Automatic transmissions are fine, we guess. They provide the easiest, simplest way to get from point A to point B without drama—and that's kind of the whole idea. No drama. They also lack a lot in the fun department. It's just our opinion, but real transmissions require stepping on a clutch pedal and ripping the shifter through the gate. Modern technology simply can't replace the satisfaction of dumping the clutch and powershifting like a hooligan. While real manual transmissions are on the verge of disappearing from production cars, American Powertrain makes it easy to swap a manual overdrive into just about any old-school Mopar.

...American Powertrain makes it easy to swap a manual overdrive into just about any old-school Mopar.

To get a firsthand look at how straightforward the process is, we tagged along as Bill Reilly and Chuck Witner of Reilly Motorsports swapped a TREMEC Magnum six-speed manual overdrive into a 1969 Dodge Dart. Reilly Motorsports is a company that needs little introduction. RMS single-handedly jumpstarted the Chrysler aftermarket suspension industry by developing a full line of handling parts for Mopars. The car that started it all was Bill Reilly's personal project, a green '69 Dart we featured not too long ago. After over a decade of beating on it for the sake of parts development, RMS restored it from the ground up and retired it from R&D duty. As such, the purpose of this latest '69 Dart project is to pick up the slack in the fun department.

That initial big-block Dart and its attendant front-end mass was the impetus behind the creation of Reilly Motorsports and its line of handling parts. Still, Bill was never fond of that Dart's weight. This time around, Bill and the RMS crew plans on building a leaner and meaner A-body—the one you see here—and a six-speed swap is an essential part of that formula. "The green Dart is a lot of fun, but with the 528ci Hemi it weighs 3,900 pounds. For this new test car, the goal is to keep the weight down to 3,000 pounds," Bill explains. "As a test car, it's obviously going to have the latest suspension components out of the RMS catalog, but we don't want to make it look too Pro Touring. It's going to have black wheels and a black vinyl top to keep it old school. The engine combo is a 550-horsepower small-block, and matching it up with a TREMEC six-speed trans will make the car lots of fun to drive around town and on the autocross."

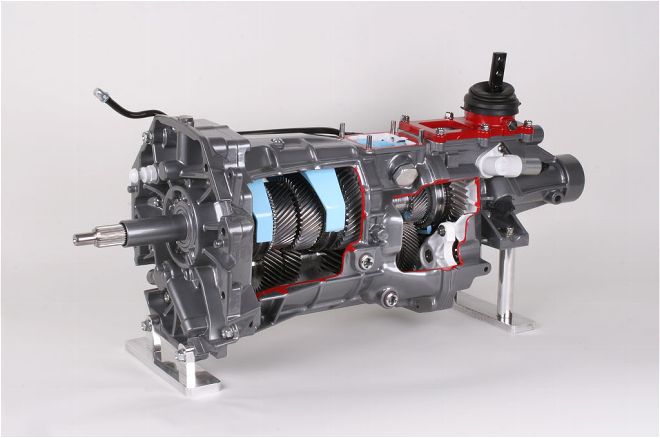

Since versions of the TREMEC TR6060 6-speed manual—and its predecessor, the Borg-Warner T56—have been more popular at the OE level in GM and Ford vehicles over the years, Mopar guys might not be as familiar with the latest variant, the Magnum. Compared to the TR6060, the Magnum boasts larger input and output shafts, fortified gears, a stronger case, double- and triple-cone synchronizers, beefier shift forks, shorter throws, an improved heat treatment process, and an astounding 700 lb-ft torque capacity. While the Magnum is similar to the TREMEC TR6060 six-speed factory installed on the SRT Viper and Challenger, it has been optimized for aftermarket applications thanks to its multiple shifter locations, mechanical and electric speedometer pickups, and compatibility with both mechanical and hydraulic clutch setups. In other words, it's one bad mother of a transmission.

While the Magnum is similar to the TREMEC TR6060 six-speed factory installed on the SRT Viper and Challenger, it has been optimized for aftermarket applications...

But a lone transmission would be a tall order for most DIY guys to install, and that's where American Powertrain comes in. American Powertrain has done all the tough engineering math, parts scrounging, and fabrication of the key pieces like the throwout bearing, pedal assembly, crossmember, flywheel, and clutch. Their kits are turnkey. Says Gray Fredrick of American Powertrain: "Most of what we do is make pieces in-house of our own design. We don't buy somebody else's stuff, we have it made to our specs, or we make it in-house." That ethic extends to service after the sale, with phone tech support available pretty much 24/7. "It's better if people call us when they have their tools out. They can keep work moving forward instead of stalling or letting the frustration build." As we found out here, American Powertrain sells complete 5- and 6-speed TREMEC kits with everything you'll need included. And as for stuffing one into the tight confines of a vintage A-Body, you'll just have to check out the accompanying photos to see how easy it can be!

American Powertrain has done all the tough engineering math, parts scrounging, and fabrication of the key pieces...Their kits are turnkey.

1. American Powertrain offers TREMEC five- and six-speed transmission kits for A-Body, B-Body, and E-Body Mopars. The '67-76 A-Body six-speed kit includes a Magnum 6-speed Magnum trans, a flywheel, clutch, bellhousing, shifter assembly, speedometer, and reverse light hookups, an aluminum driveshaft, and a crossmember for around $4,500. The hydraulic clutch system is a popular option at around $650.

2. The ancestor to the TREMEC TR6060—the Borg-Warner T56—was often criticized for its ridiculously tall 0.50:1 Sixth gear ratio. TREMEC now offers the Magnum in a close-ratio configuration that uses a 2.66:1 First, 1.78:1 Second, 1.30:1 Third, 1.00:1 Fourth, 0.80:1 Fifth, and 0.63:1 Sixth gear ratio. Bill Reilly happily opted for the close-ratio version.

3. Since the RMS Dart was originally equipped with an automatic transmission, the stock brake pedal assembly was swapped out for American Powertrain's stock-appearing brake/clutch pedal assembly. AP builds these in-house and they look stock enough to fool the toughest critics.

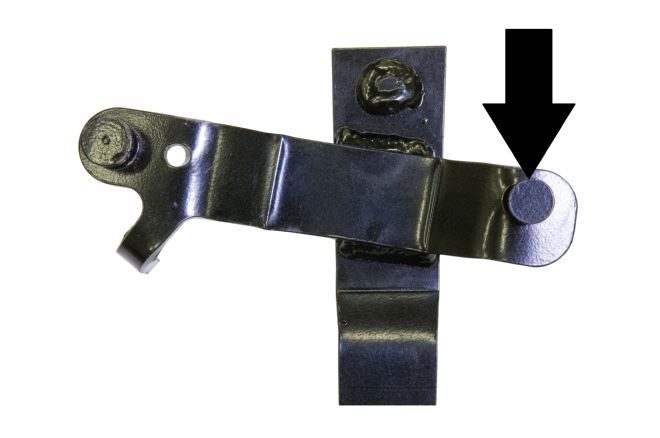

4. The factory clutch linkage attaches to a pin (arrow) welded to the pedal assembly, but it's no longer necessary when upgrading to the hydraulic actuation system. The pin's positioning also interferes with where the new hydraulic linkage must mount. Consequently, the RMS crew removed the pin with a cutoff wheel, then ground it flat.

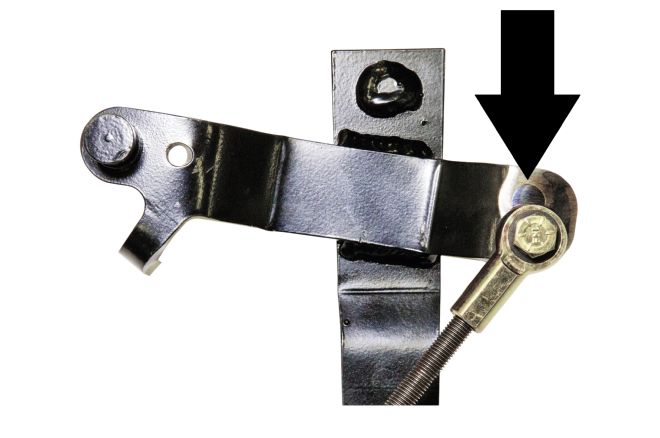

5. With the factory linkage pin removed, RMS drilled a 3/8-inch hole directly beneath it (arrow). For test-fitting purposes, the new linkage was temporarily bolted to the pedal assembly.

6. American Powertrain's proprietary Hydramax firewall bracket locates the clutch master cylinder at the hole in the firewall for the factory clutch linkage. In this location, all three factory bolt holes can be re-used as well.

7. Providing support for the new master cylinder assembly is a square backing plate that RMS tack welded to the interior side of the firewall. With the master cylinder mounted in the engine compartment, the firewall is sandwiched between the backing plate and the master cylinder. A threaded adjuster connects the master cylinder linkage to the pedal linkage.

8. The Hydramax master cylinder bracket adjusts to the original clutch rod angle providing for a factory pedal sweep ratio. It also ensures a linear action between the rod and the bore of the master, preventing wear on the master bore seals. RMS tilted the top of the master cylinder rearward to smooth out the linkage operation. This required cutting a small section of metal out of the inner fender in order to clear the bottom of the master cylinder. Afterwards, he lined the hole with weather stripping to prevent chaffing of the hydraulic line.

9. With the clutch master cylinder mounted, RMS bolted American Powertrain's billet fluid reservoir to the firewall. As luck would have it, he was able to re-use two factory holes that matched the spacing of the bracket perfectly.

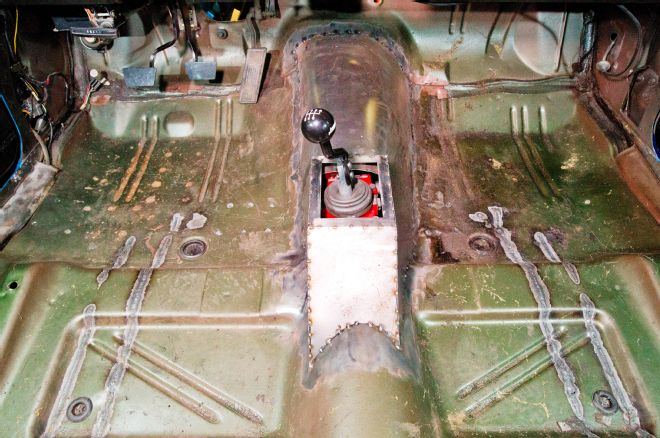

10. Perhaps the most difficult part of the T56 swap is cutting the factory trans tunnel. After installing the motor and attaching the bellhousing, RMS raised the Magnum into position with a transmission jack, bolted it up, and marked the floorboard around the shifter base. Next, all of the carpet was removed.

11. Cutting the tunnel is a multi-step process which requires first cutting a small circle above the shifter using a cutoff wheel or hole saw. This creates clearance for the shifter base, and allows raising the transmission up against the tunnel in order to establish the cut lines around the transmission case.

12. After temporarily lowering the transmission, Chuck Witner cut out the factory trans tunnel with a cutoff wheel, then cleaned up the edges with a grinder. Instead of removing the tunnel as a single piece, it was cut out in several smaller sections. Bill Reilly says this allows saving as much of the factory metal as possible.

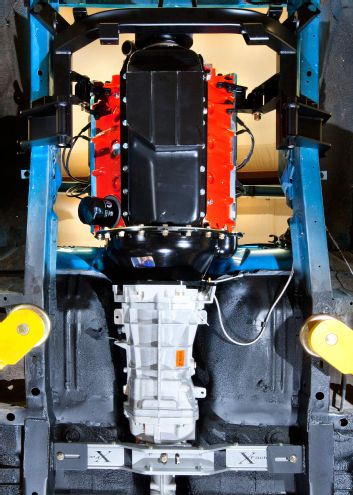

13. With the factory tunnel removed, the transmission was re-attached to the bellhousing before tilting it back at a two-degree angle. If the transmission is tilted back too far, it will place additional stress on the U-joints and cause vibrations. Next, the American Powertrain crossmember was attached to the tailshaft housing.

14. Installing the crossmember is as simple as welding the mounting brackets to the subframe connectors then bolting it down. (We'll have a story on installing these US Cartool subframe connectors very soon! We consider them an essential for any Mopar with serious performance aspirations.) RMS leveled and squared the crossmember in relation to the subframe connector rails, tacked the brackets into position, then measured one last time before finish welding them.

15. Although staring at a giant hole in the floorboard may be daunting, fabricating a custom tunnel isn't that difficult. The RMS crew decided to build it in two sections. To form the front section, they wrapped a piece of posterboard around the trans case, leaving approximately one inch of clearance beneath it. They then marked a line where the posterboard intersected the floorboard. Using the posterboard as a template, Bill cut out a piece of 20-gauge sheetmetal. The metal is flexible enough to tack weld to one side of the tunnel and bend around the transmission before tacking it down to the other side of the tunnel.

16. To fabricate the rear section of the trans tunnel, RMS first made a custom shifter bezel by using a Lokar bezel as a template. This piece was then centered around the shifter and welded to the back of the tunnel. Next, they created paper templates for the remaining three sides of the tunnel.

17. After transferring the templates onto 20-gauge sheetmetal, they were cut out using an air shear. As with the factory floorboard, the edges must be cleaned prior to welding.

18. No one likes cutting into factory metal, but the results were well worth the effort. Once confirming the fitment of the new trans tunnel, Chuck Witner of RMS laid down the final welds.

19. With the trans lowered onto a workbench, the Hydramax hydraulic throwout bearing and retainer plate slides onto the input shaft, and allen bolts secure the plate to the front of the transmission. A pin prevents the bearing from rotating. The upper hose attaches to the master cylinder, while the lower port is used for bleeding.

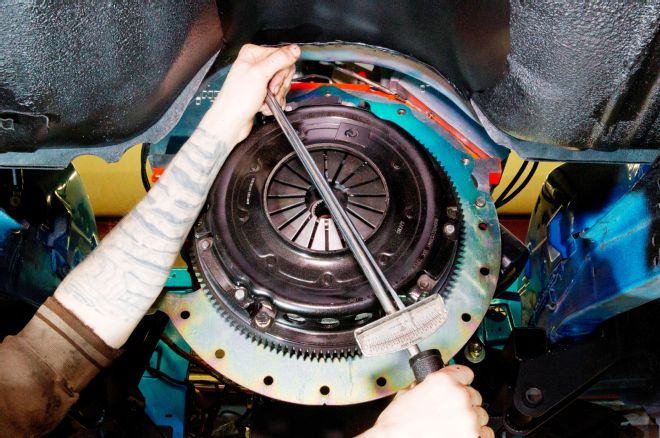

20. Since the factory undercoating had to be removed prior to welding, RMS sprayed the exposed sheemetal with some rust inhibitor. After tapping a new pilot bearing into the back of the crankshaft, RMS bolted up the QuickTime engine plate, flywheel, and clutch. Next, the QuickTime bellhousing and transmission were torqued down one final time.

21. Despite the fact that the TREMEC Magnum is quite a bit larger than any factory A-Body trans, the RMS handiwork makes the finished product look stock. With the trans in place, wrapping up the install involved connecting the wires for the electric speedometer and reverse lockout, hooking up the hydraulic lines, and filling the clutch reservoir with brake fluid and bleeding the system. The slave is pre-bled out of the top of the system by just pumping the pedal. A lower port can be used to bleed air out of the system if necessary.