Testing carburetors on an engine dyno can sometimes be misleading. We've all seen tests showing large-cfm carburetors making more power—even on a small engine that nobody in their right mind would run such a large carburetor on in the real world. On the street, idle quality and part throttle drivability make the difference between a car we drive, and one we wish we drove more. When we test different components on an engine dyno, we can do more than compare power at wide open throttle. Putting a load on an engine to simulate cruising down the road or up a hill can be enlightening.

We had been testing different intake manifolds on our 360 budget engine, and noticed that after a switch to an air-gap style manifold, that our trusty Holley 670 street avenger was having a hard time idling. With its isolated runners and true split-plenum design, the carburetor just could not provide enough fuel through the idle circuit. We had a combination of parts that just seemed to be out of the realm of what our carburetor was designed to work with, even though the parts seem to be pretty common these days. The intake was making the low-vacuum signal of our Comp Thumper cam wreak havoc with our tuning.

After we opened up our idle feed restrictor from .026 to .030-inch to cure not being able to get an A/F reading better than 15.5 at idle, we had a nice performing engine again. We now were able to get a steady idle mixture of 14.0. We did end up jetting the carburetor's main jets up a few sizes also, but this is pretty normal for the pump gas available to us where we were testing. As we went to full throttle, the A/F reading went as lean as 16.5 from 2,000 up to 3,500 rpm, and then richened up to 13.8 at the top end before the jetting change.

After swapping the factory jetting from 65/68 to 68/72, we were at a much nicer A/F reading of 13.5 at cruise, and the top end was at 12.5, which brought us up to where we needed to be.

We had to wonder how many guys drop in a performance cam, and then can't get things dialed in because they either can't or won't start drilling out carburetor circuits after shelling out their hard earned money for a new carburetor.

We ended up testing a few other Holley carburetors to see if it was an across the board issue, and to see how each performed from idle through cruise, and on to the higher rpm range. We decided to try a 4777 (650 Double Pumper) to see if it acted the same. The idle circuit in this carburetor was calibrated much richer, and required no modification. The 650 performed pretty well everywhere, but we did notice that the carburetor went extremely lean at part throttle again. On our little 360, the idle circuit worked well enough, but our part throttle mixture was again in the mid 15's. A jetting change from 67 to 69 on the primary side brought our midrange tuning in line at 13.8, while only changing the top end slightly to 12.7 from our previous 12.8.

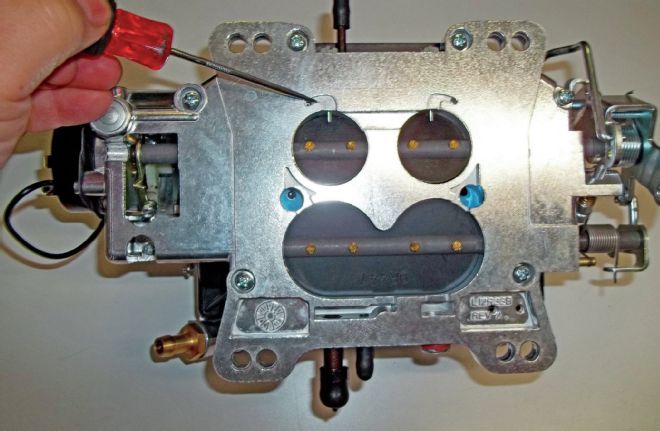

1. First for our test was the Holley 3310 750 vacuum secondary carburetor. It has long been considered one of the best street-performance carburetors you can get.

2. We had been using a Holley 670 Street Avenger with good results prior to an intake change. The swap to an air-gap intake weakened the vacuum signal.

3. A Holley 650 Double Pumper is calibrated more for performance as opposed to street use. We have to agree, that it performed well on our street 360 regardless.

4. We finally got to try a new Street Demon carburetor with a polymer body.

We also tested a carburetor that is arguably the single most successful performance carb ever sold—the Holley 3310 750 vacuum secondary. This carb has been installed on many well performing cars for as many years as we care to remember. The out of the box tune on this carburetor gave us an idle mixture of 14.5, a midrange mixture of 13.2, and a top end mixture of 13.8. This carburetor does not have rear jets that could be changed, but instead relies on a drilled orifice in the metering plate. We swapped the front jets from 72 to 75, and that had us too rich during cruise, showing 12.6. We then went back to the factory 72 jets, and changed the rear metering plate for a new metering block with adjustable jets. The factory-drilled orifice was equal to a 75 jet, which was verified with a backup pull. Jetting the rear up to 78's had us at 13.0 air fuel. When working on one of these carburetors, ideally, a tuner should use the jetting for midrange tuning and the power valve circuit should be dialed in to provide final wide open throttle tuning. This carburetor seemed to be adding more fuel than necessary through the power valve channel restriction, which kept us from getting the proper mixtures everywhere. Aftermarket metering blocks are available with an adjustable restriction to take care of this, but it was beyond the scope of this testing.

We now have an option previously unavailable that sounds like a good fit for these types of builds—the new Street Demon. A 625 cfm version was tested here, but we were assured that a 750 version will be released shortly as well. We ordered ours with the polymer main body, so we could also test the claims of cooler fuel temperature advertised with them. We have to admit, we were pleasantly surprised when everything they advertise about a product proved to be true. We installed the Demon with its supplied plate, which is designed to help shear fuel as it leaves the slot on the idle circuit in the baseplate. Once we primed the fuel, the engine started easily, and the mixture at idle was nearly perfect at 14.0. In factory trim, we had the best idle and part throttle tuning, and our top end horsepower was on par with the best we had gotten with other carburetors after they had been tuned. Our cruise mixture was 13.8, and the top end was 13.2.

We ordered the tuning kit with our Street Demon, so we would be able to dial it in as close to perfect as possible. With our low vacuum at idle, as soon as the throttle was cracked open, the metering jets would open, requiring a change to a lighter spring. The primary side of the Street Demon uses a metering rod/jet combination, while the secondary side uses standard Holley type main jets. Since our A/F was slightly lean for best power, we tuned the primary side for a nice cruise power mixture of 13.5, and as the Demon's manual stated, we tuned the secondary jets for a good top-end A/F mixture. It took quite a jump in jet size to make much of a difference in the overall mixture. On a typical Holley, we would normally make jet changes in two stop increments. But the Holley-type jets in our kit were 86 and 90. With the factory installed jets being 80, we ended up moving up to the kit's 86 jets, which proved to make a very small change in the mixture, so we moved up to the largest jets (90) to bring us up to a perfect A/F mixture for our engine of 12.5. We now had even better performance throughout our testing.

While testing the modular Holley carburetors, we checked temperatures of the fuel bowl area after making our dyno pulls. The fuel bowl temps were always within 10 degrees of the intake manifold. With a water temperature of 180 degrees, the intake below the carburetor averaged 144 degrees. The fuel bowl was, on average, 134 degrees. The Street Demon kept the main body cooler, which is where the fuel resides, averaging 95 degrees. That much of a drop in fuel temperature should really help on a hot summer day when idling in traffic causes extreme under hood conditions to boil fuel.

It is refreshing to see a company devote the research and tooling into making a nice improvement in carburetors for those of us that don't want to make the switch to fuel injection. With the response and tuning ability of the Street Demon, it would be hard to beat for a nice, street-driven hot rod. Check out the charts at www.moparmuscle.com, which show the performance of each carburetor, with an out of the box tune, and with our tuning to see how the results stack up.

5. The Street Demon features an idle transfer configuration that helps shear the fuel as it enters the manifold.

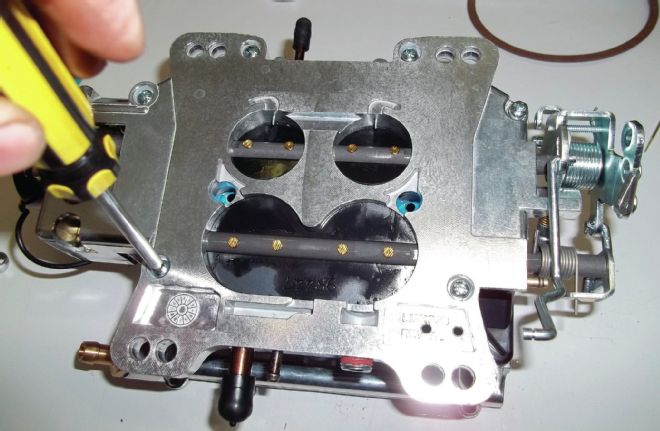

6. Changing jets in the Demon caburetor requires you to remove the carburetor, drain the fuel, and remove several screws from underneath.

7. The primary jets (pointer) or the secondary jets can be changed as well as the primary metering rods.

8. Part throttle tuning can normally be dialed in on the Street Demon without disassembling the entire carburetor by changing the metering rods and their actuation springs.