Long before the first Pontiac automobile rolled off the assembly line in late 1926, the Pontiac Buggy Company, formed by Edward M. Murphy was selling horse-drawn buggies to giddy customers looking for that feeling of, well, 1 hp. As he looked toward the future, Murphy saw the horsedrawn buggy going the proverbial way of the buggy whip and created the Oakland Motor Car Company in 1907. A couple years later when GM acquired Oakland, they went through some serious growing pains, but emerged as a customer-savvy competitor for the popular Fords under the Pontiac banner. Unfortunately Murphy, true to the law sharing his name, was unable to bask in the success of his creation, having died unexpectedly the summer after joining the GM family.

Pontiac of course went on to become one of the leading-edge marquees in the automotive world, and fortunately for us was (and I don't care who argues the point) the first to create a muscle car. The '64 GTO had it all: handling, good looks, and power. And it had it in spades. That car brought to life a whole other world of gearheads different than their predecessors, the kind of gearheads like Don Johnston of DCI Motorsports. He has devoted his life to building horsepower, and doing it the Pontiac way.

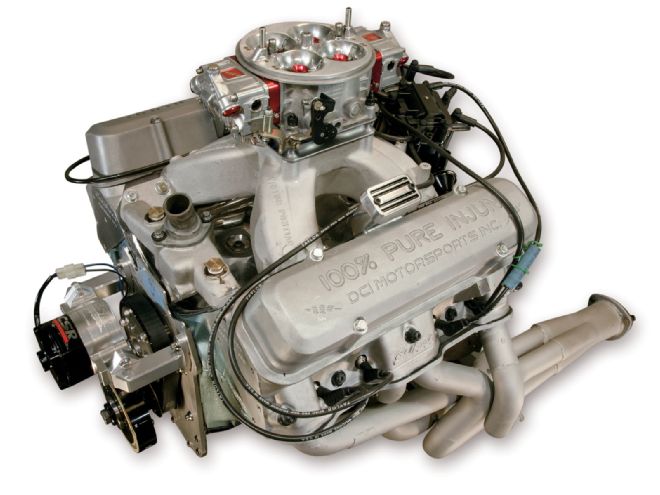

As a long-time carb tuner and engine builder, Johnston takes great pride in his work, and when afforded the opportunity to build an engine for the 2008 Engine Masters Challenge, he readily accepted, but only if he could build a Pontiac.

Johnston started his career in the world of horsepower as a curious 11-year-old taking apart carburetors and rebuilding them. "My dad was an old hot rod mechanic and in those days, those guys didn't really know anything, so if something didn't work, they'd take it off and throw it in the corner and go get another one. He had a pile of carburetors sitting in the garage, so when I got my first car I decided I was going to try to figure these things out. I'd been tearing them apart and putting them back together since I was 11 years old. When you're a kid you don't have any money so you buy an old $100 clunker. I just kept playing with it until I got it to run right. That's how I got into doing carburetors." That fledgling curiosity and talent lead to an apartment basement business as the local carb specialist. As a young 18-year-old who had just gotten married, Johnston's sideline business had grown so much that he had to finally move it into a legit shop as Johnston's Carburetors Inc. in 1983.

During the emergence and growth of the Fastest Street Car racing series in the late '80s, Johnston was racing an '80 Grand Prix with a Pontiac 455, running 11.4s in the quarter-mile but was not competitive with the other cars running high 10s. Dropping that 455 into an '81 body slashed the weight of the car from 4,400 to 3,700 pounds, and instantly ran 10.6s to be in the hunt. At that point, nobody else was running Pontiacs with those timeslips so he began to get noticed by those with tiger blood in their veins. Eventually he began building engines like his 455 for customers begging for a touch of his talent.

As he was building this particular 455 for the Engine Masters Challenge, Johnston called upon all of his previous experience to point him in the right direction. When the 455 emerged in 1970 it was designed for big torque. It had more stroke than bore, but the block and mains were beefed up to handle the increased load. The blueprint for Johnston's engine began with a stock GM 455 block that was cleaned up, bored, honed, and decked by Johnston's machinist, Anthony Milano. At the power level planned for the engine, they felt that very little was required to strengthen the block. Big half-inch ARP main studs in the first four caps and massive 9/16-inch ARP main studs in the rear cap kept the doweled mains in place with no problems. Minor deburring of the oil passages and the Melling M-Select oil pump proved more than adequate to supply the critical Royal Purple lubricant to the engine. As is common with potent Poncho powerplants, oil restrictors were placed in each of the lifter bores to keep from flooding the top end and starving the bearings.

The crankshaft was a stock GM cast piece proving that it could handle plenty of torque. Johnston says he typically knife-edges and bullnoses the crank throws but as this was a last-minute deal (literally done during the week before Engine Masters), he didn't have time to rub on it with the loving that he normally gives the cranks. Swinging on the end of the almost 4.25-inch arms were a set of box-stock Eagle H-beam rods with ARP rod bolts.

Ross provided the forged pistons that Johnston and Milano modified in-house. "We did dimple the tops of the pistons and the combustion chambers to help atomize the fuel," he says. When asked about any empirical evidence that the dimpling did anything to actually help, Johnston referred back to a 409 Pontiac he built for a previous EMC competition. They tested that engine with stock-type chambers first. "It looked fat in areas and the combustion chamber had wet spots where it would puddle in there. I thought, 'You know what, I'm gonna try this.' Because I've seen some articles done on this but I've never seen any testing and nobody knows where to put these things, so I just kind of randomly made it look like a golf ball in the combustion chamber. We didn't do anything to the pistons on that motor." Between just the dimpling of the chamber and also changing the spark plug depth where the electrode would protrude slightly into the chamber, that engine picked up almost 40 hp and Johnston was sold. With the dimpling done to this 455, the pistons and chambers looked like fuel had never touched them. They were also able to run significantly less timing for best power.

Speed Pro standard tension rings lend credence to the fact that this isn't some dyno queen. It could run on the street without any oiling or blow-by issues. DCI has also been ahead of the curve when it came to ring gaps. They prefer to run a fairly tight top gap with a second ring gap that is slightly larger. This concept has only recently gained favor in the racing world. The theory is that any combustion gasses that escape past the top ring build up between the top and second rings. Unless some method of escape is provided for those gasses (such as a large second ring gap), the pressure could unseat the top ring and reduce power.

Another key ingredient to the stout short-block is the COMP Cams bumpstick. Per requirements of the EMC, they used a solid flat-tappet camshaft with stock diameter lifters. That didn't mean they would have to use some tame grind though. "That was a pretty aggressive flat tappet in that motor. We used a Ford lobe design that requires an .875-inch lifter, but after talking with Dean Harvey at COMP Cams and trying to explain what we were doing-and he knew what the other guys in the competition were doing-he said 'Don you're going to have to run this lobe. It's probably not going to live, but you're going to have to run it.' Believe it or not that thing held up nice. I ended up selling that cam to one of my customers and he's still running it." To help that cam survive with on-the-edge spring pressure and lobe design, COMP used their in-house nitriding service to treat the shaft. Pro Plasma TM Nitriding is a process that uses pulsed nitrogen plasma to infuse nitrogen ions into the surface of the cam up to a depth of approximately .010 inch. It sounds technical, and it is, but the end result is that with the oils of today, nitriding a flat-tappet cam gives an extra level of safety against lobe failure.

Connecting the crank and cam is a BOP Engineering beltdrive. Though the use of a beltdrive might seem like overkill for what is supposed to be a pump-gas street engine, it quickly proves its worth as changes on the dyno are made quickly and accurately. With dollars being spent for every minute on a dyno, it makes perfect sense for anyone looking to maximize their combination while on the pump.

Feeding air to this tiger was a set of Edelbrock heads that were considerably massaged. Prior to dimpling the chambers, the heads were milled down, then unshrouded to give it more of a heart shape and get it to the final 74cc's. Johnston's chamber design also incorporated a little "ski jump" around the radius of the intake valve to promote swirl and atomization of the incoming charge. In the intake runners, they played around with different port designs, using epoxy to reshape the runners to the desired dimensions. When all was said and done, the tall and thin runners flowed an incredible 376 cfm at .630 lift. Regarding the tall and thin design of the ports, Johnston says, "A lot of people look at that as a detriment. Look at the LS1 stuff. Those heads are phenomenal and make gobs of torque. I think that Pontiac, because of its inherent port design, actually has a benefit in the contest."

The low point in history for big-inch Pontiac intake manifolds was during the smog device-laden '75-78 model year range, when the powers above at GM decided to cast the secondary openings under the carb in a blocked off D-shape. Whether this was done as a structural change to support the intake with the advent of EGR heat now coarsing through the intake, or just some method of making the bean counters think that their engineering team was forward thinking is unclear. For a high-performance intake, its odd shape would not suffice. In more modest builds, strangely, the smogger intake performs every bit as well as the early '67-72 castings that are more sought after. Picking a manifold for this engine, however, was as simple as opening the Jegs catalog and choosing an Edelbrock Victor intake. Long sweeping bends and a generous plenum made for a great start. Widening the intake runners at the bends and toward the plenum netted big gains in cfm as well as keeping the velocity of the runners in check. Using an unported intake with variations in height and width can lead to changes in the speed of the air/fuel mixture as it flows through the runner. Those variations freak out the strength of the incoming charge as well as the signal to the carburetor.

Hoping to take advantage of his carb-tuning background to perfect the mixture of Shell 91-octane pump gas used in the Challenge, Johnston ordered a Holley carb to customize, but in the thrash to finish the engine before the early October deadline, the carb didn't make it in time. Instead, he snatched a buddy's carb from his 700 hp Poncho and slapped it on top. Final adjustments were made literally in the back of the truck as the engine was being driven to the Challenge, and they arrived just in time to make their dyno date.

The DCI crew had been working for the last week with almost no sleep to finish their project and it was go-time. It was the perfect opportunity for the luck of our old friend Murphy to rear his ugly head. Due to the last-minute announcement that they were in as an alternate, DCI had zero dyno time on the engine. Zero time with the carburetor. And their timing light took a dump as soon as they fired the engine. Setting the timing by ear, and jetting by the seat of their pants, they had the DTS dyno operator yank the handle like a slot machine. The MSD fired up the gasses and the TCI damper spun round and round. It didn't come up a 777 jackpot, but instead, 618 hp and almost as much in U-joint-punishing torque howled through the Magnaflow Mufflers. Not bad at all for a wild guess tune-up and a last-minute thrash. Digging deeper into the dyno sheets and flow tests reveal that this combination could very well be a mind-spinning 700hp performer with further testing. As it was, the DCI team was just happy to have made it.

As the Pontiac marquee now sings its swan song, its devotees are only strengthening their resolve to support the brand and the muscle car generation it fathered. Pontiac engines, like the one that Johnston and his crew built, show a heritage in performance and perseverance that could survive not only the distant passing of Edward Murphy, but also the more immediate wrath of Murphy's Law.

BY THE NUMBERS DCI 455 PONTIAC Bore: 4.160 inches Stroke: 4.21 inches Displacement: 457 actual cubic inches Compression ratio: 10.49:1 Camshaft: COMP solid flat-tappet Cam duration: 260/268 degrees at .050-inch tappet rise Valve lift: .653/.677 inch Rocker ratio: Harland Sharp 1.65 ratio Top ring: 1/16-inch Speed Pro Second ring: 1/16-inch Speed Pro Oil ring: 3/16-inch Speed Pro Piston: Ross dished Block: OEM Crankshaft: OEM Rods: Eagle 6.800-inch H-beam Cylinder head: Edelbrock Intake valve diameter: 2.230 inches Exhaust valve diameter: 1.770 inches Intake manifold: Edelbrock Victor Pontiac Carburetor: Quick Fuel modified Holley 1050 Dominator Header: Hedman Ignition: MSD 6AL Damper: TCI Rattler

DTS DYNO DATA RPM TQ HP 2,500 438 208 2,600 454 225 2,700 477 245 2,800 499 266 2,900 514 284 3,000 525 300 3,100 538 317 3,200 546 333 3,300 547 344 3,400 538 349 3,500 524 349 3,600 513 352 3,700 520 366 3,800 532 385 3,900 544 404 4,000 556 424 4,100 569 444 4,200 580 464 4,300 590 483 4,400 593 496 4,500 594 509 4,600 591 518 4,700 593 530 4,800 590 539 4,900 585 546 5,000 581 553 5,100 575 558 5,200 570 564 5,300 569 574 5,400 569 586 5,500 566 593 5,600 562 599 5,700 557 604 5,800 549 606 5,900 544 611 6,000 539 616 6,100 532 618 6,200 523 617 6,300 510 612 6,400 497 606 6,500 487 603