| chevrolet Big Block engine

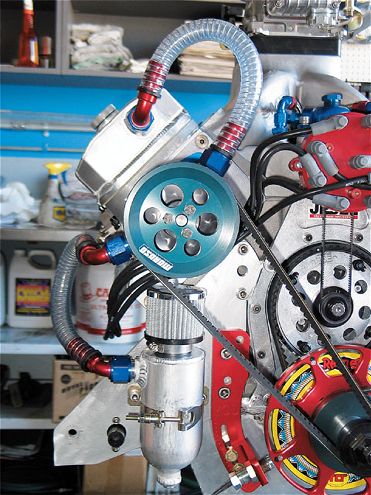

A few years ago, Sport Truck introduced a grandiose project, called "the small-block from hell." Remember that deal? Well we've taken It 10 steps further with a big block Chevy. We wanted a lightweight engine that would eclipse the 1,000 hp mark without a supercharger, nitrous, or a blower, and we wanted to be able to roll right up to a gas pump and top off the tank. That's right. We wanted to have our cake and eat it, too.

The engine, an all-aluminum 572ci powerplant, was built by DNE Motorsports Development's owner, Dave Ebbert. The combination of parts is the result of what we had on hand and what Dave wanted to use to achieve our goal of building a lightweight and streetable 1,000hp engine. This engine is one of many Dave has put together to eclipse that power level on sub-par, 91 octane pump gasoline. It's a very tall order, but this is the real deal. The heads and camshaft are huge, the motor isn't cheap, and the compression ratio is pretty high, but it didn't knock once during any of the 30-plus dyno runs we put it through. It made 1060 hp on the dyno, which is a success in our book.

| chevrolet Big Block aluminum Block

In terms of its streetability, yes, it does run on pump gas. But, it also likes to run cool, which means that if you are going to stuff a motor like this into your truck, then you'd better have one hell of a cooling system on board for the ride. We also have to mention that although it does idle happily around 1,000 rpm, it makes peak torque at 5,900 rpm and peak horsepower at 7,100 rpm. This means that the right gearing and stall converter will be important in making this engine fun to drive, especially with an Overdrive-equipped transmission.

So, there are a few detractors to building a motor like this, but the payoff is worth the effort and expense. Every gas station along the highway will have exactly what you're motor is craving. Here's a look at the parts that make up this beast and the changes Dave made to allow them all to work in harmony.

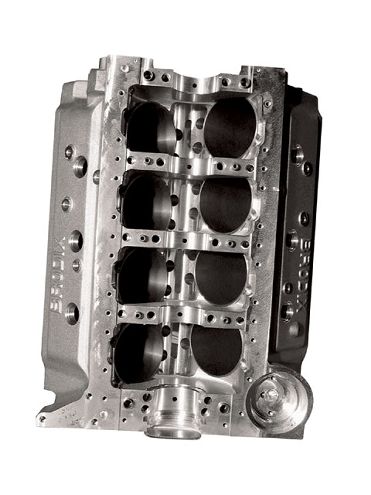

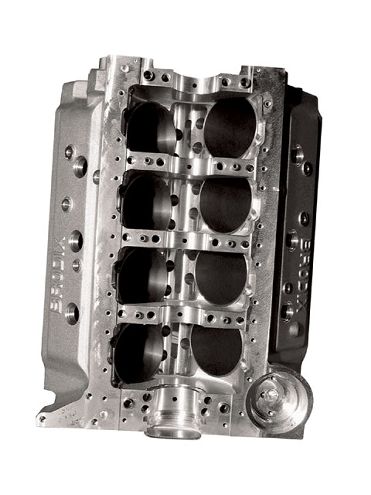

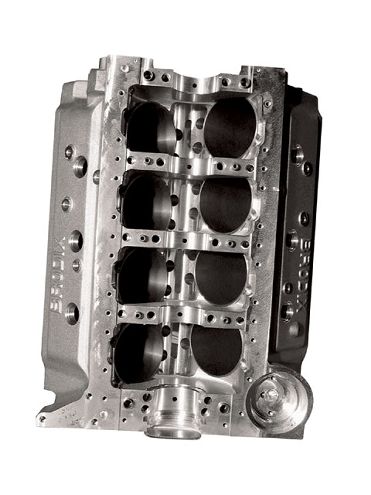

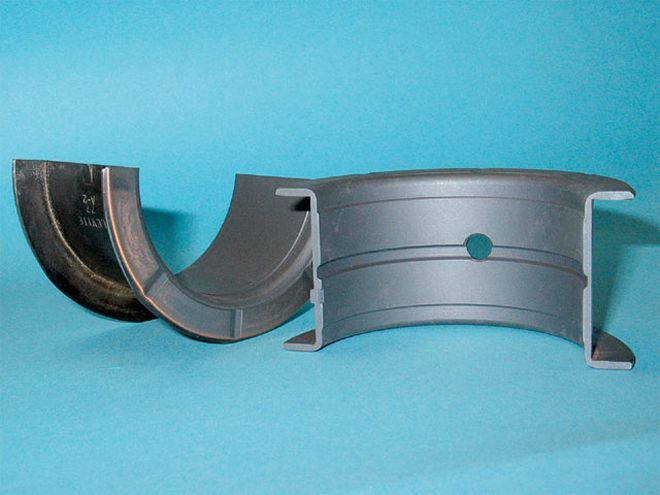

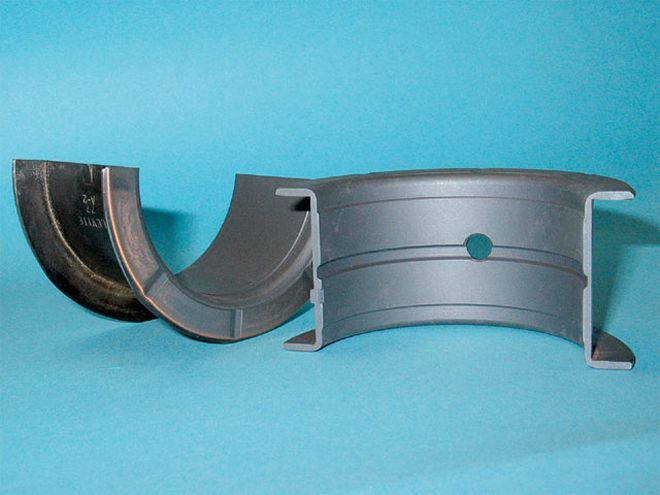

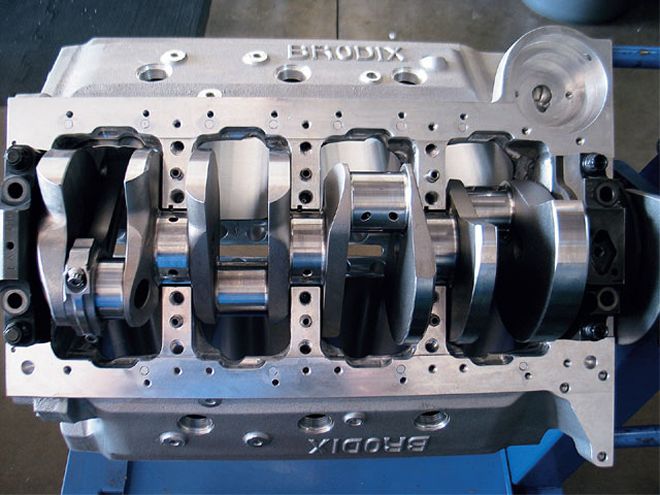

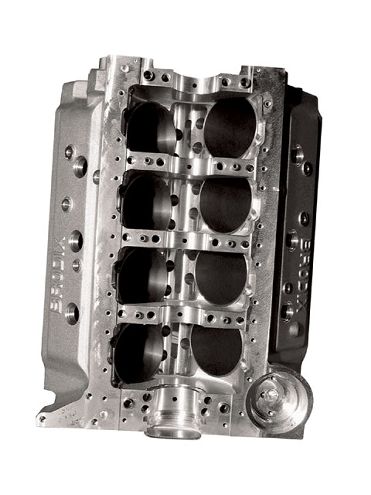

Part One: The Bottom EndThe foundation of this build is a tall-deck Brodix 8B 2000 aluminum block. It's cast from A-356 virgin aluminum, and we opted for the billet steel splayed main caps, raised cam location, and enlarged cam bores for 55mm roller cam bearings. The 0.400-inch-plus raised cam bore is a must, when going with the large-diameter roller bearings in this block, in order to ensure there is enough material left in the lifter bores for oiling purposes. The block weighs just 128 pounds without the main caps in place, which is approximately 100 pounds lighter than your average OEM iron big-block.

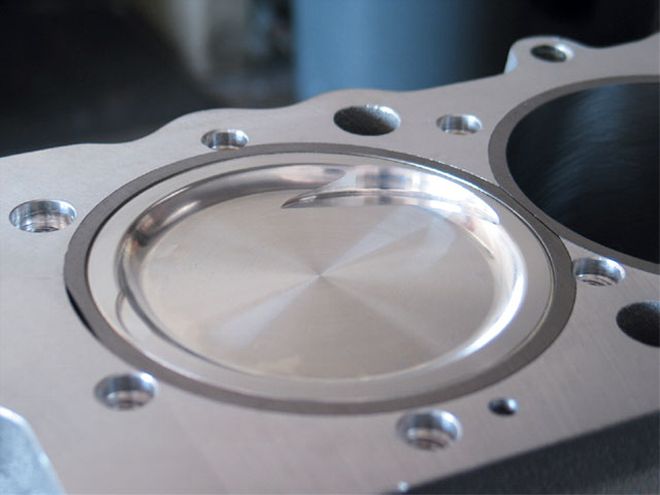

| chevrolet Big Block top Piston

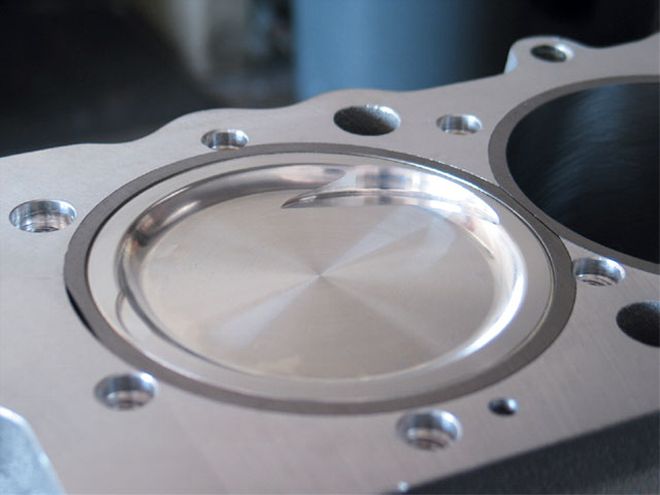

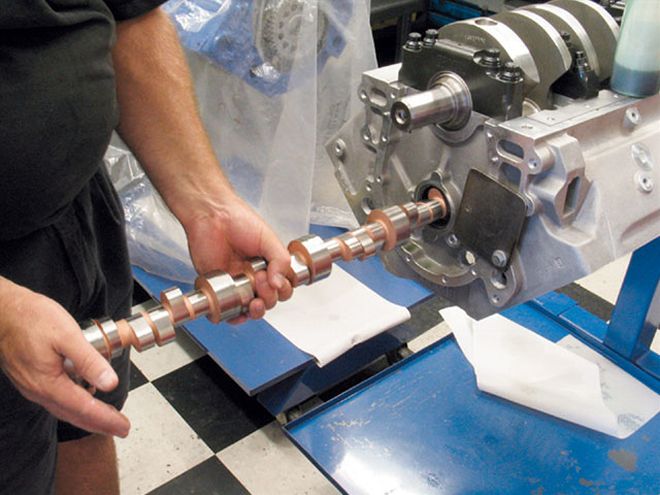

Part Two: The TopsideOur rotating assembly places the pistons 0.002 inch below the 10.190-inch-tall deck. Note that although the dish takes up most of the piston face, sizable reliefs still needed to be cut into the face for the valves. The photo on the right was taken during the mock-up phase of the build, so you'll notice that the top of the piston doesn't have the thermal barrier coating applied yet.

| chevrolet Big Block engine

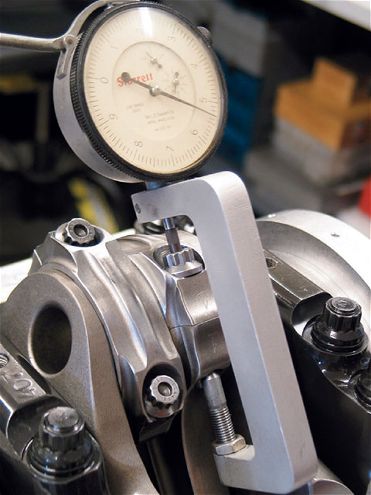

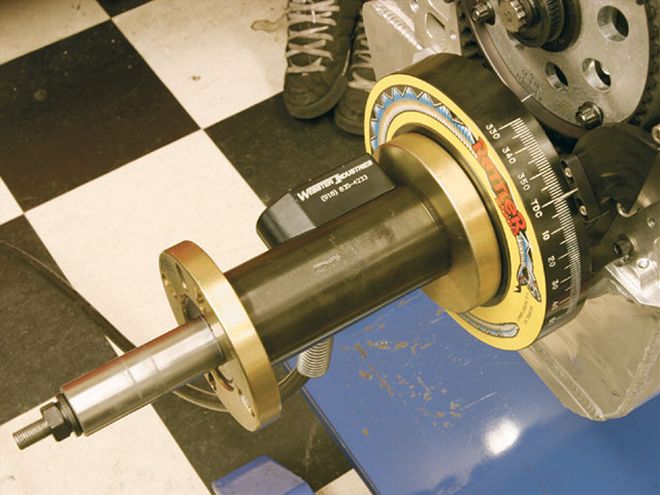

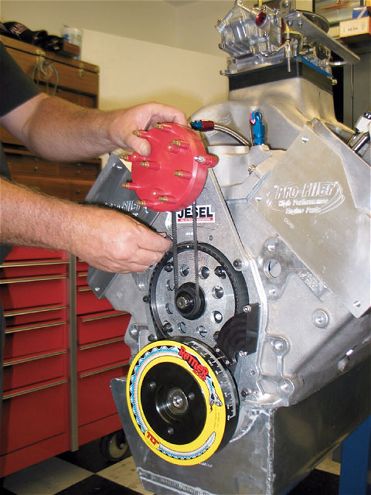

The Final WordThis engine made 1,008 hp at 7,000 rpm and 814 lb-ft of torque at 5,900 rpm during its first full pull on the dyno. The fuel curve looked fairly smooth, but Dave felt there was more power sitting on the table with fuel and timing adjustments. We spent the next 5 hours testing different header designs, various cam and ignition timing maps, and carb jetting changes during more than 30 pulls on the dyno. The motor never dropped below the power level of the first pull. In the end, we discovered this motor liked 29 degrees of timing advance, 2.5 degrees of advance for the camshaft, and 90/97 jetting. It also ran best with 2-1/4-inch primary tube/4-inch collector headers. Advance or retard the ignition timing or cam timing from there, and the power falls off. Allowing the engine to run to 7,300 rpm showed that the power began to fall off just after 7,200 rpm, with a peak of 1,060 hp. The torque peaked at 5,900 rpm with 827.5 lb-ft.

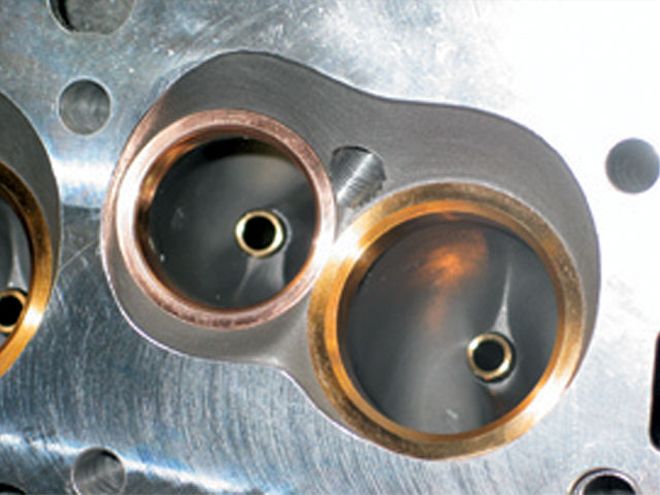

| Before

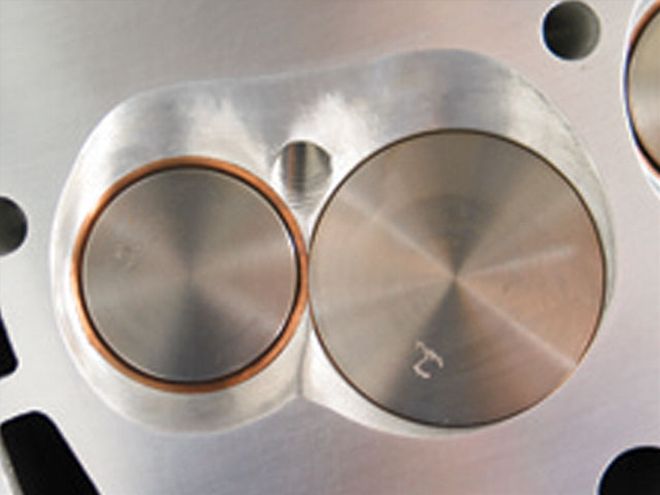

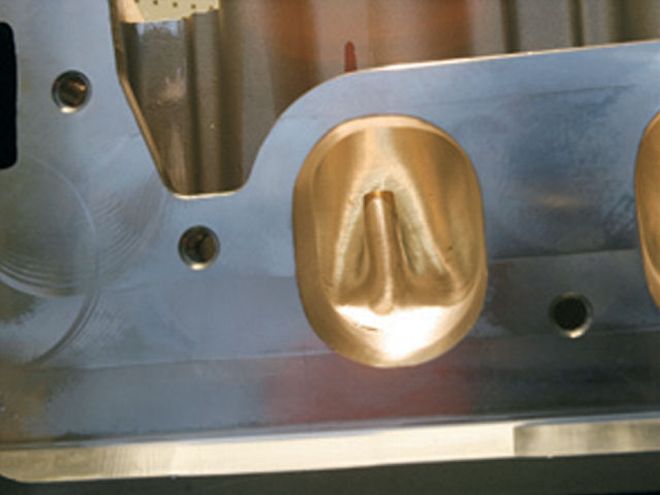

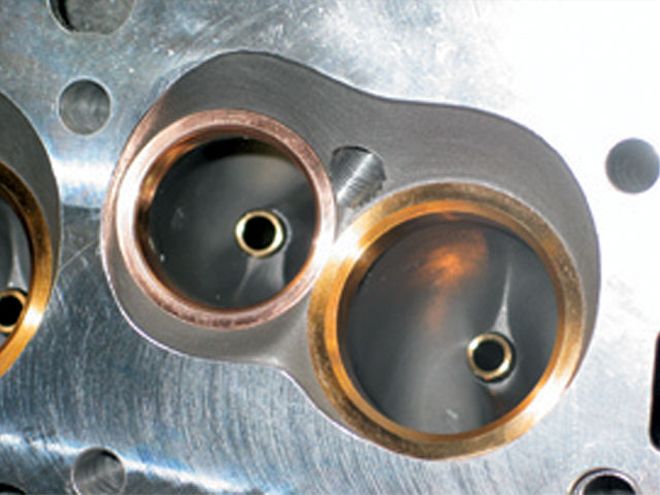

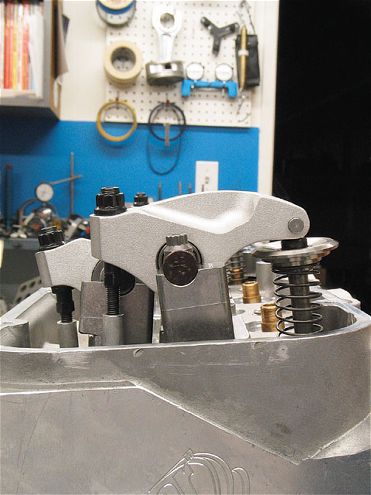

The HeadsWe used Pro Filer's 12-degree Hitman cylinder heads because DNE has built several engines with them and had the experience to make prepping these heads for our motor fairly painless. Dave sent the bare heads to MBE Performance Parts to have the chambers blended, a 5 angle valve job performed, and the runners cleaned up. The exhaust ports are huge to begin with, so those were left untouched. For an as-cast part, out of the box, these heads are pretty nice, and the work that MBE did really took these heads to competition level quality. The 12-degree valve angle promotes high-speed airflow into the chambers, and the port designs work really well in a naturally aspirated configuration. After the port work was finished, Dave chucked the heads into his mill to clearance the intake ports for the pushrods. We also spent a considerable amount of time cc'ing every single port and chamber as part of the design phase of this engine. Here's how the heads spec'd out after the port work:

(Flowed on a Super Flow 1020 bench at 28 inches of water)

Intake runner: 507 cfm

Exhaust runner: 319 cfm

Intake port volume: 475 cc

Exhaust port volume: 187 cc

Chamber volume: 55.5 cc

According to Dave, with this chamber volume the compression ratio is around 12:1 and, based upon previous engines he's built that are still running, is completely safe as long as you pay attention to the details and maintenance required of an engine like this one.

| chevrolet Big Block engine

A few years ago, Sport Truck introduced a grandiose project, called "the small-block from hell." Remember that deal? Well we've taken It 10 steps further with a big block Chevy. We wanted a lightweight engine that would eclipse the 1,000 hp mark without a supercharger, nitrous, or a blower, and we wanted to be able to roll right up to a gas pump and top off the tank. That's right. We wanted to have our cake and eat it, too.

The engine, an all-aluminum 572ci powerplant, was built by DNE Motorsports Development's owner, Dave Ebbert. The combination of parts is the result of what we had on hand and what Dave wanted to use to achieve our goal of building a lightweight and streetable 1,000hp engine. This engine is one of many Dave has put together to eclipse that power level on sub-par, 91 octane pump gasoline. It's a very tall order, but this is the real deal. The heads and camshaft are huge, the motor isn't cheap, and the compression ratio is pretty high, but it didn't knock once during any of the 30-plus dyno runs we put it through. It made 1060 hp on the dyno, which is a success in our book.

| chevrolet Big Block engine

A few years ago, Sport Truck introduced a grandiose project, called "the small-block from hell." Remember that deal? Well we've taken It 10 steps further with a big block Chevy. We wanted a lightweight engine that would eclipse the 1,000 hp mark without a supercharger, nitrous, or a blower, and we wanted to be able to roll right up to a gas pump and top off the tank. That's right. We wanted to have our cake and eat it, too.

The engine, an all-aluminum 572ci powerplant, was built by DNE Motorsports Development's owner, Dave Ebbert. The combination of parts is the result of what we had on hand and what Dave wanted to use to achieve our goal of building a lightweight and streetable 1,000hp engine. This engine is one of many Dave has put together to eclipse that power level on sub-par, 91 octane pump gasoline. It's a very tall order, but this is the real deal. The heads and camshaft are huge, the motor isn't cheap, and the compression ratio is pretty high, but it didn't knock once during any of the 30-plus dyno runs we put it through. It made 1060 hp on the dyno, which is a success in our book.

| chevrolet Big Block aluminum Block

In terms of its streetability, yes, it does run on pump gas. But, it also likes to run cool, which means that if you are going to stuff a motor like this into your truck, then you'd better have one hell of a cooling system on board for the ride. We also have to mention that although it does idle happily around 1,000 rpm, it makes peak torque at 5,900 rpm and peak horsepower at 7,100 rpm. This means that the right gearing and stall converter will be important in making this engine fun to drive, especially with an Overdrive-equipped transmission.

So, there are a few detractors to building a motor like this, but the payoff is worth the effort and expense. Every gas station along the highway will have exactly what you're motor is craving. Here's a look at the parts that make up this beast and the changes Dave made to allow them all to work in harmony.

Part One: The Bottom End

| chevrolet Big Block aluminum Block

In terms of its streetability, yes, it does run on pump gas. But, it also likes to run cool, which means that if you are going to stuff a motor like this into your truck, then you'd better have one hell of a cooling system on board for the ride. We also have to mention that although it does idle happily around 1,000 rpm, it makes peak torque at 5,900 rpm and peak horsepower at 7,100 rpm. This means that the right gearing and stall converter will be important in making this engine fun to drive, especially with an Overdrive-equipped transmission.

So, there are a few detractors to building a motor like this, but the payoff is worth the effort and expense. Every gas station along the highway will have exactly what you're motor is craving. Here's a look at the parts that make up this beast and the changes Dave made to allow them all to work in harmony.

Part One: The Bottom End

| chevrolet Big Block top Piston

Part Two: The Topside

| chevrolet Big Block top Piston

Part Two: The Topside

| chevrolet Big Block engine

The Final Word

| chevrolet Big Block engine

The Final Word | Before

The Heads

| Before

The Heads