Whether you dial in your car through trial and error or with the use of computer software, changing spring rates is all part of the process of finding a balanced setup. The setup in the car can be balanced through the use of many different combinations of spring rates. The middle of the turns must remain balanced, but what might need to be improved is the entry and exit. Various front and rear spring split combinations will feel different to the driver and may result in a change in performance.

One way to quickly enact a spring rate change in cars is through the use of spring rubbers that increase the rate of the spring. This is useful with asphalt stock cars, and almost essential with dirt stock cars. The spring rubber causes an increase in the rate of the spring by reducing the effectiveness of one coil in the spring. Multiple spring rubbers can be used in a spring if that will provide the necessary change.

How To Rate A Rubber

The success you achieve by using spring rubbers is only as good as the knowledge of how much the spring rate changes. The rate change for a particular size and hardness of spring rubber is different for each rate and design of spring and for different amounts of preload on a certain rate of spring.

If a 25-pound-per-inch spring rubber is installed in a 200-pound spring, the amount of rate change will be different as the magnitude of preload on the spring changes. A 200-pound-per-inch rated spring that holds up 950 pounds will be compressed 431/44 inches, whereas a 200-pound spring that holds up 500 pounds will only compress 211/42 inches. There is a different gap between the coils for each application, and the spring rubber will be compressed more in the spring that supports 950 pounds than the one that supports 500 pounds.

It is also true that if we change to a 150-pound-inch rated spring in place of the 200-pound spring, the compressed height on the corner holding 950 pounds will be 611/43 inches, and the spring rubber will be compressed even more, yielding a greater spring rate of its own.

The correct way to rate a spring rubber for a particular use is to do it like rating a spring in a spring tester. First, install the spring without the rubber into the tester. Compress the spring to the same compressed length as when it is installed in the car with all of the competition-related weight in the car. Then, rate the spring in the next inch or two. This establishes the actual installed rate of the spring itself.

Spring rubbers come in different "rates," or hardness, and styles. They can be used with the large stock type of coil springs or the coilover sizes. The longer coilover springs have more room to place multiple rubbers.

Spring rubbers come in different "rates," or hardness, and styles. They can be used with the large stock type of coil springs or the coilover sizes. The longer coilover springs have more room to place multiple rubbers.

Next, relieve the pressure on the spring and install the spring rubber. Repeat the process, compressing the spring to its competition height, and go another inch or two and record the rate. The increase over the "spring only" rate is the rate of that spring rubber for that corner of the car and that particular spring.

There can be several springs rated the same in pounds per inch, but have a different number of coils and/or diameter of wire. This difference in construction means they will be different in the size of the gap between coils, and therefore there will be a difference in how much a particular spring rubber will affect the spring rate.

Uses For Spring Rubbers

Spring rubbers are used to compensate for changes in the racetrack surface grip, as on dirt throughout the day and night, and to affect changes in handling for entry and exit to and from the corners.

Many dirt tracks start out wet and tight and usually transition to a more slick condition as the event goes through the stages of practice, qualifying, heat races, and the main events. The spring rates must change as the track loses grip, and spring rubbers can be utilized to adjust to the conditions.

As in the original setup, install the best spring combination for the slick conditions, and then install spring rubbers at one or more corners to get the car set up for the tighter track condition early on in the event. As the track dries out, the spring rubbers can then be removed.

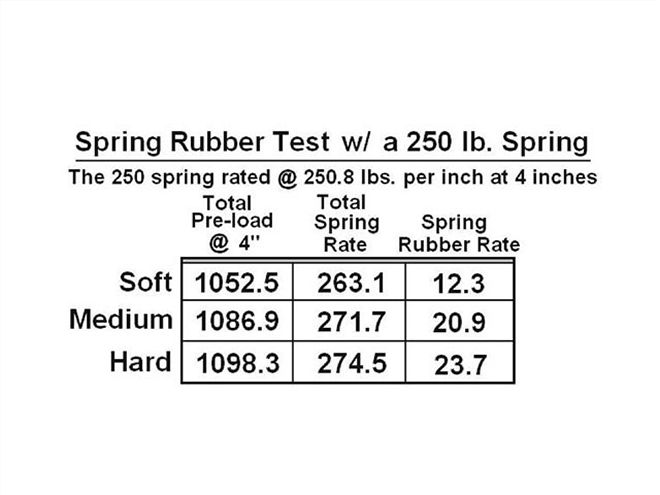

This chart indicates how the spring rate increases with the use of different hardness of spring rubbers. Always rate the spring at or near its installed height to get accurate results. You will know exactly how much the spring rates are with the use of each spring rubber.

This chart indicates how the spring rate increases with the use of different hardness of spring rubbers. Always rate the spring at or near its installed height to get accurate results. You will know exactly how much the spring rates are with the use of each spring rubber.

Several rubbers of a softer compound can be installed at one corner so that we can make two changes as conditions deteriorate. An example would be to install a 150-pound spring in the right-rear corner that would be great for a dry-slick track. Then, two 25-pound spring rubbers could be added to that spring to start out the day's practicing, and maybe qualifying with the equivalent of a 200-pound right-rear spring.

When the track has begun to dry out somewhat, but is not yet dry-slick, the heat races can be run with only one spring rubber for a combined 175-pound rate. If the track becomes drier and slicker, the remaining rubber can be yanked out for the main event.

For asphalt, you might want to experiment with various amounts of spring split in the front and rear. Spring split in the front usually doesn't greatly affect the middle handling, but can help entry into the corner on some types of tracks. If there is an equal rate of springs across the front, you can experiment with a reverse spring split up front by installing a 50-pound pre-rated spring rubber in the left-front to see if having a 50-pound split helps corner entry. Many times, it will help the transition into the corners on the flatter racetracks.

Changing the spring split in the rear greatly affects the mid-turn handling, so care must be taken when making changes to the rear springs in order to affect corner exit performance. For example, when we are using a 25-pound spring split (right-rear softer than the left-rear) in the rear to help bite off the corner, we can install a 10-pound rated spring rubber in the right-rear spring to see if only a 15-pound split will suffice. The Panhard bar height will need to be lowered along with this spring change in order to remain neutral through the middle of the corner.

The advantage of using spring rubbers to change our spring rate on each corner of the car is the speed and ease of making those changes. Do not guess the resulting rate change when putting in the rubbers; use a spring tester and rate your spring rubbers for each corner and each spring that will be used in that corner. The change in rate will be predictable, and you will be able to see the true results.

Changing springs during testing is all part of the process of finding the best combination that will make the car faster. To make the test session go better, use spring rubbers to simulate different spring rates. Rubber inserts are much faster to install and will display the same results if done correctly.

The space between the coils is greatly diminished when there is full preload on the spring. The view on top is an unloaded spring, and on the bottom is a spring with average preload. The space difference affects the rate and effectiveness of the spring rubber.

Note the difference in space between the coils outside the spring rubber and the space inside the rubber. At full preload, the rubber effectively takes almost 100 percent of one coil out of the spring equation.