In the specialty muscle car engine world, Pontiac retains one of the most loyal followings. With a heritage that includes some of the most iconic vehicles of the era, that loyalty is founded in a tradition of performance. For the hard-core Pontiac enthusiast, real Pontiac engines are the only way that performance is delivered. Engine builder Mark Dalquist of Throttle's Performance found himself in a convergence of circumstances that led him to build one of the most impressive examples of Pontiac performance we had ever seen for the 2013 AMSOIL Engine Masters Challenge.

As Mark tells us, "I have watched Engine Masters since the very first one, and it is far and away my favorite event of the year. I have always wanted to do Engine Masters, but the budget has never been there to do it right. The opportunity presented itself and we went for it. The engine we built was a customer's engine, and he wanted to do an engine for the AMSOIL Engine Masters Challenge. The one stipulation was that it had to be a Pontiac engine. It was actually the first Pontiac I have ever built."

One of the key elements to the success of the effort was building a team with the event experience and specialized knowhow that would be critical for a first-time competitor. The Throttle's Performance team included a number of veteran competitors from the deceased Dan Miller's early Chrysler Hemi team. Mark tells us, "I was doing some engines for David Vizard's big-block Chevy engine book, and one of them was an EFI motor, so I was looking for an EFI specialist. I saw what Scott Clark had done with the early Hemi at Engine Masters, and decided that he was the guy I wanted to do my EFI. Right after I finished the big-block for the book, we went right into the Engine Masters Pontiac. I asked Scott if he wanted to be involved with the Engine Masters team, and it just so happened that they didn't have an Engine Masters entry, so some of the guys from the early Hemi team came aboard my Pontiac Team."

Another key to the personnel puzzle was cylinder head man, Chad Speier. Mark continued, "I have been watching what Chad has been doing for a while, and he is a talented man with a grinder. When I started looking at the Engine Masters rules, out of the cylinder heads that were available for the Pontiac, I picked the Edelbrock Pro Port. It had the most potential because of the port location, and it allowed us to do our own chamber. I called Chad and asked him what it would take for him to do the cylinder head development and have them digitized and CNC a pair of heads. He asked what we were doing, and when I told him it was for Engine Masters, he jumped on board taking charge of the entire cylinder head program."

"This block comes with bronze bushed lifter bores, but I ordered them undersized so that we could finish size the lifter bores to our lifters. We decked it to 10.215 inches, and that left the pistons 0.015 inch in the hole, and the boring and honing. That was pretty much it for the block work on this one; the block really just didn't need anything more."

The bore and stroke combination comes to 428 ci, a displacement identical to some of the most powerful factory Pontiac engines. Per chance, the final displacement was derived by the bore and stroke combination that best suited the engine for competition. As Mark relates, "I asked Chad what we needed to make the cylinder head work, and he said ‘really it's going to take the biggest intake valve that will fit,' which for us was 2.350 inches. I asked how much bore would it take to get that to work, and we came up with the 4.350-inch bore.

"From there I started playing around with the stroke, and at 3.600 inches we were at 428 ci, which is a legacy Pontiac number. Our rod-to-stroke ratio with this setup came down to 1.84:1, which really isn't ideal for Engine Masters, but if I shortened the stroke up any more the ratio would have gone even higher. I wanted to keep the rod-to-stroke ratio under 1.8:1, and ended up at 1.84:1, but if I went with even less stroke I would have been over 1.9:1, and that would have been awful."

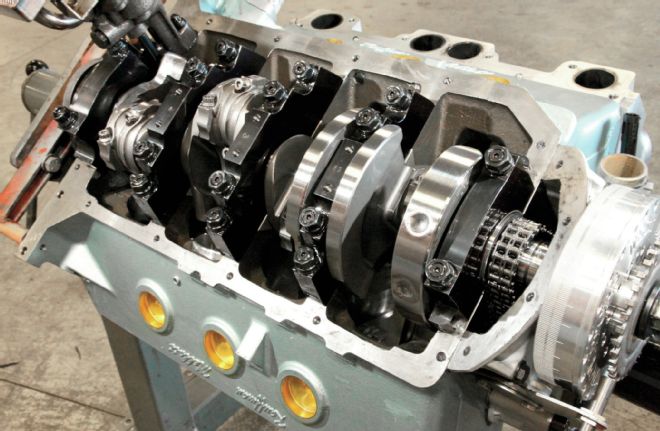

1. Looking into the crankcase of the Throttle’s Pontiac, the sheer beef of the Kauffman block greatly exceeds the strength of any production Pontiac block. The Scat crank features pendulum cut and profiled counterweights, and provides 3.600-inch of stroke.

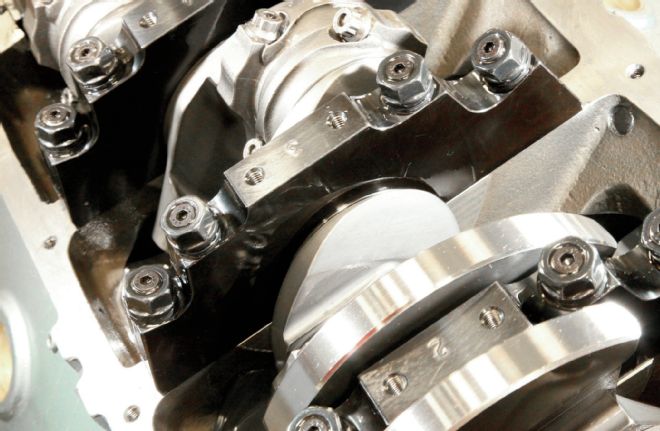

2. This detail reveals the massive structure of the Kauffman block’s billet steel splayed main bearing caps. The block features the 3.00-inch Pontiac “small” mains, as opposed to the 3.25-inch mains used by Pontiac on their largest engines. ARP studs provide the clamping force, while the bearings are from SpeedPro.

3. The AMSOIL synthetic motor oil is pushed through the engine via a Melling oil pump. The pickup tube is welded in place and features a strut to prevent failure in service.

4. Holding the AMSOIL synthetic is a Stef’s fabricated aluminum pan, with a built-in screen and baffle system. This pan is an NHRA stock eliminator class legal unit for the Pontiac application.

5. Pistons are custom units from Ross cut for a 4.350-inch bore size specifically for the Edelbrock Pro Port cylinder heads. The Scat I-beam rods are for a big-block Chevy application and measure 6.700 inches, while SpeedPro bearings and Total Seal rings complete the package.

With the bore and stroke combination in mind, it was simply a matter of filling the bottom end with the required parts to make the most of the configuration. Mark continued: "The crank is from Scat. The crank had a Chevy pin on the rod journals, with 3.00-inch small-journal Pontiac mains. From my experience the Scat stuff I've had in the past has always offered a very good product for the price. They had a forging on the shelf that would go 3.600 inches, so that was perfect. I ordered it from Scat with the profiled counterweights, and it just dropped right into the engine."

"I used 6.700-inch Scat I-beam rods for a big-block Chevy application. These are really their entry-level rod, but at the rpm we are turning, their entry-level rod is strong enough. I personally don't like the H-beam rod, because to me it looks like it will collect oil.

"The pistons are custom by Ross. As it turns out, they provided the best customer service I have ever experienced from any aftermarket manufacturer. Originally I had another company make a set of pistons, but they were wrong. They basically just forgot about me after that and we were three months into the build. We needed to get onto the dyno, and I still didn't have pistons. I called Ross on a Monday, and said we were doing the Engine Masters Challenge, and they were familiar with the Edelbrock Pro Port heads, and had the key data like the valve locations. I said I need the trickest pistons you have and I need them right away. They did an expedite order and I had a set of full custom pistons by Friday.

"The rings are a set of .043/.043/3mm AP steel piston rings from Total Seal. It is their high-end ring, and I use them in everything I build. The quality control is second to none, and with the steel top ring there is no wear, and I use the Napier second which I feel gives much better oil control, and with the low-tension oil ring it is a ring package that is very hard to beat."

Power Parts With a well-built bottom end providing the necessary durability, a strong power curve would depend upon a well-developed set of heads, a capable induction system, and the cam timing to make the most of the engine's potential. Mark explained how it all came together, "The heads are our design from the ground up. Chad, of course, did all of the velocity mapping and the actual port work. We talked back and forth on where we were at, and we had the heads over 430 cfm at one point, however, at the rpm range and cubic inches we were running, it was too much head. We pulled them back, and the thing we experienced with the head was that the velocity in the port is really fast. Even when we made the port bigger, the velocity stayed fast, the head just flows more air. Chad just put an incredible amount of effort into the intake port of the cylinder head. It is a raw casting, and a huge amount of aluminum needed to be removed.

"The entire engine build was based around that 2.350-inch intake valve. The big intake valve will flow more air at mid lift and low lift. With the big valve comes a big port bowl, so we can slow the air down around the short side. It allows us to have very high velocity through the port and then we can slow the air down at the turn so it doesn't separate off the floor. This really creates a high pressure area above the valves, and it seems to work well."

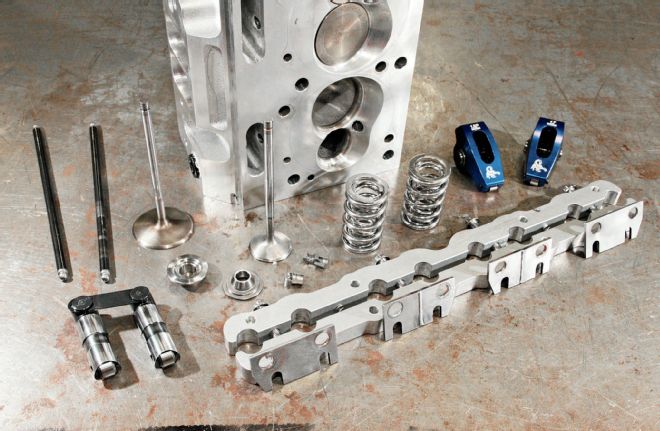

All of the valvetrain is Manley, with the exception of the valves, which are REV. The stud girdle is made by Jomar, while the guideplates are custom. A unique item is the rocker set from Scorpion. The offset rocker arms are custom rockers that Scorpion made specifically for this engine. The rocker body is actually a part made for the big-block Chevy application, which Throttle's found fit perfectly on their Pontiac cylinder heads. Working within the tight confines of the Pontiac architecture, Scorpion manufactured the rocker arms with a special offset of 0.250 inch. Scorpion also provided the hydraulic roller lifters, which were used 100 percent out of the box. An area of difficulty was with the pushrods. Clearance limitations only allowed for a pushrod diameter of 11/32 inch. It took very careful attention to detail in the valvetrain to make that work.

As with the cylinder heads, the camshaft design included input from a leader in the field. Mark tells us how it came about: "We played with simulations on the lift and duration, and we kind of knew where we needed to be according to the simulation. I called cam designer Harold Brookshire and discussed the combination. Right off the top of his head, he came up with numbers within a degree or two of what we had been talking about. I had Harold design the cam specifically for our engine."

6. The Kauffman block comes through with bushed lifter bores. Throttle’s specified an undersized finish on the bushing so that they could precisely size the bushings to the lifters. The limited-travel Scorpion lifters roll on a custom Lunati cam spec’d by cam guru Harold Brookshire. Note the reliefs in the lifter valley to provide clearance for the lifters.

7. To top the engine, Throttle’s started with Edelbrock’s Pro Port cylinder head castings, which are manufactured semi-finished. This essentially requires creating your own ports and chambers.

8. To feed the Poncho, Throttle’s Performance tapped cylinder head man Chad Speier to handle the head development. Speier cut the port and chamber shapes and then developed the CNC program to duplicate the effort.

9. The valves were manufactured by REV, with a large diameter 2.350-inch intake valve being a central aspect of the engine build. The exhaust valve measures 1.650 inches.

10. The valvesprings, retainers, and keepers were all Manley items, while the stud girdle was from Jomar. Throttle’s custom fabricated the required guideplates to work with the 11/32-inch pushrods.

11. Custom-built Scorpion stud-mounted rockers operate the valves. Based on big-block Chevy rocker bodies, the rockers were built with a custom intake offset of .250 inch, providing clearance for wider intake ports.

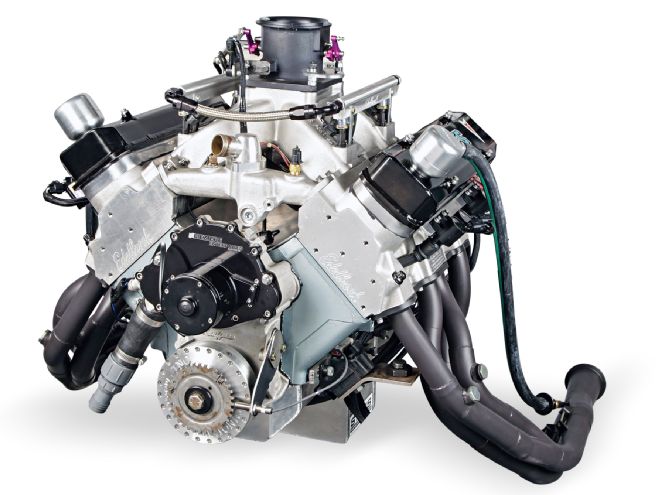

Supplying the airflow is an Edelbrock Victor single-plane manifold, which Mark says saw minimal modification. "The intake manifold is an out-of-the-box Edelbrock Victor set up for EFI. Chad just did a really quick plenum blend to it and a port match, and that was it." Mark did see significant variation in power related to the throttle body. "We had three throttle bodies we tested, and we also tested a carburetor. The EFI outperformed the carburetor by 17 points, however, that was only with the Ron's throttle body. With the other two throttle bodies, the carburetor would have outperformed them. The Ron's outperformed the others all the way through the rpm range, from 3,000 to 7,000 rpm. We think the mono blade throttle body had a smoother transition into the plenum, while the four-blade throttle bodies have a more abrupt entrance to the plenum, and more turbulence there."

One of the most impressive aspects of the engine had to be its elaborate engine management and electronics package. As Mark details, "The electronics on this thing are wild. We wanted to run a coil-on-plug ignition. The spark plugs are angled in toward each other, so we needed coils with a 45-degree bend. I thought the coils from a modular Ford would work, so I ordered up a set and they fit. Scott Clark was able to make them work with the MegaSquirt management system. That's how we picked the coils."

"Scott is a big proponent of the MegaSquirt, and we went with the MS3-Pro. I just didn't realize the capabilities of the MegaSquirt electronics. It is a $1,300 ECU that has more features than some of the top systems in the market. The capabilities of the MegaSquirt are just amazing. We coupled the NGK wideband O2 sensors to the MegaSquirt so that we actually had individual cylinder air/fuel trim control that is self correcting. All the way through a pull our air/fuel ratio per cylinder stands within a 0.1 ratio of target on each cylinder."

Another important aspect of the engine's power production was the header configuration. As Mark explains, "We tested three sets of chassis headers plus the set that I built. We played with collector choke sizing, secondary length, and collector length. We did a fair amount of exhaust testing and found the smoother and gentler the primaries are, the more power it will make. You want to run the smallest tubing you can—the tube doesn't need to be any bigger than the area of the exhaust port to start off with. The higher velocity small tubes will make more power. Also, the four-into-two-into-one design is going to have a wider power curve than the four-into-one; the four-into-one will be peakier."

By The Numbers: 428ci Pontiac

Bore: 4.350 inches Stroke: 3.600 inches Displacement 428 ci Compression ratio: 11.48:1 Camshaft: custom Lunati hydraulic roller Valve lift: .840/.772 inch Rocker and ratio: Scorpion 1.85/1.7:1 Piston rings: Total Seal 0.043 inch Piston: Ross forged Block: Kauffman MR1 Crankshaft: Scat Rods: Scat 6.700 inches Cylinder head: Edelbrock Pro Port Intake valve diameter: 2.350 inches Exhaust valve diameter: 1.650 inches Intake manifold: Edelbrock Throttle body: Ron's Header: Throttle's Performance Engine management: MegaSquirt Damper: Innovators West Oil Pan Stef's Fuel VP 100 unleaded Oil AMSOIL 5w20

On The Dyno: 428ci Pontiac

RPM: TQ: HP: 3,000 480 274 3,100 479 283 3,200 485 296 3,300 501 315 3,400 518 335 3,500 533 355 3,600 551 378 3,700 566 399 3,800 579 419 3,900 590 438 4,000 602 459 4,100 610 476 4,200 619 495 4,300 624 511 4,400 630 528 4,500 634 543 4,600 639 559 4,700 641 573 4,800 644 589 4,900 647 603 5,000 648 617 5,100 647 628 5,200 648 641 5,300 650 656 5,400 651 669 5,500 652 683 5,600 650 693 5,700 647 702 5,800 643 710 5,900 638 717 6,000 633 723 6,100 627 728 6,200 621 733 6,300 614 736 6,400 605 738 6,500 596 737 6,600 584 733 6,700 567 723 6,800 552 714 6,900 536 704 7,000 522 695

12. Delivering the airflow to the heads is an Edelbrock Victor single-plane manifold with provisions for port injection. The Ron's throttle body features a single butterfly and proved to be the best performing throttle body tested.

13. Speier handled the intake manifold porting, blending the plenum and port matching the runners.

14. The headers are a tri-Y configuration custom fabricated by Throttle's Performance. This layout proved to offer a broader power curve than a typical four-into-one design.

15. An extensive electronics package was employed in the engine management system, centering on a MegaSquirt MS3 Pro firing OEM Ford coil packs. Here we see the digital readout for the individual cylinder air/fuel ratio management. Note the reams of wiring in neatly loomed harnesses.

16. On the dyno at the 2013 AMSOIL Engine Masters Challenge, Throttle's highly developed Pontiac delivered remarkable power, recording 738 hp and 601 lb-ft of torque.

17. At the 2013 AMSOIL Engine Masters Challenge, Throttle's team leader Mark Dalquist (left) and the Throttle's crew (left to right) Scott Clark, Mat Adams, Tony Wright, Mike Hed, and Chad Speier proved that Pontiac muscle is alive and well.