The Hemi engine. Your feelings depend on whether you're an aficionado or an infidel. While aficionados revel in it, infidels fear it. It's been the subject of countless stories, songs, and bench-racing sessions. The question now arises: Is there a way to update the Hemi mystique? We are not talking about the 5.7 Hemi engine that now graces the area between the fenderwells of the Dodge truck. We're referring to the behemoth that has stricken fear into countless boulevard lightweights that dared to try and overthrow a king.

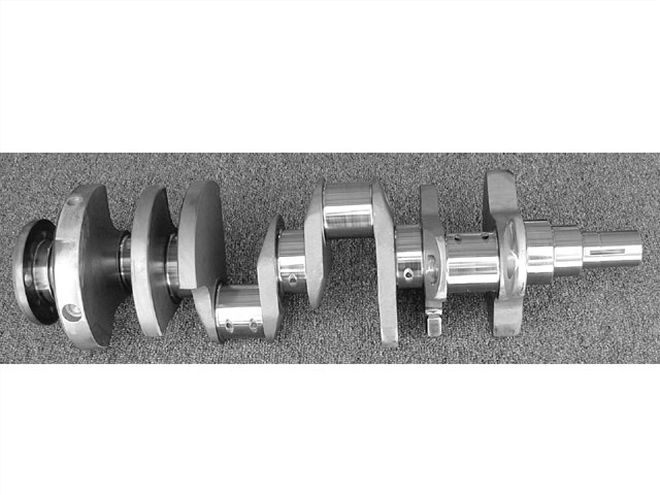

A Mopar Performance Mega-Block was chosen because of its proven past. Here, the Clevite bearings are checked for clearance.

A Mopar Performance Mega-Block was chosen because of its proven past. Here, the Clevite bearings are checked for clearance.

Bringing the old-style Hemi into the 21st century is Mopar Engines West. MEW is the brainchild of Richard Nedbal, a true Mopar guy with his roots embedded deeply in the heyday of pre-'70s performance. Richard was born in Chicago in 1945, and his first Mopar drag car was a '58 dual-quad Plymouth. Later, he drove and raced a '64 Dodge on the streets of the northwest suburbs. It was the heyday of Mr. Norm, whose dealership was right down the street from where Richard lived. After college and a stint overseas fighting for Uncle Sam, Richard landed a job doing semiconductor and EFI research at Carnegie Mellon Institute. He was then hired to help design a microprocessor-based sequential EFI system with spark control. In case you haven't gotten the picture yet, he is, by his own admission, a combination gearhead, Mopar lover, and electronics nerd.

Timing Is Everything

When Richard called and informed us that he had created a working Hemi engine with fuel injection and no distributor, he had our attention, to say the least. His trick-he found a coil that would fit down into the spark-plug tube. Why use eight separate coils with eight separate wires leading to each plug? You might as well use a distributor instead and make it simple. Since when do we settle on making things simple? Richard explained that both the sequential EFI, and particularly the electronic distributor that F.A.S.T. calls EDIST, would need a cam signal. A crank trigger is fine for timing the injectors, and for letting a particular spark plug know when to fire. But, knowing which plug to fire and which injector to pulse requires that the system understand where the engine is during its cycle. It needs one pulse for each revolution of the cam. Richard explains that this is usually done with a modification to the distributor. Simply grind off seven of the eight reluctor points on an MSD distributor, and you will now get one pulse per cam revolution. Now you need to use a crank trigger for the crank signal since you no longer have a distributor that can do that. This works great and is Richard's preferred method. The problem: There would still be a distributor housing in the motor, even if it didn't have plug wires connected to it.

Enter the use of a Jesel beltdrive instead of a timing chain. One nice feature of the Jesel is the cam gear is exposed outside the timing cover, making cam-timing changes easy. With an exposed aluminum cam gear, Richard simply drilled a hole for a small magnet, fabricated a bracket for the cam sensor itself, and voil-a cam signal. To cover the distributor hole, he fabricated a simple distributor plug with a dummy idler-shaft from an old distributor, then machined a billet hold-down clamp and the EDIST Hemi took on a whole new look.

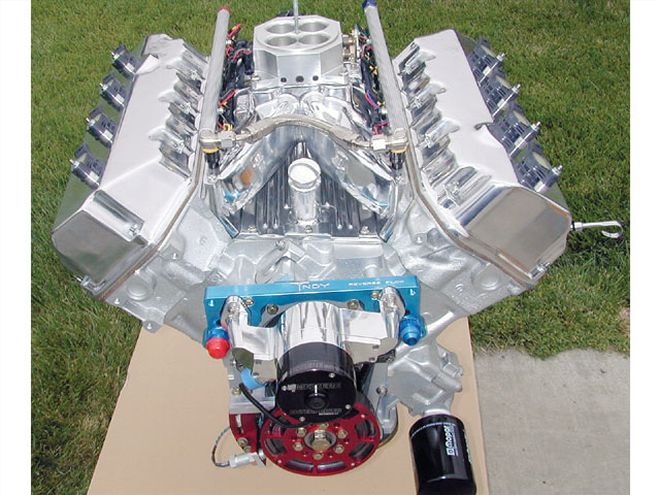

An ECU and distributerless ignition box from F.A.S.T. controls the spark and fuel delivery.

An ECU and distributerless ignition box from F.A.S.T. controls the spark and fuel delivery.

Coiled To Strike

Some real searching was done before settling on the proper coil for this concoction. The search led Richard to Diamond Electric-an OE vendor to DaimlerChrysler,Toyota, and Lexus. Diamond Electric is not a retailer, and as such, doesn't sell to the public. The company was, however, very helpful with assisting in this project. Richard wanted the driver electronics to be part of the coil to minimize heat buildup in the EDIST box. The universal EDIST box can drive coils directly, but with the trend toward low-impedance coils that are less than 1 ohm, Richard was concerned about how much heat would be generated in the EDIST box. Lance Ward, a chief engineer at F.A.S.T., verified that coils with on-board driver electronics would be the way to go if it were physically possible, and if the interface signals could be made to work. Diamond provided sample coils and Richard went to work. He built an electronic breadboard to test and debug the system. Some special wiring is required; such as shielded lines with custom circuitry that Richard had to engineer to minimize the effects of EMI noise. In fact, each trigger wire to each coil is really RG-174 coax with a built-in filter under the jacket.

Richard also machined extensions for the spark plugs since the coils ended up a little short of reaching them when installed. The setup is long enough to provide a water seal when installed. The coil tops have rubber seals that would fit inside the Hemi's spark-plug tubes, once Richard machined the tops of each tube. Studs with spacers are used to mount each coil to the valve cover. The result is fully functional and quite pleasing to the eye. So what if you wanted to duplicate this engine? Where would you get the coils? Stroll down to you local Lexus dealership and order replacement coils for the '03 RX 330 Lexus.

To give the F.A.S.T EDIST box its cam signal, a small hole was machined into the Jesel cam gear, and a small magnet was installed. Now the EDIST box knows every time the cam makes a full revolution.

To give the F.A.S.T EDIST box its cam signal, a small hole was machined into the Jesel cam gear, and a small magnet was installed. Now the EDIST box knows every time the cam makes a full revolution.

It's Hemi Time

The engine is destined to fall into the engine bay of a '71 Challenger convertible, owned by Ed Sternfeld, one of the principal owners of Dependable Dodge in Canoga Park, California. Since this is to be a one-of-a-kind Hemi, Ed wanted only the best. So how about a 528 Hemi, designed to run on pump gas, with a solid-roller cam? Ed wanted a level of power and that special sound that only serious cam duration gives you. Richard's EFI experience showed that a sequential EFI system could tame a big Hemi even with a somewhat radical cam. So what are the cam specs? The cam is a custom grind from Comp Cams. The duration comes in at a healthy 252/260 degrees duration at .050, with a lift of .400/.412 inch. With the Stage-V roller rockers, this equates to .640 inch at the valves. The lobe separation angle (LSA) is 112 degrees, and the cam is installed 4 degrees advanced. A relatively low valve lift-as compared to what a typical 252/260 roller would have-was chosen to give the engine longevity. A 112-degree LSA gives back some street driveability and enhances idle vacuum. Even with this cam, the engine has 12 inches of vacuum at a 900-rpm idle.

The block is a Mopar Performance 4.498 rough-bore Mega-Block that Richard deburred, finish-honed, indexed, and parallel-decked. The crankshaft is an Eagle eight-bolt 4340 piece, with a healthy 4.15-inch stroke and radiused journals. Manley H-beam rods and JE custom pistons with a .990 wrist-pin round out the rotating assembly.

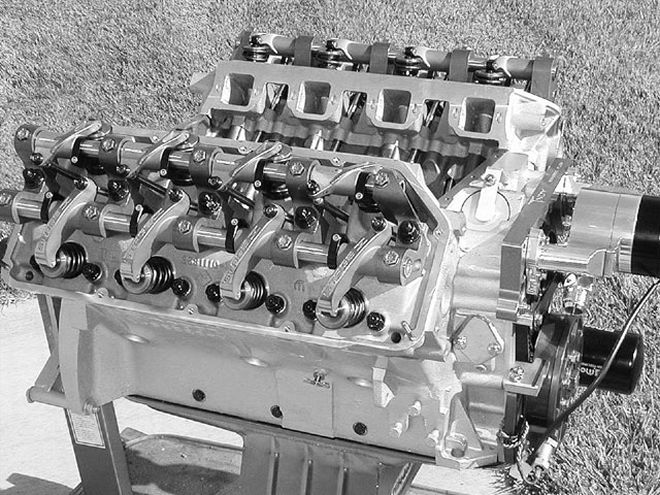

Our assembled Mopar Performance heads feature Comp Cams springs, retainers, and cups, as well as parts from Stage V.

Our assembled Mopar Performance heads feature Comp Cams springs, retainers, and cups, as well as parts from Stage V.

The heads are PN P4529336 bare-aluminum heads from Mopar Performance. Bare heads were used because Richard presses out and replaces the valveguides so he can achieve the correct stem clearance with the chosen Ferrea or Manley valves. The heads also receive a complete valve job with bowl blending and stage-one porting. Then there are the Comp Cams titanium retainers, Viton seals, and head machining for the use of spring cups, which Richard likes better than shims. With this combination, installed height modifications and special street roller valvesprings are used. Stage-V polished-stainless-steel roller rockers that the top fuelers use are employed. For street use, Richard makes sure they have the extra oiling provisions for the pushrod cup. Rocker supports are from Mopar, and the pushrods are custom length, with hardened thick-walls from Smith Brothers. The oiling system is all Milodon, with a high-volume pump and the special windage tray for stroker motors.

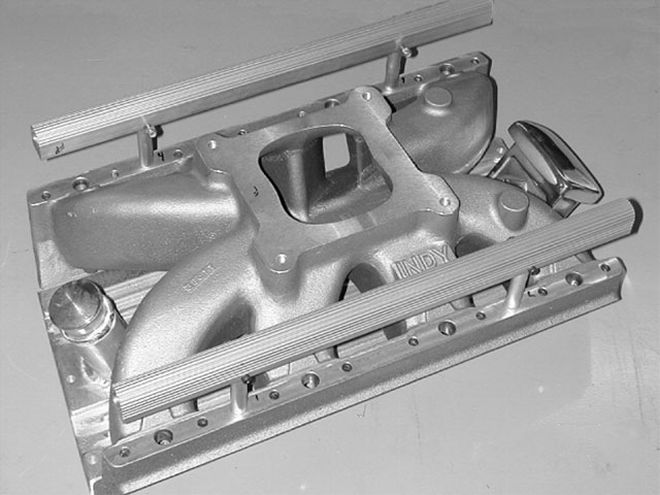

The modified intake is an Indy Cylinder Heads piece to which Richard added abreather and an oil filler-tube.

The modified intake is an Indy Cylinder Heads piece to which Richard added abreather and an oil filler-tube.

The Intake manifold is from Indy Cylinder Heads, but Richard also makes his own. He welded the oil filler and the Mopar logo breather onto the Valley plate so that the Stage-V polished valve covers would stay clean looking. The sequential EFI system and electronic distributor are from F.A.S.T., and Richard likes to use the MSD 1,000-cfm throttle body. The injectors are 48-lb/hr ACCEL units, and the spark plugs are Champion RN12YC with extension modifications. Resistor plugs must be used in this configuration.

So, what Mopar Engines West has done is to fill an old-style Hemi with accessories to bring it into the 21st century. How hard was it to dial-in, and how did it fair on the dyno? You'll have to tune in next month for the results.