The Rochester Quadrajet, which was used on Pontiac V-8s from ’67 forward, evolved into what’s arguably one of the most reliable four-barrel carburetors ever designed. A great number of them remain in service today, but finding quality replacement components can be rather difficult. Fortunately there are a few companies dedicated to Quadrajet preservation, and they supply the hobby with complete rebuild kits with soft parts compatible with ethanol-blend fuel, and metering calibration kits.

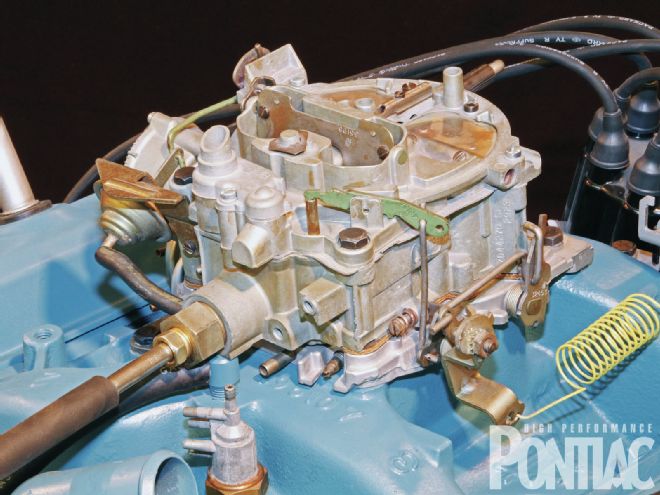

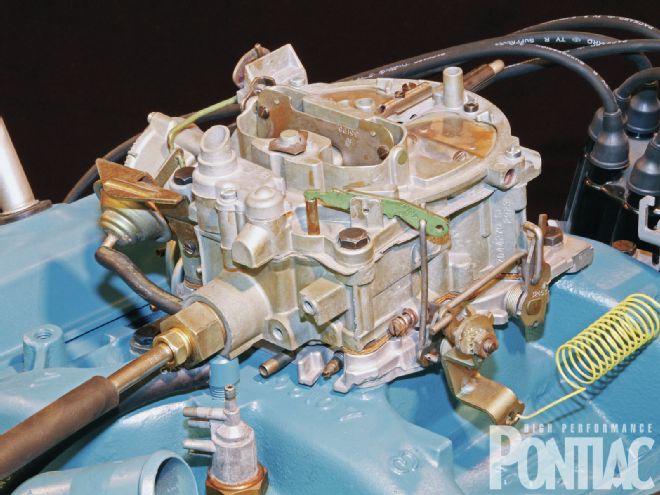

This Rochester Quadrajet may look as if it’s in impeccable condition, but it suffers from a common malady that plagues many Quadrajets today. Leaky bottom plugs let raw fuel drip directly into the intake manifold, especially after sitting for several minutes after hot shutdown, and that can make the engine very difficult to restart. The float bowl will eventually run dry after a few days as well.

This Rochester Quadrajet may look as if it’s in impeccable condition, but it suffers from a common malady that plagues many Quadrajets today. Leaky bottom plugs let raw fuel drip directly into the intake manifold, especially after sitting for several minutes after hot shutdown, and that can make the engine very difficult to restart. The float bowl will eventually run dry after a few days as well.

One Quadrajet malady that continues to plague Pontiac hobbyists, however, is difficult hot-restarts. You probably know the condition--the engine acts as if it’s flooded but you haven’t touched the accelerator since the engine was shut down a couple of hours prior. The cause is most likely leaky bottom (well) plugs. For years, many owners sealed them with epoxy but it was rarely a permanent repair, as the fuel would break it down over time. The other choice was a professional repair, but that’s no longer required. Now you can restore your ailing Q-jet in less than an hour with a $20 remedy. Here’s how.

The Basics

Rochester drilled several passageways through the Quadrajet casting during the manufacturing process. Aluminum, brass, or lead plugs, depending upon the year and location, were used to seal the main body’s external holes and prevent outward leaks. The plugs located on the bottom of the casting, directly beneath the primary and secondary metering jets, are most susceptible to leaks.

As the Quadrajet evolved over the years, it saw refinements, including new plug types and retention methods, which improved its performance and reliability. While some bottom plugs remain leak-free today, particularly in later castings produced during the ’80s, a lifetime of heating and cooling cycles, and the resultant expansion and contraction of the dissimilar metals used in early castings, have compromised the plugs’ effectiveness in preventing fuel leaks.

On a Quadrajet, the small plugs (left) located directly beneath the primary metering jets and the larger plugs (right) located beneath the fixed secondary jets were installed after the machining process was complete. They seal the external access holes required to drill the internal passageways that allow fuel to flow throughout the casting. It’s quite common to find these plugs leaking today.

On a Quadrajet, the small plugs (left) located directly beneath the primary metering jets and the larger plugs (right) located beneath the fixed secondary jets were installed after the machining process was complete. They seal the external access holes required to drill the internal passageways that allow fuel to flow throughout the casting. It’s quite common to find these plugs leaking today.

Cliff’s High Performance in Mount Vernon, Ohio, rebuilds hundreds of Q-jets each year, and the number of leaky plugs that owner Cliff Ruggles sees is on the rise. "Along with the aging castings, the increase could also be related to ethanol-blend fuel. I’d say that 30 percent of the early castings we see have leaky front plugs. The secondary wells were sealed with brass cup-plugs through ’68, and all of them leak horribly. Aluminum plugs and a new swaging process was introduced in 1969, and it was much more effective--I’d say only about 15 percent of those plugs leak."

A common method hobbyists use to test their Quadrajet for leaky bottom plugs is to fill the bare casting with gasoline or solvent and set it on a bench for several days, watching for fuel drops. Ruggles thinks that method is ineffective. "Leaky plugs drip continually only when the casting is warm. We can artificially warm it on the bench, but it generally cools down too quickly, making the method unreliable. It just doesn’t replicate what the carburetor sees on the engine."

The most effective way to determine if a particular casting has leaky bottom plugs involves compressed air. "We apply a soapy water mixture to the plugs and place the nozzle of an air gun into the jet area from the float bowl. A steady stream of bubbles will quickly appear from the plug area on any casting that’s prone to leak. The bottom plugs must be replaced or the owner could face any number of operating issues," he adds.

The Fix

Cliff’s High Performance has recently released a complete kit that permanently seals the bottom plugs of any ’69-and-later Quadrajet casting. "Our Bottom Plug Repair Kit sells for $19.95. The size of the front plugs is all the same regardless of year, but early Quadrajets use 1/2-inch-diameter, brass cup plugs at the rear. Those castings are oftentimes too fragile for cutting threads into, and in those instances we suggest hobbyists send their casting to us for repair. Our kit includes 7/16-inch-diameter plugs for castings produced from 1969 on."

Closely following the supplied instructions, we found that the front plugs of our particular Quadrajet casting were leaking, which was certainly in agreement with the operational issues we were experiencing. Within an hour, our Quadrajet’s well plugs were permanently sealed; within 24 hours, our Pontiac was once again driving down the road. Best of all, we effectively eliminated the hot-restart condition that had plagued us for so long--and we did it for less than $20!