Tony Bischoff and BES Racing Engines are names familiar to those who follow our annual Engine Masters Challenge engine building competition. Bischoff and his expert crew at BES Racing Engines have come to the competition since 2003, and in the process earned the championship no fewer than four times. Coming into the 2011 AMSOIL Engine Masters Challenge, the recent changes to the competition format seemed to be tailor-made for an organization like BES Racing. For the first time the competition was divided into two categories: Street and Xtreme Street. The build rules for the Xtreme class presented the opportunity for competitors to really bring on the heavy-hitting hardware and make serious power. Making serious power happens to be just what BES Racing does best.

A Dart block provides a bulletproof foundation for this radical Ford small-block. The block’s massive main structure secures a 4.00-inch stroke Eagle crankshaft riding on Clevite bearings. Note the contoured profile of the Eagle crank’s counterweights to reduce windage. Rods are Eagle 6.125-inch H-beams.

A Dart block provides a bulletproof foundation for this radical Ford small-block. The block’s massive main structure secures a 4.00-inch stroke Eagle crankshaft riding on Clevite bearings. Note the contoured profile of the Eagle crank’s counterweights to reduce windage. Rods are Eagle 6.125-inch H-beams.

The wild 441-cube Ford small-block examined here was BES Racing’s weapon of choice, and judging from the 913 peak horsepower produced, it proved to be as effective as it was deadly to the competition. For Bischoff and crew, it was all in a day’s work, since this is the very type of engine the shop builds on a routine basis. Bischoff tells us: “We build a lot of these engines using that particular cylinder head. It’s a good combination for us and I thought it would do well in the contest.” Of course, building it for the competition required a unique development process, though the basic parts combination relied on components that were well proven.

Bottom End Beef

The Ross Pistons feature an inboard pin boss that helps create a very rigid piston skirt, providing a big advantage with short compression heights. The design also allows for a much shorter piston pin, which reduces weight.

The Ross Pistons feature an inboard pin boss that helps create a very rigid piston skirt, providing a big advantage with short compression heights. The design also allows for a much shorter piston pin, which reduces weight.

The build started with a Dart block with the bore size machined to 4.180 inches, and other than the basic machining prep and bushing the lifter bores for .904-inch lifters, there was little to do here. Dart’s block comes with all the beef and strength needed for reliability at high power levels, with revised oiling and a massive bottom end structure. For Bischoff, it is the right choice when targeting high power output. A 4.00-inch Eagle 4340 crank with Eagle’s Armor Coating fills the crankcase, providing a displacement of 441 ci. The crankshaft was indexed at BES Racing, and other than a minor detailing it was used without modification. Eagle was also the source for the connecting rods, with Bischoff selecting their lightweight 6.125-inch H-beam rods, which were also treated to Eagle’s Armor Coating process.

Filling the bores is a set of Ross pistons, which feature the modern inboard pin boss design. As Bischoff tells us, the major advantage here is strength: “These really work well with the short compression height stuff. They have a rigid skirt and pin boss, because they put those support struts in there. They seem to make more power because they are that much more rigid.” The pistons were cut for a .043/.043/3mm ring package, and Bischoff opted to go with a set of Total Seal rings. The ring set featured a gapless top ring, a configuration that Bischoff has not used frequently in the past, but as he tells us, the results were impressive. Bischoff relates: “It was the best sealed motor I have ever built.” To complement the top ring, the Total Seal second ring featured a Napier-style face, which definitely improved oil control.

BES Racing selected a set of Total Seal rings in a .043/.043/3mm configuration. The ring set includes Total Seal’s unique Gapless Top rings, resulting in what Tony Bischoff tells us is one of the best compression-sealing engines he has ever built. The second ring features a Napier face profile to aid in oil control.

BES Racing selected a set of Total Seal rings in a .043/.043/3mm configuration. The ring set includes Total Seal’s unique Gapless Top rings, resulting in what Tony Bischoff tells us is one of the best compression-sealing engines he has ever built. The second ring features a Napier face profile to aid in oil control.

With the small dish pistons, the final compression ratio worked out to 14.5:1, though Bischoff believes the engine would have benefited from even more: “I think we left a little on the table with the compression ratio, and the engine could have made a little more power with more compression. The ratio was just left where we started at, and I was happy enough with the numbers when we dyno’d it that we just left it there.” We questioned Bischoff further about where he sees the point of diminishing returns with compression ratios on this type of engine. He explained: “On the dyno, with the kind of octane fuel we were running [VP Racing Fuel Q-16], typically you will see the power keep increasing right up to 17:1, however, on the racetrack it may not show up because most of the time you can’t control the temperatures as well, and the cylinder-to-cylinder variations can get further off. So, it may not run any better down the racetrack with that much compression, but it will dyno better.”

Power Parts

The view shows the deep port bowls and pockets of the SC-1 heads. The epoxy work is also machined by the CNC; the port is literally mudded with the epoxy prior to the ports being machined.

The view shows the deep port bowls and pockets of the SC-1 heads. The epoxy work is also machined by the CNC; the port is literally mudded with the epoxy prior to the ports being machined.

Bischoff says, the key to making this engine deliver its outstanding power is in the cylinder heads: Edelbrock’s Glidden SC-1. The cylinder heads are modified while taking into consideration the rpm range and cubic inches, as well as the camshaft profile. Experience is the key here, as Bischoff tells us: “The cross-sectional area has to work as we pass through the lower rpm range; we look at the flow and cross-section and the required cam area to make the engine speed come in where it needs to be. It comes down to experience. We keep records of everything we have done in the past, and it gives us a frame of reference. The particular ports on this engine we had never run on anything else; we developed it just for this engine. We relied on previous experience, and just put it on there and it worked.” The heads come with undersized ports designed for custom porting, and BES Racing has their own CNC machine to do the job. For this particular port, the port size is a resized version of BES Racing’s drag racing port. Bischoff expanded: “I’m impressed with the software on the Rottler CNC machine. We can go in and make changes to the ports on the machine’s programming instead of the way we used to do it, starting over with hand grinding. We were able to alter the size and even slightly modify the position of the ports with the machine.”

One of the features of the engine that attracts attention is the unique intake manifold arrangement. The Edelbrock intake manifold was fitted with a custom-made 4-inch plenum spacer, which was custom blended to the manifold plenum, in addition to an HVH-tapered 2-inch spacer. Bischoff says: “We built that spacer to try and pick up the score, but we tested a manifold that just used a conventional spacer, and it scored exactly the same. It didn’t even change the rpm range. In the end we just left it on there because it looked good.” The carburetor is a 1250 Holley, reworked by Pro Systems, and it was simply adjusted with air bleed and jets at BES Racing. Bischoff says: “We could have spent more time on it, but we didn’t want to wear the engine out on the dyno.”

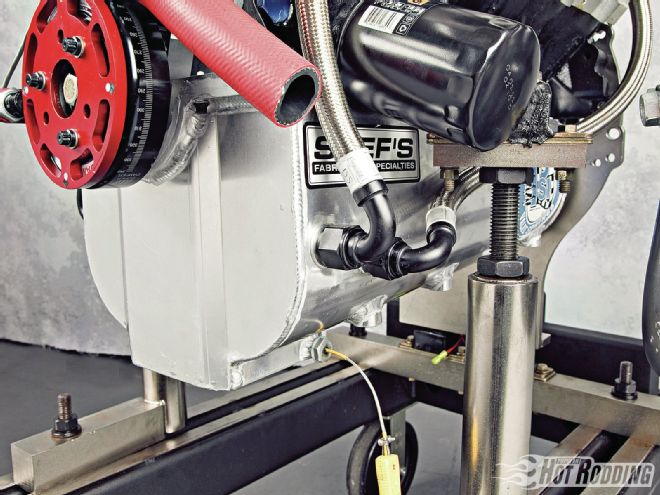

All of the oil from the cylinder heads is drained back externally via these lines to the oil pan. This keeps the majority of the oil away from the rotating assembly, reducing drag.

All of the oil from the cylinder heads is drained back externally via these lines to the oil pan. This keeps the majority of the oil away from the rotating assembly, reducing drag.

The block was fitted with 55mm roller cam bearings to accept a large-journal custom COMP roller cam. The large journal allows larger lobes, which makes the cam much more stable and accurate, especially with the heavy valvespring loads used on this engine. COMP ground the cam with 252/262 degrees duration at .050 and a lobe separation angle of 112 degrees. Lift works out to a whopping .940 inch with the very high ratio 2.00/2.08:1 Jesel shaft-mounted rocker arms. Believe it or not, Bischoff says this cam profile is a bit milder than what he would consider optimal: “We didn’t run lobes that were nearly as aggressive as we considered, but we started there, and were happy with the output and just left it.” Jesel also was the supplier of choice for the .904-inch diameter tie-bar roller lifters. With the PSI valvesprings delivering 410 pounds of seat load and 1,000 pounds open load, the valvetrain all has to be bulletproof. Bischoff says the SC-1 engine combination has a very good valvetrain layout: “One thing I really like about the head is that the valvetrain is really good; it is easy on the springs and is very durable.”

With a high-rpm, high-lift engine combination, the valvetrain becomes critical. The stout PSI springs deliver 1,000 pounds open load, which will devastate inferior valvetrain components. Jesel shaft-mount rockers and lifters, and Smith Brothers pushrods handle the punishment.

With a high-rpm, high-lift engine combination, the valvetrain becomes critical. The stout PSI springs deliver 1,000 pounds open load, which will devastate inferior valvetrain components. Jesel shaft-mount rockers and lifters, and Smith Brothers pushrods handle the punishment.

Other key details included the custom-built headers put together from a Schoenfeld Sprint Car kit. Bischoff says: “We started with the primary tubes a little longer, and shortened them some, and it helped the score a few points.” A complete ICE ignition system provides the spark, including an ICE Ignition Booster, which increases the voltage. Bischoff says, in his experience, the ICE ignition seems to produce more spark energy than competitive ignition systems.

A highly modified Edelbrock intake manifold feeds the cylinder heads. BES racing custom built a very large plenum spacer that was blended to form an integral part of the plenum. The HVH tapered spacer provides a smooth transition from the carb butterflies into the manifold.

A highly modified Edelbrock intake manifold feeds the cylinder heads. BES racing custom built a very large plenum spacer that was blended to form an integral part of the plenum. The HVH tapered spacer provides a smooth transition from the carb butterflies into the manifold.

Taking this concept of a proven combination based on familiar parts to the dyno at the 2011 AMSOIL Engine Masters Challenge, BES Racing was clearly ready to show their capabilities. In qualifying trials, the engine handily made its way to the front of the pack, belting out as much as 913 peak horsepower in the process. Bischoff and crew went into final eliminations as solid front-runners. In the finals, Bischoff advanced the cam by a single degree, which cost 12 hp at peak. Nevertheless, the engine was still over the 900hp mark in peak output, with the incredible torque curve ensuring a lock on First Place. With big power being the name of the game, BES once again found themselves in the winner’s circle.

By The Numbers 441ci Small-Block Ford Block: Dart Bore: 4.18 inches Stroke: 4.00 inches Displacement: 441 ci Compression ratio: 14.5:1 Crankshaft: Eagle 4340 with Armor Coat Camshaft: COMP Cams solid roller Timing chain: Jesel beltdrive Lifters: Jesel .904-inch, tie-bar Pushrods: custom Smith Brothers Springs: PSI 1255 RML Installed height: 2.200 inch Spring load closed: 410 pounds, seat Spring load open: 1,000 pounds at 1.160 inches Retainer: Victory 10-degree Titanium Valve locks: Manley +.100 beadlock Duration intake: 252 degrees at .050 Intake lift: .940 inch Duration exhaust: 262 degrees at .050 Exhaust lift: .940 inch Rockers: Jesel Rocker ratio: 2.0 / 2.08 Lobe separation: 112 degrees Installed centerline: 107 degrees Ring pack: Total Seal; .043 inch, .043 inch, 3mm oil Ring endgap: .020 top/.025 second Piston: Ross custom pistons Piston clearance: .010 Main fasteners: Dart by ARP Rods: Eagle 6.125 H-beam with Armor Coating Main bearings: Clevite H Rod bearings: Clevite HN Main journal diameter: 2.75 inches Rod journal diameter: 2.100 inches Main clearance: .0025 inch Rod clearance: .0025 inch Cylinder heads: Edelbrock SC-1 Head fasteners: ARP custom studs Intake manifold: Edelbrock Intake port flow: 440 cfm at .900 Exhaust port flow: 300 cfm at .900 Intake valve: 2.25-inch Victory titanium Exhaust valve: 1.60-inch Victory titanium Cylinder head gaskets: Fel-Pro 1041 (.041 inch) Piston/head clearance: .041 inch Engine gaskets: Fel-Pro 1135 Carburetor 1,250-cfm Holley / Pro Systems Carb spacer HVH Header: Schoenfeld Coil ICE ignition Ignition ICE ignition Spark plug wires: ICE ignition Damper: ATI Water pump: Meziere electric Oil pan: Stef’s custom aluminum pan Oil pump: Melling M83 Oil: AMSOIL 5w30

RPM TQ HP 3,500 564 376 3,600 575 394 3,700 582 410 3,800 591 428 3,900 601 446 4,000 607 462 4,100 608 474 4,200 609 487 4,300 616 504 4,400 632 529 4,500 645 553 4,600 657 576 4,700 665 595 4,800 674 616 4,900 686 640 5,000 696 662 5,100 704 683 5,200 710 703 5,300 714 721 5,400 719 739 5,500 722 756 5,600 725 773 5,700 727 789 5,800 729 806 5,900 729 819 6,000 728 832 6,100 726 842 6,200 723 854 6,300 721 865 6,400 718 875 6,500 714 883 6,600 708 889 6,700 700 893 6,800 691 895 6,900 683 898 7,000 675 900 7,100 666 901 7,200 654 897 7,300 642 893 7,400 632 891 7,500 624 891