When we last left our intrepid Chevrolet Performance Great Crate small-block we had bolted on the Edelbrock Performer RPM cylinder heads and managed to push the power to a smidge over 380 hp and the torque just cleared 400 lb-ft high bar. The results were acceptable but frankly we were a little underwhelmed. These days, four bills has become the new standard and if you can't make it, then you're just not trying hard enough. So we had to lean on this mouse motor a bit.

Looking at our package, we had most everything we needed. If you recall, we started with an affordable Chevrolet Performance 290hp 350 crate engine that came with an 8:1 compression, 76cc iron heads, and a mild hydraulic flat-tappet cam. Because this is STREET RODDER we couldn't be expected to leave this rascal stock, so we added a 268 Xtreme Energy hydraulic flat-tappet COMP cam, a set of Edelbrock Performer RPM aluminum heads, good rocker arms, a Holley 750-cfm carburetor, and a set of headers. The question now was "Where do we go from here?"

The answer was simple but calculated. The RPM heads had the potential to flow more air if we could just add more lift. We tried pushing the lift envelope by adding 1.6:1 rocker arms to bump the lift. While this worked, it was obvious that we were going to need more duration to go any further. We could have jacked up the duration with a flat-tappet cam, but that would have made the engine too radical for the street. The compromise with flat-tappet camshafts is that in order to increase lift, there's a limitation on the amount of lift you can create. This amount of lift is restricted in terms of lift per degree of duration. This limitation is set by the diameter of the lifter. A larger lifter (like a Ford 0.875-inch diameter versus 0.842 for Chevrolets) would help, but using Ford lifters would mean subjecting the engine block to expensive block machining. The smarter move is to just upgrade to a hydraulic roller-style cam. Roller lobes allow much more lift for roughly the same duration. Of course, there's no free lunch and a roller cam and lifters are much more expensive than flat-tappet versions. So if you wanna play, you have to pay.

We opened up our COMP Cams catalog and turned to the Extreme Energy hydraulic roller section. The devil rodder on our left shoulder wanted to go right to the bottom of the page, but we resisted and listened to the wiser rodder on our right shoulder and we selected a slightly more conservative yet still aggressive XR288 cam with 0.520/0.540 inches of valve lift with only a slight 12-degree increase in duration. The key here was to select a cam with more lift to take advantage of the Edelbrock heads' flow potential without killing the low-speed torque.

Short duration cams tend to build low-speed torque and make great off-idle power, but are limited when engine speed increases much past 5,000 rpm. To make more horsepower, more duration helps the high-rpm breathing. The beauty of the roller design is we can benefit from greater valve lift without having to resort to a long duration cam that kills the low-speed torque. If you look at our cam specs chart, the XR288 cam bumped the lift roughly 0.040 and 0.060 inch (using the 1.5:1 rocker ratio) while the duration increased only 12 degrees for the intake and 11 for the exhaust. In order to bump the valve lift that much with a hydraulic flat-tappet cam, we would have had to run all the way to the biggest XE294H cam with 250/256 degrees of duration at 0.050-inch lift. Frankly, that cam would be way too big for a 9:1 compression 350 and would be miserable to drive on the street.

Once we chose the cam, we knew that this more aggressive hydraulic roller lobe would require more valvespring pressure in order to maintain control of the valves. Generally, a hydraulic roller lobe will require 130-plus pounds of spring load with the valve closed. Flat-tappet cams are more comfortable (and will live longer) with seat loads closer to 110 pounds. COMP has done the homework for you to match the springs and retainers with the cam so that all you really have to do is order the K-kit. But again, since we are control freaks, we found a new COMP beehive spring we wanted to try. We've listed both the entire K-kit for the one-stop shoppers as well as the step-up beehive spring part numbers for those who wish to follow our lead. Once the parts arrived, we began unzipping our Great Crate small-block.

Cam Install

The only thing we changed this time around was a COMP hydraulic roller camshaft and better valvesprings to our Great Crate small-block. That simple swap was worth 50-plus horsepower and a nice bump in torque.

The only thing we changed this time around was a COMP hydraulic roller camshaft and better valvesprings to our Great Crate small-block. That simple swap was worth 50-plus horsepower and a nice bump in torque.

Installing a hydraulic roller cam in a traditional small-block Chevy is slightly more complicated than a flat tappet version because the roller requires limiting fore-aft cam movement in the block. Included in the COMP Cams K-kit is a small nylon bumper that fits into the hollow centersection of the cam drive gear. This bumper is designed to be used with the stock timing cover and actually works quite well. We decided to upgrade to a two-piece COMP aluminum timing chain cover that allows us much quicker access to the cam while also using a nicer roller bearing cam limiter. Another reason for using the more expensive two-piece timing cover is it offers a small access hole for a dial indicator to check cam endplay. The spec is 0.004- to 0.010-inch clearance and we were able to get the number down to 0.006 inch. The main reason for ensuring this minimal clearance is to prevent the cam from moving forward in the block. If the cam moves forward too far, the distributor drive gear on the cam will retard ignition timing as engine rpm increases. So it's important to ensure that the cam has minimal movement. The Gen II small-block that first incorporated hydraulic roller lifters uses a cam stop plate to prevent cam movement but these first generation small-blocks do not have that feature so we have to use a thrust limiter.

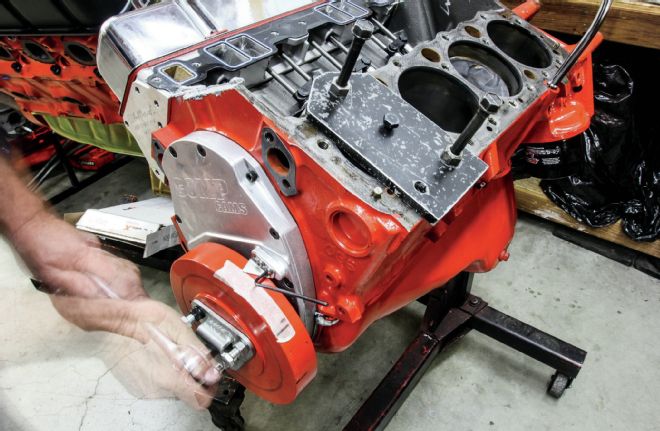

After we installed the new timing chain cover, we forgot to recheck TDC on the harmonic balancer with the cylinder head removed. Our spark plug–style piston stop wouldn't work with dished pistons, so we estimated the position of TDC and figured we were within a couple of degrees. That estimate would come back to haunt us on the dyno.

Because the hydraulic roller cam is more aggressive, we also had to change valvesprings again. We chose to use a set of COMP beehive springs with rather conservative seat load to see if these new springs would still control the valves. We installed the springs at the recommended 1.800-inch installed height. Looking back now, if we were to run the engine again, we'd shorten the installed height to 1.700. This would increase both the seat and open load by roughly 30 pounds. But for this test, the seat load was left conservative since this will make it much easier on the valvetrain. After we had the engine reassembled, we were ready for another round on the dyno.

Dyno Day

We initially thought this would be an easy test session since we didn't have to thrash to change a bunch of parts in a short period of time. Once the Great Crate engine was on the dyno again, we warmed it up and Westech's Steve Brule pulled the handle. The results were hardly impressive. Compared to the previous test session, we lost close to 20 hp! That had us scratching our heads. Brule re-checked the dyno to ensure it was accurate and we attempted to confirm TDC, but all we could do was estimate it without an accurate piston stop, which would have required removing the driver side head. We added more timing and the engine responded so we kept adding more timing until the balancer read 53 degrees of total timing! This is where the engine made its best power—with the numbers at 431 hp at 6,000 rpm with peak torque coming in at 424 lb-ft at 4,200.

After we returned to the shop with the engine, we removed the driver side head and confirmed that TDC was retarded by nearly 14 degrees. Subtracting this from 53 degrees gave us an accurate total timing figure of 39 degrees, which is still a bit high but reasonable considering the combination of a somewhat low 9:1 compression ratio and the 288 roller cam. We've seen several instances where less compression requires more total timing to make best power.

Conclusions

Hydraulic roller cams are quickly becoming the smart move when it comes to making power for street engines. It used to be that these cams were limited in rpm potential, but we've done some testing that saw a Westech small-block spin very cleanly up to 8,500 rpm with a set of hydraulic roller lifters, so rpm is not a problem. In this application, we saw a dramatic increase in power of over 50 hp over the previous flat-tappet cam. Granted, the hydraulic roller was a full 12 degrees longer in duration than the flat tappet and also offered more lift even with the stock ratio 1.5:1 rockers.

If you look at our accompanying power graph, you can see that this additional duration did lose some torque at engine speeds below 3,600 rpm. This will mean the engine will be a bit less responsive to throttle but beyond that point, the increase in power is readily apparent. In peak-to-peak comparisons, we improved the torque by 22 lb-ft and the horsepower jumped a solid 50 hp. But if you look at the power difference at 6,000 rpm, you can see the cam change was worth a stunning 64 hp. We stopped our testing at 6,200 where the power curve was just barely tipping over. At 6,400, the power dropped off quite abruptly, which indicated to us that we had run into a valve float problem. We didn't have the time on the dyno to make any major changes, but if we had increased the spring pressure by tightening up the installed height to 1.700 (reducing it by 0.100 inch), this would have bumped the seat load from 110 to 138 pounds, which probably would have allowed the engine to spin all the way up to 6,500 or perhaps beyond.

This is important because you can improve quarter-mile e.t. by shifting roughly 300 to 500 rpm past the peak horsepower point. With the roller cam making over 60 hp more at the higher engine speeds compared to the flat-tappet cam, shifting at 6,500 could easily be worth a much quicker e.t. What's all this power worth? We plugged these power numbers into our Quarter, Pro dragstrip simulation program and in a 3,000-pound street rod with a three-speed automatic with a 3,000 stall speed converter, 3.55:1 rear gears, and good traction from sticky tires, this mild small-block could potentially run 11.50s at 116 mph! That's a mighty quick ride for a 9:1 pump gas street motor. In fact, you might just call this a Great Crate success story.

1. Last time, bolting on a set of Edelbrock heads and the COMP flat-tappet hydraulic cam made 381 hp, but we knew that a bunch more power was there for the taking.

2. This is the COMP Cams Xtreme Energy hydraulic roller cam and kit assembly. It comes with the selectively austempered ductile iron (SADI) camshaft, hydraulic roller lifters, springs, retainers, locks, valves seals, pushrods, timing gear set, and a nylon button. SADI cams can run a standard iron distributor gear.

3. You can use the nylon button with a stock timing cover, but COMP sells a reinforced stamped steel timing cover that comes with a much stiffer ribbing plus a roller bearing thrust button.

4. We decided to use the COMP two-piece aluminum timing chain cover that allows quick access to the timing chain assembly without having to lower the oil pan. This cover is designed to be used with the roller thrust bearing that comes with the kit along with all the hardware.

5. We installed the cam along with some COMP cam lube. One additional advantage of any roller cam is that you don't have to worry about breaking the cam in and potentially losing a lobe.

6. We degreed the cam with the cover off to ensure that the cam was in correctly. It's rare that we find the cam off more than 1/2 degree, as in this case where the intake centerline was exactly where it was supposed to be at 106 degrees ATDC. Most COMP street cams are advanced 4 degrees from the factory.

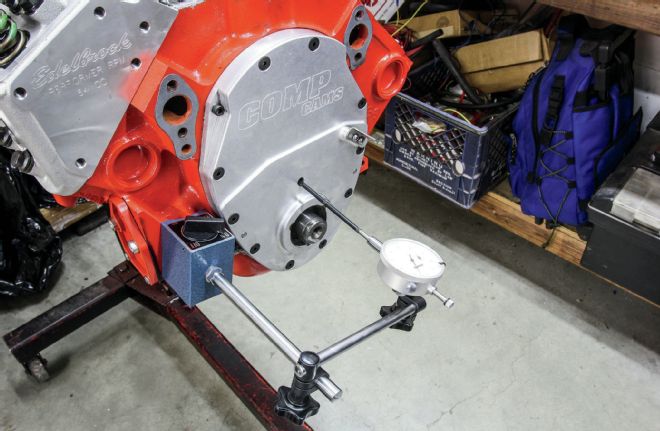

7. We installed the roller thrust button and checked the endplay using the access hole in the two-piece timing cover. Without this hole it is much more difficult to check cam thrust clearance. The endplay spec is 0.004 to 0.010 inch and we ended up at 0.006 inch.

8. The standard spring combination for our cam is the COMP PN 986 dual spring with retainers that are part of the K-kit. The beehive spring in the foreground is the upgrade PN 26986 spring and retainers. The dual spring offers more seat and open load pressure, but is heavier. Note how much smaller the beehive retainer is than the standard version.

9. Here is a comparison of the standard diameter spring on the left versus the beehive on the right. Since the top half of the spring and the retainer travel the full valve lift distance, a lighter upper spring and retainer requires accelerating less mass. This reduced force means more spring pressure is available to control the valve instead of the retainer and spring.

10. We also upgraded to COMP's Ultra-Gold aluminum roller rockers. These rockers not only reduce heat with a full roller bearing trunion over the roller tipped Magnum rockers but also come with a lifetime warranty.

11. With the engine reassembled, we drained the break-in oil and filter and replaced it with a new AMSOIL filter and Dominator 5W-20 full synthetic race oil, which contains a higher percentage of zinc and phosphorous—high-pressure lubricants for the roller lifters and valvetrain. Plus, the lighter weight oil should help a little with power and reduce windage.

12. After returning from the dyno with odd ignition timing numbers, we rechecked TDC and discovered we'd incorrectly placed the TDC timing pointer, making it 13 degrees retarded. After double-checking true TDC, we now have 39 degrees of total timing and all is right with the world.

13. This was our latest version of the Great Crate small-block, complete with its Edelbrock Performer RPM heads and intake, a Holley 750-cfm Street HP carburetor that was near perfect right out of the box, a DUI HEI distributor, MSD spark plug wires, and 1-3/4-inch open dyno headers.

By The Numbers

RPM TQ1 HP1 TQ2 HP2 TQ HP 2,600 329 163 333 165 +4 +2 2,800 347 185 328 175 -19 -10 3,000 359 205 334 191 -25 -14 3,200 367 223 353 215 -14 -8 3,400 383 248 376 243 -7 -5 3,600 392 268 397 272 +5 +4 3,800 394 285 412 298 +18 +13 4,000 401 306 421 320 +20 +14 4,200 402 322 424 339 +22 +17 4,400 399 334 421 353 +22 +19 4,600 395 346 418 366 +23 +20 4,800 389 355 413 378 +24 +23 5,000 382 363 408 388 +26 +25 5,200 375 371 404 400 +29 +29 5,400 370 381 401 412 +31 +31 5,600 354 378 395 421 +41 +43 5,800 336 371 388 428 +52 +57 6,000 321 367 377 431 +56 +64 6,200 --- --- 364 430 --- --- Peak 402 381 424 431 Avg. 371.9 300.9 387.3 323.914. This graph quickly illustrates how a longer duration cam changes the power curve. While the shape changes, if you look at the two curves generically, the longer duration cam curve shifts to the right by pushing the power out to a higher rpm. Below 3,400 rpm the roller cam's torque is down by as much as 14 lb-ft of torque, but by 3,600 rpm the curve steadily grows in the roller's favor. That's +57 hp at 5,800 and +64 at 6,000! Average torque improved 15.4 lb-ft for the entire curve. The average increase from 3,800 to 5,800 rpm is 30 lb-ft! The overall averages were computed from the entire curve—every 100 rpm, not the numbers listed here—in case you are checking our math.

Cam Specs

Camshaft Adv. Duration Duration at 0.050 Lift (inches) Lobe Sep. Angle XE-268 Intake 268 224 0.477 (0.508) 110 XE-268 Exhaust 280 231 0.480 (0.512) --- XR-288 Intake 288 236 0.520 110 XR-288 Exhaust 294 242 0.540 ---Both cam specs list valve lift at 1.5:1. The numbers in parenthesis list the lift with a 1.6:1 rocker ratio. We did not test the roller cam with 1.6:1 rockers.

Power Chart

This is a condensation of the entire Great Crate power program from all three stories. The last change to the hydraulic roller camshaft really punched up the numbers. Since starting with the stock 290hp crate engine with headers, we've added the intake, heads, hydraulic roller camshaft, and valvesprings, which have increased the peak horsepower from 320 to 431 hp— a gain of 111 hp!

Test Peak TQ Peak HP TQ Gain HP Gain Avg. TQ Avg. HP Avg. TQ Gain Avg. HP Gain Base 311 290 --- --- 293.2 224.4 --- --- Headers 348 320 37 30 319.1 257.6 25.9 33.2 Intake 349 326 1 6 321.1 260.1 2.0 2.5 Camshaft 368 330 19 4 335.9 270.3 14.8 10.2 Valvesprings 370 334 2 4 339.7 273.4 3.8 3.1 Heads 397 376 27 42 369.2 292.6 29.5 19.2 1.6 Rockers 403 381 4 5 371.5 300.8 2.3 8.2 Roller Camshaft 424 431 21 50 387.3 323.9 15.8 23.1Parts List

Description PN Source Price 290hp Crate engine 12499529 Summit Racing $2,069.97 Edelbrock Performer RPM intake 7101 Summit Racing 184.97 Edelbrock Performer RPM heads 60999 (2) Summit Racing 1,359.00 Holley Street HP 750-cfm carburetor 0-82751 Summit Racing 549.95 Fel-Pro head gasket 1003 Summit Racing 69.94 (2) Fel-Pro intake gasket 1256 Summit Racing 17.97 Autolite spark plugs (8) 3924 Summit Racing 23.92 (8) COMP cam kit, XR288HR hyd. Roller* K12-433-8 Summit Racing 903.97 COMP hydraulic roller lifters* 853-16 Summit Racing 449.97 COMP front timing cover, aluminum 210 Summit Racing 257.97 COMP front timing cover, steel 208 Summit Racing 119.97 COMP valvesprings* 986-16 Summit Racing 86.97 COMP retainers* 740-16 Summit Racing 54.97 COMP locks* 611-16 Summit Racing 22.97 COMP beehive valvesprings 26986-16 Summit Racing 184.97 COMP retainers, for beehive springs 795-16 Summit Racing 54.97 COMP timing set* 2100 Summit Racing 27.97 COMP nylon button* 202 Summit Racing 5.97 COMP Hi-Energy pushrods* 7809-16 Summit Racing 37.97 COMP Cams Ultra Gold rockers, 1.5:1 19001-16 Summit Racing 290.97 AMSOIL INC. Racing 5W-20 oil RD20QT AMSOIL INC. 12.75 (ea.) AMSOIL INC. oil filter EAo59 AMSOIL INC. 18.70These parts are included in the K-kit. The kit saves roughly $60 over purchasing the components separately.