Rick Péwé

Editor-in-Chief, 4Wheel & Off-Road

Photographers:

Rick Péwé

Rick Péwé

Editor-in-Chief, 4Wheel & Off-Road

Photographers:

Rick Péwé

Back in the late '70s and early '80s, the much maligned smog pump was being ripped off of engines left and right by Jeep owners in search of more horsepower. Back then, the thinking was that the pump not only didn't do any good, it hurt horsepower by being beltdriven off the engine. And in those days, who checked for pollution equipment anyway?

Nowadays, most people know that the OE smog pumps actually make the engine run better, help somewhat with tailpipe emissions, and have minimal parasitic drag on the engine. But most importantly, new smog laws require the original equipment controls to be in place and functioning, or, in many areas, you can't register your Jeep.

Rather than swapping plates with a legit vehicle or moving your Jeep registration to Bolivia, the easy way to pass inspection is to renovate the Air Injection System (AIS). The problem lies with finding the necessary parts at the right price. If you've ever been to the dealer, you know how expensive all the components are-if they're still available. And junkyard shopping will yield the same results. Most components are indeed junk after sitting for years; the ones of any value have been carried off by those who got there first.

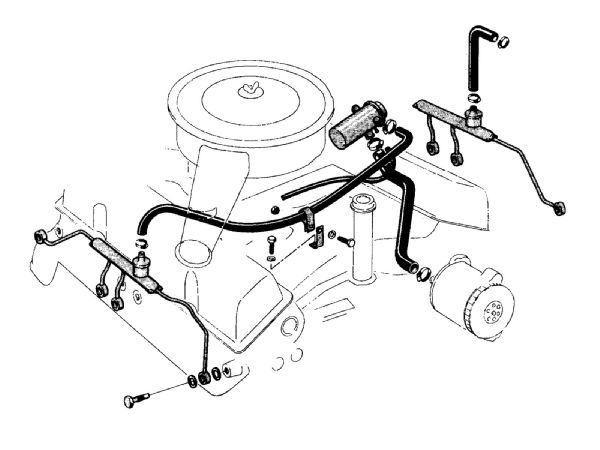

The complete smog pump kit from 4 Wheelers Supply has all the parts needed to refit the AIS. The driver-side manifold spider has only three hookups, since the power brake booster is in the way. All the factory exhaust manifolds are made that way, and the system bolts right in.

The complete smog pump kit from 4 Wheelers Supply has all the parts needed to refit the AIS. The driver-side manifold spider has only three hookups, since the power brake booster is in the way. All the factory exhaust manifolds are made that way, and the system bolts right in.

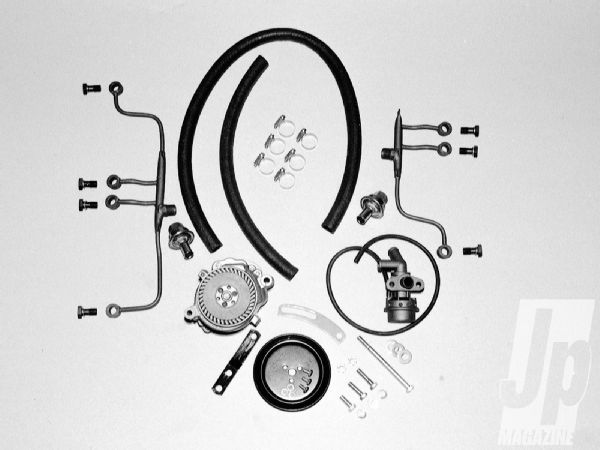

The solution is to buy the components in a kit. We found that 4 Wheelers Supply in Phoenix, Arizona, stocks the popular Jeep applications as well as many Chevy and Ford kits. 4 Wheelers has been a specialist in parts and service for Jeeps for over 40 years, and was able to supply a kit that's complete down to the vacuum tubing.

The kit we installed for an AMC 360 V-8 equipped with power steering came with the air pump, manifold tubes, check valves, diverter valve, pump brackets, and all the hoses, clamps, and bolts needed. Follow along to see how easy it is to get your Jeep emissions-legal as far as the smog pump system.

PhotosView Slideshow