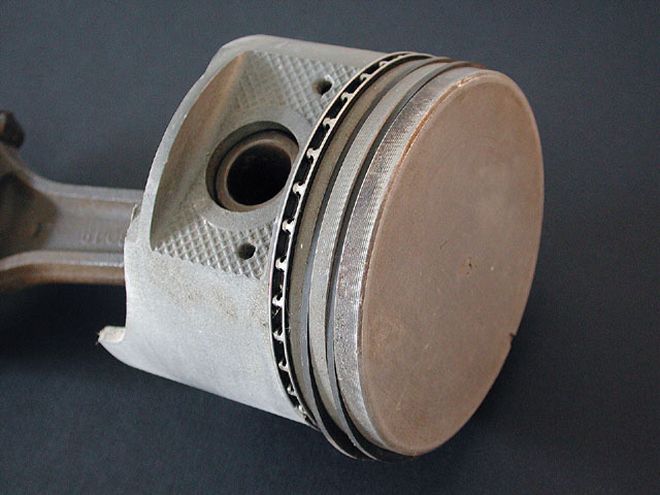

Here we have a baseline cast replacement piston for a 383. These pistons are cheap, but consider the drawbacks of no valve relief, a compression height putting them .080 inch down the hole at TDC, their hefty mass, not to mention Russian Roulette with the material at high rpm-and they really aren't a bargain in a high-output engine.

Here we have a baseline cast replacement piston for a 383. These pistons are cheap, but consider the drawbacks of no valve relief, a compression height putting them .080 inch down the hole at TDC, their hefty mass, not to mention Russian Roulette with the material at high rpm-and they really aren't a bargain in a high-output engine.

It goes up, compresses a violent explosion, and goes down. A piston's job is easy enough to understand, but if you examine what it's required to do, you may be amazed it works at all. Think about it-at 6,500 rpm, a piston moves up and down the bore 108 times a second, coming to a complete stop twice on each trip. A piston in a 440 engine at that rpm reaches a speed of 6,627 feet per minute by the time the crank turns to 76 degrees past TDC. That's 0 to 75 mph in just 1.66 inches of travel off TDC; compare that to your 60-foot time. With more rpm or stroke, the numbers get meaner, so it pays to be serious about piston selection if you're serious about reliable performance.

Cast vs. Forged

One of the first distinctions in the way a piston is manufactured is whether it's cast or forged. We've all heard these terms applied to pistons, but what's the difference? Actually, the difference is in the way the piston blank is created. In the casting process, molten aluminum is formed in a mold to the general shape of the piston. Casting has several advantages from a manufacturing point of view. Close tolerances can be held in relation to the piston's finished quality. This minimizes the final machining costs and allows for a lighter piston to be produced with less effort than forging. Cast pistons offer excellent wear and thermal characteristics, allowing for long ring land and skirt life as well as tight running clearances for quiet operation. The main drawback is that cast aluminum is limited in terms of ductility. In other words, an over-stressed cast piston will suddenly and destructively break when it fails.

Stock and some cast replacement pistons feature steel struts cast into the pin area to reduce heat expansion.

Stock and some cast replacement pistons feature steel struts cast into the pin area to reduce heat expansion.

Forgings, on the other hand, have metallurgical characteristics different from cast aluminum pistons. Blanks for forged pistons are created from a slug of solid aluminum under extreme pressure in a forging press. The aluminum is pressed into heavy forging dyes to arrive at the rough shape of a piston, forming the piston blank. Unlike a cast piston, a forged piece results in a denser, more ductile material. A piston-forging die must be designed so that the two halves of the die can be separated and the piston blank removed. This precludes the possibility of designing undercuts in the raw forging. As a result, a forged piston blank needs considerable machining to create the modern lightweight forged racing piston we are accustomed to seeing. A forged piston is inherently stronger and more forgiving when its limits are exceeded, typically distorting rather than grenading.

The working characteristics of both forged and cast pistons vary considerably with the specific material and processes involved in their manufacture. Not all cast pistons are created equal, and the same can be said of forged pistons. Generally, the manufacturer considers the intended application of the piston when the design specifications are determined. It pays to follow their guidelines when deciding whether a certain type of piston is suitable for a specific application.

Cast Piston Types and Materials

OE manufacturers fitted their production-based engines with cast pistons-except for a few special high-performance or factory race applications. The economic savings of tooling for large quantity part runs, the desirable characteristics of tight skirt clearances for quiet operation, and the inherent wear resistance of a silicone aluminum alloy fit the bill for OE manufacturers. OE Mopar engines were typically equipped with cast pistons with steel struts cast into the pin area to limit expansion, for very tight clearances. OE Mopar pistons were relatively heavy but adequately over-designed to be durable in performance application. How far can stock Mopar pistons be pushed? Like anything else, they are great until the day they break, and the timing of the break depends on the luck of the draw. A sensible limit would be to keep output under 1 hp per cubic inch, and rpm under 6,000. We know guys have gotten away with much more, and we have pushed these limits dramatically ourselves, but it's a gamble.

Hypereutectic alloys, as used in the KB 318 piston on the left and the Federal Mogul 360 piston at the right, make a good choice for performance on a budget. Unlike stock replacement pistons, these slugs are designed from the get-go with performance in mind. They feature a generous valve relief to swallow a sizable cam, and compression heights put it near zero deck. They can be the basis of an excellent dual-purpose performance engine. The stable alloy makes for excellent wear resistance and tight cylinder-wall clearance, helping with oil control and cylinder-pressure sealing.

Hypereutectic alloys, as used in the KB 318 piston on the left and the Federal Mogul 360 piston at the right, make a good choice for performance on a budget. Unlike stock replacement pistons, these slugs are designed from the get-go with performance in mind. They feature a generous valve relief to swallow a sizable cam, and compression heights put it near zero deck. They can be the basis of an excellent dual-purpose performance engine. The stable alloy makes for excellent wear resistance and tight cylinder-wall clearance, helping with oil control and cylinder-pressure sealing.

Aftermarket choices in cast pistons begin with low-cost OE replacement pistons. These bottom-of-the-line slugs are typically patterned as direct replacements and are usually weight-matched close to the stock pistons so the engine won't need custom balancing during the rebuild. The cast-piston layout is usually not designed with high-performance use in mind. Features like valve notches for clearance with high-performance cams, adequate compression height for higher compression ratio, or effective quench clearance will not be found. What you will find when shopping the catalogs for OE replacement pistons are plenty of low-compression dished pistons with no valve notches, or pistons that sit way down in the hole at TDC. Another thing you'll find is that the strength and reliability is often far below what the factory fitted in your Mopar engine, and usually this is a lesson learned the hard way. If building a high-performance engine, these types of pistons are almost always a risky purchase.

A significant step up are cast hypereutectic pistons. Hypereutectic gets its name from the aluminum alloy used in the manufacturing. Cast piston alloys incorporate silicone as a key alloying element, which adds to the wear resistance, durability, and thermal characteristics of the aluminum. There is a limit to how much silicone can be added to the aluminum and still be absorbed into the structure of the metal. This level, called the eutectic point, is around 12 percent. OE cast pistons are typically alloyed with no more than 9-percent silicone that is fully dissolved into the base aluminum. Hypereutectic pistons push the level of silicone beyond the amount that can be alloyed into the metal, and that's where the funny name comes from: hyper, meaning above or beyond; and eutectic, the max level of silicone that can be fully alloyed with the base metal. Hypereutectic silicone aluminum will employ 16-18 percent silicone in the alloy and will have free silicone in its structure. The hypereutectic alloy used for pistons was developed by carefully controlling the process to obtain the optimal grain size and distribution of the free silicone in the aluminum.

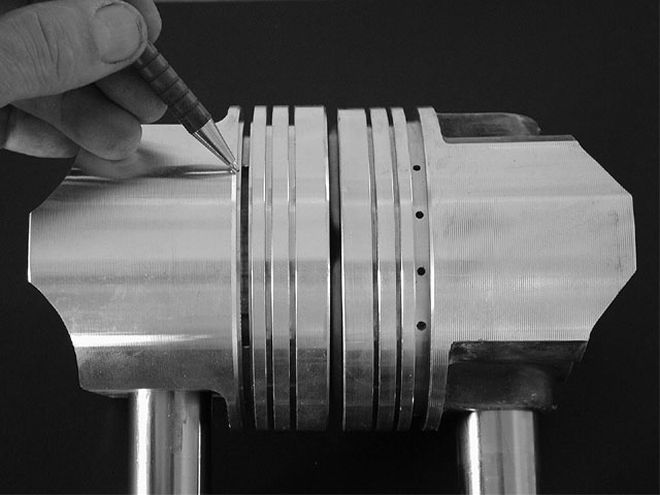

Forged pistons begin as blanks created by pressing a lump of aluminum into a die under the extreme pressure of a forging press. This raw blank from Probe illustrates the great deal of material that needs to be whittled away to make a piston.

Forged pistons begin as blanks created by pressing a lump of aluminum into a die under the extreme pressure of a forging press. This raw blank from Probe illustrates the great deal of material that needs to be whittled away to make a piston.

While hypereutectic alloy pistons are still considered a cast piston, the material exhibits several benefits over conventional piston alloys. Thermal characteristics, lubricity, scuff resistance, corrosion resistance, hardness, expansion characteristics, and high-temperature strength are all enhanced with the hypereutectic alloys. There is reason to recommend the hypereutectic pistons; however, the ductility of the material is far short of a forging, and therein lies the biggest drawback. Pushed beyond their limits, they will break similarly to a conventional cast piston. Keith Black Silvolite and Federal Mogul/Speed Pro are the main players in the hypereutectic piston market, and we have used both brands in high-performance engine builds without failures.

Forged Pistons

Although virtually all Mopar engines were factory-fitted with cast pistons, forged pistons have been and remain favored replacements when building a performance engine. There are several levels of forged pistons, from stock replacements to exotic race pieces. For years, the most popular true stock replacement pistons have been the Speed Pro PowerForged line from Federal Mogul, remembered by old-timers as TRW. These pistons were designed as durable replacement items, taking advantage of a forging's inherent strength. To create a true replacement, these pistons weight-matched the OE pistons, precluding the need for custom engine balancing. These pistons are configured to stock specs, so their design matches OE equipment in terms of compression height, valve notches (if any), and dish.

Replacement forged pistons like this 2355 Speed Pro piece were the mainstay of performance engine builds for years. Because they are similar in weight to stock, balance isn't normally an issue. The piston shown here is a replacement for a 440 Six Pack application and comes with valve-clearance notches and a near-zero deck height, making it a good basis for a street performance 440 build.

Replacement forged pistons like this 2355 Speed Pro piece were the mainstay of performance engine builds for years. Because they are similar in weight to stock, balance isn't normally an issue. The piston shown here is a replacement for a 440 Six Pack application and comes with valve-clearance notches and a near-zero deck height, making it a good basis for a street performance 440 build.

While the expansion characteristics of a forged piston normally dictate increased cylinder-wall clearance, the Speed Pro replacement pistons use slotted oil-return grooves in the oil-control ring lands. The slots cut down significantly on the heat transfer path from the piston head to the skirt, while providing more flexibility in the skirt. This move allows a tight piston-to-wall clearance at the expense of all-out strength. With the replacement line of Speed Pro, you get a stronger piston that drops in place of the stocker. In their race line of high-compression pistons based on the same forgings, the slotted oil return is replaced by drilled holes, significantly increasing the piston's strength, but requiring more bore clearance.

From a manufacturing point of view, the forging process turns smaller production runs of specialized pistons. That's fortunate, since it allows the custom-forged racing-piston industry to flourish. Modern-sportsman and racing-forged pistons are worlds away from the heavyweight cast slugs used by the OEM. A lighter piston puts less stress on the rods and crank, and, in turn, allows for a lighter counterweight on the crankshaft and a quicker revving, more reliable engine. Besides pistons for stock configuration engines, stroker pistons are readily available for many custom-crank combinations. It's not uncommon to find features in a modern forged piston that were only found in the realm of custom racing pistons of a few years ago. Modern flat-top pistons are typically manufactured with a compression height set to make a zero-deck-installed height readily achievable without excessive decking of the block. Provisions for floating piston-pin retention, deep valve notches, reduced piston-pin diameters, narrower ring packs, hollow domes, reversed deflector domes, and much more are found in many manufacturers' off-the-shelf pistons available today. About the only downside is that these modern, lightweight piston designs mandate a custom balance job as part of the engine build, but that should be part of any high-performance engine build anyway, given the factory's rough production balance tolerances.

Replacement Speed Pro pistons are designed to run with tighter piston-to-wall clearance than typical forged pistons. This is largely due to the slots running the length of the piston, isolating the skirts from the crown (left). The Speed Pro race pistons are much more ridged, with drilled oil-return holes (right), and therefore need to be looser in the bores.

Replacement Speed Pro pistons are designed to run with tighter piston-to-wall clearance than typical forged pistons. This is largely due to the slots running the length of the piston, isolating the skirts from the crown (left). The Speed Pro race pistons are much more ridged, with drilled oil-return holes (right), and therefore need to be looser in the bores.

Forged Piston Materials

We have already discussed some of the characteristics of silicone alloys in cast-aluminum pistons, and there are some different alloys used in the construction of forged pistons as well. The most common alloys offered by major forged piston manufacturers are 2618, a low-silicone aluminum, and 4032, an alloy containing approximately 11-percent silicone. The additional silicone imparts in forged pistons some of the same characteristics discussed in relation to cast pistons. The 4032 alloy is stiffer, has less thermal conductivity and expansion, and greater wear resistance. This alloy is frequently the choice in street/strip applications, selected for the tighter piston-to-wall clearance gained by the lower expansion rate and the longer skirt and ring-land life offered by the greater wear resistance of the silicone alloy.

In contrast, 2618 is a low-silicone alloy, and while it gives up the benefits derived from silicone, it is the best piston material in brutal all-out applications. The low-silicone alloy has a higher density and tensile strength than 4032, and much greater ductility and fracture resistance. A 2618 piston can be pounded into a pretzel, but it won't shatter into chunks. The high rate of thermal conductivity of low-silicone aluminum will transfer more heat into the skirts. Coupled with the material's higher expansion rates, 2618 pistons generally need significantly more bore clearance. Lacking the high silicone content, a 2618 piston is more subject to wear in the ring lands and skirts.

Stroker pistons are designed with a lower compression height, as measured from the centerline of the piston pin to the top of the piston. These are both Probe pistons for the 440 Mopar block. The piston on the left has a compression height of 2.065 inches for a standard 3.75-inch stroke, while the shorter piston on the left has a compression height of 1.865 inches for a 4.15-inch stroker crank. The stroker crank will push the piston .200 inch higher in the bore at TDC, so the piston is .200 inch shorter; the pistons will end up parking at the same height at TDC.

Stroker pistons are designed with a lower compression height, as measured from the centerline of the piston pin to the top of the piston. These are both Probe pistons for the 440 Mopar block. The piston on the left has a compression height of 2.065 inches for a standard 3.75-inch stroke, while the shorter piston on the left has a compression height of 1.865 inches for a 4.15-inch stroker crank. The stroker crank will push the piston .200 inch higher in the bore at TDC, so the piston is .200 inch shorter; the pistons will end up parking at the same height at TDC.

These are racing pistons, not the slugs to put in a truck expected to go 100,000-plus miles. If the plan calls for serious nitrous, boost, or rpm, and bulletproof is what you are after, a 2618 piston is the right choice. Modern machining and design technology have improved the 2618 piston by allowing for more sophisticated skirt designs. Manufacturers taking advantage of these advances have been able to reduce the bore clearance considerably compared to traditional requirements.

Stroker Considerations

Building Mopar stroker combinations has never been more popular, and why not? With the availability of low-cost crankshafts, the door has been blown wide open in the small-block world, while in the big-block camp, popular combos include the tried and true 451 that uses a 440 crank in a 400 low-deck. Other combos are supported by readily available aftermarket crank combinations. Another contributing factor is the ever-improving cylinder-head situation. The aftermarket is offering plenty to feed all those extra cubes and make the prospect of building a stroker combo worthwhile. Unlike some of the competing engine designs, Mopar blocks were endowed with generous cylinder deck dimensions. To fill that space, Mopar engines were fitted with relatively long connecting rods and tall pistons. The distance from a piston's wristpin centerline to the top of the piston is referred to as the compression height.

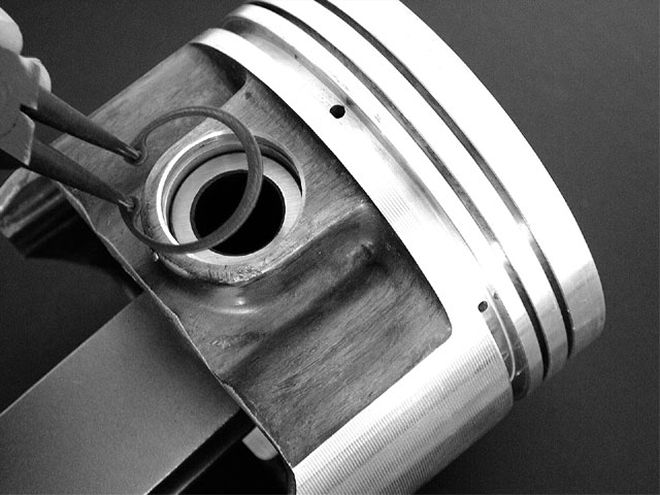

TruArc locks are used in some pistons. Resembling a standard snap ring, these locks are much easier to install and remove than Spiro Lox. Two per side are usually used. TruArcs have one side that is slightly rounded on the edge, while the flip side is square and sharp. The proper way to install them is with the sharp edge of the inner one toward the pin, the sharp edge of the outer one to the outside of the pistons, and the gaps spaced 180 degrees apart.

TruArc locks are used in some pistons. Resembling a standard snap ring, these locks are much easier to install and remove than Spiro Lox. Two per side are usually used. TruArcs have one side that is slightly rounded on the edge, while the flip side is square and sharp. The proper way to install them is with the sharp edge of the inner one toward the pin, the sharp edge of the outer one to the outside of the pistons, and the gaps spaced 180 degrees apart.

Mopar engines have excessive compression height designed in them, making the pistons heavier than they need to be. In a stroker combination, the added stroke pushes the piston higher up the bore-exactly half the distance of the increase in stroke. To compensate, the piston's compression height is reduced a corresponding amount. With some engines, there simply isn't enough room to shorten the compression height without the piston pin encroaching into the oil-ring area of the piston. In fact, Chevrolet used a shorter connecting rod in its production long-stroke 400 small-block, aggravating an already bad rod ratio. There's little worry about not finding the room in a Mopar engine. Stroke a Mopar big- or small-block, and the piston mass is considerably reduced. Once only available via special-ordered custom pistons, a wide range of stroker pistons are now cataloged items from companies such as Diamond, Probe, JE, CP, Arias, Ross, Wiseco, KB, and others.

Buying Right

With so many pistons to choose from, it's kind of tough to narrow down the choices and decide on an appropriate piece. Really, the two factors to consider are application versus dollar. Given a choice, we can't think of a reason, other than price, anyone would prefer a cast replacement piston to a modern hypereutectic or forging. But again, it's important to consider the whole picture. If the goal is an economical rebuild in a low-rpm, low-compression, low-output engine, these cheap castings will be fine. On the other hand, if you're looking to build horsepower, but the build is on a shoestring budget, those cast replacement 360 pistons are dirt cheap, but the low compression ratio is going to cost output and efficiency. For the couple of hundred bucks saved, you're stuck with 8:1 compression, and the combustion efficiency is hampered because the quench area is too big. Plus, you'll have a potential time bomb if the thing ever does make real power or turns some higher rpm. Some guys will crutch a cheap low-compression piston with massive head milling, which will gain some ratio. However, now the pushrods are too long, the intake won't fit without more milling on the intake face, and the valve-to-piston clearance, which was already in short supply with no valve notches, has shrunk by the amount milled. Add up the costs and frustration, and this approach doesn't make sense.

If you've got the guts to take a die grinder to new metal, pistons with complex or tall domes can benefit from a little hand massaging, breaking the sharp edges at the valve notches and domes. With tall dome pistons, cutting a fire slot across the dome in line with the spark plug helps flame propagation, particularly in Mopar big-blocks, with their shallow stock spark-plug position.

If you've got the guts to take a die grinder to new metal, pistons with complex or tall domes can benefit from a little hand massaging, breaking the sharp edges at the valve notches and domes. With tall dome pistons, cutting a fire slot across the dome in line with the spark plug helps flame propagation, particularly in Mopar big-blocks, with their shallow stock spark-plug position.

Setting a realistic expectation of the intended use and goals is the key to making the right purchase. The other extreme can be just as wasteful. If the goal is a dead stock rebuild in a resto application, there's no need for an overly trick piston. A replacement-style Speed Pro or Hypereutectic is more than enough to handle a mild street mill, with reliability far exceeding the stock pieces. If we move up the ladder to a more serious street/strip mill, a modern lightweight forging will begin to pay off in reduced internal loading at high rpm, and a lower bob-weight for a more responsive engine. Most of these pistons are designed to accept narrower 11/416-inch compression rings as opposed to the stock 51/464-inch pieces, reducing cylinder-wall friction in the bargain.

At the race level, the buying decision involves more specific engine-building knowledge when choosing a cataloged race or custom piston. Here we may need to consider the piston dome configuration to match the cylinder head; nonstock piston-pin diameters; pin retention; valve notch placement and depth; compression height; pin-oiling provisions; ring groove placement and specification; gas porting; and/or custom lightening options. The list of possibilities goes on and on, but fortunately, the companies that manufacture these high-end race pistons have tech representatives on hand to help with the selection process.