Dana 50 Front Differential Buildup - Do-It-Yourself Differential

| We chose a Dana 50 front differential from an '80 to '96 Ford F-250 for our differential rebuild.

Every diesel truck on the road today has a differential and ring and pinion gear set in the rear axle. Four-wheel-drive trucks add a second set of gears and another differential to the front axle to transmit engine torque to all four wheels. Yet differential modification and repair is one of the most feared and least understood aspects of diesel trucks.

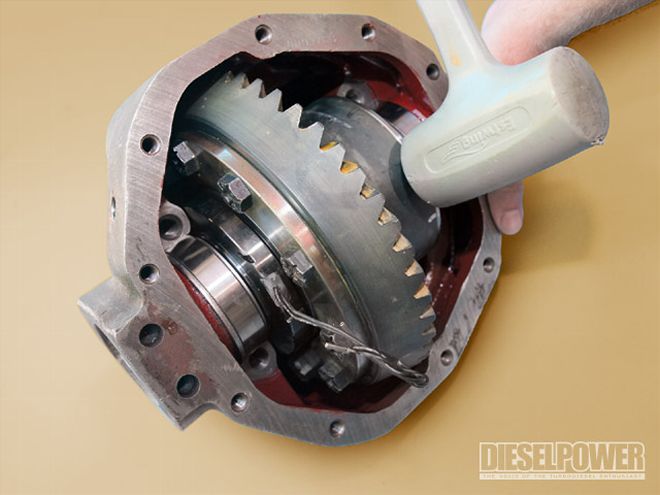

The truth is, setting up ring and pinion gears and installing traction-adding differentials isn't hard-but it is a pain and requires special tools that can mean a big investment of cash. To see how difficult installing new gears and a differential would be at home, we chose a Dana 50 front differential from a Ford F-250 to use as a guinea pig.

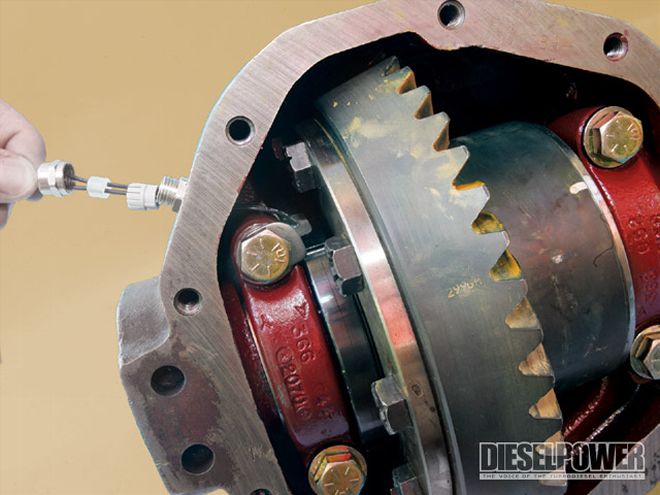

In order to do the job, we used the following tools and resources: Auburn Ected differential installation guide, vernier caliper, gear-marking compound, 3/8-inch-drive torque wrench (calibrated in inch-pounds), 1/2-inch-drive torque wrench (calibrated in foot-pounds), three-jaw puller, Dana 50 Spicer axle service manual, Differentials by Randy Lyman and Jim Allen, a piece of reduction exhaust tubing, a bearing and race driver, and a Starrett dial indicator.

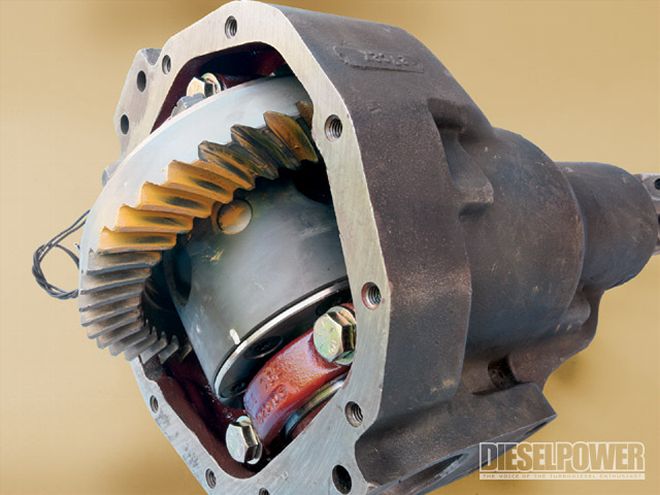

We ordered a 4.88 Yukon ring and pinion gear set, a master install kit (bearings, seals, ring gear bolts, and shims), a new Spicer pinion yoke, and Timken setup bearings from Randy's Ring and Pinion. We also called Auburn Gear to order an Ected locking differential to install with our new gears and bearings. Then we set up a workspace on a small table in our kitchen and spent the weekend setting up our differential. Here's what we learned.

| We chose a Dana 50 front differential from an '80 to '96 Ford F-250 for our differential rebuild.

Every diesel truck on the road today has a differential and ring and pinion gear set in the rear axle. Four-wheel-drive trucks add a second set of gears and another differential to the front axle to transmit engine torque to all four wheels. Yet differential modification and repair is one of the most feared and least understood aspects of diesel trucks.

The truth is, setting up ring and pinion gears and installing traction-adding differentials isn't hard-but it is a pain and requires special tools that can mean a big investment of cash. To see how difficult installing new gears and a differential would be at home, we chose a Dana 50 front differential from a Ford F-250 to use as a guinea pig.

In order to do the job, we used the following tools and resources: Auburn Ected differential installation guide, vernier caliper, gear-marking compound, 3/8-inch-drive torque wrench (calibrated in inch-pounds), 1/2-inch-drive torque wrench (calibrated in foot-pounds), three-jaw puller, Dana 50 Spicer axle service manual, Differentials by Randy Lyman and Jim Allen, a piece of reduction exhaust tubing, a bearing and race driver, and a Starrett dial indicator.

We ordered a 4.88 Yukon ring and pinion gear set, a master install kit (bearings, seals, ring gear bolts, and shims), a new Spicer pinion yoke, and Timken setup bearings from Randy's Ring and Pinion. We also called Auburn Gear to order an Ected locking differential to install with our new gears and bearings. Then we set up a workspace on a small table in our kitchen and spent the weekend setting up our differential. Here's what we learned.

| We chose a Dana 50 front differential from an '80 to '96 Ford F-250 for our differential rebuild.

Every diesel truck on the road today has a differential and ring and pinion gear set in the rear axle. Four-wheel-drive trucks add a second set of gears and another differential to the front axle to transmit engine torque to all four wheels. Yet differential modification and repair is one of the most feared and least understood aspects of diesel trucks.

The truth is, setting up ring and pinion gears and installing traction-adding differentials isn't hard-but it is a pain and requires special tools that can mean a big investment of cash. To see how difficult installing new gears and a differential would be at home, we chose a Dana 50 front differential from a Ford F-250 to use as a guinea pig.

In order to do the job, we used the following tools and resources: Auburn Ected differential installation guide, vernier caliper, gear-marking compound, 3/8-inch-drive torque wrench (calibrated in inch-pounds), 1/2-inch-drive torque wrench (calibrated in foot-pounds), three-jaw puller, Dana 50 Spicer axle service manual, Differentials by Randy Lyman and Jim Allen, a piece of reduction exhaust tubing, a bearing and race driver, and a Starrett dial indicator.

We ordered a 4.88 Yukon ring and pinion gear set, a master install kit (bearings, seals, ring gear bolts, and shims), a new Spicer pinion yoke, and Timken setup bearings from Randy's Ring and Pinion. We also called Auburn Gear to order an Ected locking differential to install with our new gears and bearings. Then we set up a workspace on a small table in our kitchen and spent the weekend setting up our differential. Here's what we learned.