. The turbocharger connects to the heads. The 4.5L design eliminated more than six dozen engine parts. That means less mass, better reliability, and less cost. Now let's discuss performance. Air restrictions and heat losses rob an engine of performance. Keeping short exhaust passages between the turbine and the cylinder heads reduced both inefficiencies. If we used outboard exhaust, long pipes would be required to carry exhaust gas into the valley where the turbo sits. These pipes increase backpressure. Noise is another important consideration. More pipes and manifolds mean more surface area, and these surfaces are where thermal energy and noise would be radiated into the engine compartment. The 4.5L's inboard exhaust arrangement avoids these pitfalls.

We can't leave out durability, which is synonymous with the Duramax brand. Losses mean inefficiency and must be overcome by higher fuel consumption for the same power density. Reduced fuel consumption helps lower thermal stress in the combustion chamber components and minimizes cranktrain and structural loads. These are good things for engine durability.

| 2010 Duramax 4500 Diesel engine Left Rear

Diesel Power:We've heard GM has some patents on the short-block of this engine, tell us a little bit about the bottom end of the new 4.5L.

Charlie Freese:This is another place where the engine architecture supports interesting design innovation. We selected compacted graphite iron (CGI) as the block material. This material delivers high strength with wall thicknesses that approach the limits of casting technology. This reduces mass with a high-performance structure. Another interesting CGI characteristic is the ability to fracture-split main bearing caps. After main bearing bores are machined, we laser-etch the caps and snap them from the block. This creates a high-friction surface with nearly perfect alignment to the block. Tight alignment establishes uniform oil film thicknesses and maximizes bearing life.

Using a proprietary design, our upper oil pan structure is used to connect the main bearing caps to the block skirt. This structural arrangement is 30% stiffer than designs using bedplates or cross-bolted mains. Because we avoided cross-bolts, wider passages were created between bearing caps and the skirt. This improves bay-to-bay crankcase breathing. The result is a highly efficient structure.

| 2010 Duramax 4500 Diesel engine Top

Diesel Power:A lot of customers, who tow or who are farmers and let their trucks idle for extended periods, have noticed poor mileage with the regeneration cycles on the LMM (6.6L Duramax). How will the new urea injection affect mileage? How often will it need to be changed?

Charlie Freese:Fuel economy is highly dependent upon vehicle usage, and idling and towing are important factors. When a vehicle idles, it burns fuel with no mileage to show for it. That always deteriorates fuel economy numbers.

When diesel particulate filters (DPFs) are added, another effect must be considered. DPFs are traps that store particulates until they can be oxidized. Oxidation occurs in two modes. The first is called passive regeneration. This happens whenever exhaust temperatures exceed approximately 1,076 degrees F without a fuel consumption penalty.

| 2010 Duramax 4500 Diesel engine Left Front

The second mode is active regeneration, which occurs when traps become filled. This situation requires the engine to force higher exhaust temperatures (1,076 to 1,200 degrees F), which induce regeneration. This active regeneration demands richer combustion, meaning more fuel is burned. More fuel burned means fuel economy deterioration.

If someone idles their vehicle for a long time, it will not generate enough exhaust heat to passively regenerate the trap. The engine still loads the DPF with particulate matter. Without passive regenerations, the engine must more frequently force active regenerations. Fuel economy will deteriorate as a result. Another consideration is performance. The 6.6L Duramax now delivers 50 hp and 140 lb-ft more torque than when it launched. Sometimes a Duramax owner needs everything the powertrain can deliver to complete the job, but other times a driver requires a fraction of the engine's capability. The problem is that drivers have a tendency to get heavy into the pedal all the time. If the Duramax can tow a load faster or accelerate quicker, then drivers use the capability. We all enjoy the experience when the light turns green and the truck throws you back into the seat. It is even more impressive when you remember the truck is towing 10,000 lbs, you are heading up a 7% grade, and it still feels like you are running empty. However, these maneuvers do not come without a price, and that price is higher fuel consumption. If you compare today's 6.6L Duramax engine with its predecessors, it is usually more efficient when run at the same loads and speeds. The problem is resisting the temptation to accelerate your 17,000-lb rig from 0 to 55 mph in record time. The best fuel economy comes from being light on the pedal.

This brings us to your question on urea injection and selective catalytic reduction (SCR) aftertreatment-4.5L and 6.6L Duramax engines will use SCR. This reduces NOx emissions through catalytic chemical reactions. Urea is consumed when injected into the exhaust system. We selected SCR-urea technology for many reasons, the first of which is high NOx reduction efficiency while maintaining fuel economy. SCR-urea systems remove more than 80% of tailpipe NOx over a broad operating range. It accomplishes this without regenerations and fuel-rich combustion modes. Competing technologies, like lean NOx traps (LNTs), require frequent rich regeneration events, which deteriorate fuel efficiency.

SCR also helps separate combustion events from aftertreatment requirements, as we enjoy with gasoline four-way catalysts. This means we can better optimize engine operation, pull back some injection timing, and improve fuel efficiency. SCR systems are also robust to contaminants like sulfur. Sulfur is present in diesel fuel, even with new ultra-low sulfur diesels that are available today. LNTs quickly become poisoned by this sulfur and lose their ability to reduce tailpipe NOx.

SCR systems require the operator to periodically refill a urea tank. For many users, this occurs at oil change intervals. Heavy users that operate at much higher loads will consume more urea and may require additional refills between their oil change events.

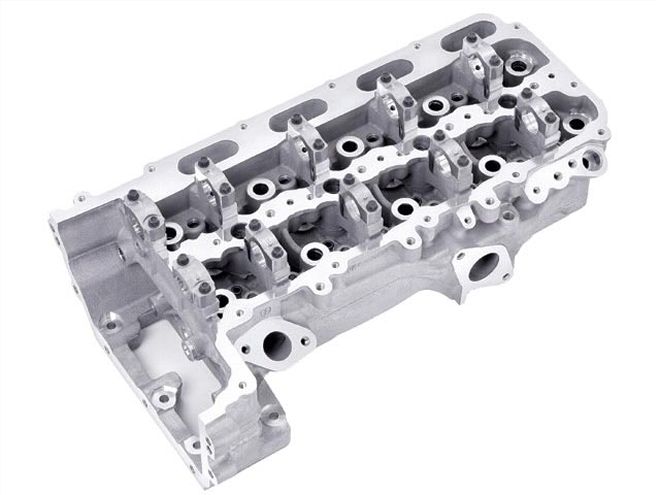

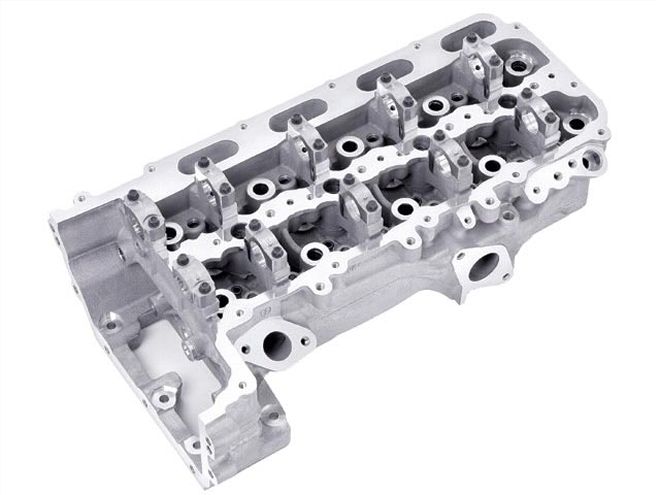

| The cylinder heads on the 4.5L are like nothing we've seen before. Check out the curved intake runners on the nearside of the cylinder head.

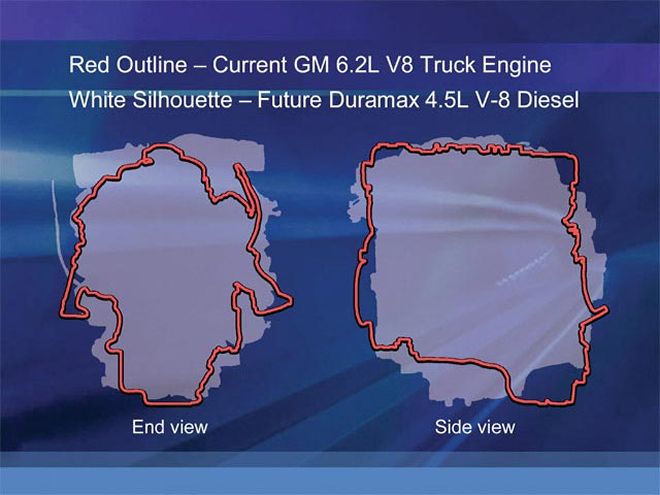

Diesel Power:For a diesel engine, the 4.5L LMK seems small, as in both narrow and short. It's said to fit pretty much anywhere a small-block Chevy will fit, is this true?

Charlie Freese:Yes. As you mentioned, the engine is quite compact. This was achieved through a few key design decisions. We selected a 72-degree bank angle, rather than a more traditional 90-degree V-8 configuration. The block material is compacted graphite iron (CGI), which allows us to do some interesting things with the bottom end that stiffen the structure and reduce engine height. We eliminated the outboard manifolds, making the engine narrower. The inboard exhaust arrangement allows turbochargers to package close to the exhaust ports and provides space for a closely coupled oxidation catalyst. This is an essential part of the new emissions aftertreatment system. By keeping aftertreatment hardware close, we can warm it up and light it off quickly. This enables a clean diesel with better fuel efficiency. These design characteristics allow the 4.5L V-8 Duramax to fit into about the same packaging envelope as a small-block gasoline engine.

| From the top, you can see where the runners curve up and end in the intake ports. In case you were wondering, the valve cover also doubles as an intake manifold!

Diesel Power:With diesel and gasoline up over $5.00 a gallon, fuel mileage is a big concern. How will this engine compare to a similarly equipped gasoline engine as far as fuel economy goes? Any idea on how much of a premium people will have to pay for the 4.5L diesel?

Charlie Freese:We expect the 4.5L V-8 Duramax to deliver about 25% better fuel efficiency than a comparably powered gasoline engine under light load operation. However, when the truck is used for work (towing and hauling), its fuel efficiency advantage extends into the 40-70% range. Think of this as a situation where you are towing a heavy load over a mountain. That is where the diesel best demonstrates its advantages. Naturally aspirated gasoline engines must run richer and go into catalyst protection mode. A diesel does not. We have not announced option pricing for the new 4.5L Duramax. It is still a little early for that.

| On the exhaust side there are no ports, just a couple of outlets where the exhaust will connect to the turbocharger and EGR system.

Diesel Power: There are a lot of different details within the 4.5L LMK that people might not notice; such as the cam arrangement, valvetrain, head flow characteristics, balance shaft, EGR cooler, compression ratio, and injection system. Tell us a little bit about those.

Charlie Freese:Sure. To start with, the 4.5L employs a four-valve-per-cylinder DOHC architecture. This provides a very stiff valvetrain for efficient operation over a wide speed range. Hydraulic lash adjusters deliver maintenance-free operation with very low noise. Camshafts are chain driven from the front of the engine. Engine breathing is another place where inboard exhaust offered interesting design options. We eliminated intake manifolds by porting the intake down through rocker covers. Air enters the cylinder heads from above.

| 2010 Duramax 4500 Diesel head Underside Exhaust

This eliminated parts, narrowed the engine, avoided leak paths, and reduced engine mass. Because exhaust ports exit toward the engine's valley, we shortened the passages into the turbine and the exhaust gas recirculation system. This approach better manages thermal energy and lowers fluid flow losses. By retaining more exhaust, gas heat, turbocharger, and oxidation catalyst performance are improved. Because we selected the 72 bank angle, this engine uses a single-balance shaft low in the block. We selected a rear-mounted nodal chain drive to minimize torsional vibrations. Considering manufacturing tolerances, a 72 V-8 engine can actually deliver better balance than a 90 engine.

The EGR cooler package is another interesting area. With all the exhaust components centered in the valley, we can more easily plumb the EGR system. Cooler, valves, and pipes are efficiently located with minimal cost, mass, and space penalties. The 4.5L operates with a 16:1 compression ratio, which supports our fuel efficiency, emissions, and durability objectives. Cold start requirements are satisfied using glow plugs, an air intake heater, control software, and proven practices from the 6.6L Duramax.

The fuel system is a high-pressure common rail. Peak injection pressures are set at 29,000 psi. Injectors are piezo-controlled, allowing multiple injections, precise fuel metering, and minimal dwell times. We can inject multiple pilots, split the main injection event, and achieve multiple post injections for optimal combustion and aftertreatment performance.

| While photos are impressive, the GM crew was also nice enough to bring a complete engine to show off. We got a firsthand look at the new cylinder heads, which by the way will be featuring overhead camshafts.

Diesel Power:OK now we have a couple general questions. At the seminar, you mentioned that these 1/2-ton trucks may encourage a new group of customers to purchase a diesel vehicle. Tell us about that.

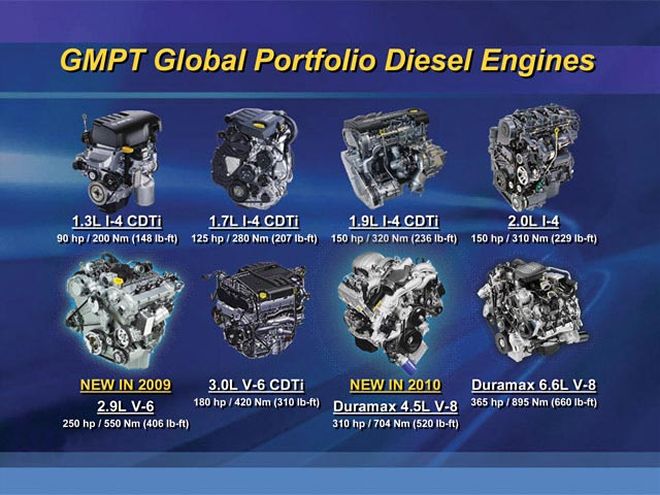

Charlie Freese:The 6.6L V-8 Duramax has been extremely successful. Duramax was introduced in 2001 with a 310-hp and 520-lb-ft rating. At its introduction, General Motors only had a 1.1% share in the heavy-duty pickup market. Duramax and the Allison transmission established new performance and refinement benchmarks that changed many customer perceptions about diesels. Duramax soon captured one third of this important market. Since its introduction, Duramax routinely resets the bar for torque and power leadership. It now delivers 365 hp and 660 lb-ft of torque. Duramax has become a reason for purchase with many 3/4- and 1-ton truck customers.

| The short-block also features some trick main caps, and is made out of compacted graphite iron, which should save 50+ pounds over a traditional iron block.

We expect the new 4.5L V-8 Duramax can do the same thing for light-duty pickup trucks. Some customers don't need a 3/4-ton truck, but still need tow trailers and expect efficiency. The 4.5L Duramax that we showed today can match the original 310-hp and 520-lb-ft rating of the first 6.6L Duramax. It does this with 2.1L less displacement. Rated speed will be in the 4,000-rpm range with a broad torque curve. This gives the vehicle low-end, stump-pulling torque and high-speed operation that feels more gasoline-like. This is important because some buyers may not be accustomed to diesel engines. The diesel veterans will find they like it too. We continue to improve the 6.6L Duramax for those customers that require the biggest, most capable truck available. The 6.6L will serve the 2500 and 3500 pickups (Chevrolet Silverado and GMC Sierra), fullsize vans (Chevrolet Express and GMC Savanna), and commercial trucks (Kodiak and Topkick).

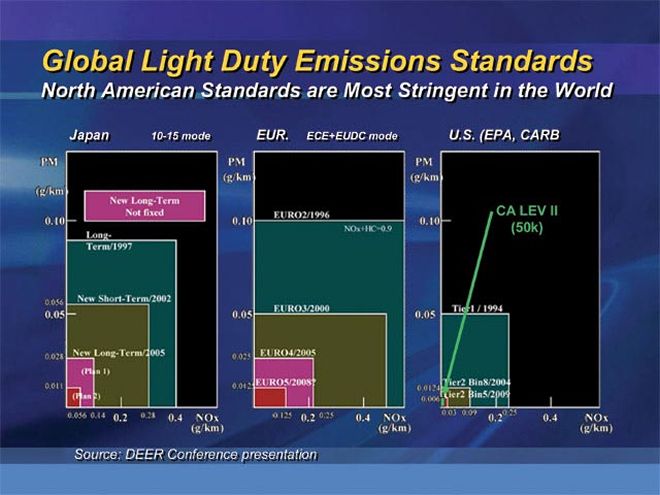

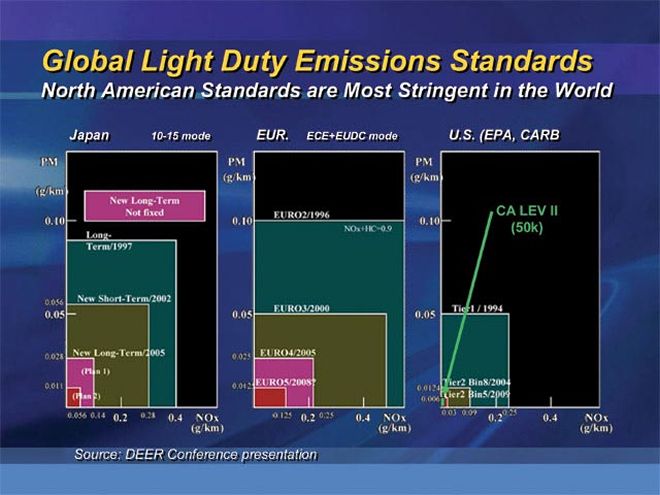

| The new 4.5L LMK also has to meet some of the strictest emissions requirements in the world. Don't believe us? Check out this chart that shows the new 2010 emissions (arrow) compared to the old European standards.

Diesel Power:OK one last question. We're willing to bet that within a year of release, somebody will have one of your little 4.5L LMKs producing more than 600 hp. What do you think about modifications that take these engines to such an extreme level?

Charlie Freese:We all enjoy the power and aggressive low-end torque modern diesel engines deliver. It can be appealing to test your skills at tuning these engines, and I personally understand the temptation. I grew up twisting wrenches in my dad's motorcycle and snowmobile shop.

Our customers are passionate about these diesel products. However, anyone who plans to modify their truck must understand the endeavor is risky. Subtle design features may be critically important to a part's function. People are still approaching me about the LMM exhaust cooler, thinking it is only a styling feature. These powertrains were developed after years of analysis and hundreds of thousands of test hours.

| To help meet emissions, an electronic throttle is used to precisely monitor the amount of air that the engine will receive.

Component limitations were carefully mapped and balanced against all the design imperatives. The situation is even more complex with active aftertreatment devices on the vehicle. The onboard computer constantly compensates for the ambient environment, operating conditions, exhaust backpressure changes, and system temperatures. Seemingly simple modifications can severely compromise functionality. We didn't leave horsepower needlessly on the table.

Engine design is all about balancing competing design imperatives. Tampering with design or calibration parameters can cause catastrophic engine damage and void your warranty. If someone is willing to risk a $10K repair bill for a day at the track, then why stop at 600 hp?

Diesel Power:Thanks so much for your time Charlie. We're genuinely excited about this engine and it looks like you did an excellent job designing it. We can't wait till they are in a production vehicle. Give us a call if you ever need us to drive one!

| In reference to fuel, incredibly fast piezo injectors can shoot up to five times per injection cycle, which is a big reason why the LMK can make big power while still meeting emissions.

Charlie Freese: You are welcome. It is always fun to talk about the product. We have a great engineering team working on this new engine. I am sure they will not let you down, and we may have some future surprises for you. Stay tuned!

| Why is this man smiling? Because he's Charlie Freese, the man behind the new 4.5L Duramax engine. The 4.5L meets the world's strictest emissions requirements and still manages to produce 310 hp and 520 lb-ft of torque.

We recently attended a seminar on the new 4.5L LMK Duramax that will be making an appearance in light-duty trucks for 2010. This potent mill will not only have at least 310 hp and 520 lb-ft of torque (final figures have yet to be released), but it makes these ratings while meeting stricter emissions regulations. How? With a lot of technology. To get the lowdown on this new tech-heavy engine, we're going to have a Q&A session with our new friend Charlie Freese. Who is Charlie? Well, he's one of the guys who spearheaded the 4.5L buildup, as well as the Executive Director of Diesel Engineering over at GM.

Diesel Power:

| Why is this man smiling? Because he's Charlie Freese, the man behind the new 4.5L Duramax engine. The 4.5L meets the world's strictest emissions requirements and still manages to produce 310 hp and 520 lb-ft of torque.

We recently attended a seminar on the new 4.5L LMK Duramax that will be making an appearance in light-duty trucks for 2010. This potent mill will not only have at least 310 hp and 520 lb-ft of torque (final figures have yet to be released), but it makes these ratings while meeting stricter emissions regulations. How? With a lot of technology. To get the lowdown on this new tech-heavy engine, we're going to have a Q&A session with our new friend Charlie Freese. Who is Charlie? Well, he's one of the guys who spearheaded the 4.5L buildup, as well as the Executive Director of Diesel Engineering over at GM.

Diesel Power: | This is the type of vehicle that will receive the new 4.5L engine. We're expecting 14-second quarter-mile times and 20+ mpg right off dealer lots.

Efficiency and capability are key reasons to select diesel powertrains, and exceptional durability is the price of entry for any engine that will carry the Duramax badge. Cost, packaging, and mass are all necessary constraints that determine if the engine can work in a vehicle and be successful in the marketplace. Inboard exhaust supports all these requirements. It helps to take a deeper look at how the exhaust arrangement interacts with the design imperatives.

Let's start with emissions-2010 Tier-2 and LEV2 emission standards are challenging. Exhaust aftertreatment gains additional importance. We will use particulate and NOx aftertreatment, and these devices work best when quickly heated to operating temperatures. Exhaust energy warms aftertreatment components, but exhaust heat represents fuel energy that didn't make power. We want to minimize thermal losses and warm the aftertreatment system efficiently. In Europe, we closely couple aftertreatment hardware to exhaust manifolds. European 4-cylinder engines simplify this situation because exhaust exits from one side of the engine. Things get trickier for V-engines, so using traditional outboard exhaust requires a compromise. Either a separate aftertreatment system would be needed for each bank, or the hardware must be located remotely. That could mean 6 feet away from the engine, so inboard exhaust provides a better solution. By collecting exhaust inboard, we can position the turbocharger and oxidation catalyst in the valley and avoid extra plumbing.

| This is the type of vehicle that will receive the new 4.5L engine. We're expecting 14-second quarter-mile times and 20+ mpg right off dealer lots.

Efficiency and capability are key reasons to select diesel powertrains, and exceptional durability is the price of entry for any engine that will carry the Duramax badge. Cost, packaging, and mass are all necessary constraints that determine if the engine can work in a vehicle and be successful in the marketplace. Inboard exhaust supports all these requirements. It helps to take a deeper look at how the exhaust arrangement interacts with the design imperatives.

Let's start with emissions-2010 Tier-2 and LEV2 emission standards are challenging. Exhaust aftertreatment gains additional importance. We will use particulate and NOx aftertreatment, and these devices work best when quickly heated to operating temperatures. Exhaust energy warms aftertreatment components, but exhaust heat represents fuel energy that didn't make power. We want to minimize thermal losses and warm the aftertreatment system efficiently. In Europe, we closely couple aftertreatment hardware to exhaust manifolds. European 4-cylinder engines simplify this situation because exhaust exits from one side of the engine. Things get trickier for V-engines, so using traditional outboard exhaust requires a compromise. Either a separate aftertreatment system would be needed for each bank, or the hardware must be located remotely. That could mean 6 feet away from the engine, so inboard exhaust provides a better solution. By collecting exhaust inboard, we can position the turbocharger and oxidation catalyst in the valley and avoid extra plumbing.

| 2010 Duramax 4500 Diesel engine Left Rear

Diesel Power:

| 2010 Duramax 4500 Diesel engine Left Rear

Diesel Power: | 2010 Duramax 4500 Diesel engine Top

Diesel Power:

| 2010 Duramax 4500 Diesel engine Top

Diesel Power: | 2010 Duramax 4500 Diesel engine Left Front

The second mode is active regeneration, which occurs when traps become filled. This situation requires the engine to force higher exhaust temperatures (1,076 to 1,200 degrees F), which induce regeneration. This active regeneration demands richer combustion, meaning more fuel is burned. More fuel burned means fuel economy deterioration.

If someone idles their vehicle for a long time, it will not generate enough exhaust heat to passively regenerate the trap. The engine still loads the DPF with particulate matter. Without passive regenerations, the engine must more frequently force active regenerations. Fuel economy will deteriorate as a result. Another consideration is performance. The 6.6L Duramax now delivers 50 hp and 140 lb-ft more torque than when it launched. Sometimes a Duramax owner needs everything the powertrain can deliver to complete the job, but other times a driver requires a fraction of the engine's capability. The problem is that drivers have a tendency to get heavy into the pedal all the time. If the Duramax can tow a load faster or accelerate quicker, then drivers use the capability. We all enjoy the experience when the light turns green and the truck throws you back into the seat. It is even more impressive when you remember the truck is towing 10,000 lbs, you are heading up a 7% grade, and it still feels like you are running empty. However, these maneuvers do not come without a price, and that price is higher fuel consumption. If you compare today's 6.6L Duramax engine with its predecessors, it is usually more efficient when run at the same loads and speeds. The problem is resisting the temptation to accelerate your 17,000-lb rig from 0 to 55 mph in record time. The best fuel economy comes from being light on the pedal.

This brings us to your question on urea injection and selective catalytic reduction (SCR) aftertreatment-4.5L and 6.6L Duramax engines will use SCR. This reduces NOx emissions through catalytic chemical reactions. Urea is consumed when injected into the exhaust system. We selected SCR-urea technology for many reasons, the first of which is high NOx reduction efficiency while maintaining fuel economy. SCR-urea systems remove more than 80% of tailpipe NOx over a broad operating range. It accomplishes this without regenerations and fuel-rich combustion modes. Competing technologies, like lean NOx traps (LNTs), require frequent rich regeneration events, which deteriorate fuel efficiency.

SCR also helps separate combustion events from aftertreatment requirements, as we enjoy with gasoline four-way catalysts. This means we can better optimize engine operation, pull back some injection timing, and improve fuel efficiency. SCR systems are also robust to contaminants like sulfur. Sulfur is present in diesel fuel, even with new ultra-low sulfur diesels that are available today. LNTs quickly become poisoned by this sulfur and lose their ability to reduce tailpipe NOx.

SCR systems require the operator to periodically refill a urea tank. For many users, this occurs at oil change intervals. Heavy users that operate at much higher loads will consume more urea and may require additional refills between their oil change events.

| 2010 Duramax 4500 Diesel engine Left Front

The second mode is active regeneration, which occurs when traps become filled. This situation requires the engine to force higher exhaust temperatures (1,076 to 1,200 degrees F), which induce regeneration. This active regeneration demands richer combustion, meaning more fuel is burned. More fuel burned means fuel economy deterioration.

If someone idles their vehicle for a long time, it will not generate enough exhaust heat to passively regenerate the trap. The engine still loads the DPF with particulate matter. Without passive regenerations, the engine must more frequently force active regenerations. Fuel economy will deteriorate as a result. Another consideration is performance. The 6.6L Duramax now delivers 50 hp and 140 lb-ft more torque than when it launched. Sometimes a Duramax owner needs everything the powertrain can deliver to complete the job, but other times a driver requires a fraction of the engine's capability. The problem is that drivers have a tendency to get heavy into the pedal all the time. If the Duramax can tow a load faster or accelerate quicker, then drivers use the capability. We all enjoy the experience when the light turns green and the truck throws you back into the seat. It is even more impressive when you remember the truck is towing 10,000 lbs, you are heading up a 7% grade, and it still feels like you are running empty. However, these maneuvers do not come without a price, and that price is higher fuel consumption. If you compare today's 6.6L Duramax engine with its predecessors, it is usually more efficient when run at the same loads and speeds. The problem is resisting the temptation to accelerate your 17,000-lb rig from 0 to 55 mph in record time. The best fuel economy comes from being light on the pedal.

This brings us to your question on urea injection and selective catalytic reduction (SCR) aftertreatment-4.5L and 6.6L Duramax engines will use SCR. This reduces NOx emissions through catalytic chemical reactions. Urea is consumed when injected into the exhaust system. We selected SCR-urea technology for many reasons, the first of which is high NOx reduction efficiency while maintaining fuel economy. SCR-urea systems remove more than 80% of tailpipe NOx over a broad operating range. It accomplishes this without regenerations and fuel-rich combustion modes. Competing technologies, like lean NOx traps (LNTs), require frequent rich regeneration events, which deteriorate fuel efficiency.

SCR also helps separate combustion events from aftertreatment requirements, as we enjoy with gasoline four-way catalysts. This means we can better optimize engine operation, pull back some injection timing, and improve fuel efficiency. SCR systems are also robust to contaminants like sulfur. Sulfur is present in diesel fuel, even with new ultra-low sulfur diesels that are available today. LNTs quickly become poisoned by this sulfur and lose their ability to reduce tailpipe NOx.

SCR systems require the operator to periodically refill a urea tank. For many users, this occurs at oil change intervals. Heavy users that operate at much higher loads will consume more urea and may require additional refills between their oil change events.

| The cylinder heads on the 4.5L are like nothing we've seen before. Check out the curved intake runners on the nearside of the cylinder head.

Diesel Power:

| The cylinder heads on the 4.5L are like nothing we've seen before. Check out the curved intake runners on the nearside of the cylinder head.

Diesel Power: | From the top, you can see where the runners curve up and end in the intake ports. In case you were wondering, the valve cover also doubles as an intake manifold!

Diesel Power:

| From the top, you can see where the runners curve up and end in the intake ports. In case you were wondering, the valve cover also doubles as an intake manifold!

Diesel Power: | On the exhaust side there are no ports, just a couple of outlets where the exhaust will connect to the turbocharger and EGR system.

Diesel Power:

| On the exhaust side there are no ports, just a couple of outlets where the exhaust will connect to the turbocharger and EGR system.

Diesel Power: | 2010 Duramax 4500 Diesel head Underside Exhaust

This eliminated parts, narrowed the engine, avoided leak paths, and reduced engine mass. Because exhaust ports exit toward the engine's valley, we shortened the passages into the turbine and the exhaust gas recirculation system. This approach better manages thermal energy and lowers fluid flow losses. By retaining more exhaust, gas heat, turbocharger, and oxidation catalyst performance are improved. Because we selected the 72 bank angle, this engine uses a single-balance shaft low in the block. We selected a rear-mounted nodal chain drive to minimize torsional vibrations. Considering manufacturing tolerances, a 72 V-8 engine can actually deliver better balance than a 90 engine.

The EGR cooler package is another interesting area. With all the exhaust components centered in the valley, we can more easily plumb the EGR system. Cooler, valves, and pipes are efficiently located with minimal cost, mass, and space penalties. The 4.5L operates with a 16:1 compression ratio, which supports our fuel efficiency, emissions, and durability objectives. Cold start requirements are satisfied using glow plugs, an air intake heater, control software, and proven practices from the 6.6L Duramax.

The fuel system is a high-pressure common rail. Peak injection pressures are set at 29,000 psi. Injectors are piezo-controlled, allowing multiple injections, precise fuel metering, and minimal dwell times. We can inject multiple pilots, split the main injection event, and achieve multiple post injections for optimal combustion and aftertreatment performance.

| 2010 Duramax 4500 Diesel head Underside Exhaust

This eliminated parts, narrowed the engine, avoided leak paths, and reduced engine mass. Because exhaust ports exit toward the engine's valley, we shortened the passages into the turbine and the exhaust gas recirculation system. This approach better manages thermal energy and lowers fluid flow losses. By retaining more exhaust, gas heat, turbocharger, and oxidation catalyst performance are improved. Because we selected the 72 bank angle, this engine uses a single-balance shaft low in the block. We selected a rear-mounted nodal chain drive to minimize torsional vibrations. Considering manufacturing tolerances, a 72 V-8 engine can actually deliver better balance than a 90 engine.

The EGR cooler package is another interesting area. With all the exhaust components centered in the valley, we can more easily plumb the EGR system. Cooler, valves, and pipes are efficiently located with minimal cost, mass, and space penalties. The 4.5L operates with a 16:1 compression ratio, which supports our fuel efficiency, emissions, and durability objectives. Cold start requirements are satisfied using glow plugs, an air intake heater, control software, and proven practices from the 6.6L Duramax.

The fuel system is a high-pressure common rail. Peak injection pressures are set at 29,000 psi. Injectors are piezo-controlled, allowing multiple injections, precise fuel metering, and minimal dwell times. We can inject multiple pilots, split the main injection event, and achieve multiple post injections for optimal combustion and aftertreatment performance.

| While photos are impressive, the GM crew was also nice enough to bring a complete engine to show off. We got a firsthand look at the new cylinder heads, which by the way will be featuring overhead camshafts.

Diesel Power:

| While photos are impressive, the GM crew was also nice enough to bring a complete engine to show off. We got a firsthand look at the new cylinder heads, which by the way will be featuring overhead camshafts.

Diesel Power: | The short-block also features some trick main caps, and is made out of compacted graphite iron, which should save 50+ pounds over a traditional iron block.

We expect the new 4.5L V-8 Duramax can do the same thing for light-duty pickup trucks. Some customers don't need a 3/4-ton truck, but still need tow trailers and expect efficiency. The 4.5L Duramax that we showed today can match the original 310-hp and 520-lb-ft rating of the first 6.6L Duramax. It does this with 2.1L less displacement. Rated speed will be in the 4,000-rpm range with a broad torque curve. This gives the vehicle low-end, stump-pulling torque and high-speed operation that feels more gasoline-like. This is important because some buyers may not be accustomed to diesel engines. The diesel veterans will find they like it too. We continue to improve the 6.6L Duramax for those customers that require the biggest, most capable truck available. The 6.6L will serve the 2500 and 3500 pickups (Chevrolet Silverado and GMC Sierra), fullsize vans (Chevrolet Express and GMC Savanna), and commercial trucks (Kodiak and Topkick).

| The short-block also features some trick main caps, and is made out of compacted graphite iron, which should save 50+ pounds over a traditional iron block.

We expect the new 4.5L V-8 Duramax can do the same thing for light-duty pickup trucks. Some customers don't need a 3/4-ton truck, but still need tow trailers and expect efficiency. The 4.5L Duramax that we showed today can match the original 310-hp and 520-lb-ft rating of the first 6.6L Duramax. It does this with 2.1L less displacement. Rated speed will be in the 4,000-rpm range with a broad torque curve. This gives the vehicle low-end, stump-pulling torque and high-speed operation that feels more gasoline-like. This is important because some buyers may not be accustomed to diesel engines. The diesel veterans will find they like it too. We continue to improve the 6.6L Duramax for those customers that require the biggest, most capable truck available. The 6.6L will serve the 2500 and 3500 pickups (Chevrolet Silverado and GMC Sierra), fullsize vans (Chevrolet Express and GMC Savanna), and commercial trucks (Kodiak and Topkick).

| The new 4.5L LMK also has to meet some of the strictest emissions requirements in the world. Don't believe us? Check out this chart that shows the new 2010 emissions (arrow) compared to the old European standards.

Diesel Power:

| The new 4.5L LMK also has to meet some of the strictest emissions requirements in the world. Don't believe us? Check out this chart that shows the new 2010 emissions (arrow) compared to the old European standards.

Diesel Power: | To help meet emissions, an electronic throttle is used to precisely monitor the amount of air that the engine will receive.

Component limitations were carefully mapped and balanced against all the design imperatives. The situation is even more complex with active aftertreatment devices on the vehicle. The onboard computer constantly compensates for the ambient environment, operating conditions, exhaust backpressure changes, and system temperatures. Seemingly simple modifications can severely compromise functionality. We didn't leave horsepower needlessly on the table.

Engine design is all about balancing competing design imperatives. Tampering with design or calibration parameters can cause catastrophic engine damage and void your warranty. If someone is willing to risk a $10K repair bill for a day at the track, then why stop at 600 hp?

Diesel Power:

| To help meet emissions, an electronic throttle is used to precisely monitor the amount of air that the engine will receive.

Component limitations were carefully mapped and balanced against all the design imperatives. The situation is even more complex with active aftertreatment devices on the vehicle. The onboard computer constantly compensates for the ambient environment, operating conditions, exhaust backpressure changes, and system temperatures. Seemingly simple modifications can severely compromise functionality. We didn't leave horsepower needlessly on the table.

Engine design is all about balancing competing design imperatives. Tampering with design or calibration parameters can cause catastrophic engine damage and void your warranty. If someone is willing to risk a $10K repair bill for a day at the track, then why stop at 600 hp?

Diesel Power: | In reference to fuel, incredibly fast piezo injectors can shoot up to five times per injection cycle, which is a big reason why the LMK can make big power while still meeting emissions.

Charlie Freese:

| In reference to fuel, incredibly fast piezo injectors can shoot up to five times per injection cycle, which is a big reason why the LMK can make big power while still meeting emissions.

Charlie Freese: