There's a pretty simple answer to making horsepower, no matter what engine you're working with: airflow. Air needs to enter the cylinders as efficiently as possible, and exhaust needs to exit just as quickly. Things get complicated from there, however, because that's when you need to decide on things like compression ratio, cam specs, and timing. Other factors to consider include transmission ratios and rear-axle ratio—variables that affect how effective your engine is at getting power to the ground, but those are for later articles. Here, we are showing one specific way to get maximum horsepower from modest displacement and a set of cast-iron cylinder heads.

IMM Engine and Dyno is a small, father-and-son shop in Indio, California. Brian Hafliger bought the business from his father, Fred, about 12 years ago, and the two have been churning out some impressive engines through the years, all while continuing to work on everything from flathead Fords to old tractor engines. Brian has a reputation as a specialist of the small-block Mopar engines for a while. It's a natural fit; he owns a 10-second 1971 Duster. This build is an evolution of one Car Craft ran in the June 2010 issue that made 480 hp with a set of these cast-iron cylinder heads, installed right out of the box. Ever since then, Brian has been curious about just how much horsepower can be made with these castings, which are now manufactured by Indy. He experimented with some porting and had his best-flowing version scanned and turned into a CNC program, which was used to port this set of heads here. Let's check out what goes into a 600hp, small-block Mopar.

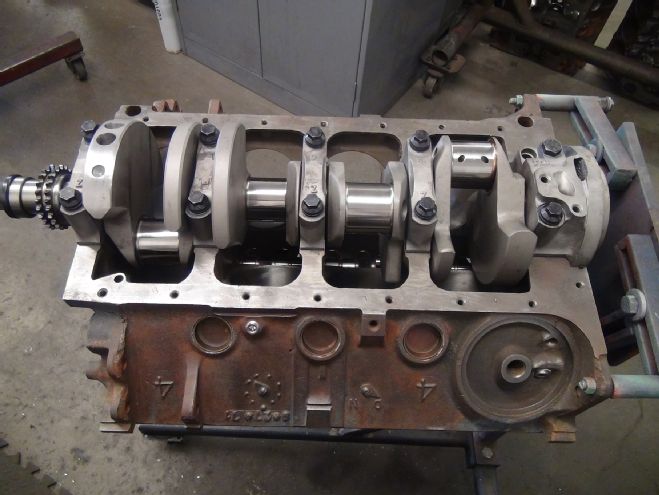

The foundation of this builds begins with a production Dodge 340 engine block Brian plucked from a local wrecking yard. He bored the engine to 4.060-inch using a BHJ torque plate and decked the block to set the pistons 0.005 inch in the hole.

Brian selected a 3.79-inch-stroke crankshaft from Molnar Technologies. Forged from 4340-alloy steel, it is reasonably priced and will take lots of abuse in the form of high rpm and maybe a hit if nitrous if Brian is so inclined. Brian chose this stroke length because it will put the engine at the rpm he wants to run through the lights at the track. Note how this small-block easily swallows nearly a 4.00-inch-stroke crankshaft without any grinding for clearance.

The crank is paired with a set of Molnar's steel 6.20-inch H-beam connecting rods. These are actually small-block Chevy rods (gasp!) with a 0.927-inch pin diameter and a 2.160-inch crank journal. The rod bearing clearance was 0.0027 inch.

Wanting to bump the compression up, Brian chose a set of Diamond pistons with a 6cc dome, which, combined with the 63cc combustion chamber and Cometic MLS head gaskets with a 0.040-inch compressed thickness, yielded a compression ratio of 13.00:1. Get the race gas ready! Note the extra material above the top ring land. This allows for a deeper valve relief on the domed piston. Brian measured 0.125-inch piston-to-valve clearance on the intake side and 0.1200-inch on the exhaust. The piston-to-wall clearance is 0.005 inch. The rings are from Hastings and include a 1.5mm, moly-faced, ductile iron top ring, a 1.5-mm Napier second ring, and 3.0mm oil control rings. Brian gapped the top rings to 0.020 inch and the second rings to 0.044 inch, which allows any pressure that builds in the space between the top and second ring to escape more easily, making the top ring seal better.

As is his standard practice, Brian opened up and smoothed the oil passages in the block leading from the pump to the oil galleries and did the same to the outlet passage on the oil pump.

Assembly of the short-block was completed with the installation of a Melling high-volume oil pump. ARP main and rod bolts were used to secure the rotating assembly.

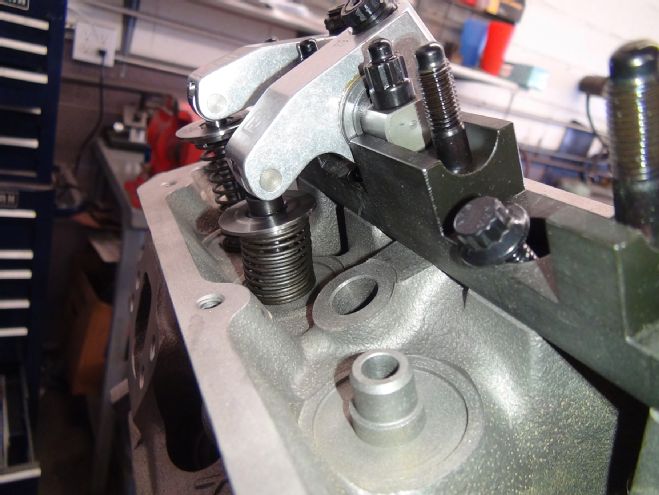

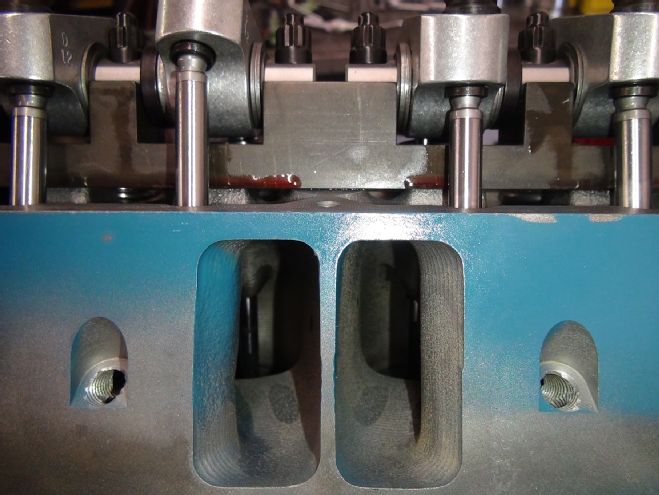

One way to make big horsepower numbers is through lots of rpm, but to do that, you need to build a stable valvetrain; in this case, 5/16-inch valve stems, lightweight valves, titanium retainers, and pushrods and rocker arms that don't flex or bend under the relatively high spring rates needed to control the valves at 7,000-plus rpm. Brian chose these paired-assembly T&D shaft-mount rocker arms because they fit the criteria. Seen here with checking springs installed, the T&D rocker arms offer a 1.7:1 ratio on the intake and 1.6:1 on the exhaust (1.6:1 is stock) and oil through the pushrods, like the later Magnum-style cylinder heads. The Manton pushrods measure 11/32-inch with a 0.140-inch wall thickness.

The Comp solid roller cam offers 267/272 degrees duration at 0.050-inch tappet lift, 0.685/0.650 gross valve lift, ground on a 107-degree lobe-separation angle. Brian had to bush the lifter bores because the high lift numbers pushed the lifters high enough to uncover the oil grooves, which cause a major internal oil leak. That's a pushrod-checking tool being used here, which allows Brian to measure the exact length pushrods he will need to get the rocker arm to contact the tip of the valve correctly.

Running the engine through a full cycle, Brian checked the rocker arm's sweep across the tip of the valve to ensure it was centered over the valve. Note the use of ARP fasteners on the valvetrain components.

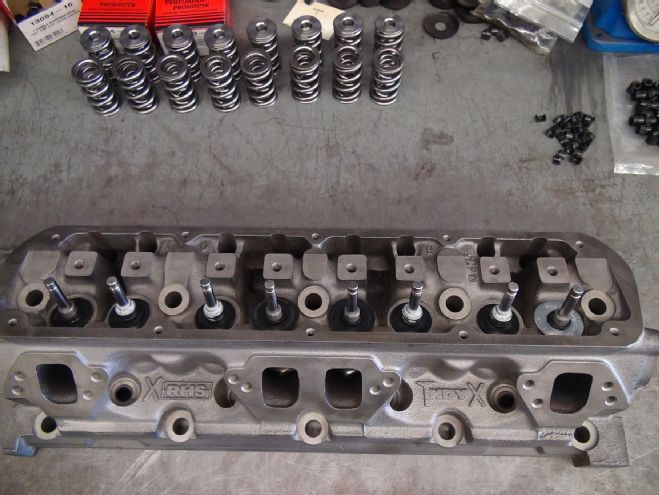

Having established the correct pushrod length, Brian assembled the heads with IMM/Ferrea 6,000-series valves (2.02-inch intake, 1.60-inch exhaust) and IMM's solid-roller cam spring kit, which measures 210 pounds on the seat and 525 pounds of open pressure.

You can see the effectiveness of porting these heads, which are limited on the intake side by the protrusion of the pushrod passage into the intake runner. The porting opens up this area as much as is effective to maximize airflow through the port, paying close attention to the port's cross-sectional area and a complete flow curve. The intake runners measure 200 cc.

Nearing completion, the Innovators West dampener and Indy's single-plane intake manifold were installed. The manifold is a good fit for the engine speeds and power curve we want the engine to generate.

On the Dyno

On IMM's DTS engine dyno, the engine made its best power with a Holley's 1,000hp carb, the valves set to 0.018-inch lash, an MSD billet distributor, MSD's Digital 6 ingnition box, and MSD's HVS II coil. The timing was set to 32 degrees total timing, and TTi headers had 1-7/8 primary tubes with 3-inch collectors. These are the same headers that will be used when this engine is installed in a car. For all pulls, the oil temperature was 160 degrees and the water temperature was 140 degrees. The engine ran on VP Racing 110-octane unleaded gasoline. The first couple of pulls were disappointing, with power levels at just 574 hp, but advancing the timing just 2 degrees yielded nearly a 20hp increase to 593. Tightening the lash unleashed a few more ponies, and the engine ultimately made 606 hp at 6,800 rpm. The engine made more than 600 hp from 6,400–7,000 rpm and Brian carried the dyno pulls to 7,300 rpm, about where his car would run through the traps at the dragstrip.

RPMHPLB-FT 4,500419489 4,600434495 4,800462506 5,000488513 5,200513518 5,400532517 5,600546512 5,800561508 6,000576504 6,200589499 6,400600492 6,600606481 6,800606468 7,000602452