John Cappa

Former Editor, Four Wheeler

John Cappa

Former Editor, Four Wheeler

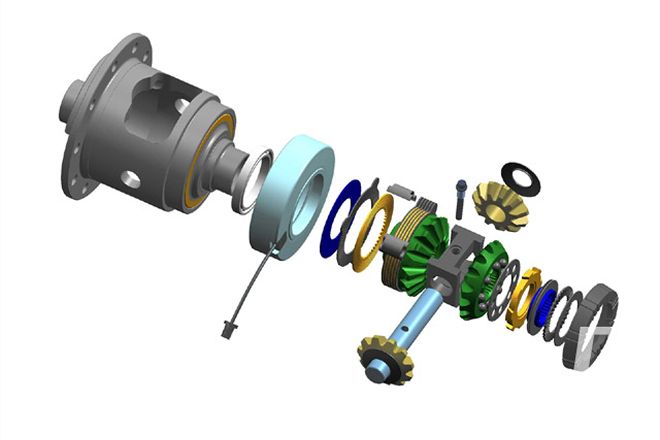

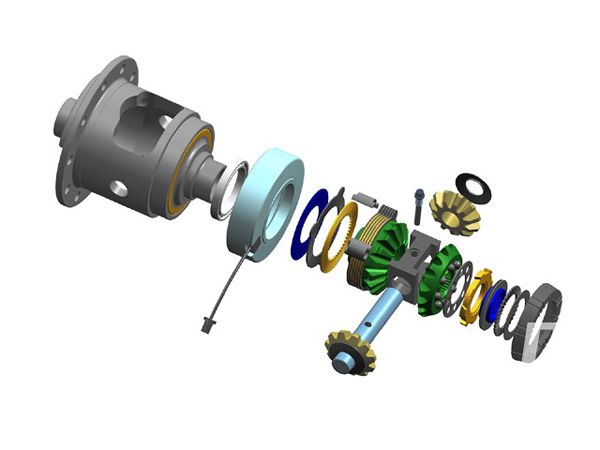

Ten years ago, selectable locking differentials were about as rare as a brain in a celebutant's head. Today, selectable lockers are more common than child-star substance abuse. These lockers can be locked and unlocked using everything from air pressure to cables, and in this case, 12-volt electricity. The Auburn ECTED is actually a limited slip and a true locking differential all wrapped into one. The limited slip mechanism of the ECTED is a clutch plate-style limited slip. The locking mechanism is engaged by an electromagnet via a 12-volt switch. It's a fairly simple install if you have a few key tools and some axle experience available to you.

How's It Work?

On our first test drive it felt like the limited slip of the ECTED would not slip to allow differentiation between the two rear wheels when cornering. And when it did allow some slip, it would chatter loudly. So we called Auburn and asked one of the engineers about our problem. He said a short break-in period may be needed for the limited slip. He recommended doing some figure-eights at a medium speed in a parking lot to get the limited slip clutches to seat. After the reassurance that our ECTED was working properly, we simply we put about 200 miles and an off-road trip on our ECTED, forgoing the parking lot break-in procedure. After that the limited slip function worked perfectly. In fact, it's likely the best-performing limited slip we've ever used. It's barely noticeable on the street; however, you'll get some tire chirp on tight corners when on the throttle. On most trails we rarely need to flip the switch and lock the locker; the ECTED's limited slip gets us through all but the worst situations. But when we do need to lock it, the action is quiet and instant. There is virtually no lag time between flipping the switch and locking or unlocking the unit. Since the ECTED utilizes friction materials, it can wear out over time. And that's really our only complaint. If or when the clutches do wear out, the unit has to be sent back to Auburn to be rebuilt. However, it is covered under the company's Differential Replacement Exchange program (D-REX). So far we've had the ECTED installed for nearly a year in the rear Dana 44 of our fullsize Jeep pickup and it has been problem-free even with 37-inch tires, a V-8, and a manual transmission with a granny-low First gear.