Nothing defines the personality of a performance engine quite like the camshaft. From the power to the operating range, and even the curbside bark at idle, the cam sets the tone. With the appropriate cast of supporting components, including the heads, induction, and compression, you can generally expect more peak power as the camshaft is stepped up. On the flip side, those long-duration numbers loathe low-rpm operation, snuffing idle vacuum and driveability. Here lies the classic trade-off in a dual-purpose performance machine—determining how much cam is enough and how much is too much. If your plans are easy street cruising in choked urban traffic, that line is quickly crossed. Contrarily, if max high rpm power with a lumpy boulevard idle announcing your presence is the aim, more cam is usually the word.

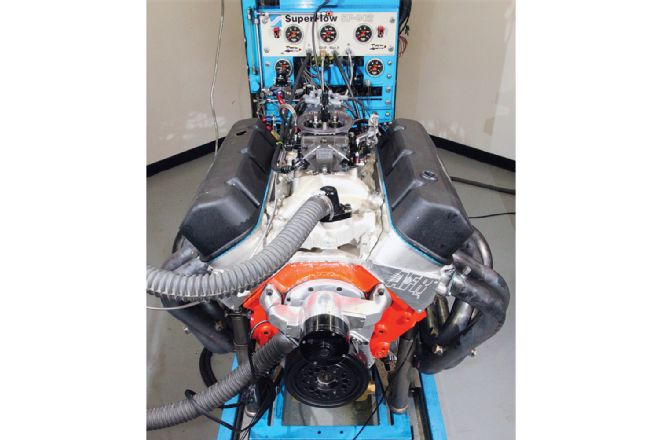

To get a handle on how this all plays out in a real-world engine combination we decided to hit the dyno with three hydraulic roller grinds from Crane Cams. Our test engine is nothing more exotic than a production big-block Chevy 454. The engine was prepped by boring it out for a set of short-dome JE pistons to bring the compression ratio over the 10:1 mark, adding a set of Scat H-beam rods for durability, while freshening the stock Chevy crank. Up top, we went with a set of deceptively capable oval-port AFR cylinder heads. The heads feature a modest port volume of just 265 cc, but these fully CNC-ported castings have the airflow to support healthy output. Supplying the air is an Edelbrock Performer RPM Air-Gap intake manifold fed by a Holley 950 Ultra HP 4150-series carburetor. In short, our engine is the type of budget performance Chevy big-block you’ll find on streets across the United States, based on production components and spiced up with aftermarket goodness where it counts.

With the popularity of hydraulic roller cams in today’s street builds, it made sense to select that cam configuration for our dyno session. The advantages of the juice roller include virtually eliminating unexpected cam lobe/lifter failure in initial running, and the ability to add enough valvespring reliably to spin up some high-rpm power. The roller profiles offer much more lift than we would expect to run reliably on a flat-tappet combination, giving the potential for serious power production. To complement the cam, we opted for a set of Crane’s standard retrofit hydraulic roller lifters, PN 13532-16, along with Crane’s excellent 13763TR-16 aluminum-bodied roller rocker arms. The cylinder heads were ordered with AFR’s excellent hydraulic roller spring combination, so we were covered there.

To best illustrate the varied characteristics affected by cam size, it made sense to step the specifications up fairly substantially between the cams. We opted for sizable jumps of 12 and 14 degrees duration as measured at .050-inch lift. Our baseline cam, with 222/230 degrees duration at .050 would be considered a baby cam by performance veterans, but with lift of .576/.598 inch, it moves the valves with authority, and with a healthy lope can in no way be construed as a stock cam. Testing showed that even this small stick has its big-boy pants on, taking our mild 454 combo up to 570 hp at 5,800 rpm, and pulling cleanly over 6,200 rpm.

That’s healthy power for a pump-gas street 454. What was more impressive came lower in the operating range, where the torque right off the hit at 3,000 rpm was 539 lb-ft, twisting strongly to a peak of 587 lb-ft from 3,900 to 4,100 rpm. Our small cam delivered the torque needed to launch heavy street metal, while dishing plenty of punch up top. While the duration specs would seem conservative, don’t be fooled, this unit definitely proved to be performance minded. The smallest of our trio of cams idled with a noticeable performance lope and registered a healthy 15 in-hg of vacuum at a 1,000-rpm idle.

Our next step in cam size moved up to 234/242 degrees duration at .050, a neighborhood that is popular with today’s street performance enthusiasts. We tore the engine down as it sat on the dyno for the cam change, retaining everything else exactly as it was in our previous combination. The upsized cam featured a significant jump in lift, shoving the valves to well over the .600-inch mark. We expected the increase in lift and duration to tap into more of the excellent high-lift airflow of the AFR heads, and bump top end power. The dyno numbers showed a textbook example of what is gained and what is lost as the cam timing is increased. Up top, we now recorded 599 hp at 6,100 rpm, gaining in both output and usable rpm, however, the bump of 12 hp up top shaved 8 lb-ft from peak torque, and shifted the torque peak higher up the rev range. This move in the torque curve was most noticeable in the lower end of the rev range, with substantial torque losses below 4,000 rpm. Idle lope was noticeably more pronounced and vacuum measured 12 in-hg at 1,000 rpm.

Here lies the classic trade-off in a dual-purpose performance machine —determining how much cam is enough and how much is too much.

…even this small stick has its big-boy pants on, taking our mild 454 combo up to 570 hp at 5,800 rpm…

Our intermediate cam was clearly favoring the upper end of the rpm range, and at this level of cam duration a single-plane intake manifold would likely further complement the high-rpm power. To explore the effects of a change in manifold configuration, we swapped the intake to Edelbrock’s Victor Jr. 454-O, a single-plane designed for the oval-port heads. With no other changes to our test engine, the swap resulted in a classic example of a single-plane versus dual-plane comparison. Up top, we now recorded 609 hp from 6,000-6,200 rpm. With handily over 600 hp on tap, we definitely gained in bragging rights, but it came with a clear loss in torque at lower rpm. The point at which peak torque occurred moved up and moved peak torque rpm up by a surprising 900 rpm. The single-plane runner layout also resulted in a small penalty in idle vacuum, now recorded at 11.7 in-hg at 1,000 rpm.

Our first move up the ladder bumped the intake duration at .050 by 12 degrees with a 234/242-degree stick, and boosted lift to .610/.632 inch. We lubed the cam and installed it with no other changes to the engine combo.

Our first move up the ladder bumped the intake duration at .050 by 12 degrees with a 234/242-degree stick, and boosted lift to .610/.632 inch. We lubed the cam and installed it with no other changes to the engine combo.

Our final test configuration featured another large move up in camshaft specs, this time to 248/256 degrees duration at .050- and .630-inch lift, retaining the single-plane manifold from our previous test. Our big cam definitely made itself known with a raucous lope and just 7.0 in-hg of vacuum at 1,000 rpm. Following the pattern of our previous tests, the big stick once again traded torque downstairs for horsepower at the upper reaches of the tach. We now had an impressive 630 hp on tap at 6,400 rpm, with the combination pulling cleanly to a maximum of 6,700 rpm. Those numbers are pretty imposing for a pump-gas street 454!

With the “bigger” cam noticeably favoring the top end of the power curve, this level suggested a single-plane intake might further help peak output. We swapped to the Edelbrock Victor Jr. 454-O and saw an even 10 hp gain up top.

With the “bigger” cam noticeably favoring the top end of the power curve, this level suggested a single-plane intake might further help peak output. We swapped to the Edelbrock Victor Jr. 454-O and saw an even 10 hp gain up top.

The penalty here, as you might expect, is more torque skinned off the lower rpm range. Compared to our baseline combo we were down over 80 lb-ft at 3,000 rpm, although looking at torque from peak to peak the difference shrinks to just 10 lb-ft. As had been the case through each of our changes, the powerband moved up, trading bottom end output and idle quality for more all-out power. These compromises are the essence of what performance enthusiasts are faced with when making their camshaft decision. Our baseline cam delivered mountains of low-end grunt, and has the legs for excellent power up top. The ferocious idle of our big cam would definitely come with compromises in street driveability, but might just offer the boulevard presence and power curve you are after. With a serious converter and street tires, the torque lost down low would likely never even make itself known. When it comes to cams, one size doesn’t fit all, the right cam is tailored to your application and goals.

The “bigger” intermediate cam exhibited exactly the change to the engine’s characteristics one might expect, increasing output up to just shy of 600 hp, while taking torque numbers off the bottom of the rev range. Idle vacuum dropped from 15 to 12 in-hg.

The “bigger” intermediate cam exhibited exactly the change to the engine’s characteristics one might expect, increasing output up to just shy of 600 hp, while taking torque numbers off the bottom of the rev range. Idle vacuum dropped from 15 to 12 in-hg.

With our final cam change our 454 was carrying a big stick, with duration at .050 now at 248/256, and lift at .632/.632 inch. The big cam sounded off with the characteristic window-rattling lope, while extracting 630 hp from our pump-gas big-block.

With our final cam change our 454 was carrying a big stick, with duration at .050 now at 248/256, and lift at .632/.632 inch. The big cam sounded off with the characteristic window-rattling lope, while extracting 630 hp from our pump-gas big-block.

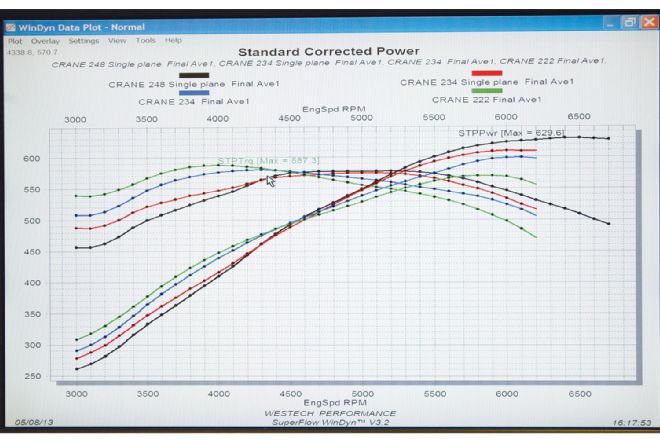

Illustrated graphically, it is clear how each larger cam stepped up the top end power but sliced ever larger chunks from the low-end torque. Is the trade worth it? The answer is as individual as your own objectives from your engine.

Illustrated graphically, it is clear how each larger cam stepped up the top end power but sliced ever larger chunks from the low-end torque. Is the trade worth it? The answer is as individual as your own objectives from your engine.

TQ: HP: RPM: 222DP 234DP 234SP 248SP 222DP 234DP 234SP 248SP 3,000 539 508 487 457 308 290 278 261 3,100 539 508 487 457 318 300 287 270 3,200 542 513 491 462 330 313 299 282 3,300 549 523 501 474 345 329 315 298 3,400 558 535 512 488 361 347 332 316 3,500 567 547 521 500 378 365 347 333 3,600 575 557 528 508 394 382 362 348 3,700 581 564 533 516 409 397 376 363 3,800 585 569 539 524 423 412 390 379 3,900 587 573 543 532 436 426 403 395 4,000 587 576 547 538 447 439 416 410 4,100 587 578 552 545 458 452 431 426 4,200 585 580 558 554 468 464 446 443 4,300 583 580 563 564 477 475 461 461 4,400 580 579 567 570 485 485 475 478 4,500 576 577 569 574 493 495 488 492 4,600 572 575 571 576 501 504 500 505 4,700 567 572 572 577 508 512 512 516 4,800 563 570 574 577 515 521 524 528 4,900 559 568 574 577 522 529 536 538 5,000 555 565 575 577 528 538 547 549 5,100 552 563 575 577 536 546 558 560 5,200 549 559 574 577 543 554 568 572 5,300 545 556 572 577 550 561 578 582 5,400 541 552 569 576 556 567 586 592 5,500 536 548 566 573 561 574 592 600 5,600 530 544 561 569 566 581 598 607 5,700 524 541 555 565 569 587 602 613 5,800 516 537 549 559 570 593 606 617 5,900 507 531 542 552 569 597 608 620 6,000 497 524 534 546 568 598 609 624 6,100 485 516 524 538 563 599 609 625 6,200 470 505 516 530 555 597 609 626 6,300 524 628 6,400 517 630 6,500 509 629 6,600 500 628 6,700 491 627

Crane grind number: Duration at .004 inch: Duration at .050 inch: Lift: LSA: HR 222/239-2S-10 284/292 degrees 222/230 degrees 0.576/0.598 inch 110 degrees ZHR-296-2S-12 296/304 degrees 234/242 degrees 0.610/0.632 inch 112 degrees HR-248/372-2S-10 310/318 degrees 248/256 degrees 0.632/0.632 inch 110 degrees

See More Online

We captured our three-cam, two-intake dyno test on video, so if you want more, log on to our Video page at PopularHotRodding.com!