Since the original A-990 cars were equipped with 426 Hemi engines and a cross-ram intake with dual Holleys, it would be against the laws of the Mopar world to build a clone of one of these magnificent cars and not install a Hemi engine. It would also go against Bill Goldberg's credo.

Today there are several choices for those who want a Hemi engine. Many individuals build Hemi engines to spec, and many suppliers offer Hemi crate engines in a variety of displacements and horsepower levels. While at one of Charlie Blankenship's Chrysler Classic shows, Goldberg asked his friend Charlie, who has owned and raced many Hemi cars, for some advice on a Hemi engine. Blankenship just smiled and escorted Goldberg to meet Russ Flagle, owner of Indy Cylinder Head-one of the nation's premier Hemi engine builders.

No matter what engine you're building, the right heads are paramount for power. Indy Cylinder Head's shop has the latest CNC machines to maintain consistency and accuracy in the machining process. Here, an Indy Legend Hemi cylinder head is being machined on one of Indys' 16 CNC machines.

No matter what engine you're building, the right heads are paramount for power. Indy Cylinder Head's shop has the latest CNC machines to maintain consistency and accuracy in the machining process. Here, an Indy Legend Hemi cylinder head is being machined on one of Indys' 16 CNC machines.

Thirty-five years ago, Flagle and his brother were drag racers. They discovered they could make more horsepower than the competition with modifications to increase port volume to the heads of their race car. The design they chose for the ports of their Chrysler RB engine led them to build their first proprietary Mopar heads in both cast iron and aluminum. The success of those heads gave them the seed money to invest in the CNC machinery they needed to expand their business. Their first love was Wedge engines, but they saw the demand for high-quality Hemi engines and soon were building their own.

Goldberg told Flagle that he wanted a Hemi that could be street driven, but still develop plenty of horsepower. He'd had his fill of temperamental race Hemis and wanted an engine that would be user-friendly. Flagle explained that Indy Cylinder Head offered eight Hemi engines that ranged in horsepower from 540 to 1,120. In addition, all the Indy engines are fully dyno tested and tuned prior to delivery. They use the best components available to produce a reliable but powerful package.

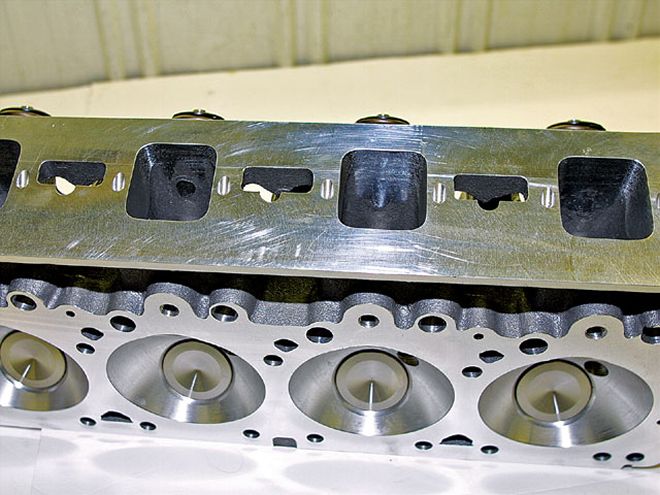

CNC porting ensures that each port is exactly the same as the others. This Legend head is turned up, revealing the exceptionally large intake ports. Indy's cylinder head design provides exceptional port volume for maximum horsepower.

CNC porting ensures that each port is exactly the same as the others. This Legend head is turned up, revealing the exceptionally large intake ports. Indy's cylinder head design provides exceptional port volume for maximum horsepower.

Goldberg looked through the list and found Indy's 650hp Street Legend to his liking. The 650hp rating met his approval for a powerful street engine. it featured a single 850-cfm Demon four-barrel carburetor, MSD distributor, a Comp Cams hydraulic camshaft, and ran on pump gas, which fulfilled his user-friendly requirement. Goldberg then asked Flagle if he could have a few cosmetic items changed. One thing led to another, and before long they came to an agreement to create 20 limited-edition "Who's Next" Goldberg Hemi engines.

Goldberg's "Who's Next" tag line came about eleven years ago soon after he started wrestling. After a match he was having a beer with a few friends, one of whom was a TV director. His advice to Goldberg was: "Always take care of the camera and develop a catch phrase or slogan that belongs to you." Just then the waitress walked up and said, "Who's next?"

Each Indy 650hp "Who's Next" Goldberg engine features special black wrinkle-coated intake manifold and valve covers. "Goldberg" and "Who's Next" are machined into each valve cover. Goldberg was thrilled to have his name on one of the most famous engines in history. He says, "How many people have ever had their name on a Hemi engine? I also realize this engine will not look exactly like the cross-ram Hemi that Dodge put in these cars back in 1965, but it will develop more horsepower than the original 426 and can be driven on the street without detuning."

Indy Cylinder head's proprietary roller rockers were used, and both intake and exhaust feature roller tips.

Indy Cylinder head's proprietary roller rockers were used, and both intake and exhaust feature roller tips.

Blankenship also introduced Goldberg to Rick Allison, founder of A&A Transmission. Allison cut his racing teeth on the quarter-mile in the mid-'70s and found his niche building high-performance TorqueFlite transmissions. Today, his 16,000 square-foot operation is filled with CNC machines that create the parts that Allison and his team of engineers design for the TorqueFlite transmissions. Their testbeds are their own cars, ensuring that each component is fully race-proven before it's sold to a customer. Goldberg told Allison that he didn't want a reverse-pattern manual valvebody. In his conversations with those who have built A-990 clones, the fun of manually shifting an automatic quickly fades after a few miles of city driving. Allison provided Goldberg with one of his bulletproof 727s with a standard shift pattern and full kick-down capability. Because of the '65's unique column cable shifter, a Bouchillon cable kick-down kit was ordered from YearOne. YearOne also provided the flexplate and a Precision Industries torque converter with a 2,500-rpm stall speed.

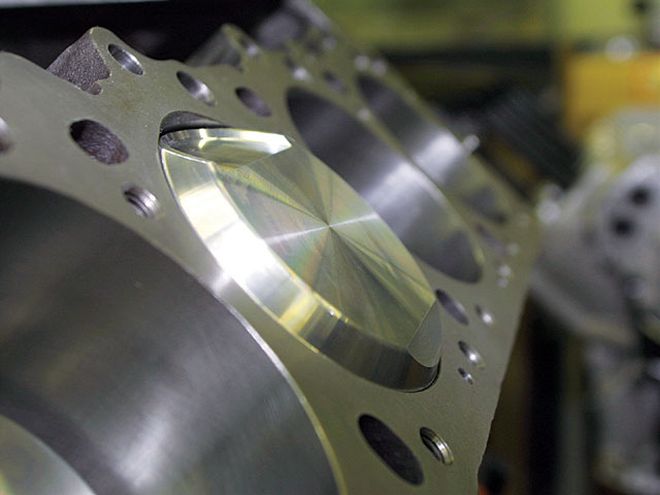

Popping up out of the Indy-prepped Mopar block are 4.310-diameter, 10.25:1 Wiseco forged pistons. A priority for this build was to keep the compression ratio at a level that would make it easy to buy fuel at any corner gas station.

Popping up out of the Indy-prepped Mopar block are 4.310-diameter, 10.25:1 Wiseco forged pistons. A priority for this build was to keep the compression ratio at a level that would make it easy to buy fuel at any corner gas station.

TTI makes headers to fit an iron-headed Hemi with the original '65 K-member, but if raised-port aluminum heads are used-such as those on the Indy Goldberg Hemi engine-along with tti headers, a '66-'70 B-Body K-member must be used. A local Mopar collector produced a well cared for, but greasy, '66 K-member at a reasonable price. It was cleaned and all the welds checked. This must have been a "Monday morning" or "Friday afternoon" K-member because many of the welds were of poor quality. With over 600 pounds of Hemi torque being exerted on the K-member, it was decided that for safety, all the welds for the motor mounts would be redone. If a stock '65 K-member is used, it must be notched for oil pan clearance, but not so with the '66-'70 version. Once all the work was done, the K-member was sent out for powdercoating. Schumacher mounts were added as the final connection between the engine and K-member.

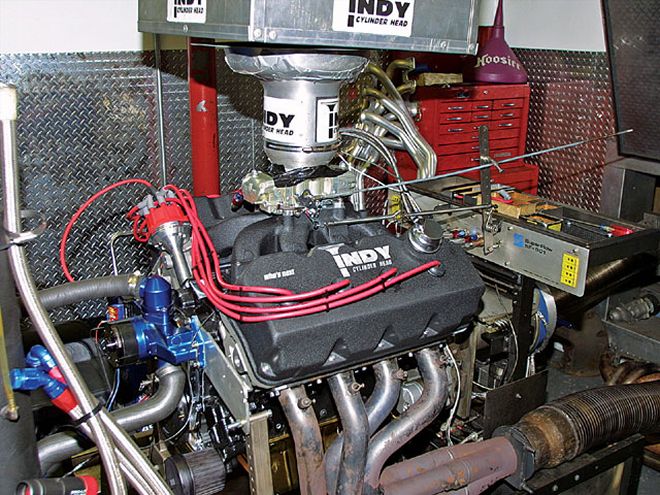

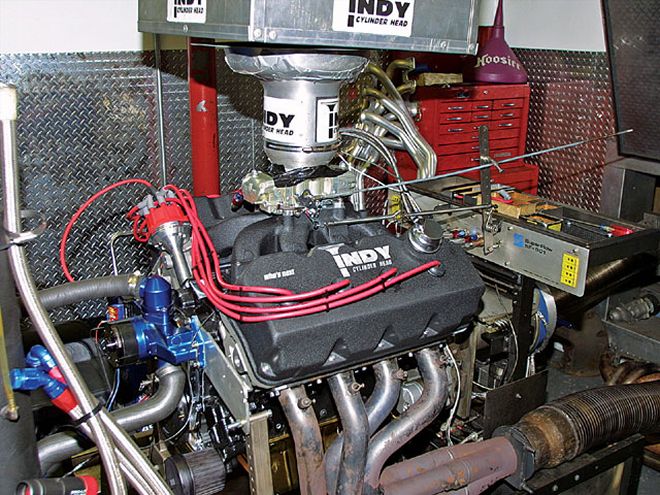

With everything put together, the first Goldberg "Who's Next" Hemi engine is on Indy's dyno cell. After some fine tuning, it registered 650 hp with 625 lb-ft of torque.

With everything put together, the first Goldberg "Who's Next" Hemi engine is on Indy's dyno cell. After some fine tuning, it registered 650 hp with 625 lb-ft of torque.

Remember when we said a '66-and-up B-Body V-8 K-member would allow us to use tti headers in a '65 B-body without any modifications? Well, the process of marrying the engine (with K-member, headers, and transmission) and the body is a carefully choreographed slow dance. Luckily, Goldberg has access to a hoist, and this allowed the body to be dropped straight down over the engine/K-member assembly. With the car on a hoist, the engine and transmission assembly mounted to the K-member was rolled underneath. The Hemi engine, from valve cover to valve cover, is wider than the opening between the body rails, so to facilitate this difference in dimensions, the righthand valve cover was removed. Even with this valve cover removed, there is only about 1/4-inch clearance on each side as the widest part of the engine passes between the body rail flanges. Once past the rails, the assembly was moved a small amount toward the righthand side of the car. Chrysler originally offset the engine to the righthand side of the body to provide clearance for the steering box. You will recall the righthand shock tower was modified so the righthand valve cover could be removed when the engine was in the car.

With everything in place and two friends to help, the process of dropping the body over the engine started. Once the heads cleared the body rails, the K-member was pushed back and to the right so the mounting holes would line up with the attaching points on the bottom of the rails. The attaching bolts were aligned with a drift, and then, one at a time, they were installed but not fully tightened. A jack was placed under the transmission to lift it into position and the crossmember was installed without the rubber mount to support the rear of the transmission. But something was wrong. The transmission was too tight in the tunnel. The transmission mount did not line up with the crossmember!

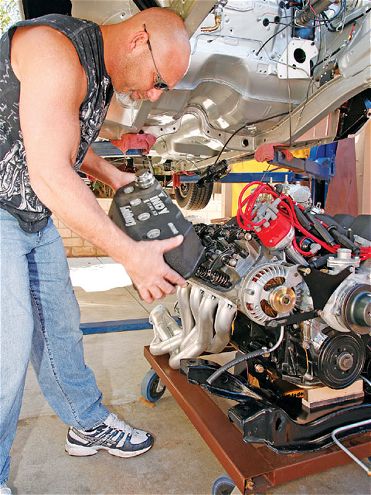

Goldberg in the process of removing the right-side valve cover so it will clear the framerails when installing the Hemi from the bottom. It's a tight fit.

Goldberg in the process of removing the right-side valve cover so it will clear the framerails when installing the Hemi from the bottom. It's a tight fit.

Goldberg and his assistants surveyed the engine compartment and noticed that the engine was awfully tight to the firewall. An attempt to install the righthand valve cover failed because of a lack of clearance to the firewall. The attempt to install the steering column also failed. In 1965, Chrysler used a unique cable shift mechanism for the TorqueFlite. Attached to the lower end of the steering column is a unit that contains the mechanism for the cables. This unit contacted the cylinder head and prevented the connection of the steering shaft to the steering box. Too many things didn't line up! Some adjustments were tried but it was apparent there was a mismatch of components. The scene soon looked like a reality TV program with lots of swearing, yelling, and wrench throwing. It was clear that while the engine "fit," it would not work in its current location.

That night several calls and e-mails went out to ask advice from builders and owners of '65 Hemi Mopars. The responses all centered on the questionable use of the '66 K-member. everyone said they never knew of anyone using a '66-and-later K-member. A call was placed to the source of the original "use a '66 K-member" information, and he said, "I knew it moved the engine back a little." According to Schumacher, the distance is actually 15/8 inches. Nice for a drag racer who wants the rearward weight bias, is willing to hack the firewall, and who will not be using the original column cable shifter, but totally impractical for a street-driven car that is being built to resemble a factory A-990.

As the body came down over the engine, Goldberg realized there was a lot of room between the engine and the radiator support, and very little room between the engine and the firewall. The engine "fit," but not in the right location for a street-driven car.

As the body came down over the engine, Goldberg realized there was a lot of room between the engine and the radiator support, and very little room between the engine and the firewall. The engine "fit," but not in the right location for a street-driven car.

Goldberg made the decision to take a step back and use the original '65 V-8 K-member with Schumacher's Hemi mounts. That meant the tti headers would either have to be replaced by custom headers or be modified to fit. Because of the engine position, the '65 K-member needed to be notched for oil pan clearance.

The engine, mounted on the K-member along with the tti headers, was taken to Warner's Muffler shop in Oceanside, California. The owner, Jim Warner, has been doing exhaust systems and making custom headers for 25 years. After looking at the situation, he decided it would be easy to modify the headers as opposed to building an entirely new set. To build a new set would require the engine to be in the car. The unmodified shape of the tti headers defined the basic envelope in which any modifications must fit. The right side was easy with only one pipe that needed to be rerouted. The left side required more work and was complicated by the steering box. Warner cut, fitted, and welded, and in a short amount of time, successfully modified the headers. Once complete, they were sent out to be Jet-Hot coated. Warner also reinforced the factory welds on the K-member, and for additional strength, added a boxing plate to the lefthand side motor mount stanchion, again for more strength. Then back to the powdercoater with the modified '65 K-member.

The engine, with its accessories bolted to the K-member, rests on a heavy-duty frame with castors for easy adjustment while dropping the body.

The engine, with its accessories bolted to the K-member, rests on a heavy-duty frame with castors for easy adjustment while dropping the body.

With the engine, headers, and transmission assembly mounted on the '65 K-member, Goldberg went back to the lift for another shot at mating the body to the engine/K-member. Having done this operation a week before made this installation much easier. With the engine in place, only a few minor tweaks were needed on the exhaust for tie-rod and pitman arm clearance. This was done with a 3/4-inch socket held on a long extension and impacted with a 5-pound sledge. Not elegant, but it works. Clearance in these areas should be at least 1/4 inch.

Goldberg also added a complete set of Right Stuff Detailing disc brakes. While these A-990 cars were originally equipped with drum brakes, it would be foolish to build a car like this without adequate braking power. The kit includes all the properly bent lines and a dual master cylinder. More exotic conversions are available, but Goldberg liked the simplicity of the Right Stuff system and the fact that replacement parts (calipers, master cylinder, and pads) can be bought at any local parts store.

Goldberg selected a brake kit from Right Stuff Detailing because it included everything, and the major components are not exotic, hard-to-find pieces. Having a hoist puts this job at eye level. For those without a hoist, the brakes and front suspension can be added to the K-member prior to mating it to the body.

Goldberg selected a brake kit from Right Stuff Detailing because it included everything, and the major components are not exotic, hard-to-find pieces. Having a hoist puts this job at eye level. For those without a hoist, the brakes and front suspension can be added to the K-member prior to mating it to the body.

Everything fit well, but bad juju hit again when the left-side caliper developed an instant leak. Things can always go wrong, but it's the way in which the problem is resolved that matters. The folks at Right Stuff guessed that the mounting surface on the caliper for the hose may have been nicked in transit, creating a small exit path for the brake fluid. They suggested taking a look at that surface. Sure enough, there was a small nick that didn't allow the copper washer to properly seat. Careful work with a file eliminated the nick, and when reassembled, the connection was dry.

With the engine and transmission in place, a lot of work could be done that couldn't have been done before. Many engine compartment components could now be added, and smaller components, such as the MSD box and accessory gauges, could be installed.

Many of the A-990 specific components still need to be installed to give the car the correct look-stay tuned.

PARTS IS PARTS