Those of us who are married know the drill. Whenever you pay big bucks for parts and services, you spend just as much time trying to hide the money trail as you do working on the actual car. You do what you can on your own, throwing your sweat equity into it, whether it's doing bodywork, assembling an engine, or rehabbing the suspension. But there are certain jobs that require too many specialized skills, tools, or parts to do on your own, and for but a lucky few, restoring the instrument cluster is one of those.

You see, few things in a vintage muscle car will stare at you longer than the dashboard. If the rest of the car is primo, but the instrument panel looks like junk, you'll be in a funk. Fortunately, there is an easy solution: Let the guys at Instrument Specialties handle the job for you. It started when Mike Mancini began restoring Mopars as a hobby and could not find a company that could restore gauges to his high standards, so he created IS to fill a void for quality and correctness in the market place. Since its inception, IS has worked with thousands of customers, assisting with their interior component restoration.

Looking at a set of IS restored gauges for the first time will simply take your breath away. They look so good, they've got to cost bank, right? In fact, our Valiant's instrument panel cost just $650 to rehab back to new (not including a few custom upgrades we'll mention in a minute). When you see how much effort, what unique skills are required, the rare old-school processes, and the exacting level of detail that goes into each instrument panel resto, it dawns on you that $650 really isn't that much.

A job like ours has a waiting time between 10 and 12 weeks, which is due to the extended time of rehabbing the chromed plastic bezel. If your bezel is in good shape and you just need the gauges, then eight weeks is more normal. Either way, there's a lot of disassembly, cleaning, diagnosis, repairing, calibrating, lubricating, painting, and reassembly. In our case, every dial face was stripped and reprinted (including custom artwork for a new 150-mph speedo with special red "caution" limit), and our two factory idiot lights (one for brakes, one for low oil pressure) were replaced by one gauge that reads oil pressure on a scale. IS can change the font (as they did in our case from wide numbers to skinny, condensed numbers) or make dials in the original writing style. It's all done with the same photo-chemical printing process used to manufacture the gauge faces originally by Chrysler.

When you get your bezel rehabbed, it goes through a major transformation. After being stripped and repaired, they use the original vacuum metalizing process to re-chrome it. This is followed by careful masking and painting of the blacked-out areas, then steady-handed detail painting of the lettering. Clear plastic lenses are carefully separated from the bezel (they were plastic welded from the factory), cleaned, buffed, polished to like-new, then re-welded to the bezel during final assembly. When you get it back, you absolutely won't believe that it's a 40- or 50-year-old instrument panel.

As for the mechanical operation of the gauges, the IS crew disassembles every one of them, acid cleans them, verifies the electrical operation of the bimetallic movement, calibrates them as necessary, re-rivets the restored dial faces in place, cleans and repaints the pointers, and lubes the switches with dielectric grease and reassembles them. The IP's circuit board is acid cleaned, checked for continuity, repaired if necessary, and the pins are inspected and replaced if required. In addition to these operations, the speedometer gets extra attention; a new "jewel" is placed in the frame (analogous to the same part used in a hand-made watch), the speed cup gets a magnetic calibration, the pointer is cleaned and airbrushed with new paint, the odometer rolls are inspected, cleaned (and reprinted in many cases), and the speedo dial face is reprinted. We took that opportunity to upgrade ours from 120 mph to 150 mph, and get a matching calibration.

Let's say you're more into doing a perfect chalk-mark restoration. Fear not, IS can handle it. They have cataloged every font, typeface, dial, paint color, ink tone, stamp, and factory marking, and they can reproduce it like new. We're told they are the only company that has all of the original ink formulas and artwork negatives from the original manufacturers of these gauges. IS tells us that the metal instrument case that houses the gauges has irreplaceable markings and stamps on the outside, which are often damaged beyond recognition. In those situations, a core in better condition may be required if those markings need to match, otherwise, media blasting to clean the case will permanently obliterate the markings (although the case will work just fine).

If you want something unique, such as a different style font, different colors to match your interior, or a different speedometer range, there is an up-charge based on the additional labor for creating the artwork. Printing the dial faces themselves is the same cost as making the stock ones, so the added cost is minimal and easy to justify if you think you want it. It's also worth noting that the $650 cost for our resto is a ballpark figure that may go up if you need IS to locate a new core for you, or if your car's IP has more gauges or a more elaborate instrument panel. (The Valiant/Duster is one of the simplest ones Plymouth made.)

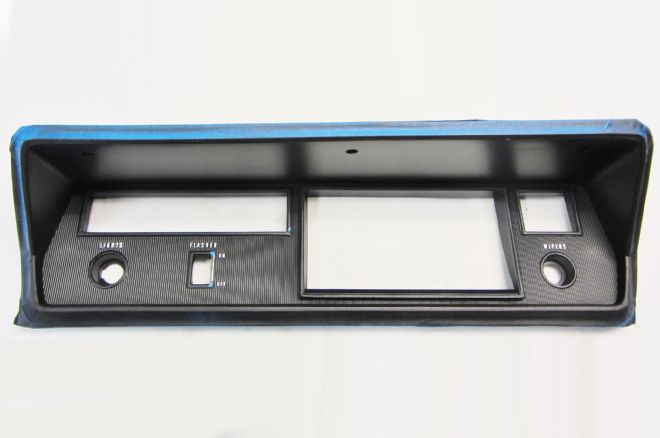

Perhaps the most eye-opening part of this story is the overwhelming number of small, seemingly insignificant parts that make up a vintage factory gauge cluster. Most of these parts are long out of production, or in the case of some switches, are reproduced cheaply—and often inaccurately—overseas. IS almost always elects to rehabilitate the factory switches, such as those for the headlight/high beam/dimmer, flashers, and wipers. Electrical components such as the voltage limiter are rebuilt to factory specs (upgraded to solid-state circuitry in the case of the voltage limiter), new OE-style bulbs are used, and the external surface of every component is cleaned and/or repainted to look like new.

Why such fanatic attention to detail? Because for every part that is restored on an instrument panel, the one nut or bolt that isn't restored will stand out even more. IS sets a very high bar throughout, and when you put one of their IP restos in your machine, it will have a cascading effect on your interior. That new headliner, carpet, dashpad, or upholstery will look that much better at the end of the day. Now let's take a look at the transformational magic that IS can bestow on a simple set of Valiant gauges.

1. Here's our '68 Valiant's original instrument panel. We decided to leave it in service and have Instrument Specialties locate a core to begin their work. This costs extra, but allows you to drive your car during the waiting period.

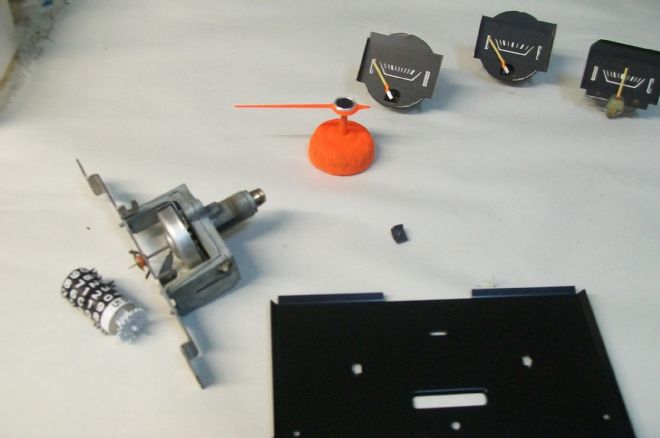

2. IS carefully disassembles the instrument panel; there are no repop replacement parts for any of this, so every original part must be manufactured from scratch or refurbished. You can begin to see the scope of what's involved with this many parts.

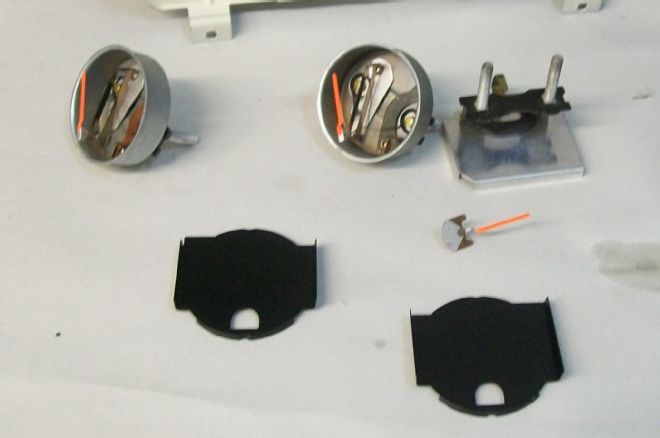

3. The three left-side stock auxiliary gauges, removed from the IP. The frame in the foreground that they sit behind is called a "badge:" it adds depth to the assembly while screening out any side light that may spill around the gauge faces from the instrument case.

4. The auxiliary gauges—fuel, temp, and oil pressure—are all electrically operated. Instrument Spcialties owner Mike Mancini jokes that the factory should've put the word "about" in from of each gauge call-out: Notice the bimetallic strip inside both cups? The mechanism is driven by voltage, which warps the bimetallic strip to varying degrees. IS cleans and recalibrates these to be as accurate as possible.

5. This is the circuit board for the instrument cluster; it's attached to the back of the gauge case. Besides a thorough acid cleaning, IS is looking for delamination of the electrical circuit trace from the fiber backing board, proper electrical continuity, and the integrity of the contact pins. Any problems are corrected.

6. These two things are the speedometer bridge (top), and the speed cup. The speed cup's needle-like axle rotates in the white cylinder in the bridge—called a jewel. The jewel wears out over time and must be replaced. The small red cylinder on the right is the new jewel.

7. Here Mancini works on our Valiant's speedometer assembly.

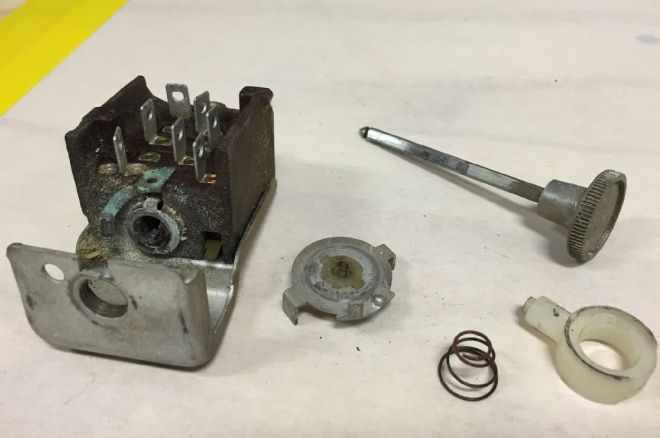

8. This is our headlight switch in disassembled form. In reality, it's three switches in one: running lights, headlights, and an instrument panel dimmer switch. It's all cleaned, reassembled, lubed with dielectric grease, then electrically checked.

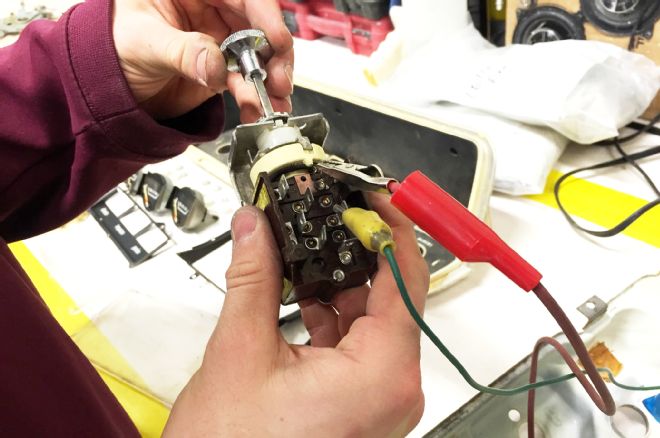

9. IS confirms the proper electrical operation of the refurbished headlight switch with test gear.

10. This grouping of restored switches (left to right) is the headlight switch, wiper switch, and flasher switch. All three look like they came off the assembly line yesterday, and work just as good. They're ready to be installed, but much more work must take place first!

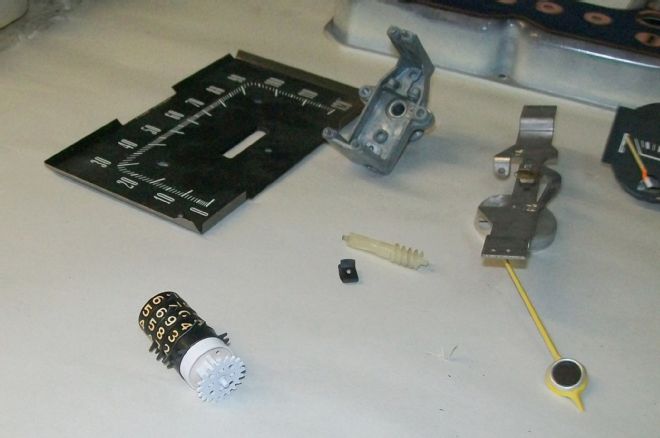

11. This collection of parts goes with the speedometer and includes (clockwise from upper left) the original 120-mph speedometer dial, the speedometer frame, the speedometer bridge, speedometer needle, and odometer rolls. Note the small white worm gear (center) that drives the odometer wheel.

12. Just to the right of the odometer roll is the refurbished speedometer assembly, consisting of the frame, bridge, and speed cup. To the right of that is the freshly airbrushed speedo needle. Take note of its vibrant new orange color compared to the previous photo.

13. Mancini begins the careful reassembly of the speedometer on his workbench. Note the rehabilitated gauge bezel waiting for the speedo assembly.

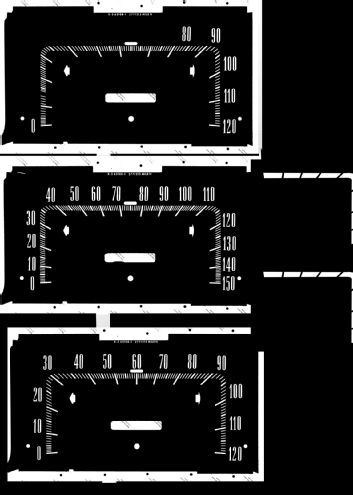

14. This is digital artwork of the stock Valiant speedometer dial (top & bottom), and newly created artwork of a stock-appearing 150-mph speedo (center). These are output as a film negative that helps print a color image on the final gauge dial. The two "L" shaped things will be our red "caution" zone from 100 to 150 mph.

15. It all looks like this when the new dial is reprinted, attached to the speedometer, and installed in the restored instrument case. Two things to note: See how the instrument case has been cleaned and painted, and check out how our low-oil/brake idiot lights have been replaced by a single working oil-pressure gauge (foreground).

16. Here is our gauge bezel after it's been re-chromed. Prior to this, it was stripped of its paint and chrome (actually atomized aluminum) in a proprietary chemical bath, the surface was cleaned and scuffed, imperfections in the plastic were repaired, and given a fresh re-chrome using the factory original vacuum metalizing process. But it's not done yet!

17. Areas that remain in chrome must be carefully masked off. There is no cutting corners here—this is difficult, tedious work that takes the patience and hand/eye coordination of a watchmaker.

18. Here's what our bezel looked like after being airbrushed with an antiglare satin black lacquer. Note how a small portion of the chrome mask around the flasher opening has been carefully removed with tipped blade.

19. The final restored bezel, after the mask has been removed and the lettering has been applied in white paint by hand. We showed it to guys on Facebook, and they all said no way was this a 47-year-old gauge bezel!

20. The process continues with the lenses. These often look horrible after decades of abuse and exposure, but they can be made like new by carefully being wet sanded (800 grit progressively up to 5,000 grit) then polished. Here, Mancini polishes the central speedometer lens with a high-speed rotary polisher.

21. Finally, the finished instrument panel is ready for shipping to the customer (us!) from IS' North Kingstown, Rhode Island, facility.

22 & 23. Close-ups of the left side of our instrument panel (after and before restoration) show the subtle change in script style of the auxiliary gauges, as well as the vast improvement in appearance.

24 & 25. Likewise, the right side of the IP shows the change from the original low-oil and brake system idiot lights, to the full-sweep oil pressure auxiliary gauge. We want to limit the number of aftermarket gauges down the road, and this move helps us do that.