For some fans of classic trucks, embracing the latest technology has been a challenge. Those who appreciate the simplicity of a carbureted Gen I small-block Chevrolet and have spent years tinkering with them are often skeptical of the more complex contemporary offerings from GM despite their performance potential. Then there are those who have trucks they're anxious to modify, but smog laws and inspections ensure that compliance stands in the way. But thanks to Chevrolet Performance you can have the latest and greatest engines GM has to offer and get the blessing of your state's tailpipe sniffer with an emissions-compliant E-ROD package.

As we explained in the November issue of CLASSIC TRUCKS, E-ROD engines meet California Air Resources Board (CARB) aftermarket requirements and each carries an Executive Order, or EO number from that agency, meaning they come with paperwork making them smog legal in all 50 states. Currently there are three E-ROD engines, the LC9 5.3L (327 cubic inches) rated at 315 horsepower, LS3 6.2L (376 cubic inches) rated at 430 horsepower, and the supercharged LSA (376 cubic inches) rated at 556 horsepower.

While E-ROD engines are sophisticated, that doesn't mean you have to be a rocket scientist to install one. Special motor mount adapters may be required when replacing an earlier engine along with an LS-compatible transmission, but the scary part for most of us, the electronic control module and wiring harness, is truly plug and play. To keep things easy, the various sensors have unique plugs so the labeled wiring harness can't be installed incorrectly.

Continuing the trend of making something sophisticated simple, Chevrolet Performance engine controllers don't require any tweaking with a laptop computer as they come calibrated for older vehicles. That means many of the features necessary for new cars to function properly have been eliminated as they can degrade performance and trigger trouble codes. E-ROD engines, control systems and LS-style transmissions are available separately or in the recently introduced Connect-and-Cruise systems. These new packages include the engine, transmission with a torque converter and installation kit, and control systems for the engine and trans.

01 This is the throttle body. The only real fabrication necessary to install our E-ROD engine was the air intake system leading to it.

02 To build our intake system we used a U-Build-It kit from Airaid. It comes complete with the filter (not shown).

03 Fabricating the intake system is simply a matter of figuring out how and where it has to be routed, then cutting the tubing to fit.

04 After the tubing is cut to the proper length the individual sections are hooked together with Airaid's slip-on connectors.

05 The critical part of this installation is locating the MAF sensor properly. It has to be in a straight section of the intake and 10 inches from the throttle body.

06 The MAF sensor is secured to the intake tubing with the mounting boss and hardware included in the E-ROD wiring harness.

07 Like the rest of the sensors the wiring harness has a unique plug for the MAF sensor and the harness is labeled.

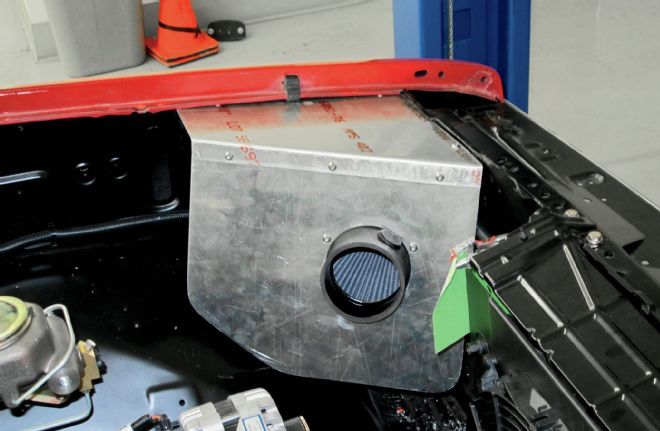

08 To house the Airaid filter element and direct air to it, Jason fabricated a sheetmetal enclosure.

Along with the ECM in our control kit (which is weather-resistant and can be mounted under the hood) an electronic throttle pedal and a pair of oxygen sensors are included. The only part of the engine-management system that requires any fabrication is the mounting of the mass airflow meter, or the MAF. It must be installed in a 4-inch diameter tube with at least a 6-inch straight section. The sensor must be mounted in the center of the tube at least 10 inches from the throttle body and the connector end should be positioned between horizontal and fully upright.

To build our intake system we turned to Airaid for a U-Build-It (UBI) intake kit. UBI master kits and individual intake tubes are available in 3-, 3.5-, 4-, 5-, and 6-inch diameters. The roto-molded intake tubes feature multiple angles and straights that allow the routing of the intake to any desired location in the engine compartment. The master kits include an intake tube, coupler, hump hose, reducer, brackets, hose clamps, hardware, and a premium Airaid filter.

The Test

The basic problem with the internal combustion engine is that it produces a number of pollutants in the process of producing power, such as:

Hydrocarbons: These emissions result when the engine does not burn all the gasoline taken in. Hydrocarbons react in the presence of nitrogen oxides and sunlight to form ground-level ozone, a major component of visible smog.

Nitrogen Oxides (NOx): Created by high-temperature combustion, nitrogen and oxygen atoms form NOx. Like hydrocarbons they contribute to ozone and the formation of acid rain.

Carbon Monoxide (CO): A product of incomplete combustion and occurs when carbon in the fuel is partially oxidized rather than converted to carbon dioxide (CO2).

Carbon Dioxide: In recent years, the U.S. Environmental Protection Agency (EPA) has started to view carbon dioxide, a product of "perfect" combustion, as a pollution concern. Carbon dioxide does not directly impair human health, but has been labeled as a "greenhouse gas."

Evaporative Emissions: Hydrocarbons also escape into the air through fuel evaporation from a variety of sources, including the fuel tank and carburetor as well as during refueling.

To get ready to have the truck's tailpipe probed there is one last task: the ignition pickup has to be re-synced to ensure proper spark timing. A coupon for this procedure, redeemable at any GM dealer, is included in the E-Rod literature.

Next step, the sniff test to get the blessings of the state.

09 The finished intake system is clean and simple and adds a custom touch to the engine compartment.

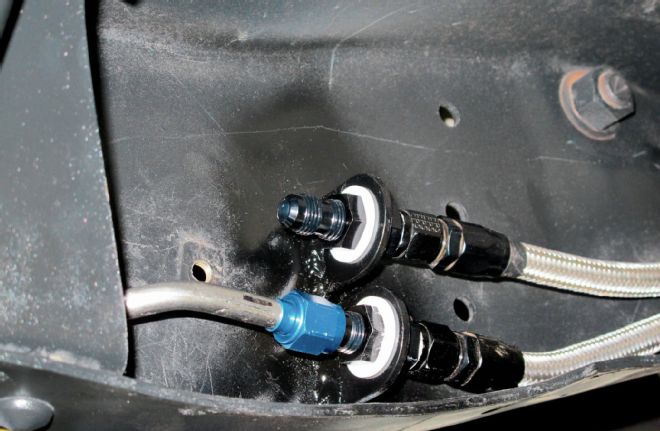

10 One other bit of fabrication necessary is the running of a fuel return line to the gas tank. Two tabs were welded to the frame to mount bulkhead fittings from Earl's.

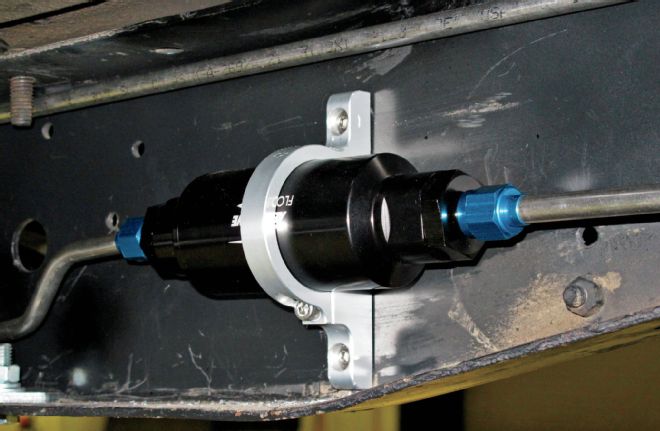

11 To ensure a clean fuel supply an Aeromotive filter with a cleanable element was installed.

12 Fuel is supplied by an in-tank Aeromotive fuel pump with pressure controlled by a same make regulator.

13 To accommodate the EFI system a fuel return line is necessary. Rather than modify the original tank we chose a replacement from Rock Valley.

14 One of the items left off the original installation was the PCV valve connection. It has since been plumbed into the Airaid intake system.

15 Another minor tweak, the new evaporative control canister was attached to the underside of the cab floor.