Great ideas never really go away. They simply go on hiatus from time to time. That’s been the case for the last 60-plus years that encompass all three generations of the legendary Chrysler Hemi. Although the Hemi has taken a break from production-car duty multiple times in its decorated history, it always comes roaring back leaner and meaner than before. It’s not easy to determine which generation of Hemi is best, but it’s a very good problem to have. To settle the score, the AMSOIL Engine Masters Challenge established a new Hemi Showdown class for 2015. Led by Corey Short, Team Triple S proudly represented the Gen II platform with a 514ci monster that rips out 801 hp. Although the odds are always stacked against privateers electing to go toe to toe with professional engine builders, the team Triple S entry makes a compelling case for why the Elephant motor is still the best Hemi of them all.

First unveiled in ’51, the Gen I Hemi established the precedent of setting the performance bar to almost unattainable levels. By many accounts, the 354 Hemi was the first domestic V-8 to hit 1 hp per cubic inch, beating the fuelie 283 small-block Chevy to the punch by a year. The Gen I Hemi reached new heights in 1957, with raised-deck 392s producing 375 hp. Despite the early Hemi’s exceptional performance, bean counters decided that production costs were too high and pulled the plug.

With the muscle car wars heating up by 1964, Chrysler revived the Hemi with the sole purpose of destroying the competition in NASCAR. By designing an all-new hemispherical cylinder head that was easily adapted to the existing big-block wedge architecture, the famed 426 Gen II Hemi was born. Equipped with massive 2.250-inch intake valves, the Hemi cylinder heads out-flowed a standard big-block Chrysler wedge head by 80-plus cfm. The result was a staggering (yet underrated) 425 hp, more than enough to kick Chevy and Ford hinny. Hemi-powered machines finished 1-2-3-4 in the 1964 Daytona 500, prompting NASCAR to impose stricter homologation requirements.

And therein lies the mystique of the Hemi. It was essentially a full-blown race motor that Chrysler had to package into street cars in order to legalize them for competition. Not surprisingly, for many Mopar guys the only real Hemi is a Gen II Hemi. While the current crop of Gen III Hemi small-blocks are great engines that hold their own against contemporary adversaries, they certainly lack the racing pedigree of their Gen II forbears. The fact that the Elephant shares so much in common with a standard wedge motor architecture, thus lowering the barrier of entry, only enhances their appeal.

Although Corey Short has built plenty of wedge motors in his day, nothing tugs at his heartstrings like the Hemi. “Compared to a big-block wedge, the thing that surprises me most about a Hemi is the torque curve. If you build a Hemi and a wedge that both have a similar cam and compression ratio, the torque curve jumps up extremely early in the rpm range with a Hemi,” Corey reports. “It might not jump up as high, but Hemis produce a much flatter torque curve that extends much higher in the rpm range without dropping off. That translates to more horsepower. It takes a lot more work to adjust the valves, but it’s definitely worth the effort. ”

Gearing Up

Veterans of eight Engine Masters Challenges, Team Triple S has fielded a total of four Hemis over the years. Using lessons learned on the battlefield to improve each successive engine combination, Corey has been refining the Triple S entry each year with his dad, Bill, and his mom, Margie. Attending Engine Masters at the University of Northwestern Ohio each year has become a family tradition, and the Short’s deep-rooted love of Mopars serves as a continual source of motivation. “I’ve been a Mopar fan ever since I was a kid. When we first started competing in Engine Masters, not a lot a people were entering Mopar engines, so I thought we could represent,” Corey recalls. “Our engine ran well that year, and we continued to build off of that success. When the Hemi class was announced, we felt that we had a head start on the build because we had already been running a Hemi for several years.”

Although critics sometimes bash Engine Masters for being a showcase of dyno mules, that clearly isn’t the case with the Triple S 514. “We actually built this motor for my dad’s ’69 Road Runner convertible. Hemi heads are not prone to detonation, so with a good radiator and aluminum heads we will be able to run 11.4:1 compression on the street just fine on pump gas,” Corey explains. “Having lots of valve lift tends to chew up the springs, so we’ll put a smaller cam in it when it comes time to install the motor in the car. Obviously, we’re going to swap out the tunnel-ram for hood clearance reasons, but otherwise the rest of the engine combination will be very happy once it’s in a car.”

Corey says, success at Engine Masters isn’t necessarily defined by a stack of radical and exotic parts. Before an engine can put up a good score, it must first make it to the end. “The most important thing I’ve learned throughout the years is you must first show up with an engine that will run,” he reflects. “Lots of people build great engines that have lots of potential, but they haven’t spent a lot of time running them on the dyno. When you’re in the heat of competition, little gremlins will give you big headaches very quickly.”

Short-Block Design

Since the Engine Masters scoring system divides engine output by cubic inches, bigger isn’t always better. In fact, just the opposite is often the case. Nevertheless, Corey and his crew stuck to their guns and assembled an Elephant that would work well in a street car without breaking the bank, then took the necessary steps to adapt it to compete in Engine Masters. “We had a 4.440-inch-bore World Products iron Hemi block that we used in prior events. Since large motors can have a hard time competing with smaller motors at EMC, we didn’t want to put a lot of stroke in it,” Corey explains. “We decided on an Eagle 4.150-inch crank to limit displacement and to improve the rod-to-stroke ratio. The 7.100-inch rods put less side loading on the cylinder walls. Since we’re going to put this motor into a street car, we wanted longer rods that won’t taper the cylinder walls as much. The pistons are custom Wiseco domes. Straight out of the box, they don’t have any sharp edges that can catch and hold heat.”

To manage airflow in and out of the cylinders, Corey consulted with COMP Cams to spec out a 261/261-at-.050 solid-roller with .731/.731-inch lift. The cam situates the intake and exhaust lobes 108 degrees apart, and the big Hemi responded best to four degrees of advance on the dyno. Using the lessons learned from past EMC competitions, Corey resisted the temptation to opt for an overly aggressive cam. “Hemi cylinder heads flow so well on the exhaust side that you don’t need much exhaust duration at all,” Corey explains. “We experimented with a dual-pattern cam, but the engine ran better with a single-pattern cam. Reducing the overlap by going with less exhaust duration builds more cylinder pressure.”

Cylinder Heads

Of course, the key to the Hemi’s legendary performance are its hemispherical cylinder heads. Positioning the intake and exhaust valves on opposite sides of the combustion chamber offers significant performance advantages that both inline and canted-valve wedge heads struggle to match. Not only does a Hemi head allow fitting a larger valve for any given bore diameter, the design also places the valves farther away from the cylinder wall to decrease shrouding. The result is a big bump in airflow, particularly at low valve lift. Furthermore, placing the exhaust valve on the opposite side of the intake valve creates a circular, cross-flow phenomenon where exhaust gas exiting the combustion chamber can assist with cylinder filling as the intake valve opens. All these cumulative benefits enhance volumetric efficiency, and result in more horsepower and torque per cubic inch than a wedge motor.

More than 50 years later, factory Hemi cylinder heads are still impressive pieces that flow well over 300 cfm. Skilled porting can increase that number by 25 to 30 percent. Seeking to throw down the gauntlet, Corey stepped up to a set of Indy Legend 426-1RA aluminum castings. Thanks to massive 295cc ports and 2.400-inch intake valves, these beastly heads flow 510 cfm straight out of the box at .900-inch lift. As Corey learned many years ago, however, producing a broad powerband that performs well at EMC takes more than impressive peak airflow numbers.

“You really have to pay close attention to the port cross-section more than anything. Flow is important, but I’ll sacrifice some airflow to increase port velocity any day,” Corey explains. “If the port is efficient, it will carry that torque curve farther into the rpm range and give you a good score. The Indy heads are already big, so we didn’t want to make them any bigger. I touched up the short-side radius a bit, but other than that, I didn’t mess with the heads a whole lot. I also went with a smaller 2.250-inch intake valve. At .700-inch lift, these heads flow 465 cfm.”

Induction

There are very few downsides of having cylinder heads that move tons of air, but keeping up with eight hungry intake ports requires a highly efficient induction package. Corey has tested several different intake manifolds over the years, and decided to give an Indy tunnel-ram a try. Of all the different shapes and sizes intake manifolds are available in, it’s tough to beat the all-out performance of a tunnel-ram. With long runners to boost low and midrange torque and prodigious plenum volume to ensure high-rpm breathing, a tunnel-ram represents the best of both worlds. “The nice thing about the Indy tunnel-ram is that it has changeable intermediate plates. That lets you change the plenum volume to fine tune it for low- or high-rpm performance,” explains Corey. “Compared to a single-plane intake, the tunnel-ram jumps on the torque curve very quickly and it stays flat all the way across the rpm range. It also extends the torque range by 500 rpm. From one pull to the next, the gains are very repeatable. We matched it up with a pair of Demon 825cfm carbs.”

On the Pump

Big Hemis are all about big power, and the Triple S 514 definitely lived up to its reputation. With the ignition timing set to 34 to 36 degrees and 83 carb jets all around, the Hemi punished the dyno with 801 hp at 7,000 rpm and 660 lb-ft of torque at 5,300 rpm. The power had yet to level off by 7,000, indicating that there may have been a few more ponies left in the tank. The impressive performance was good for a Third-place finish in the Hemi Generational Challenge class. Although the EMC scoring system places a premium on average horsepower and torque between 3,000 and 7,000, the fact that the Triple S Hemi posted the second-highest peak horsepower total is impressive nonetheless. That’s not the second-highest in the Hemi class, mind you, but the second-highest peak horsepower number among every single engine entered into the entire competition.

Even so, rules are rules and everyone has to follow the same laws of the land. Cory admits that the ports are simply too big for a competition like EMC, and the massive Indy cylinder heads need more cam duration and rpm to really shine. Not surprisingly, great things can happen when you do exactly that, and even less surprisingly, Corey has some tasty numbers for everyone to chomp on. “We’ve tested this same motor with a 272/272-at-.050 cam, and it made 900 hp at 8,000 rpm. At that point, those too-damn-big intake ports finally hit their stride,” Corey quips.

As impressive as that may be, there’s even more potential to uncork. By big-block standards, a 2.250-inch intake valve is quite modest. By stepping up to 2.400-inch valves and increasing lift to .900 inch, this is a combo that could easily crack 1,000 horsepower. Needless to say, it’s tough to argue with anyone who thinks that the Gen II Hemi is the best Hemi of them all.

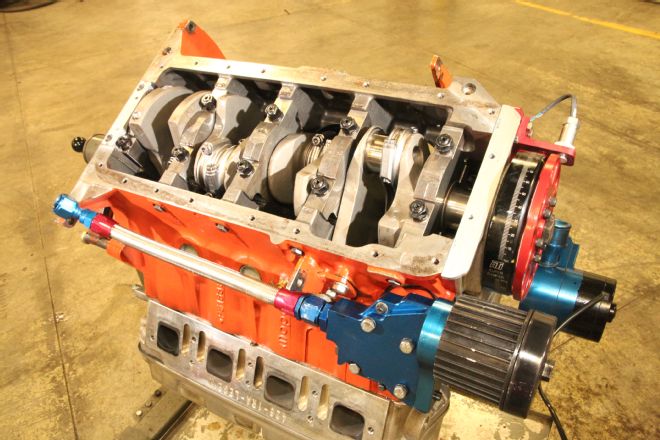

1. The beefy World Products Hemi iron block has been bored, honed, decked, and align-honed. The forged 4.150-inch Eagle crank fits with plenty of room the spare. In fact, the block can accommodate up to a 4.750-inch stroke.

2. Cross-bolted four-bolt main caps distinguish the beefy Hemi block from a standard RB block. ARP fasteners secure them in place. Relief notches cut into each cap promote more efficient bay-to-bay breathing.

3. The massive 170cc combustion chambers in conjunction with a modest 4.150-inch stroke require a large piston dome to achieve the target 11.4:1 compression ratio. The custom Wiseco pistons have been matched with 7.100-inch Eagle rods to achieve a more favorable rod-to-stroke ratio.

4. To help manage oil entrainment and foaming, the 514 relies on both an OE windage tray as well as a tray built into the Charlie’s oil pan. The B-Body pan features an external pickup, and is the same pan that will be used in Bill Short’s Road Runner.

5. Pressurizing the oil galleys is an Indy Maxx billet pump. The World Products block allows the oil pump to be mounted in multiple configurations for easier underhood packaging.

6. Sharp edges create hot spots, which can lead to detonation. Wiseco rounded off all the sharp edges from the piston crowns prior to shipping.

7. Converting the camshaft’s rotating motion into reciprocating motion is a set of .904-inch COMP Cams solid-roller lifters. The World Products block boasts reinforced lifter bores for additional support.

8. Notches sliced into the lifter valley create a passageway for the exhaust pushrods to actuate the exhaust valves on the opposite side of the cylinder head. The exhaust pushrods slip inside holes drilled into the center of the cylinder head and the deck surface. This virtually eliminates pushrod pinch, and makes room for the gargantuan intake ports.

9. The Indy Legend heads feature raised intake port entries that create a straighter flow path into the combustion chambers. When combined with Indy’s CNC-porting, 500-plus cfm is the result. Big-block Chevys require Pro Stock–inspired spread-port castings to come anywhere near this level of flow.

10. The exhaust ports on the Indy castings are capable of flowing up to 330 cfm at .900-inch lift. Compared to stock castings, the ports have been raised .750 inch.

11. By positioning the valves on opposite sides of the chamber, both the intake and exhaust valves move away from their respective sides of the cylinder walls as they open. This contributes to the phenomenal flow potential of the Hemi architecture. The exhaust valves are tilted an additional 2 degrees in the Indy castings to create more valve-to-valve clearance during overlap.

12. In a Hemi, each set of valves gets its own rocker shaft. Unlike the factory heads, the Indy castings feature cast-in pedestals that make it much easier to shim up the rockers. Rounding out the valvetrain are Indy rocker arms, and K-Motion valvesprings (285 seat pressure, 690 open pressure) retainers, and locks.

13. Increasing plenum volume typically increases top end horsepower. The trick Indy tunnel-ram allows changing the plenum volume by adding or removing plates in between the top and bottom halves of the intake manifold. Twin 825-cfm Race Demon carbs meter a steady stream of fuel into the cylinders.

14. The Hemi exhales through off-the-shelf Hedman B-Body headers featuring 2-inch primaries and 3.5-inch collectors. Corey experimented with larger headers, but the smaller tubes provided a much broader powerband despite sacrificing a couple of horsepower on top.

15. In addition to adapting an inexpensive small-block Chevy water pump to a Hemi block, the Indy water pump plate reverses the flow of the coolant into the heads and out of the block. By cooling the cylinder heads before the block, the potential for detonation is reduced.

16. An MSD billet distributor provides the spark, and is controlled by an MSD 6AL ignition box. Since the ignition box must be mounted directly to the engine, over the years Corey has learned that a durable ignition system is a must. He reports that the MSD box has had no problem enduring the vibrations encountered during dyno testing.

17. Valvetrain flex can lead to imprecise ignition timing. To eliminate this variable, the Triple S Hemi uses an MSD crank trigger. The trigger wheel mounts directly on top of the ATI damper, while the sensor bolts to the timing cover.

18. The big Triple S 514 lived up to the Hemi’s larger-than-life reputation by cranking out 801 hp. Arguably one of the best-looking motors at EMC, the Hemi posted the second-highest peak horsepower of the entire event.

On The Dyno: 514ci Gen II Hemi RPM: TQ: HP: 3,000 539 308 3,100 542 320 3,200 538 328 3,300 527 331 3,400 522 338 3,500 528 352 3,600 540 370 3,700 556 382 3,800 571 413 3,900 583 433 4,000 594 452 4,100 603 471 4,200 608 486 4,300 610 500 4,400 613 514 4,500 617 529 4,600 623 545 4,700 630 563 4,800 634 579 4,900 640 597 5,000 645 614 5,100 652 634 5,200 659 653 5,300 660 666 5,400 659 678 5,500 656 687 5,600 655 699 5,700 656 712 5,800 654 722 5,900 658 739 6,000 656 749 6,100 653 759 6,200 652 770 6,300 645 773 6,400 638 778 6,500 629 778 6,600 623 784 6,700 618 789 6,800 613 794 6,900 610 801 7,000 601 801

Fast Facts: 514ci Chrysler Hemi Bore: 4.440 inches Stroke: 4.150 inches Displacement: 514 ci Compression Ratio: 514 ci Camshaft: Custom COMP solid-roller Valve Lift: 0.731/0.731 inch by BES Racing Engines Duration: 261/261 degrees at 0.050 Lobe separation angle: 108 degrees Cam installed centerline: 104 degrees Rocker and ratio: Indy 1.6:1 shaft-mount Lifters: COMP Cams 0.904-inch solid-roller Pushrods: Manton Piston Rings: Total Seal .043/.043/3mm Piston: Custom Wiseco forged aluminum Block: World Products iron Crankshaft: Eagle 4.150-inch forged 4340 Rods: Eagle 7.100-inch steel Main journal diameter: 2.750 inches Rod journal diameter: 2.200 inches Bearings: Clevite H-series Cylinder Head: Indy Legend 426-1RA aluminum castings Intake port flow: 465 cfm at 0.700-inch lift Chamber volume: 301 cfm at 0.700-inch lift Intake valve diameter: 170cc Exhaust valve diameter: 2.250 inches Valvesprings: 1.940 inches Spring retainers: K-Motion 1.645-inch Head gasket: K-Motion steel Intake manifold: Cometic 0.051-inch MLS Carburetor: Indy tunnel-ram Headers: dual Demon 825 cfm Headers: Hedman 2.000-inch long-tube Ignition: MSD billet distributor Damper: ATI Water pump: Meziere Oil pan: Charlie’s Oil pump: Indy Maxx billet Fuel: VP 101-octane unleaded Timing advance: 36 degrees