| Though more power is available from the aftermarket, testing was conducted with stock P30 (manual transmission) cams. The aftermarket cam sprockets were adjusted to "0" to simulate factory timing spec's

| Though more power is available from the aftermarket, testing was conducted with stock P30 (manual transmission) cams. The aftermarket cam sprockets were adjusted to "0" to simulate factory timing spec's

A Little Tuning Goes A Long Way

The question seems simple enough: What's a turbocharged Honda engine's most important component? The variety of answers is surprising though. Naturally, the usual suspects are quick to appear-there's the turbo itself, forged pistons, even connecting rods and sleeved cylinders. Intercoolers often make their way into the conversation as do fuel injectors, fuel pumps, even things like billet fuel rails and camshaft timing. While each is an important component to any successful buildup, the key to any turbo engine's success lies with tuning. Turbochargers, blowers and nitrous oxide don't ruin otherwise perfectly good Honda engines, detonation does. Controlling ignition timing becomes even more critical once boost is added to the equation. Miscalculate by a degree or two and it can be off to the Internet forums for new piston research.

Who's To Blame

Speaking of online research, while the Web generally proves useful, morons attributing catastrophic engine failures to Honda's "notoriously inferior" connecting rods abound. Ditto for the "cheap" cast pistons, the "undersized" injectors and the "insufficient" fuel rails. Never mind the fact that Honda's B16A engines easily exceeded 8,000 rpm from the factory, came with a lengthy warranty and that the number of those who've successfully run otherwise stock engines in 24-hour endurance races-including this author-are not few. Despite the facts, those who insist it's got to be those pesky connecting rods will never shut up but the reality is that the B-series VTEC engine's weakest link is, more often than not, the owners themselves-that and the lack of a proper tune.

Tuning Is Key

Tuning is important in terms of safety and power but is absolutely critical when it comes to turbo engines. What better way to illustrate the importance of tuning and further fuel the well-deserved reputation the B-series has for making big power then to crank up the boost on a near-stock B16A. Despite the occasional need for block guards, sleeved blocks and forged reciprocating assemblies, the majority of the stock components are fairly stout and require little more than the magic of proper tuning to produce big numbers. Don't think for a minute we're condemning the use of forged components, proper block preparation and things like ARP head studs. No, the point here is to highlight just how important tuning really is.

At lower boost levels, which generally go hand in hand with pump gas, most turbo engines can safely operate using many factory components. It's surprising just how far the stock stuff can take you with proper tuning. Keep in mind: the turbo engine's number one killer is detonation. While many are quick to point to the connecting rods' "poor" design, "weak" cast pistons or even something as silly as a "low-flow" fuel rail, the reality is that they're likely to blame for cranking up the boost without spending a bit of quality time tuning on that dyno.

| In normally aspirated trim the B16A was run with an A'PEXi header and 3-inch open exhaust.

| In normally aspirated trim the B16A was run with an A'PEXi header and 3-inch open exhaust.

The Engine

Behold, the test engine: a well-used B16A originally purchased from a local Japanese engine distributor. According to Internet sources-and arguably less than savvy tuners-the B16A block itself is notoriously weak, requiring, at a minimum, a block guard or even a full sleeve treatment. Often times, the measures taken to outfit the average street-bound B16A are nothing short of overkill. While dedicated race engines can be pushed to stratospheric power levels once sleeved, decked and stuffed with all manner of custom reciprocating components, the majority of these steps are unnecessary for typical street use. Combined with poor tuning, any block, sleeved or otherwise, can be easily damaged. Steel crankshafts, forged rods and top-of-the-line forged pistons are not spared when it comes to an improper tune. When appropriately tuned, the factory cylinders, connecting rods and crankshaft can withstand more power than most are likely to utilize in, say, your typical turbocharged EG street car. Just how much is too much? How about 500 hp paired with more stock components than any sane person would otherwise dare?

With a goal of 500 hp, forged pistons become mandatory. While B-series pistons are by no means inferior, cast metal is what it is and just can't put up with the cylinder pressures associated with 500 hp-despite the tuning. Placing confidence in the remainder of the factory components is easy but previous testing has shown that the factory cast P30 pistons tend to fail well before the 500hp mark. A set of Arias pistons were employed and tied to the factory B16A connecting rods. The Arias pistons feature a flat-top design that lowers the compression ratio to 9.0:1. Naturally, this drop in compression reduces the power output in normally aspirated trim but allows for higher boost levels, especially on the street. Avoiding detonation is critical when it comes to street use and the power lost from compression can easily be compensated for with boost. Were this a race-only engine we'd opt for higher compression, but for street use the drop in static compression is nothing short of a blessing.

It should be noted that confidence in the factory connecting rods' strength should not run short (the author has posted a number of record-setting, stock-rod Bonneville runs utilizing a turbocharger, nitrous, even a blower, not to mention countless miles of road racing in naturally aspirated trim). In truth though, most enthusiasts will opt for forged rods when using forged pistons but this exercise points out that it's possible to get by with the factory rods for those with tight finances. While most builders might sleeve the block, install a block guard to minimize the horrors of cylinder distortion or at least re-machine it, we didn't. Out came the factory B16A pistons and in went the new Arias slugs and rings-even the old rod bearings were reused. Remaining true to form, the idea to use aftermarket head studs was tossed aside and, instead, the factory head bolts that had been through countless torque cycles were used, along with a factory head gasket. Obviously, this is not the way to properly build a serious turbo engine but it goes a long way toward demonstrating just how strong the stock stuff really is and what a good tune can yield. The long-block was finished off with such exotic performance hardware as the stock P30 intake manifold and throttle body-you can't make this stuff up.

The Turbo

Attaining 500 hp requires a healthy turbo, not to mention a suitable intercooler. A Turbonetics T66 was selected to help get there. According to the supplied compressor maps, 500 hp should be realized at a calculated pressure ratio of 2.70, that's 25 psi assuming a peak normally aspirated power output near 175 hp. This would yield an efficiency of 76 percent. As it turned out, the normally aspirated engine didn't quite make that much, however the turbo combination bettered the power/boost formula allowing the goal to be met with less than 25 psi of boost. Things were looking good.

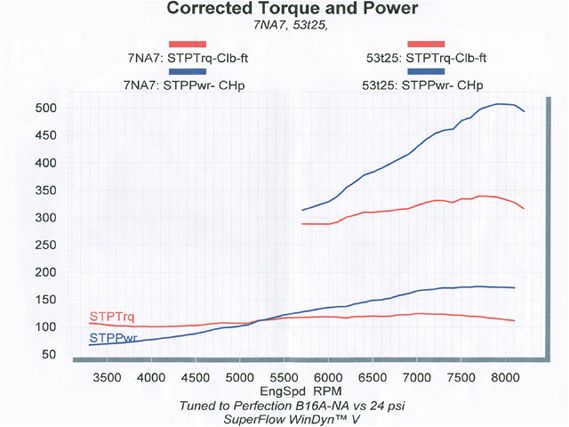

| A number of boost levels were experimented with before settling on a maximum of 24 psi. In near-stock trim the turbo B16A ultimately produced 507 hp and 339 lb-ft of torque-a far cry from its 171hp naturally aspirated baseline. Remember that 500 hp worth of stock-block B16A goodness (except for forged pistons) was made possible by little more than some good old-fashioned tuning.

| A number of boost levels were experimented with before settling on a maximum of 24 psi. In near-stock trim the turbo B16A ultimately produced 507 hp and 339 lb-ft of torque-a far cry from its 171hp naturally aspirated baseline. Remember that 500 hp worth of stock-block B16A goodness (except for forged pistons) was made possible by little more than some good old-fashioned tuning.

The T66 mates to a HP Performance tubular header that positions the turbo in the factory AC compressor location and boost control is handled by an Innovative wastegate. Pressure settings come via a Turbo XS manual controller, which allows peak boost pressure to be dialed in from 10-25 psi. A dual pass Spearco air-to-water intercooler cools the B16A's incoming air charge and should be considered mandatory when running 20-plus psi worth of boost.

Everything Else

Since fuel flow is a critical element in safe power production, an AEM aluminum fuel rail designed to accept a set of 720cc Bosch injectors good for over 500 hp was selected. Sure, the factory fuel rail is more than adequate but simply wasn't compatible with the Bosch injectors. The B16A's distributor was modified by removing the internal coil to allow for an MSD ignition amplifier. A FAST stand-alone engine management system was also used to dial in timing and fuel curves, which is after all what tuning is all about. With a pan full of Lucas synthetic oil, the engine was ran in normally aspirated trim on a SuperFlow engine dyno to help seat the new rings and get the new pistons acquainted with the old cylinders. After a short break-in period, the B16A produced 171 hp and 125 lb-ft of torque, approximately what was hoped for given the header, intake and low-compression ratio. Boost was next. After installing the turbo, several sub-10psi pulls followed, which resulted in 325 hp and 218 lb-ft of torque. There was more peak power to be had here with a bit more tuning but dyno time was limited and the desire to up the boost took precedence.

The 500hp Stock-Block Test

Following low-boost success the pressure was upped in 3psi intervals. At 14.6 psi the engine produced 387 hp and 260 lb-ft of torque. At 18 psi the numbers jumped to 425 hp and 286 lb-ft of torque while 20 psi brought 454 hp and over 300 lb-ft of torque. Don't forget, save for pistons, this engine is nearly stock. While all of this sounds as easy as cranking up the boost, understand that ignition timing was reduced to less than 18 degrees and tailored to each new boost level to accommodate a safe mixture. The tuning sequence was as follows: Drop ignition timing, dial in the air/fuel mixture then run full timing at the new boost level. Anything else could have easily resulted in a bent or broken rod from excessive cylinder pressure. A turn of the boost controller's screw brought 22.4 psi and 485 hp right along with it. A slightly rising boost curve produced a peak torque output of 324 lb-ft of torque at 7,800 rpm. The quest's final step for 500 hp was to increase boost pressure to 24 psi where the little B16A produced peak numbers of 507 hp and 339 lb-ft of torque. As fate would have it, dyno time was concluded shortly after reaching the 500hp mark.

Don't forget 507 hp from a near-stock B16A shows what is possible with proper tuning. While safeguards like sleeved cylinder walls, block guards, head studs and other precautionary measures are never a bad idea, remember that a little tuning goes a long way.