It seems that the one thing that gets overlooked the most when modifying a truck just happens to be the one thing that can save all of that custom work in a panic stop situation. That’s right, we’re talking about brakes. We contacted Todd Gartshore at Baer Racing in Phoenix and he told us that they had a Baer Claw kit.

Founded in 1986 by Hal Baer, Baer Racing started out as a racing team that competed and won in various professional road racing series as well as several amateur classes. The business originally provided race preparation to racers and hardcore enthusiasts. This included building rollcages, suspensions, and even complete racecars.

Baer Racing eventually realized that most of the passing in races occurred during braking, so the company set out to learn as much about braking systems as it could. With the newfound knowledge applied to the cars it built, Baer-equipped cars began beating out teams that were substantially better funded. This created a demand for Baer Racing brake expertise from which Baer Claw brake systems were born. Once it was entirely focused on brakes, Baer Racing was then able to concentrate its efforts on design, testing, and improving its braking systems for the ultimate in stopping power.

As the business grew along with Baer Racing’s reputation, the company began designing and building custom braking systems for special projects being built by various OE manufacturers, and eventually became a supplier of systems and components for OEMs such as ASC-McLaren, GM, Ford, Roush, and Shelby. Today, Baer Racing is one of the leading manufacturers of aftermarket braking systems and its reputation speaks for itself. One of the major misconceptions about brakes is that the easier it is to lock up the wheels, the better the brakes are. This is far from the truth. A locked wheel uses the tire’s adhesion properties to stop the vehicle, instead of the brake’s ability to turn momentum into heat. When brakes are applied, the forward momentum of the vehicle is converted into heat through the friction between the pad and the rotor. Since heat is a brake’s natural enemy, the brake’s ability to absorb and dissipate heat is what really gives the brakes better performance.

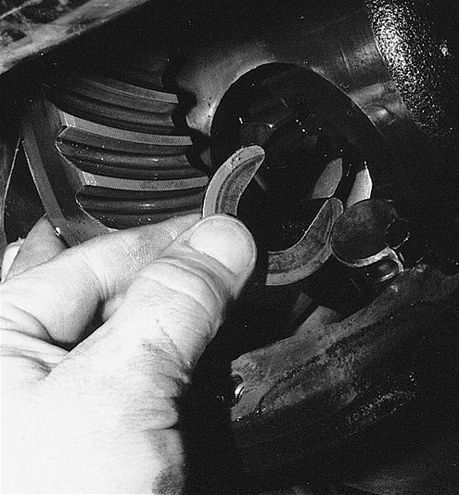

Baer Racing achieves superior brake performance in its systems through the use of the three ingredients needed for good stopping. The first is caliper stability. The mounting of the caliper and the rigidity of the caliper body itself are important to provide solid clamping forces of the brake pad to the rotor.

Next comes capability of the rotor. Two factors enter into this. The diameter of the rotor is important because a larger rotor gives the brakes greater leverage and thus increased stopping power. The other factor is rotor mass. The rotor must be able to absorb and dissipate heat for proper brake performance, so it’s natural that a rotor with increased mass is more capable of absorbing and storing energy.

The third ingredient is good friction material. Gartshore says, “Pads are truly the ‘wild card’ in ultimate brake performance. Baer indicates that an optimum pad for performance street use must be a balance of excellent levels of initial friction (when you first tip into the pedal), good to high maximum friction (the greatest torque which can be generated in a panic stop), good progression (how easy it is to modulate friction levels with the brake pedal), and resistance to temperature-related fade. All must be accomplished with a minimum of noise and dust—a balance that Baer believes is substantially harder than finding the right race-only pad.” Baer Racing strives for a balance between these three factors and this is what gives the company its edge.

Baer Racing uses both PBR and Alcon calipers for its kits. PBR is an Australian company that supplies many high volume OE applications. PBR calipers have quickly become an industry standard for high-performance brake calipers, and the company’s combination of design, performance, and durability is tough to beat for the price. In fact, GM uses PBR calipers extensively for OE applications. Baer Racing is also the exclusive U.S. source for Alcon road-going calipers. These high-performance multi-piston calipers are actually built by the same technicians that build Alcon’s racing calipers. In fact, Baer uses Alcon racing calipers that have been fitted with proper dust and weather seals for better performance during the rigors of daily driving.

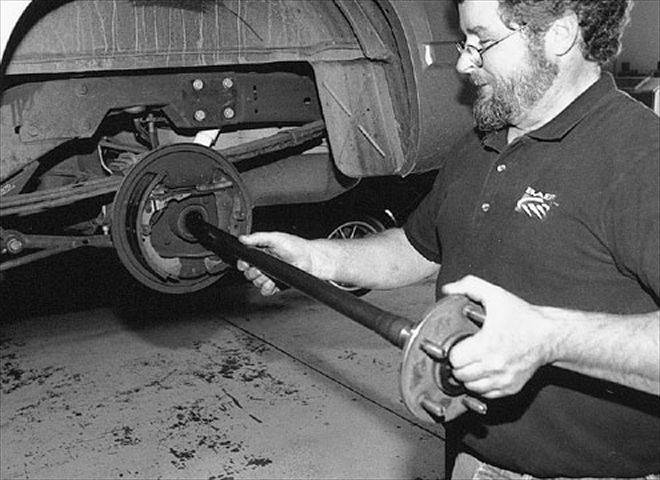

Out in the shop, we had Dutch, one of Baer Racing’s expert technicians, show us the proper way to install a Baer Claw kit onto a ’99 Tahoe.