QuestionQUESTION: starter pull cord jams but if I remove spark plug it will easily pull. any help

appreciated

ANSWER: Hello Alice:

>>From your Description it Sounds like 1 of the Following Conditions Exists.

1- >>The Exhaust Port or Muffler is Clogged and Requires Cleaning/Replacing.

>>The Following is a Basic Instruction File for Doing a Diagnostic on the Engine for this Problem. Any Input is Appreciated.

>>**Remove the Muffler and Make Sure the Exhaust Port is Clear. If it is, then Try to Start the engine with the Muffler Off. If it Starts and Runs Properly, then Clean the Spark Arrestor Screen in the Muffler or Replace the Muffler if Required.

1- The Flywheel Key is Damaged and Requires Replacing.

>>The Following is a Basic Instruction File I made for Removing the Flywheel and Replacing the Flywheel/Flywheel Key.

>>Remove the Cover that Houses the Starter Assembly.

>>Remove the Spark Plug and Use a Bolt the Same Diameter and Threads as the Spark Plug and About 3" Long.

>>Thread the Bolt into the Spark Plug Hole Until it Engages the Piston.

>>Slowly Tighten the Bolt Until you have Locked the Piston and it Does Not Move. **BE CAREFUL A LOT OF TORQUE IS NOT REQUIRED PISTON DAMAGE CAN OCCUR IF TO MUCH TORQUE IS USED ON THE STOP BOLT**

>>Now Remove the Flywheel Nut.

>>Use a 3 Jaw Puller and Attach the Puller to the Flywheel.

>>Look for a Puller with Flat Jaws. These Slide Under the Flywheel and Allow for Easier Removal.

>>Tighten the Puller and then Hit the Puller with a Hammer. Tighten and Hit Again Until the Flywheel is Loose and Can be Removed from the Crankshaft.

**Note the Key that Aligns the Flywheel to the Crankshaft.**

>>This Key is Most Likely Sheared or Bent and Causing the Plug to Fire Slightly Out of Time and Causing a Compression Lock. There is Not Enough Compression to Kick Back But Enough to Cause the Engine to Seem to Have High Compression or it May Seem to have Low Compression and Not Backfire at All.

>>**Some of the Newer Units have the Flywheel Key as a Part of the Flywheel and the Complete Flywheel has to be Replaced.**

>>You can View a Breakdown of this Unit at this Site Addy; http://www.homelite.com/service_support and Select Order Parts. Now Select "Click to Launch Homelite Catalog". Now Enter the Model Numbers (UT10618-A) and Click Search. Now Double Click on the Model in the Results Area. Now you can View the Breakdowns for this Unit.

>>Please, Do Not Hesitate, If you Hit a Snag, if I Missed Something or this Does Not Correct the Problem, I am Here if You Require More Assistance. Hope this Helps. Let me Know What Happens, Please. May the All Mighty Bless You and Yours. Thanks.

Good Luck

Respectfully

John

>>PS: I am Allowed to Answer 10 Questions a Day. If you See I am Maxxed Out, then Try Submitting your Question at or Just After 8pm EST (US). My New Day Starts then. Comments and Ratings are Greatly Appreciated. Thanks.

Respectfully

John

---------- FOLLOW-UP ----------

homelite

homelite

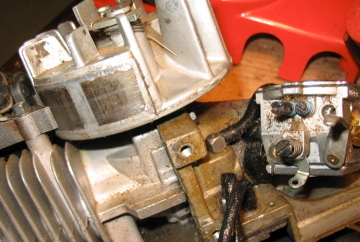

QUESTION: John, Thanks for your patience, I was able to rmove the flywheel and it does

have an integral key to align it. nothing seems unusual but I do not know what

to look for. I took some pictures and will attach. thanks, Alice

ANSWER: Hello Again Alice:

>>Thanks for the Picture. I can Never get Mine to Turn Out that Good.

>>Is the Key Damaged? Look Closely at the Key for Any Signs that it is Bent or Cut where it Rests in the Groove of the Crankshaft.

>>Does the Magnet/s on the Flywheel Look like they/it has Moved or is Missing some of it? If No, then

>>If the Flywheel Key Looks Good and the Exhaust Port and Muffler are Clear, Assemble the Flywheel Back onto the Engine.

>>Since the Flywheel, Muffler and Exhaust Port are Good, then Remove the Carburetor and with the Carburetor (and the Reed Plate Assembly and Spacer behind the Carburetor) "Removed" and the Spark Plug "In" Pull the Starter as if Trying to Start the Engine. Is the High Compression Still Present?

>The Answer to this Question will Tell me which Direction the Diagnostics of the Engine will be going from here.

>>Thanks.

Respectfully

John

>>PS: I am Allowed to Answer 10 Questions a Day. If you See I am Maxxed Out, then Try Submitting your Question at or Just After 8pm EST (US). My New Day Starts then. Comments and Ratings are Greatly Appreciated. Thanks.

Respectfully

John

---------- FOLLOW-UP ----------

flywheel/starter

flywheel/starter

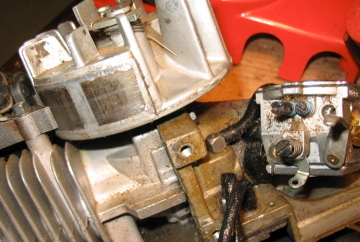

QUESTION: I am attaching a picture of the flywheel where the magnets (?) strike the

starter (?) when I spin the flywheel it requires more pressure to get the

flywheel past this point..it offers resistence somewhat like it does when

pulling the cord is this normal? (see pic) I have not removed the carburetor

yet, in case this resistence is the cause of the problem. If I still should

remove it , how do I manage that? Does it have a bolt on the bottom that

threads in? sorry for the basic questions but this is a "fools rush in"

operation. thanks, Alice

AnswerHi Alice:

>>No Worries. The Volunteers here at All Experts are here to Assist All the "Fools that Rush in"" Questioners as well as the Novice Mechanic. LOL.

>>From the Picture it Looks like the Ign Coil/Armature May have Loosened and is Striking the Magnets. It Look like there are Scratch Marks on the Magnets.

>>***Anytime a Magnet that is Set to the Correct Distance from the Armature/Ign Coil Pickups, the Armature/Ign Coil will Fire the Plug if it is Good. The Armature/Ign Coil Gap should be .015in or .020in (.015in for your Engine) between the Flywheel and the Armature/Ign Coil Pickups. You can Use a Side Panel from a Drink Carton (Mt Dew, Pepsi, ect) and Place it Between the Flywheel and the Armature/Ign Coil. Allow the Magnets on the Flywheel to Pull the Armature/Ign Coil Together and then Tighten the Armature/Ign Coil Bolts. Carefully Turn the Engine while Pulling the Cardboard Out from between the Armature/Ign Coil Pickups. The Armature/Ign Coil is Now Properly Set.***

>>As Always, Please Do Not Hesitate, If you Hit a Snag, if I Missed Something or this Does Not Correct the Problem, I am Here if You Require More Assistance. Hope this Helps. Let me Know What Happens and May the All Mighty Bless You and Yours. Thanks.

Good Luck

Respectfully

John

>>PS: I am Allowed to Answer 10 Questions a Day. If you See I am Maxxed Out, then Try Submitting your Question at or Just After 8pm EST (US). My New Day Starts then. Comments and Ratings are Greatly Appreciated. Thanks.

Respectfully

John

****Special Note: If you are Unable to Send Another Follow Up Question, then Simply Start a New Thread. The Site Only Allows a Certain Number of Follow up Questions and this is Not my Refusing to Accept Any More Follow Ups. Sometimes it can Take 6 or More Questions to Locate and Correct a Small Engine/ATV Problem.**** Thanks Again for Using All Experts.

Respectfully

John