When Jeff Latimer of Southern California’s JGM Performance Engineering advised us he was about to build an American Motors 401 for an AMX, it brought back memories of the way AMC muscle cars were perceived when I was in high school back home in Bowie, Maryland. American Motors—we all laughed. However, I wasn’t laughing when I got shellacked by a 390 AMX one night on Route 3 when it was more rural highway than interstate. I believed my ’67 Mustang had it all over him. I put the pedal to the metal and so did he. His AMX left a lasting impression still with me to this day. It was at that moment I realized there was more to the AMC 390 and 401 than the stigma of Rambler power. That darned thing was fast.

Though AMC has always been considered the muscle car underdog, it bites. And it bites with fury. If you’re driving around in a Chevy, Ford, or Mopar with your ego in tow, get ready for unexpected embarrassment from AMC because you’re going to get passed up.

On the surface, all American Motors Gen 2 and Gen 3 V-8s look the same. They range in displacement from 290 to 401 ci. The 290, 343, and 390 were Gen 2 short-deck blocks employed in ’66-’69 models. Why Gen 2 and 3 are confusing is because for 1970 there was another 390, a tall-deck block with 0.016 inch more deck height. The short-deck 390 was ’68-’69 only. The tall-deck Gen 3 390 was ’70 only and was replaced by the 401 in the ’71 model year.

The 390 and 401 have the same 4.165-inch bore size. Where the 390 and 401 differ is in their stroke. The 401 has a 3.860-inch stroke, which gives it raw mechanical advantage over the 390’s 3.574 inches. Another advantage both the 390 and 401 share is a steel crankshaft, compared with the nodular iron crank in the 304 and 360. The ’70 tall-deck AMC 390 has a unique piston-and-rod combo that makes it different from the ’68-’69 variety. The 401 has 2.090-inch rod and 2.248-inch main journals, which means you can swap the 401’s reciprocating backbone into a 390 Gen 3 block. The Gen 3 block also has half-inch head bolts versus 7⁄16-inch for the Gen 2.

The 401 at JGM Performance Engineering is a mild street motor going into a ’70 AMX. The owner, Bob Martinez, has opted for a hot hydraulic flat-tappet grind from Comp Cams, Edelbrock heads and induction, MSD ignition, and Doug’s headers with a cool ceramic coat. JGM is providing the expertise and dyno time.

On the dyno, Martinez’s 401 made a healthy 459 hp and a whopping 509.3 lb-ft of torque. This AMX mill is big on torque with a flattering amount of horsepower. It is not a stroker. It has the stock AMC steel forged crankshaft and rods topped with Wiseco PT116H3 forged aluminum dished pistons and compression that’s happy with pump gas.

1] The platform for a good AMC 401 comes from precision machine work that gets the block as true as possible. JGM begins by boring 0.025 over with a 0.005-inch hone to achieve a 0.030-inch overbore. Bore size is now 4.195 inches.

1] The platform for a good AMC 401 comes from precision machine work that gets the block as true as possible. JGM begins by boring 0.025 over with a 0.005-inch hone to achieve a 0.030-inch overbore. Bore size is now 4.195 inches.

2] The main bearing caps are milled in preparation for line honing. This gets the caps square with the block.

2] The main bearing caps are milled in preparation for line honing. This gets the caps square with the block.

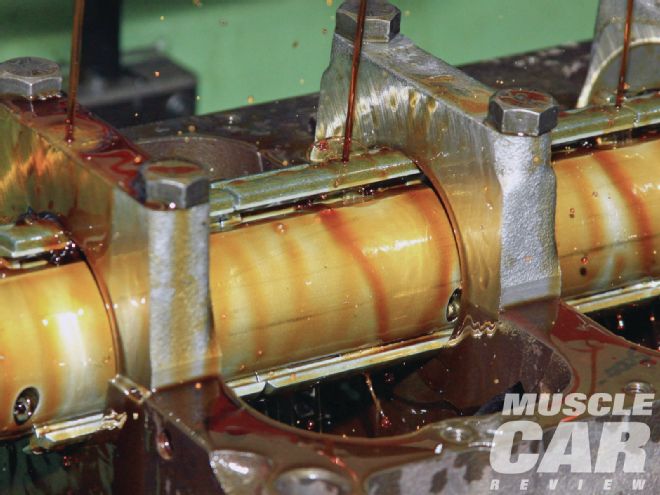

3] The main saddles are line honed to get the main bearing caps where they belong dimensionally. Before you is a very rugged 401 block with two-bolt main caps. These guys stay together and can endure a lot of punishment.

3] The main saddles are line honed to get the main bearing caps where they belong dimensionally. Before you is a very rugged 401 block with two-bolt main caps. These guys stay together and can endure a lot of punishment.

4] Jim Grubbs of JGM Performance Engineering hones his blocks based on how the engine will be used. If you’re going to run it hard, tolerances run looser. This motor is getting a Stage 2 build, for street and strip, so piston-to-cylinder-wall clearances run 0.006 to 0.009 inch.

4] Jim Grubbs of JGM Performance Engineering hones his blocks based on how the engine will be used. If you’re going to run it hard, tolerances run looser. This motor is getting a Stage 2 build, for street and strip, so piston-to-cylinder-wall clearances run 0.006 to 0.009 inch.

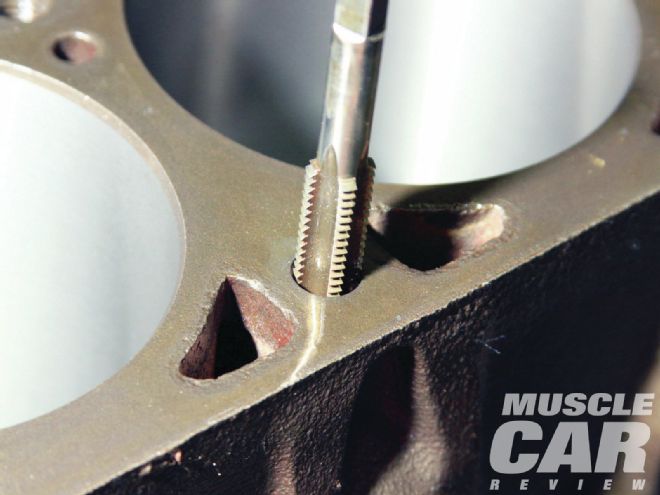

5] Grubbs chases all bolt holes to ensure accurate torque readings during assembly.

5] Grubbs chases all bolt holes to ensure accurate torque readings during assembly.

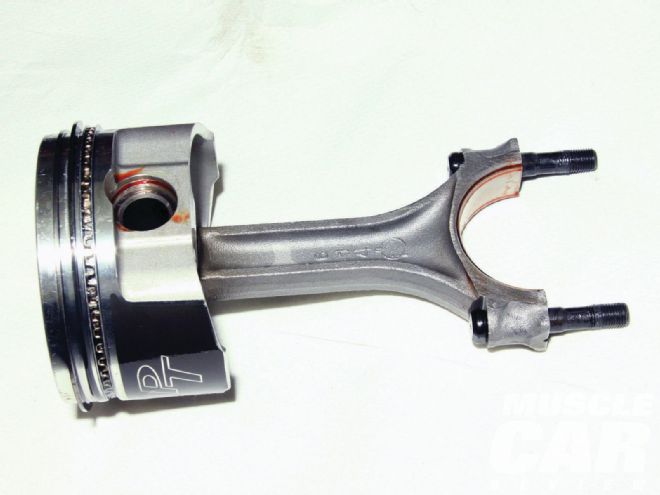

6] JGM opted for stock 401 rods with ARP bolts (PN 114-6002), a setup that’s plenty sturdy for a street/strip 401. JGM reconditioned these rods and put them through dynamic balancing. Wiseco forged pistons with ductile iron rings from Summit Racing Equipment make for exceptional cylinder sealing. Skirts are coated to reduce friction.

6] JGM opted for stock 401 rods with ARP bolts (PN 114-6002), a setup that’s plenty sturdy for a street/strip 401. JGM reconditioned these rods and put them through dynamic balancing. Wiseco forged pistons with ductile iron rings from Summit Racing Equipment make for exceptional cylinder sealing. Skirts are coated to reduce friction.

7] An adjustable ring compressor is used for installation along with liberal amounts of Comp Cams engine assembly lube. Ring end gaps are 0.013 inch and staggered at 45-degree intervals.

7] An adjustable ring compressor is used for installation along with liberal amounts of Comp Cams engine assembly lube. Ring end gaps are 0.013 inch and staggered at 45-degree intervals.

8] Piston installation is performed gingerly with rod bolt caps employed to protect rod journals. Rod journals and bearings get plenty of assembly lube. You can never use too much. Rod side clearance is 0.014 to 0.018 inch for street/strip operation.

8] Piston installation is performed gingerly with rod bolt caps employed to protect rod journals. Rod journals and bearings get plenty of assembly lube. You can never use too much. Rod side clearance is 0.014 to 0.018 inch for street/strip operation.

9] The Wiseco forged pistons are dished to keep compression conservative for today’s low-octane pump gas.

9] The Wiseco forged pistons are dished to keep compression conservative for today’s low-octane pump gas.

10] Close examination of the AMC 401’s bottom end reveals thick main webs and wide two-bolt main caps supporting a steel crank and heavy-duty I-beam rods with ARP fasteners. What this means for Bob Martinez is a very rugged bottom end for a nice balance of street and strip durability.

10] Close examination of the AMC 401’s bottom end reveals thick main webs and wide two-bolt main caps supporting a steel crank and heavy-duty I-beam rods with ARP fasteners. What this means for Bob Martinez is a very rugged bottom end for a nice balance of street and strip durability.

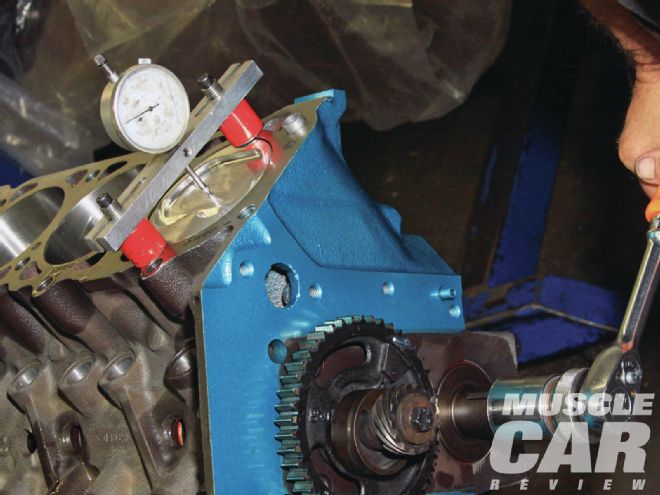

11] True top dead center is checked before cam degreeing. To ensure true TDC, a dial indicator is used to detect piston movement during crank journal rollover. At the middle of rollover straight up at 12 o’clock is true TDC.

11] True top dead center is checked before cam degreeing. To ensure true TDC, a dial indicator is used to detect piston movement during crank journal rollover. At the middle of rollover straight up at 12 o’clock is true TDC.

12] Martinez has opted for a hydraulic flat-tappet cam from Comp Cams (PN10-000-5) with 0.523/0.512-inch gross valve lift and 0.327/0.320-inch lift at the lobe on 109-degree lobe centers. Duration at 0.050 is 230/231. The cam checks out per the cam card.

12] Martinez has opted for a hydraulic flat-tappet cam from Comp Cams (PN10-000-5) with 0.523/0.512-inch gross valve lift and 0.327/0.320-inch lift at the lobe on 109-degree lobe centers. Duration at 0.050 is 230/231. The cam checks out per the cam card.

13] This is Edelbrock’s Performer 401 cylinder head (PN 60119) developed and engineered specifically for the AMC 401 with 54cc chambers, 2.02/1.60-inch valves, Manganese bronze 11⁄32-inch valve guides, 3⁄8-inch screw-in rocker studs with steel guide plates, and 185/70cc intake/exhaust runner volumes. Valve springs are chosen for the toughest applications; however, it is suggested that you match the cam profile to the spring pressure during the buildup. The Performer 401 is drilled for both early- and late-model intake manifolds. Step dowel pins are included for pre-’70 AMC blocks.

13] This is Edelbrock’s Performer 401 cylinder head (PN 60119) developed and engineered specifically for the AMC 401 with 54cc chambers, 2.02/1.60-inch valves, Manganese bronze 11⁄32-inch valve guides, 3⁄8-inch screw-in rocker studs with steel guide plates, and 185/70cc intake/exhaust runner volumes. Valve springs are chosen for the toughest applications; however, it is suggested that you match the cam profile to the spring pressure during the buildup. The Performer 401 is drilled for both early- and late-model intake manifolds. Step dowel pins are included for pre-’70 AMC blocks.

14] Edelbrock’s new Performer RPM Air Gap for AMC V-8s is available for ’67-’69 390 (PN 7530) and ’70-up 390/401 (PN 7531) applications. The advantage of the Air Gap intake is a cooler, denser intake charge because Edelbrock has engineered space—the Air Gap—for atmosphere between runners and engine. On top will be an Edelbrock Performer Series 750-cfm carburetor.

14] Edelbrock’s new Performer RPM Air Gap for AMC V-8s is available for ’67-’69 390 (PN 7530) and ’70-up 390/401 (PN 7531) applications. The advantage of the Air Gap intake is a cooler, denser intake charge because Edelbrock has engineered space—the Air Gap—for atmosphere between runners and engine. On top will be an Edelbrock Performer Series 750-cfm carburetor.

15] All new oil pumps should be disassembled and blueprinted to ensure durability. Gear side and end clearances should be checked per an AMC service manual. The pressure-relief valve should be checked for freedom of movement and proper spring pressure. Some AMC experts suggest opening up passages to get more volume. This should happen mostly ahead of the pump cavity.

15] All new oil pumps should be disassembled and blueprinted to ensure durability. Gear side and end clearances should be checked per an AMC service manual. The pressure-relief valve should be checked for freedom of movement and proper spring pressure. Some AMC experts suggest opening up passages to get more volume. This should happen mostly ahead of the pump cavity.

16] The oil pump cavity is filled with engine assembly lube to ensure plenty of lubrication upon initial fire-up. JGM uses Wix filters.

16] The oil pump cavity is filled with engine assembly lube to ensure plenty of lubrication upon initial fire-up. JGM uses Wix filters.

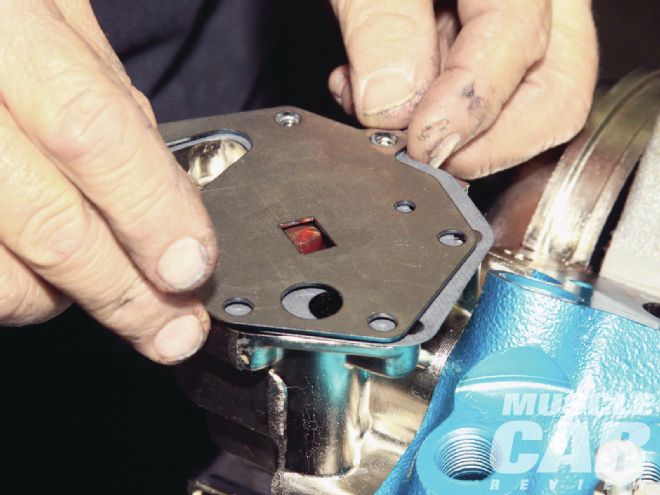

17] The oil pump separator plate is installed next, including its corresponding gaskets.

17] The oil pump separator plate is installed next, including its corresponding gaskets.

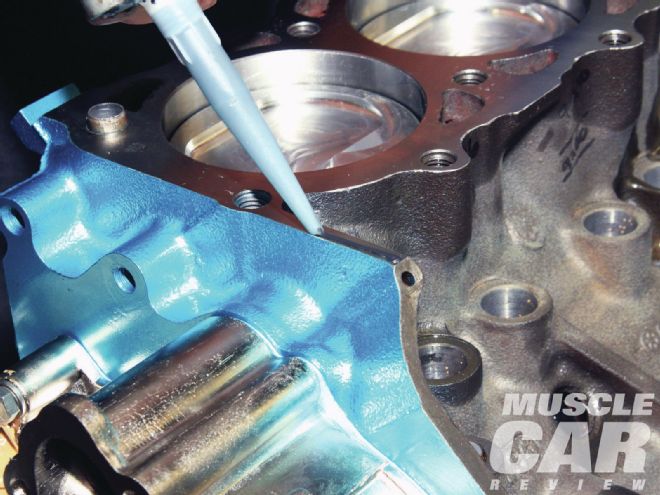

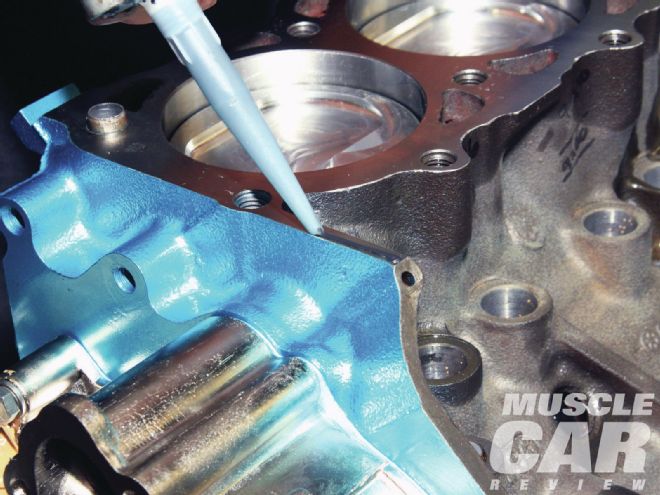

18] One abuse we see time and again is the use of too much gasket sealer. All you need is a pencil-tip-thin line of The Right Stuff from Permatex to seal all irregularities. Here, JGM uses sealer at the cylinder head/manifold/block union to eliminate oil leakage.

18] One abuse we see time and again is the use of too much gasket sealer. All you need is a pencil-tip-thin line of The Right Stuff from Permatex to seal all irregularities. Here, JGM uses sealer at the cylinder head/manifold/block union to eliminate oil leakage.

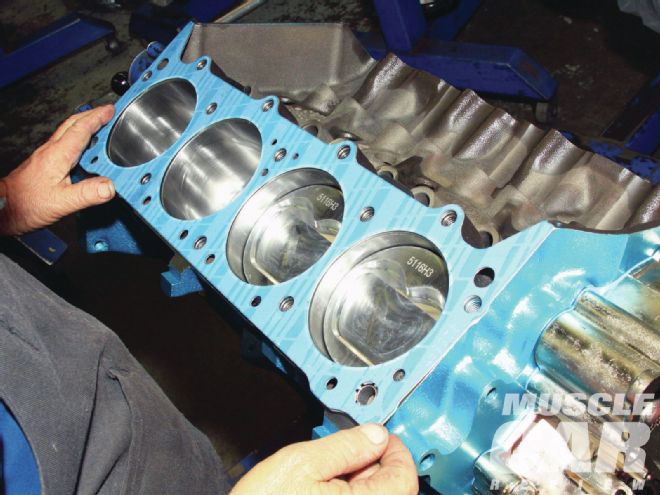

19] Fel-Pro gaskets are JGM’s gasket of choice for most of its engine builds.

19] Fel-Pro gaskets are JGM’s gasket of choice for most of its engine builds.

20] Scorpion Performance billet 1.6:1 roller rockers free up power by reducing internal friction. Optimum for this 401 would be an aggressive hydraulic roller camshaft and head port work, which would have undoubtedly sent horsepower over 500 and torque courting 550-600.

20] Scorpion Performance billet 1.6:1 roller rockers free up power by reducing internal friction. Optimum for this 401 would be an aggressive hydraulic roller camshaft and head port work, which would have undoubtedly sent horsepower over 500 and torque courting 550-600.

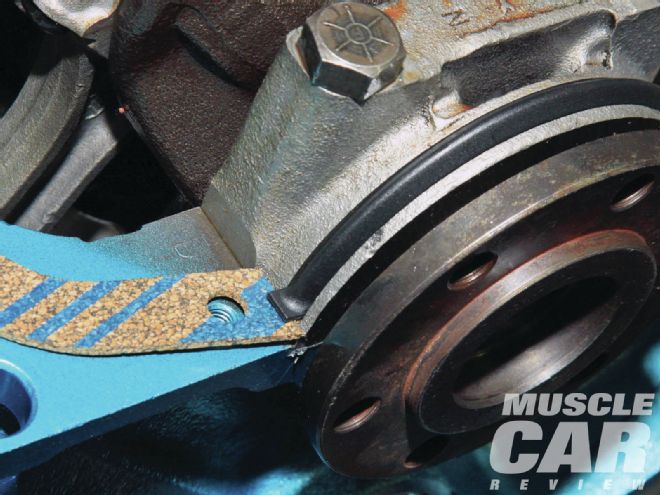

21] Pan gaskets and seals do not have to leak. Your arsenal should include Permatex’s The Right Stuff sealer used sparingly where rail gaskets meet end gaskets. All you need is a superthin bead of The Right Stuff along with clean surfaces, and oil stays inside.

21] Pan gaskets and seals do not have to leak. Your arsenal should include Permatex’s The Right Stuff sealer used sparingly where rail gaskets meet end gaskets. All you need is a superthin bead of The Right Stuff along with clean surfaces, and oil stays inside.

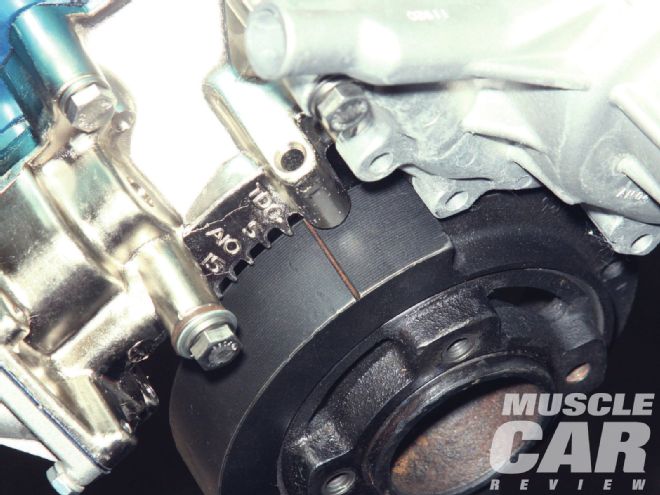

22] This aftermarket replacement balancer was improperly marked and was off by roughly 5 degrees. It was properly marked and reinstalled.

22] This aftermarket replacement balancer was improperly marked and was off by roughly 5 degrees. It was properly marked and reinstalled.

23] In factory original trim with iron heads and induction, the 401 made 335 hp at 5,000 rpm and 435 lb-ft of torque at 3,400 rpm. With a precision build and dynamic balance, coupled with the selection of an aggressive cam profile and Edelbrock induction, we gain 124 hp and 74 lb-ft of torque. Torque comes on strong between 4,000 and 4,200 rpm, with peak hp at 5,500 rpm. This build proves how much power and durability the AMC 390/401 has inherent in its design. What’s more, with more budget and imagination, this mill can go over 500 hp with nearly 600 lb-ft of torque. Although our numbers are impressive, the 401 is a Kenosha kickin’ machine capable of much more.

23] In factory original trim with iron heads and induction, the 401 made 335 hp at 5,000 rpm and 435 lb-ft of torque at 3,400 rpm. With a precision build and dynamic balance, coupled with the selection of an aggressive cam profile and Edelbrock induction, we gain 124 hp and 74 lb-ft of torque. Torque comes on strong between 4,000 and 4,200 rpm, with peak hp at 5,500 rpm. This build proves how much power and durability the AMC 390/401 has inherent in its design. What’s more, with more budget and imagination, this mill can go over 500 hp with nearly 600 lb-ft of torque. Although our numbers are impressive, the 401 is a Kenosha kickin’ machine capable of much more.

Displacement: 407 ci

Bore: 4.195 in.

Stroke: 3.680 in.

Engine Speed (rpm) HP Torque (lb-ft) 3,600 339.8 495.8 3,700 353.2 501.3 3,800 364.9 504.3 3,900 377.9 507.7 4,000 387.9 509.3 4,100 395.9 507.2 4,200 407.1 509.1 4,300 416.3 508.5 4,400 426.1 508.6 4,500 434.5 507.1 4,600 437.0 498.9 4,700 439.9 491.6 4,800 437.6 478.8 4,900 440.1 471.7 5,000 443.4 465.4 5,100 449.9 463.3 5,200 454.7 459.2 5,300 458.6 454.8 5,400 458.6 454.4 5,500 459.0 446.4

SOURCES

JGM Performance Engineering

661/257-0101