After a handful of naturally aspirated mods, we just couldn’t wait any longer before subjecting Mini Mouse (our 4.8L LR4 test engine) to some positive pressure. Mini Mouse has been built to demonstrate the power potential of the smallest factory LS. Back in part 1, we installed a mild Crane cam then followed up with a pair of Edelbrock carbureted intakes. We stepped up our game in part 2 with a more aggressive Crane cam and a set of Gen X 205 heads from Trick Flow Specialties. These mods yielded impressive power, but we were a long way from exhausting all of the available naturally aspirated mods. Fear not, as we will revisit things like headers, intake manifolds, and even changes in displacement, but how can we resist the temptation of having a pair of manifolds, a big turbo, and a sizable air-to-water intercooler sitting at the shop just begging to be tested? Turbo time, here we come.

Adding a turbo to any engine offers the promise of big power, but we wanted to demonstrate more than just the gains offered by boost. Before we get to the testing, we need to understand a little more about the effects of positive pressure. Boost from a turbo is a wonderful thing as it often acts as a multiplier of the original power output. For example, suppose we have a 400hp engine and want to add boost. Since a naturally aspirated engine is running at atmospheric pressure (14.7 psi), to double the output you’d need to double the pressure. If we add 14.7 psi of boost to our 400hp engine, we can theoretically get 800 hp. This power/boost formula also works at lower and higher boost levels. If we add 7.35 (14.7 / 2 = 7.35) psi we can expect to see a 50 percent increase in power, taking our 400hp engine to 600 hp.

However, there are—as always—reasons why turbo engines may not follow the gains predicted by the formula. These can include restrictive intake and/or exhaust flow (excessive backpressure), an improperly sized turbo, or inadequate cam timing. This is why we test engines on the dyno (it seems engines and dynos skipped a few math classes). More than just bolting a turbo to Mini Mouse, we decided to start by demonstrating the gains offered by a single-turbo kit, then install the same Gen X 205 heads and Crane cam we installed back in part 2. The easy way would simply be to add the turbo and call it a day, or even add the turbo then add the heads and cam together, but here at Super Chevy, we don’t take the easy way out. Our readers deserve better, so we installed each component individually to demonstrate the gains offered by each.

Since Mini Mouse was still sporting the TFS head and Crane cam from part 2, off they came and on went the stock heads and cam. Basically, we put Mini Mouse back in stock trim and she responded by producing 336 hp at 5,600 rpm and 345 lb-ft of torque at 4,700 rpm. The only change from our baseline in part 2 was the addition of a set of 83-pound Holley injectors. As always, the 4.8L was fed by an Aeromotive A1000 fuel system, tuned using a Holley Dominator EFI system, and cooled by a Meziere electric water pump. Also present was Lucas 5W-30 synthetic oil, QTP long-tube headers, and Accufab throttle body feeding the stock truck intake. With our baseline done, it was time to install our homemade turbo system. Dedicated kits are available for LS applications, but we decided to configure our own system for dyno use.

The current rage seems to be reversing the cast-iron factory or tubular exhaust manifolds and building your own Y-pipe to mount the turbo. We chose the low-buck, tubular manifold route. We picked up a pair of stainless turbo headers from DNA Motoring that came complete with V-band flanges for easy attachment. Using the two manifolds, we welded up our own Y-pipe to channel the exhaust from each bank to a single T4 turbo flange (supplied by CXRacing). The Y-pipe featured provisions for a pair of 45mm Turbosmart Hyper-Gate45 wastegates, ensuring maximum boost control. DNA also supplied the GT45-style turbo, which is capable of supporting over 800 hp. Boost from the turbo was fed through a massive air-to-water intercooler core from CXRacing to the Accufab throttle body. In addition to the intercooler, CXRacing also supplied flanges, silicone hose connectors, and even a trick bulkhead oil drain fitting that eliminated the need to weld or tap the oil pan.

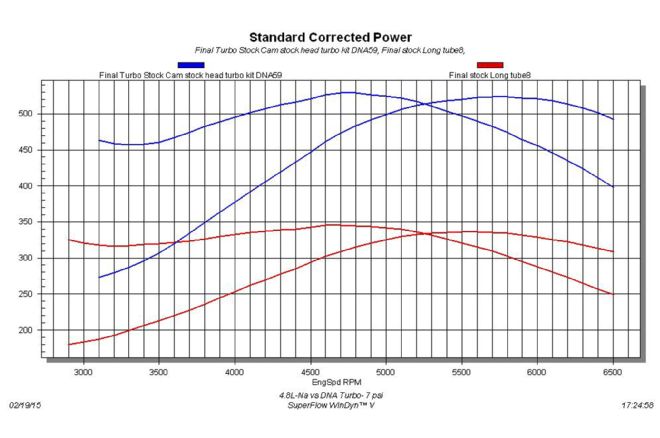

The first order of business was to install the turbo kit and run the stock engine at 7 psi (the wastegate spring setting). The 4.8L would definitely take more boost, but we wanted to demonstrate the gains offered by the heads and cam under boost, not to maximize the power output of a turbocharged stock engine. We have big plans for Mini Mouse, including a supercharger, nitrous, and possibly a stroker kit, so there was no need to set phasers on kill with this first turbo test. Tuning the turbo combination was easy with the Holley Dominator EFI, and the 83-pound injectors offered more than enough fuel to feed the turbo Mouse. Running 7 psi of boost, an air/fuel ratio of 11.8:1, and 24 degrees of total timing (on race fuel), the intercooled turbo 4.8L produced 524 hp at 5,800 rpm and 529 lb-ft of torque at 4,700 rpm. A peek at the graph reveals that the DNA turbo maximized torque production even as low as 3,000 rpm. Equipped with the turbo, the little LR4 pumped out torque like an LS7.

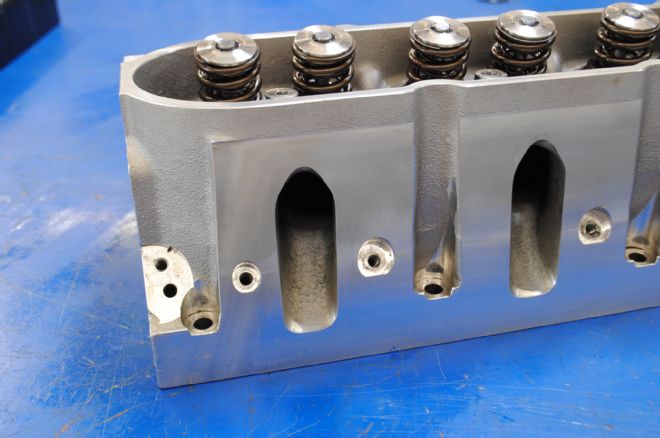

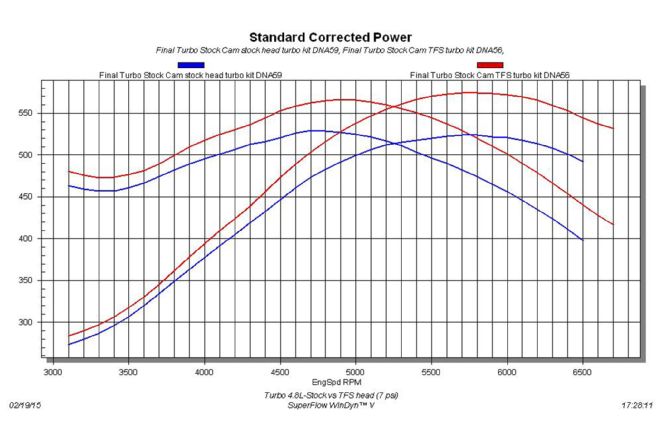

Happy with our first visit to boost-land, it was time for a few modifications. First on the list was a head swap to the Trick Flow Specialties Gen X 205 heads used in part 2 of this series. The TFS Gen X 205 heads were chosen because they were designed specifically for the small-bore 4.8L/5.3L engines. The 205cc intake ports flowed 284 cfm and the Gen X package included altered valve angles, 58cc combustion chambers, and a 2.000/1.575 valve package. The Gen X 205 heads were installed using Fel-Pro head gaskets and ARP head studs. Once installed, we ran the engine with the single DNA turbo pumping out 7 psi of boost. Equipped with the new TFS heads, the power output of the turbo 4.8L jumped to 574 hp at 5,800 rpm and 566 lb-ft of torque at 4,900 rpm. As much as we liked the peak power gains, we loved the fact that the head swap improved the power output throughout the entire powerband—a sign of a well-designed modification. Given the stock cam profile, we were surprised by the gains achieved by the head swap under boost, but that is why we test. When it comes to cylinder heads, it is obvious that turbo LS engines need something better than stock.

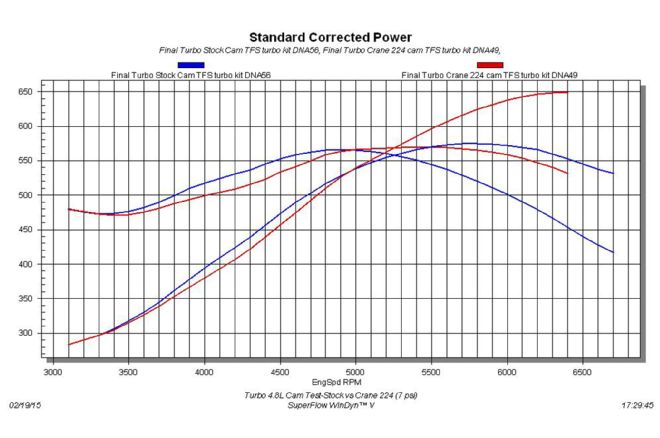

The final modification was to install the Crane 224 cam. Offering specs of 0.590-inch lift (intake and exhaust), a 224/232-degree duration split, and 115-degree LSA, the Crane cam was a significant step up from the stock cam. The TFS Gen X 205 heads featured a dual valvespring package capable of supporting over 0.650-inch lift, so there was no issue with our 0.590-lift Crane cam. The 4.8L responded very well to the cam swap, as the peak numbers jumped to 648 hp at 6,300 rpm and 569 lb-ft of torque at 5,500 rpm. Yeah, the peak power gains were impressive, but the gains were even greater higher in the rev range. At 6,300 rpm, the output was over 100 hp more than from the head test. Had we elected to run the turbo engine higher, the gains would have been even greater as the naturally aspirated engine equipped with the TFS heads and Crane cam made peak power at 6,800 rpm. Having subjected Mini Mouse to a turbo, we were ready for (you guessed it) more boost. Check back for part 4 when we add a Whipple supercharger to the mix.

1. Equipped with the stock heads, cam, and truck intake, the little 4.8L that could produced 336 hp at 5,600 rpm and 345 lb-ft of torque at 4,700 rpm.

2. The single-turbo kit revolved around these turbo manifolds supplied by DNA Motoring. The manifolds featured mandrel bends, stainless steel construction, and V-band exit flanges.

3. We welded up this custom Y-pipe to channel the exhaust gases to the T4 turbo flange.

4. To ensure adequate boost control, the Y-pipe was configured with a pair of 45mm Hyper-Gate45 wastegates from Turbosmart.

5. Boost came from this GT45-style turbo supplied by DNA Motoring. Capable of supporting in excess of 800 horsepower, the DNA turbo was not even breaking a sweat at 7 psi.

6. Truth be told, this air-to-water intercooler from CXRacing was probably unnecessary at 7 psi, but it would be on hand for future boost upgrades.

7. To eliminate the possibility of compressor surge, Turbosmart also supplied a Race Port blow-off valve.

8. Obviously, stock injectors were not going to get the job done, so we stepped up to a set of 83-pound injectors from Holley.

9. Important on a naturally aspirated engine but critical on a turbo engine, tuning came from this Holley Dominator EFI system.

10. It was necessary to drill a hole and install a bulkhead fitting in the oil pan to serve as an oil drain from the turbo. CXRacing supplied the easy-to-install bulkhead fitting.

11. Equipped with the turbo, the boosted 4.8L produced 524 hp at 5,800 rpm and 529 lb-ft of torque at 4,700 rpm. Note that these power peaks came at nearly the same rpm as the naturally aspirated setup.

12. Did the stock heads represent a restriction to flow on the turbo engine? There was only one way to find out; we installed these Gen X 205 heads from Trick Flow Specialties.

13. The 205cc intake ports on the Gen X 205 heads offered the ideal combination of port volume and flow. Though our little 4.8L could not take full advantage of the available 284 cfm, we were curious to see if the additional flow would translate into power under boost.

14. Our small-bore 4.8L required a small-bore combustion chamber. Both from a diameter and volume standpoint, the 58cc combustion chambers were sized perfectly for Mini Mouse. The chambers in the Gen X 205 heads were home to a 2.000/1.575 valve combo.

15. To ensure proper sealing under boost, the TFS heads were installed using Fel-Pro MLS head gaskets and ARP head studs.

16. The turbo 4.8L responded very well to the Gen X 205 head swap, as the power output jumped to 574 hp and 566 lb-ft of torque.

17. Next on the to-do list was a cam upgrade. Having previously installed the 224 Crane cam on the naturally aspirated combo, we decided to give it a try under boost. The Crane cam offered 0.590-inch lift (intake and exhaust), 224/232-degree duration, and 115-degree LSA.

18. The cam swap yielded impressive results, as the peak numbers jumped to 648 hp and 569 lb-ft of torque. The majority of the gains came higher in the rev range and it is likely that a slightly milder cam might be a better choice for a dedicated street application on the smaller 4.8L, but how do you argue with a 648 hp 4.8L at just 7 psi?

19. If you think we got our fill of boost, you are dead wrong. Next time we’re putting the “screws” to Mini Mouse.

Mini Mouse 4.8L. NA vs Turbo (7 psi)

For this first test, Mini Mouse was returned to stock trim so we could reestablish a baseline. Running the stock cam, heads, and truck intake, the naturally aspirated 4.8L produced 336 hp at 5,600 rpm and 345 lb-ft of torque at 4,700 rpm. After the installation of the single, intercooled turbo kit, peak power output jumped to 524 hp at 5,800 rpm and 529 lb-ft of torque at 4,700 rpm. This power gain came at a peak boost level of just 7 psi.

Turbo 4.8L Head Test. Stock vs TFS Gen X 205 (7 psi)

With the turbo kit up and running, it was time for a head upgrade. Replacing the stock 706 heads with a set of TFS Gen X 205 heads resulted in a serious chunk of horsepower. Equipped with the new TFS Gen X 205 heads, Mini Mouse stepped up to 574 hp and 566 lb-ft of torque. The head swap increased the power output from 3,000 rpm all the way through 6,500 rpm.

Turbo 4.8L Cam Test. Stock vs Crane 224 (7 psi)

The final test of the day was to replace the factory cam with a performance piece from Crane cams. The very same 224 cam used back in part 2 was installed on the turbo combination with excellent results. The Crane cam improved the power output to 648 hp and 569 lb-ft of torque. Remember, all of this testing was performed at just 7 psi of boost.