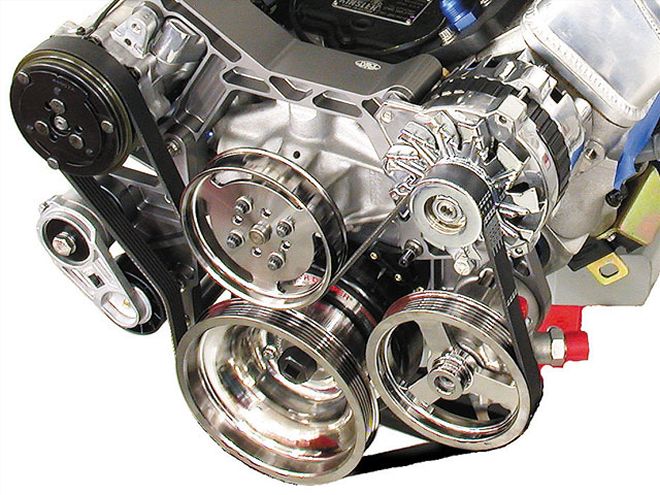

If air conditioning is in your street machine's future, consider VintageAir's Front-Runner Serpentine Drive System for both small- and big-blockChevys. This state-of-the-art factory-style system is expensive ataround $1,500, but keep in mind that it comes complete with ahigh-volume water pump, tensioner, brackets, power-steering bracket ordelete kit (does not supply the pump), pulleys, Powermaster alternator,and the A/C compressor.

If air conditioning is in your street machine's future, consider VintageAir's Front-Runner Serpentine Drive System for both small- and big-blockChevys. This state-of-the-art factory-style system is expensive ataround $1,500, but keep in mind that it comes complete with ahigh-volume water pump, tensioner, brackets, power-steering bracket ordelete kit (does not supply the pump), pulleys, Powermaster alternator,and the A/C compressor.

Whether your goal is looks, efficiency, or merely getting your engine running, pulleys are critical parts, and there are important factors that need to be considered when selecting them.

If you're operating the engine with just the bare essentials of an alternator and a mechanical water-pump, there's a pretty good chance everything will work properly, assuming you're using stock pulleys designed to fit your engine. Things get a little more complicated when you add luxuries like power steering and air conditioning, and getting everything to line up and work properly can be a challenge.

So, if your engine and its related systems are stock and you use stock pulleys, everything should be OK. However, big problems can arise when you randomly mix and match pulleys in hopes that all the accessories will rotate at the proper rpm. To sort out a custom application, you have to understand the concept of pulley ratios. The ratio of any two drive accessories can be determined by dividing the diameter of the smaller pulley into the larger one. For example, if a 6-inch water-pump pulley is used in conjunction with a 7-inch crank pulley, the pulley ratio is 1.16:1. So for every 1,000 rpm the crank pulley spins, the water pump would rotate 1,116 times. Since the water pump spins at a faster rate than the crank, it's said to be overdriven. Flop things around, and the water pump would spin slower than the crank and be underdriven. Underdrive pulley sets are often used to reduce the parasitic drag on the crankshaft to increase horsepower; however, altering the speed of the accessories can have adverse affects on the performance of the related systems, especially if they are already overburdened.

In addition to performance, looks and location are important too. There are several options. The cheapest way is to scour swap meets and junkyards. Another option is to call reputable pulley manufacturers and suppliers like Street & Performance, March Performance, Alan Grove Components, Zoops Products, Canton Racing Products, and Auto Specialties. These companies offer everything from simple factory-style replacements to complete serpentine conversions that can help optimize your current accessory system through various pulley diameters and configurations.

The only question is, with so many options available, which will you choose? Read on to find the ins and outs of various V-belt and serpentine pulley systems, along with what the various aftermarket manufacturers currently have available.

V-Groove

V-Groove

Serpentine vs. V-Groove

The gripping power of a V-belt relies heavily on the single groove of a pulley, whereas a serpentine belt offers greater surface area with a minimum of six ribs (smaller V-groove shapes) that provide greater traction with minimal slippage.

Serpentine

Serpentine

If you want a clean, modern look with a single belt driving all your accessories, a serpentine system is definitely the way to go. Keep in mind that along with this new look, most engines will also require a reverse-rotation water pump, because the single-belt routing requires the pump to turn in the opposite direction (see diagram). A serpentine conversion provides the advantage of being able to carry a single replacement belt rather than an assortment of V-belts. There's also the added bonus of gaining access to virtually any combination of pulley diameters you could ever want, allowing you greater control of under- or over-driving any particular accessory. Belt changes are easier too. Those are some of the advantages, but let's face it-even though the big three have adopted the serpentine system for most current production vehicles, V-belts are still around and they work just fine. The decision ultimately comes down to the cost of the conversion and the kind of look you're trying to achieve.

Calculating Pulley RPM

Calculating a pulley's rpm can be very handy when it comes to optimizing an accessory system or sorting out problems.

If you don't already know the overall diameter of each pulley, place a tape measure from one lip of the pulley to the other to find out. The crank pulley is used as the driver pulley (since it's the source of rotation), and the water pump, alternator, and power steering pump are called the driven pulleys. Once you have the measurements, simply plug them into the following equation for the rotating rpm. If you change the diameter of any of the pulleys, you can easily calculate the new rotating rpm along with the percentage of change. For example, let's plug in the numbers for a typical application with a small-block 350:

rpm of driven pulley = 1,000 rpm of driver pulley x Diameter of driver pulley Diameter of driven pulley Accessory Pulley dia. (in.)rpm Crank 6 5/8 1,000 Water pump 7 946 Power steering 5 47/64 1,155 Alternator 2 1/2 2,650Underdrive Pulleys

The biggest drawback to belt-driven accessory systems is that it takes precious horsepower to turn them. One method of regaining some of the power lost to the parasitic drag effect is to underdrive the system. In most cases, accessories like the water pump, A/C compressor, and power-steering pump can be safely slowed down by 25 percent; alternator speed should stay within about 10 percent or less of its stock speed because alternator output tends to fall rapidly as rpm decreases. Underdrive is generally achieved by swapping a smaller crank pulley in conjunction with slightly larger water-pump and alternator pulleys.

If we swap our imaginary small-block's 651/48-inch crank pulley to a smaller 5-inch crank pulley, we can underdrive the water and power-steering pumps by the right amount, but not without also adversely affecting the alternator. By slowing the rotating rpm of the alternator, charging output can be reduced enough to cause the headlights to dim at idle and prevent the battery from properly charging. The simple fix is to replace the 211/42-inch alternator pulley with a smaller 2-inch pulley and raise the rotating rpm from 2,000 back to 2,500, which is only 150 rpm less than the original 2,650 with the larger 651/48-inch crank pulley. In the process, we've reduced the speed of the other accessories relative to the crankshaft speed, reduced parasitic drag, and gained a few extra ponies. And to think we used to hate math in grade school.

Accessory Pulley dia. (in.) rpm Crank 5 1,000 Water pump 7 714 Power steering 547¼64 872 Alternator 21¼2 2,000Percentage Change Formula

Percentage Change =