Loyal readers of Super Chevy will immediately recognize this 454 (aka BBC Big Hero VI) as the very same engine we plucked from a wrecking yard and plopped on the dyno. In Part 1, we stripped the Gen VI 454 of its factory injection and installed a Holley carburetor, Edelbrock intake, and MSD distributor. Despite unknown mileage and internal condition, we ventured forward and subjected the engine to the rigors of the dyno. As luck (or preparation) would have it, we were rewarded with not just a decent-running BBC, but one that seemed to revel in the abuse we had planned for it. After the initial baseline runs, we stepped right up and swung for the fences by adding a ZEX nitrous system. Undaunted, our BBC hero shrugged off the chemical warfare and offered up over 500 hp and 650 lb-ft of torque. If that isn’t the quickest and most inexpensive path to an 11-second powerplant, we don’t know what is. As much as we loved the idea of a nitrous-injected, wrecking yard engine, we decided it was time to dig into the internals and make some power the old-fashioned way.

The sheer displacement meant our BBC hero had plenty of potential. All we had to do was unlock all that power. In stock trim, the low-compression and mild cam timing kept the 454 from achieving its true potential. For this test, we decided to take a look at the cam timing, as a change in compression meant head and/or piston removal, either of which was considerably more involved than a simple cam swap. Besides, the right cam would make much more of a power difference than a couple extra points of compression, and the L29 was already sporting small combustion chambers, which would all but dictate a piston change to alter compression. Changing the pistons would mean rebalancing the assembly, not to mention additional machine work, since we would want to bore the block for a fresh ring seal. After weighing the options, we settled on the cam swap, but it too was not without a little extra work.

Despite the low static compression, care must be taken when replacing the cam on a stock L29 454. The lack of valve reliefs in the pistons minimizes available piston-to-valve clearance. There is a very real limit to how much lift you can run. Another consideration is the fact that swapping in a healthy (high-lift) cam will also require a valvespring upgrade. The COMP XM284HR cam offered 0.547-inch lift (intake and exhaust), a 230/236-degree duration split, and a 112-degree LSA. After installing the cam, but before installing the COMP Cams beehive valvesprings (PN 26120), we took the liberty of checking the valve clearance. Using a light checker spring and dial indicator, we measured 0.065-inch clearance on the intake and over 0.110 on the exhaust. We’d like to see a little more on the intake but we were satisfied with the available clearance and soldiered on.

Because the stock valvesprings were both tired and inadequate (in terms of both rate and available coil-bind clearance), we replaced them with the recommended beehive springs. The beehive springs were teamed with a set of steel retainers (this low-rpm BBC did not need titanium retainers) and seat spacers (PN 4698) to replace the factory spring rotators. The spacers both located the beehive springs and maintained the necessary installed height for proper seat and open spring pressures. Though the factory hydraulic roller lifters were still in running order, we replaced them with a set of lifters (PN 900-16) for good measure. The replacement lifters were designed to work with the factory guides and retainer system. The Gen VI BBC also relies on factory non-adjustable, bolt-down, stamped-steel rockers and 5/16-inch guideplates and pushrods. We will likely upgrade the non-adjustable rockers in the future, but for now, we retained the remainder of the stock components.

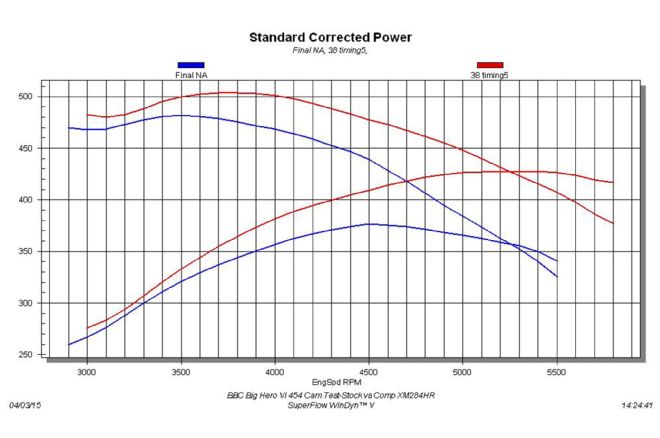

With our cam upgrade in place, it was time for more dyno testing. After the cam swap, we installed the same Edelbrock Performer RPM Air-Gap intake, Holley 750 HP carburetor, and MSD distributor run in Part 1. After installation of the induction components, BBC Big Hero VI was once again installed on the dyno and run in anger with the new cam and valvesprings. The 454 responded very well to the cam upgrade, as the peak numbers jumped from 376 hp and 482 lb-ft with the stock cam to 428 hp and 507 lb-ft of torque. An increase of 52 hp is always welcome, especially when it comes with a sizable jump in peak torque. Every bit as important was the fact that the combination never traded power down low for the extra 87 hp offered at 5,500 rpm. In fact, the cam swap improved power production through the entire rev range, from 3,000 rpm right past 5,500 rpm. With sufficient cam and displacement, what our hero needs now is a set of deep-breathing cylinder heads.

1. The good news is that the Gen VI BBC came factory equipped with a hydraulic roller cam. The bad news is that despite being a hydraulic roller profile, the wimpy specs greatly limit power production.

2. Cam replacement required the removal of the factory damper and composite front cover. Note the Gen VI BBC features a unique front cover design not shared with the previous generations.

3. Removal of the damper and front cover provided access to the factory timing chain. Note the 4X trigger wheel on the crank snout used for the electronic fuel injection. Make sure to plug the crank sensor hole before running the engine – we found out the hard way.

4. Removal of the cam gear provided access to the cam retaining plate. The factory hydraulic roller cam required a cam retaining plate to eliminate forward cam walk.

5. With our retaining plate removed, out came the factory cam to make way for our performance grind. Despite the low static compression ratio, the factory piston design limits available piston-to-valve clearance. The COMP Cams XM284HR offered 0.547-inch lift, a 230/236-degree duration split, and a 112-degree LSA.

6. The cam swap necessitated a valvespring upgrade, as the stock valvesprings were inadequate for our new cam profile. That being said, the high-mileage units were just plain worn out. The factory, non-adjustable valvetrain featured bolt-down, stamped steel rockers; guideplates; and 5/16-inch pushrods.

7. Spring removal was a simple affair, requiring only a spring compressor and feeding air to the cylinder to hold the valves in place. Removing the factory springs revealed the spring rotators.

8. The rotators were replaced by a set of rotator eliminators available from COMP Cams. The rotator eliminators were sized to locate the new springs and replace the rotators while maintaining the correct installed spring height.

9. While replacing the springs, we took the opportunity to check the all-important piston-to-valve clearance with our new cam profile. The XM284HR cam just squeezed by with 0.065-inch intake and 0.110-inch exhaust clearance.

10. After checking the clearance, we installed the COMP beehive springs (PN 26120) and steel retainers (PN 975).

11. After installation of the factory bolt-down rockers, BBC Big Hero VI was ready to test.

12. We installed the Holley 750 HP carb onto the awaiting Edelbrock Performer RPM Air-Gap intake, then stuffed in the same MSD distributor used in Part 1.

Big Hero Cam Test. Stock vs. COMP XM284HR

The right cam makes all the difference in the world, especially when you team it with the proper valvespring upgrade. Replacing the stock valvetrain components with a COMP XM284HR cam, springs, and retainers resulted in some serious power gains. Not only did the cam swap net an additional 52 horsepower (peak-to-peak), but the gains exceeded 80 hp higher in the rev range. Even better than the big peak gains was the fact that the cam swap improved power through the entire rev range. Equipped with the new cam, torque production from the 454 now exceeded 500 lb-ft.