If you have ever been racing down the straightaway at your local track and been blown away, you've probably had time to reflect on the things that you could have done better to go faster. Many times though, racers simply blame the problem on money-specifically, the opponents' overabundance of it.

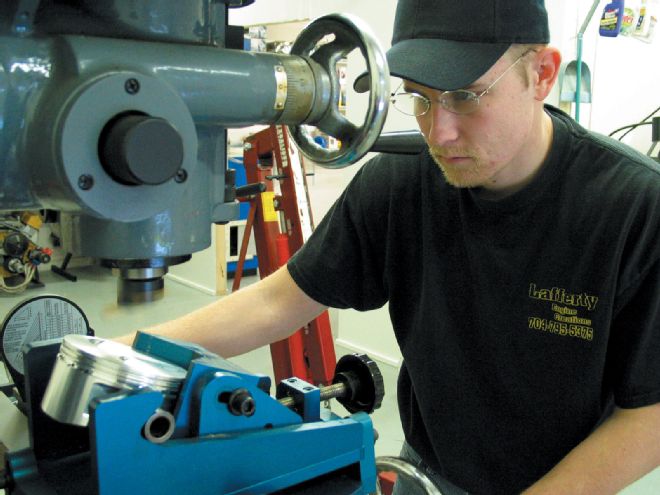

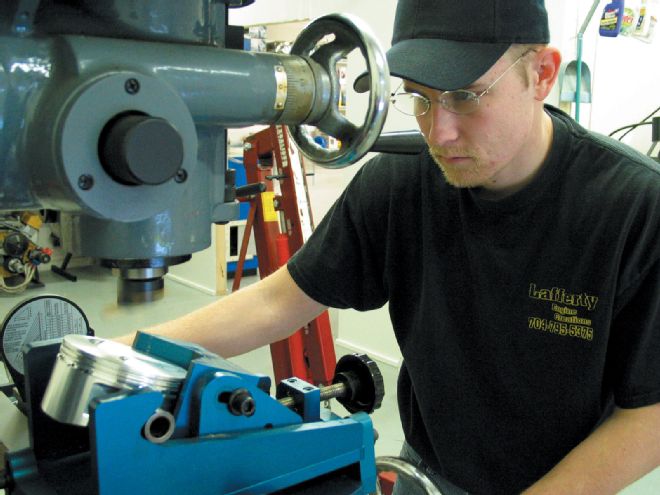

Because of the higher performance expectations, some machining processes not normally seen on street engines become vital for a racing powerplant. Here, engine builder Chris Lafferty cuts new valve pockets in a piston to achieve the proper piston-to-valve clearance. In a street application, a set of pistons with extra-large pockets would easily have been ordered up, but an engine builder simply cannot afford to give away compression like that for racing.

Because of the higher performance expectations, some machining processes not normally seen on street engines become vital for a racing powerplant. Here, engine builder Chris Lafferty cuts new valve pockets in a piston to achieve the proper piston-to-valve clearance. In a street application, a set of pistons with extra-large pockets would easily have been ordered up, but an engine builder simply cannot afford to give away compression like that for racing.

Granted, racing isn't cheap, but if you plan to go racing and expect to be competitive, there are some things you can't nickel-and-dime to death. The engine and the work performed while building it are areas where that is often done. If you are price shopping rather than quality shopping when it comes to your engine, you should probably just sell your race car and buy tickets to the next big race. That will fill your needs and save a lot of money, too.

It's no secret that people are in business to make a living. When you are beating up your engine guy for a better deal, remember that you may just be cheating yourself. His light bill doesn't get paid by doing stuff for free, so the quality of work you get back may suffer. Most engine builders charge in the $40-$70 an hour range for labor, but an engine builder with a sterling reputation can get a premium on that amount. Maybe you are paying for results, or maybe you are just paying to get his name on your valve covers. You decide.

Let's talk a bit about the machining and clearance-checking processes involved in building a good race engine, and which steps can be beneficial to you, even though the up-front costs may be steeper:

Block Deburring

We'll begin with the basics, deburring your new block. This may seem like money thrown down the drain, but if you've ever had an engine mysteriously blow up, only to find on later inspection that a piece of casting flash in an oil passage impeded flow to the rotating vitals like it was the Hoover Dam, you will understand that deburring is not just for cosmetics. Much of the time involved in this process is simply time spent at the parts washer, making sure every piece of trash is out of the oil galleries. In this business, the details make the difference between a good engine builder and a great engine builder. If you're saying, "I've built 100 race engines and never done that," remember, it only takes one.

Proper pin bore clearances are easy to miss, but they reduce friction and cut down the chance that a wrist pin can gall inside the piston.

Proper pin bore clearances are easy to miss, but they reduce friction and cut down the chance that a wrist pin can gall inside the piston.

Typical Job Time: 3-10 hours

Rod Prep

Time spent to deburr and condition your rods (even new ones) will keep debris out of an engine. The point of this exercise is to remove all sharp edges that could possibly scuff materials off the bearing, as well as keep those materials from imbedding themselves into the bearing and gouging into the crank. Also, honing the rods to make sure they are the proper size will insure the bearing will be held properly and last.

One not-so-obvious benefit is that the rod bolts must be installed during this process and torqued to race specifications. This means the bolts are stretched when torqued and should be checked for fatigue and proper torque with a stretch gauge. Doing this now reduces the chance that a fatigued bolt will make it into the engine and let you down on the track.

Typical Job Time: 3 hours

Piston Prep

Many failures have come from not taking the time to make sure a piston will be happy in the home you have made for it. Allow your engine builder the time he needs to properly check the deck clearance, dome clearance, and piston-to-valve clearance, or you might be buying pistons all over again. All pistons must also be properly deburred so that they don't nick the cylinder wall the first time the engine is fired up. Also, make sure there is proper piston pin bore-to-pin clearance. Finally, the last thing I like to do is deburr the edges of my piston pin locks (round wire style only).

Rods need to be deburred and honed to make sure the bearing has the right amount of crush once everything is torqued into place.

Rods need to be deburred and honed to make sure the bearing has the right amount of crush once everything is torqued into place.

Typical Job Time:Up to 5 hours

Crank Prep

Preparing the crank is pretty straightforward. You deburr all the sharp edges, then get the thing balanced. How easy is that?

Generally, you want the crank internally balanced, which means the rotating assembly balances without the damper and flywheel attached. That way, if you have to replace the damper or flywheel, it will not require completely tearing down the engine and rebalancing the entire rotating assembly.

Typical Job Time: Approximately 3 hours, depending on the balance of the crank

Block Prep

We have already covered the importance of deburring your block. It's time to do some machine work. When boring and decking, make sure your machinist uses truing fixtures. This will guarantee the cylinders are exactly where they are supposed to be and the deck is square with the cylinders. If possible, use a lifter true fixture to align the lifter bores so that cam timing is the same in all cylinders. Hone the main bores to perfection to align the mains as well as provide proper bearing crush during assembly (if you have changed main caps it may be necessary to line-bore the block).

Lafferty prefers to cut valve seats with circular stones because he feels it gives him more control and reduces the chance that the cutter can flex and give the seat an elliptical shape. Regardless of what machine it is performed on, a racing valve job is much more complex than necessary for a road-going automobile and requires an expert hand.

Lafferty prefers to cut valve seats with circular stones because he feels it gives him more control and reduces the chance that the cutter can flex and give the seat an elliptical shape. Regardless of what machine it is performed on, a racing valve job is much more complex than necessary for a road-going automobile and requires an expert hand.

A good cylinder wall finish is worth power, so use torque plates and insist on hot honing. This will make for the straightest cylinder walls. It may be necessary to enlarge the oil galleries in the block. This is vital to prevent starving your engine of lubricants. Drill and tap oil gallery passages and use pipe plugs to secure them instead of the crude soft plugs. If you are doing a stroker motor, don't forget to clearance the block or you'll be cussing yourself when you put everything together. Some people pin the freeze plugs into the block, but I prefer to epoxy them in place so they can't leak or fall out.

Typical Job Time: Up to a day

Cylinder Head Prep

There's a ton of power to be had in a good valve job and proper seat-cutting techniques. Personally, I can spend twice as long doing a valve job on a set of steel heads than aluminum because typical steel head rules call for no flow work and no blending. This means you have to get creative to get the most out of them. Take the time to clearance the valve guides properly or you risk sticking them. Pressure test the water jackets, check the deck surface for machining and, if necessary, add water ports to move heat away. The cylinder heads are the muscles of your engine, so don't nickel-and-dime here or you'll never take a checkered flag.

Typical Job Time: Multiple days, depending on the level of work being done

Valve Prep

To create maximum power, you have to do more than just pull them out of the box and stick them in the heads. Make sure the valve angle is cut to match your seat angle, then take the time to back-cut the valves to improve air flow. Also, don't forget to radius the margin of the valve.

When boring the cylinders, make sure a truing fixture is used to make sure the bore centers are all lined up where they should. A perfectly round bore is no good if it is in the wrong place or not square to the deck of the block.

When boring the cylinders, make sure a truing fixture is used to make sure the bore centers are all lined up where they should. A perfectly round bore is no good if it is in the wrong place or not square to the deck of the block.

Typical Job Time: 2.5 hours

Intake Manifold Prep

A ton of money spent on cylinder heads is only as good as the money spent on the intake manifold. Since the intake supplies air and fuel to the heads, it only makes sense to take the same effort you put into the heads and put it into the intake as well. If your rules will allow modifications, an engine builder can spend a day just prepping the intake, which can turn out to be the difference in taking the winner's flag.

Typical Job Time: Anywhere from the time it takes to bolt it in place, to an entire day

Miscellaneous

It's the little things that can make the difference between a winning engine and a premature rebuild. Spend time chasing all your threaded holes with a thread chaser. You can never spend too much time cleaning your parts before assembly. I have found that across the industry, more than 75 percent of all engine failures are caused by improper cleaning and dirty engine builds.

New main caps should require the block to be line-bored and honed to ensure the centers are all in line.

New main caps should require the block to be line-bored and honed to ensure the centers are all in line.

Now that the brunt of the machine work is out of the way, don't think it's time to slam that engine together. This is just the beginning. Why would you spend good money up to this point just to slap that thing together with no concern for proper clearances? Build a motor right the first time and I guarantee you'll be happy with the results. Give your engine guy time to blueprint your new motor. There are two good reasons for this: First, if your engine builder is going to document all clearances, it forces him to take the time to build your investment to the best of his abilities. Second, it gives you peace of mind that nothing has been overlooked.

Hopefully, it is now a little easier to determine the important steps in an engine buildup and where you simply cannot get away with pinching pennies. Obviously, this does not cover every machining operation. The key here is to take the time necessary to build your engine right the first time.

Chris Lafferty owns Lafferty Engine Creations, which builds and maintains race engines for every level, from Late Model to NASCAR's Busch Series.