There is no doubt that the stud-mounted rocker systems that are commonplace on Magnum small-blocks are simpler and easier to work with. But there’s a reason why any high-end race team, whether it is NASCAR or road racing—always ditch the stud-mounted rockers for shaft-mounted systems. Shaft-mounted rocker arms are more stable, they deflect less at high rpm levels, and are generally capable of making more power.

To find out more we visited the shop of former Mopar Muscle Engine Challenge competitor Hollis Page and HP Engines in Norwood, North Carolina. Page walked us through the process on a 340 LA series small-block he’s building for one of his own hot rods.

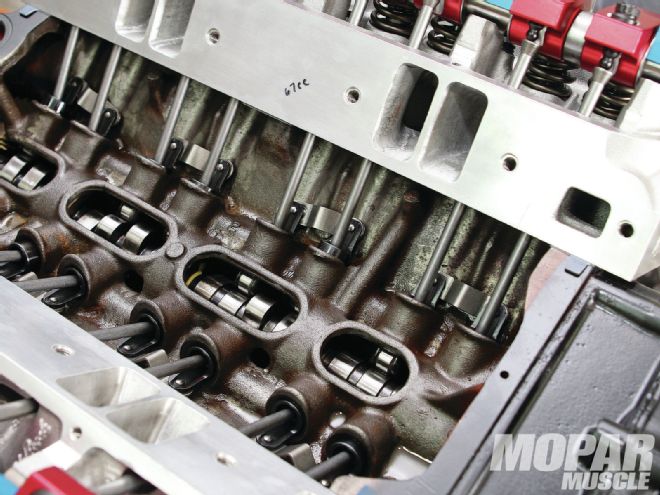

01 Like most Mopar engines, this 340 small-block utilizes a shaft-mounted rocker system that provides superior stability but requires a few extra precautions during installation to make sure the geometry is correct."> <strong>01</strong> Like most Mopar engines, this 340 small-block utilizes a shaft-mounted rocker system that provides superior stability but requires a few extra precautions during installation to make sure the geometry is correct.

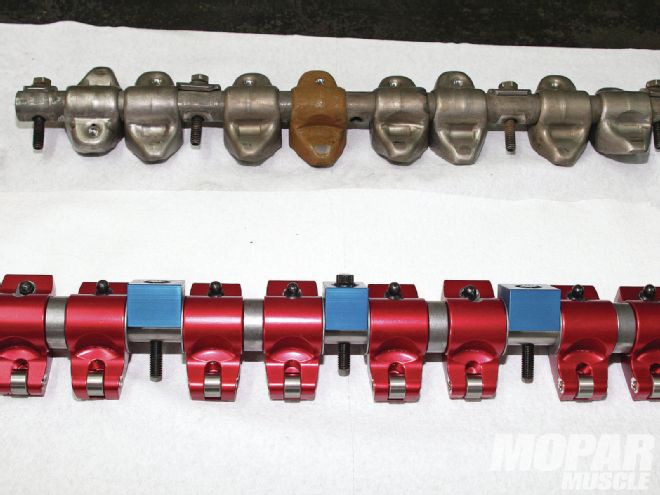

02 Whether you are using stock-style stamped steel rockers (top) or a performance aftermarket set like these from Harland Sharp (bottom), the procedures are the same. ">

<strong>01</strong> Like most Mopar engines, this 340 small-block utilizes a shaft-mounted rocker system that provides superior stability but requires a few extra precautions during installation to make sure the geometry is correct.

02 Whether you are using stock-style stamped steel rockers (top) or a performance aftermarket set like these from Harland Sharp (bottom), the procedures are the same. ">

<strong>02</strong> Whether you are using stock-style stamped steel rockers (top) or a performance aftermarket set like these from Harland Sharp (bottom), the procedures are the same.

<strong>02</strong> Whether you are using stock-style stamped steel rockers (top) or a performance aftermarket set like these from Harland Sharp (bottom), the procedures are the same.

03 Unlike the Magnum head with its stud-mounted rockers whose height can be adjusted individually, earlier shaft-mounted rocker arms mount directly to pedestals on the cylinder head. Because of this, any work on the valves, decking the heads, cam changes with a different base circle or even the plunger depth in the lifters can affect the valvetrain geometry. ">

03 Unlike the Magnum head with its stud-mounted rockers whose height can be adjusted individually, earlier shaft-mounted rocker arms mount directly to pedestals on the cylinder head. Because of this, any work on the valves, decking the heads, cam changes with a different base circle or even the plunger depth in the lifters can affect the valvetrain geometry. ">

<strong>03</strong> Unlike the Magnum head with its stud-mounted rockers whose height can be adjusted individually, earlier shaft-mounted rocker arms mount directly to pedestals on the cylinder head. Because of this, any work on the valves, decking the heads, cam changes with a different base circle or even the plunger depth in the lifters can affect the valvetrain geometry.

<strong>03</strong> Unlike the Magnum head with its stud-mounted rockers whose height can be adjusted individually, earlier shaft-mounted rocker arms mount directly to pedestals on the cylinder head. Because of this, any work on the valves, decking the heads, cam changes with a different base circle or even the plunger depth in the lifters can affect the valvetrain geometry.

But Mopar guys already know that. Shaft mounted rocker systems are standard equipment in all classic Mopar engines, and have all the benefits of improved valve control to go along with it. When properly set up and installed, Mopar rockers are efficient, work well even with high-lift cams, and provide trouble-free service.

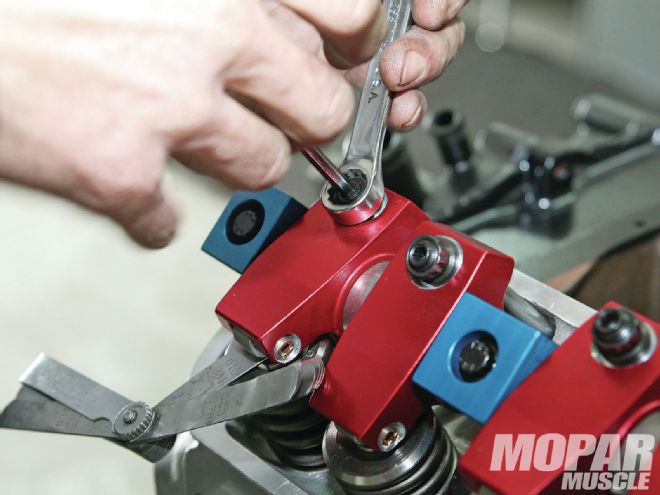

04 Often, performance rockers like these from Harland Sharp require the adjuster nuts to be installed by the engine builder. Page says that aluminum fragments can sometimes be left in the threads of the rockers, and he has even seen pieces of the anodizing flake away. Because of this, it is always a good idea to thread in the adjuster nuts by hand so you can feel if they hit any rough spots."> <strong>04</strong> Often, performance rockers like these from Harland Sharp require the adjuster nuts to be installed by the engine builder. Page says that aluminum fragments can sometimes be left in the threads of the rockers, and he has even seen pieces of the anodizing flake away. Because of this, it is always a good idea to thread in the adjuster nuts by hand so you can feel if they hit any rough spots.

05 The valvetrain layout in small-block Mopars pulls the spring and retainer in very close to the rocker’s fulcrum. Notice the cutouts in the underside of the rocker arms. It is critical to make sure each rocker is centered over the top of its valve, so that the rocker doesn’t contact the spring retainer.">

<strong>04</strong> Often, performance rockers like these from Harland Sharp require the adjuster nuts to be installed by the engine builder. Page says that aluminum fragments can sometimes be left in the threads of the rockers, and he has even seen pieces of the anodizing flake away. Because of this, it is always a good idea to thread in the adjuster nuts by hand so you can feel if they hit any rough spots.

05 The valvetrain layout in small-block Mopars pulls the spring and retainer in very close to the rocker’s fulcrum. Notice the cutouts in the underside of the rocker arms. It is critical to make sure each rocker is centered over the top of its valve, so that the rocker doesn’t contact the spring retainer.">

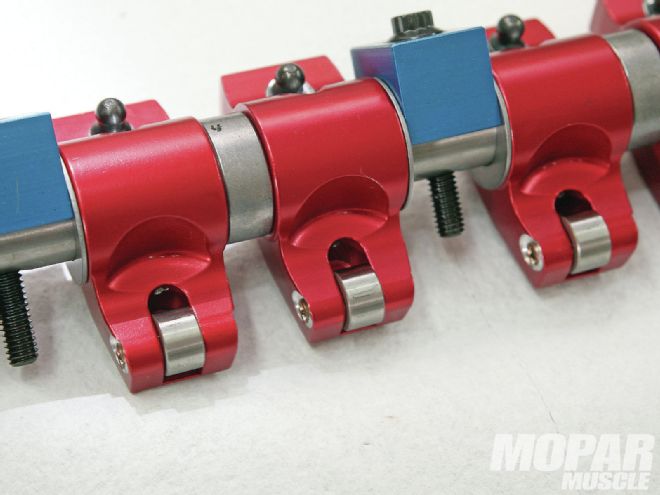

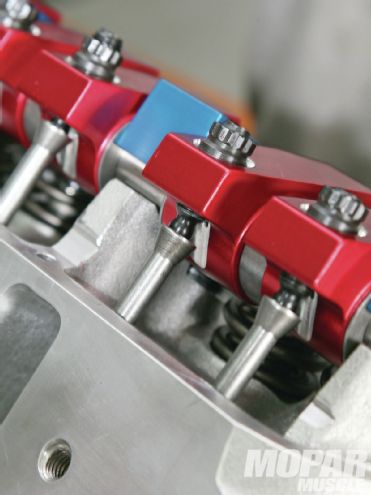

<strong>05</strong> The valvetrain layout in small-block Mopars pulls the spring and retainer in very close to the rocker’s fulcrum. Notice the cutouts in the underside of the rocker arms. It is critical to make sure each rocker is centered over the top of its valve, so that the rocker doesn’t contact the spring retainer.

<strong>05</strong> The valvetrain layout in small-block Mopars pulls the spring and retainer in very close to the rocker’s fulcrum. Notice the cutouts in the underside of the rocker arms. It is critical to make sure each rocker is centered over the top of its valve, so that the rocker doesn’t contact the spring retainer.

But along with that improved performance also comes a few more things that need to be checked when building an engine, to make sure the valvetrain is correct. There’s a little bit more to it than simply taking the components out of their wrappers and bolting them up. Improper installation without making the proper checks, can lead to poor valvetrain geometry, or, in other words, bad angles between the components that can cause mechanical problems down the road. When everything is right, the rockers open the valves by pressing straight down on the valve stem tips. When it isn’t right, a multitude of problems can occur, including side loading of the valve stem, causing it to wear the guides, which leads to burning oil and eventually a broken valve. Bad geometry can also be the root cause of poor valve control at high rpm levels, broken retainers and even the dreaded broken rocker or valve when the rocker tip pops off the end of the valve stem.

06 Most rocker systems either come with, or can be used with, shim packs to help you move the rocker side-to-side so that each is appropriately centered over its valve. In addition to keeping the rockers centered over the valve stem tips, each rocker also needs between .010 and .015-inch of endplay, to allow for proper oiling between the sides of the rockers and the hold downs. Page says you can affect endplay with the hold downs if necessary. By pushing one to the left or right and holding it there while you bolt it down, you can gain or lose a couple of thousandths clearance if necessary.">

06 Most rocker systems either come with, or can be used with, shim packs to help you move the rocker side-to-side so that each is appropriately centered over its valve. In addition to keeping the rockers centered over the valve stem tips, each rocker also needs between .010 and .015-inch of endplay, to allow for proper oiling between the sides of the rockers and the hold downs. Page says you can affect endplay with the hold downs if necessary. By pushing one to the left or right and holding it there while you bolt it down, you can gain or lose a couple of thousandths clearance if necessary.">

<strong>06</strong> Most rocker systems either come with, or can be used with, shim packs to help you move the rocker side-to-side so that each is appropriately centered over its valve. In addition to keeping the rockers centered over the valve stem tips, each rocker also needs between .010 and .015-inch of endplay, to allow for proper oiling between the sides of the rockers and the hold downs. Page says you can affect endplay with the hold downs if necessary. By pushing one to the left or right and holding it there while you bolt it down, you can gain or lose a couple of thousandths clearance if necessary.

07 The distance between the rocker’s fulcrum (pivot point), and the tip where it contacts the top of the valve stem doesn’t change. The only way to adjust the rocker ratio is to change the distance between the end of the pushrod and the fulcrum. Increasing the rocker ratio is a good way to gain power, because it increases total valve lift without significantly affecting duration. This can help increase airflow, while still providing snappy throttle response. Just be careful to check piston to valve clearance whenever changing the rocker ratio, because the increased lift puts the valves closer to the piston tops. Also, notice how the fulcrum barrel of these high-ratio rockers had to be clearanced for the pushrod, to make sure it wouldn’t touch at maximum valve lift. Increasing the rocker ratio increases valvetrain complexity. ">

<strong>06</strong> Most rocker systems either come with, or can be used with, shim packs to help you move the rocker side-to-side so that each is appropriately centered over its valve. In addition to keeping the rockers centered over the valve stem tips, each rocker also needs between .010 and .015-inch of endplay, to allow for proper oiling between the sides of the rockers and the hold downs. Page says you can affect endplay with the hold downs if necessary. By pushing one to the left or right and holding it there while you bolt it down, you can gain or lose a couple of thousandths clearance if necessary.

07 The distance between the rocker’s fulcrum (pivot point), and the tip where it contacts the top of the valve stem doesn’t change. The only way to adjust the rocker ratio is to change the distance between the end of the pushrod and the fulcrum. Increasing the rocker ratio is a good way to gain power, because it increases total valve lift without significantly affecting duration. This can help increase airflow, while still providing snappy throttle response. Just be careful to check piston to valve clearance whenever changing the rocker ratio, because the increased lift puts the valves closer to the piston tops. Also, notice how the fulcrum barrel of these high-ratio rockers had to be clearanced for the pushrod, to make sure it wouldn’t touch at maximum valve lift. Increasing the rocker ratio increases valvetrain complexity. ">

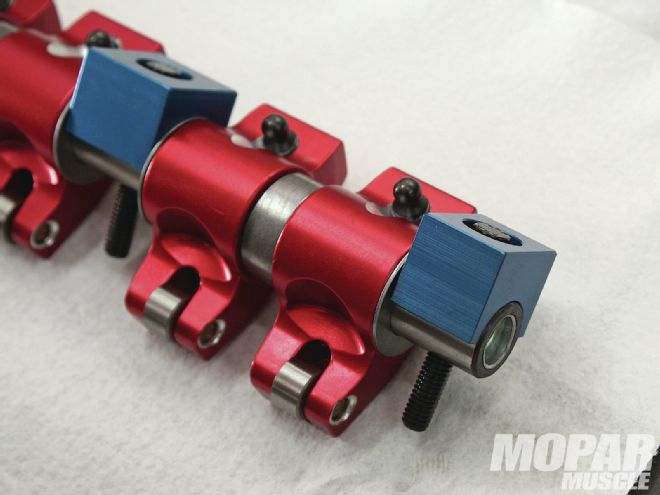

<strong>07</strong> The distance between the rocker’s fulcrum (pivot point), and the tip where it contacts the top of the valve stem doesn’t change. The only way to adjust the rocker ratio is to change the distance between the end of the pushrod and the fulcrum. Increasing the rocker ratio is a good way to gain power, because it increases total valve lift without significantly affecting duration. This can help increase airflow, while still providing snappy throttle response. Just be careful to check piston to valve clearance whenever changing the rocker ratio, because the increased lift puts the valves closer to the piston tops. Also, notice how the fulcrum barrel of these high-ratio rockers had to be clearanced for the pushrod, to make sure it wouldn’t touch at maximum valve lift. Increasing the rocker ratio increases valvetrain complexity.

08 The holes in the rocker shafts have to be properly aligned with the oil delivery hole in the head so that the rockers can be fed the lubrication they need. Stock rocker shafts make this easy with a notch that should always go to the left and point down when the shaft is installed. But an aftermarket shaft may or may not have the notch (this one doesn’t). The easy way to get this right is to always install the shaft with the small oiling holes pointed down and angled toward the exhaust ports. Page also recommends removing one or both of the end caps, so that you can properly clean and inspect the inside of the shaft. You don’t want any dirt going into the rockers and ruining your valvetrain as soon as you crank the engine. Replacement plugs should be available from the manufacturer.">

<strong>07</strong> The distance between the rocker’s fulcrum (pivot point), and the tip where it contacts the top of the valve stem doesn’t change. The only way to adjust the rocker ratio is to change the distance between the end of the pushrod and the fulcrum. Increasing the rocker ratio is a good way to gain power, because it increases total valve lift without significantly affecting duration. This can help increase airflow, while still providing snappy throttle response. Just be careful to check piston to valve clearance whenever changing the rocker ratio, because the increased lift puts the valves closer to the piston tops. Also, notice how the fulcrum barrel of these high-ratio rockers had to be clearanced for the pushrod, to make sure it wouldn’t touch at maximum valve lift. Increasing the rocker ratio increases valvetrain complexity.

08 The holes in the rocker shafts have to be properly aligned with the oil delivery hole in the head so that the rockers can be fed the lubrication they need. Stock rocker shafts make this easy with a notch that should always go to the left and point down when the shaft is installed. But an aftermarket shaft may or may not have the notch (this one doesn’t). The easy way to get this right is to always install the shaft with the small oiling holes pointed down and angled toward the exhaust ports. Page also recommends removing one or both of the end caps, so that you can properly clean and inspect the inside of the shaft. You don’t want any dirt going into the rockers and ruining your valvetrain as soon as you crank the engine. Replacement plugs should be available from the manufacturer.">

<strong>08</strong> The holes in the rocker shafts have to be properly aligned with the oil delivery hole in the head so that the rockers can be fed the lubrication they need. Stock rocker shafts make this easy with a notch that should always go to the left and point down when the shaft is installed. But an aftermarket shaft may or may not have the notch (this one doesn’t). The easy way to get this right is to always install the shaft with the small oiling holes pointed down and angled toward the exhaust ports. Page also recommends removing one or both of the end caps, so that you can properly clean and inspect the inside of the shaft. You don’t want any dirt going into the rockers and ruining your valvetrain as soon as you crank the engine. Replacement plugs should be available from the manufacturer.

09 Stock style replacement rocker systems are fairly inexpensive, but there is a reason for that. Besides them being stamped steel non-roller rockers, they also usually use a stamped hold down like you see here. If the entire purpose of a shaft-mounted rocker system is to provide maximum valvetrain stability, a thin piece of stamped steel like this isn’t the way to achieve it in a high horsepower application.">

<strong>08</strong> The holes in the rocker shafts have to be properly aligned with the oil delivery hole in the head so that the rockers can be fed the lubrication they need. Stock rocker shafts make this easy with a notch that should always go to the left and point down when the shaft is installed. But an aftermarket shaft may or may not have the notch (this one doesn’t). The easy way to get this right is to always install the shaft with the small oiling holes pointed down and angled toward the exhaust ports. Page also recommends removing one or both of the end caps, so that you can properly clean and inspect the inside of the shaft. You don’t want any dirt going into the rockers and ruining your valvetrain as soon as you crank the engine. Replacement plugs should be available from the manufacturer.

09 Stock style replacement rocker systems are fairly inexpensive, but there is a reason for that. Besides them being stamped steel non-roller rockers, they also usually use a stamped hold down like you see here. If the entire purpose of a shaft-mounted rocker system is to provide maximum valvetrain stability, a thin piece of stamped steel like this isn’t the way to achieve it in a high horsepower application.">

<strong>09</strong> Stock style replacement rocker systems are fairly inexpensive, but there is a reason for that. Besides them being stamped steel non-roller rockers, they also usually use a stamped hold down like you see here. If the entire purpose of a shaft-mounted rocker system is to provide maximum valvetrain stability, a thin piece of stamped steel like this isn’t the way to achieve it in a high horsepower application.

10 Now take a look at the billet hold-down on this system. As you can expect, a billet aluminum rocker system like this is definitely more expensive, but this provides much greater high-rpm stability.">

<strong>09</strong> Stock style replacement rocker systems are fairly inexpensive, but there is a reason for that. Besides them being stamped steel non-roller rockers, they also usually use a stamped hold down like you see here. If the entire purpose of a shaft-mounted rocker system is to provide maximum valvetrain stability, a thin piece of stamped steel like this isn’t the way to achieve it in a high horsepower application.

10 Now take a look at the billet hold-down on this system. As you can expect, a billet aluminum rocker system like this is definitely more expensive, but this provides much greater high-rpm stability.">

<strong>10</strong> Now take a look at the billet hold-down on this system. As you can expect, a billet aluminum rocker system like this is definitely more expensive, but this provides much greater high-rpm stability.

11 One of the reasons why stability is important is because of Mopar’s high camshaft location within the block. This is great for engines with a lot of stroke, but it also creates some extreme angles for the lifters, pushrods and rockers. It only gets worse when you install a high-performance camshaft with more valve lift than a stock. Because it is impossible to get everything directly in line from the camshaft lobe to the valve, it is important that the components you choose can handle the side loading. The more aggressive the cam and the higher the rpm, the more precautions you need to take.">

<strong>10</strong> Now take a look at the billet hold-down on this system. As you can expect, a billet aluminum rocker system like this is definitely more expensive, but this provides much greater high-rpm stability.

11 One of the reasons why stability is important is because of Mopar’s high camshaft location within the block. This is great for engines with a lot of stroke, but it also creates some extreme angles for the lifters, pushrods and rockers. It only gets worse when you install a high-performance camshaft with more valve lift than a stock. Because it is impossible to get everything directly in line from the camshaft lobe to the valve, it is important that the components you choose can handle the side loading. The more aggressive the cam and the higher the rpm, the more precautions you need to take.">

<strong>11</strong> One of the reasons why stability is important is because of Mopar’s high camshaft location within the block. This is great for engines with a lot of stroke, but it also creates some extreme angles for the lifters, pushrods and rockers. It only gets worse when you install a high-performance camshaft with more valve lift than a stock. Because it is impossible to get everything directly in line from the camshaft lobe to the valve, it is important that the components you choose can handle the side loading. The more aggressive the cam and the higher the rpm, the more precautions you need to take.

12 When bolting down the rocker system, make sure to follow the recommended torque specs for the system you are using. We can’t give you one number, because it varies whether you are using stock bolts are high-quality ARP fasteners. Big blocks also use a larger bolt than small blocks. If you over-tighten you run the risk of bending the rocker shaft into an egg shape which will cause premature wear of the rockers.">

<strong>11</strong> One of the reasons why stability is important is because of Mopar’s high camshaft location within the block. This is great for engines with a lot of stroke, but it also creates some extreme angles for the lifters, pushrods and rockers. It only gets worse when you install a high-performance camshaft with more valve lift than a stock. Because it is impossible to get everything directly in line from the camshaft lobe to the valve, it is important that the components you choose can handle the side loading. The more aggressive the cam and the higher the rpm, the more precautions you need to take.

12 When bolting down the rocker system, make sure to follow the recommended torque specs for the system you are using. We can’t give you one number, because it varies whether you are using stock bolts are high-quality ARP fasteners. Big blocks also use a larger bolt than small blocks. If you over-tighten you run the risk of bending the rocker shaft into an egg shape which will cause premature wear of the rockers.">

<strong>12</strong> When bolting down the rocker system, make sure to follow the recommended torque specs for the system you are using. We can’t give you one number, because it varies whether you are using stock bolts are high-quality ARP fasteners. Big blocks also use a larger bolt than small blocks. If you over-tighten you run the risk of bending the rocker shaft into an egg shape which will cause premature wear of the rockers.

13 You can use shims between the pedestals and the rocker shaft to raise the pivot point. Ideally, you want the tip of the rocker to be centered over the top of its valve’s stem through its entire travel. Side Note: Here’s an example of why going cheap can cost you in the long run. These are a set of no-name rockers purchased off of a certain internet auction site that shall remain unnamed. The rocker arms are too short, so even though there are thick shims underneath the rocker shaft, there’s no way to get the roller tip centered over the top of the valve stem. This engine will run, but the misaligned rockers will side-load the valves.">

<strong>12</strong> When bolting down the rocker system, make sure to follow the recommended torque specs for the system you are using. We can’t give you one number, because it varies whether you are using stock bolts are high-quality ARP fasteners. Big blocks also use a larger bolt than small blocks. If you over-tighten you run the risk of bending the rocker shaft into an egg shape which will cause premature wear of the rockers.

13 You can use shims between the pedestals and the rocker shaft to raise the pivot point. Ideally, you want the tip of the rocker to be centered over the top of its valve’s stem through its entire travel. Side Note: Here’s an example of why going cheap can cost you in the long run. These are a set of no-name rockers purchased off of a certain internet auction site that shall remain unnamed. The rocker arms are too short, so even though there are thick shims underneath the rocker shaft, there’s no way to get the roller tip centered over the top of the valve stem. This engine will run, but the misaligned rockers will side-load the valves.">

<strong>13</strong> You can use shims between the pedestals and the rocker shaft to raise the pivot point. Ideally, you want the tip of the rocker to be centered over the top of its valve’s stem through its entire travel. Side Note: Here’s an example of why going cheap can cost you in the long run. These are a set of no-name rockers purchased off of a certain internet auction site that shall remain unnamed. The rocker arms are too short, so even though there are thick shims underneath the rocker shaft, there’s no way to get the roller tip centered over the top of the valve stem. This engine will run, but the misaligned rockers will side-load the valves.

14 To check for proper alignment, Page paints the top of the valve stems with a magic marker, installs the rockers and rolls the engine through several revolutions. The roller tips leave a mark on the ink you can check to make sure they are centered over the valve stem tip.">

<strong>13</strong> You can use shims between the pedestals and the rocker shaft to raise the pivot point. Ideally, you want the tip of the rocker to be centered over the top of its valve’s stem through its entire travel. Side Note: Here’s an example of why going cheap can cost you in the long run. These are a set of no-name rockers purchased off of a certain internet auction site that shall remain unnamed. The rocker arms are too short, so even though there are thick shims underneath the rocker shaft, there’s no way to get the roller tip centered over the top of the valve stem. This engine will run, but the misaligned rockers will side-load the valves.

14 To check for proper alignment, Page paints the top of the valve stems with a magic marker, installs the rockers and rolls the engine through several revolutions. The roller tips leave a mark on the ink you can check to make sure they are centered over the valve stem tip.">

<strong>14</strong> To check for proper alignment, Page paints the top of the valve stems with a magic marker, installs the rockers and rolls the engine through several revolutions. The roller tips leave a mark on the ink you can check to make sure they are centered over the valve stem tip.

15 Page keeps several sets of pushrods around in order to find the correct pushrod length. But those of us not running a full-time engine shop don’t often have those resources. Instead, you can use a checking pushrod (foreground), which is easily extendable to find the correct length. These are available through Comp Cams in case you wondered.">

<strong>14</strong> To check for proper alignment, Page paints the top of the valve stems with a magic marker, installs the rockers and rolls the engine through several revolutions. The roller tips leave a mark on the ink you can check to make sure they are centered over the valve stem tip.

15 Page keeps several sets of pushrods around in order to find the correct pushrod length. But those of us not running a full-time engine shop don’t often have those resources. Instead, you can use a checking pushrod (foreground), which is easily extendable to find the correct length. These are available through Comp Cams in case you wondered.">

<strong>15</strong> Page keeps several sets of pushrods around in order to find the correct pushrod length. But those of us not running a full-time engine shop don’t often have those resources. Instead, you can use a checking pushrod (foreground), which is easily extendable to find the correct length. These are available through Comp Cams in case you wondered.

16 If the pushrods are the correct length, the adjusters will be centered in the rocker arms. For maximum strength, you only approximately two or three showing below the rocker body.">

<strong>15</strong> Page keeps several sets of pushrods around in order to find the correct pushrod length. But those of us not running a full-time engine shop don’t often have those resources. Instead, you can use a checking pushrod (foreground), which is easily extendable to find the correct length. These are available through Comp Cams in case you wondered.

16 If the pushrods are the correct length, the adjusters will be centered in the rocker arms. For maximum strength, you only approximately two or three showing below the rocker body.">

<strong>16</strong> If the pushrods are the correct length, the adjusters will be centered in the rocker arms. For maximum strength, you only approximately two or three showing below the rocker body.

17. Now you are ready to set the lash according to your camshaft manufacturer’s specifications if you are running a solid cam. Lash is a good way to test whether your cam is properly spec’ed for your engine package. Decreasing lash removes some slack in the system, and slightly increases both lift and duration. This effectively makes the cam act larger, or more aggressive. Doing the opposite, or adding additional lash, reduces both lift and duration and makes the cam act smaller. Normally, the best way to test the effects of lash changes is on a dyno, but you can also test the differences at the strip although the changes will be slight. If running a hydraulic camshaft, the proper adjustment is to remove all play from between the rocker arm, the push rod, and the lifter. Once this is done, give the adjuster approximately one more half of a turn.">

<strong>16</strong> If the pushrods are the correct length, the adjusters will be centered in the rocker arms. For maximum strength, you only approximately two or three showing below the rocker body.

17. Now you are ready to set the lash according to your camshaft manufacturer’s specifications if you are running a solid cam. Lash is a good way to test whether your cam is properly spec’ed for your engine package. Decreasing lash removes some slack in the system, and slightly increases both lift and duration. This effectively makes the cam act larger, or more aggressive. Doing the opposite, or adding additional lash, reduces both lift and duration and makes the cam act smaller. Normally, the best way to test the effects of lash changes is on a dyno, but you can also test the differences at the strip although the changes will be slight. If running a hydraulic camshaft, the proper adjustment is to remove all play from between the rocker arm, the push rod, and the lifter. Once this is done, give the adjuster approximately one more half of a turn.">

<strong>17.</strong> Now you are ready to set the lash according to your camshaft manufacturer’s specifications if you are running a solid cam. Lash is a good way to test whether your cam is properly spec’ed for your engine package. Decreasing lash removes some slack in the system, and slightly increases both lift and duration. This effectively makes the cam act larger, or more aggressive. Doing the opposite, or adding additional lash, reduces both lift and duration and makes the cam act smaller. Normally, the best way to test the effects of lash changes is on a dyno, but you can also test the differences at the strip although the changes will be slight. If running a hydraulic camshaft, the proper adjustment is to remove all play from between the rocker arm, the push rod, and the lifter. Once this is done, give the adjuster approximately one more half of a turn.

<strong>17.</strong> Now you are ready to set the lash according to your camshaft manufacturer’s specifications if you are running a solid cam. Lash is a good way to test whether your cam is properly spec’ed for your engine package. Decreasing lash removes some slack in the system, and slightly increases both lift and duration. This effectively makes the cam act larger, or more aggressive. Doing the opposite, or adding additional lash, reduces both lift and duration and makes the cam act smaller. Normally, the best way to test the effects of lash changes is on a dyno, but you can also test the differences at the strip although the changes will be slight. If running a hydraulic camshaft, the proper adjustment is to remove all play from between the rocker arm, the push rod, and the lifter. Once this is done, give the adjuster approximately one more half of a turn.