Electric cars don't need to be little econo-boxes with "look at me I'm a martyr for the environment" styling. Nor do they need to be slow or even particularly expensive. Quite the opposite; electric motors can be smaller and lighter than a gas engine making the same power, and their massive low-RPM torque makes them a good candidate for performance use. The only real drag with using electric power is that many require huge, heavy battery packs to maintain acceptable range--but there are ways of dealing with that.

Acquire any small car with a manual transmission weighing under 2,500 lbs from the manufacturer. Many EV (electric vehicle) builders like to use economy cars like the Geo Metro, Honda Civic and Toyota Corolla, but you might want to consider stepping up to something cooler. Rear-drive sports cars like the Mazda Miata or any 1980s Ford Mustang will fit the bill at a budget price.

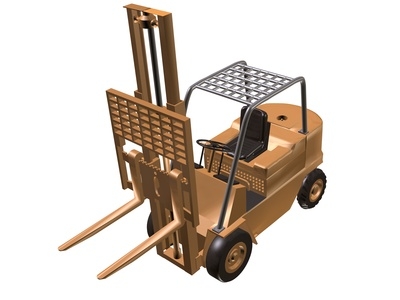

Purchase a used electric forklift with a main "traction" motor of at least 100 horsepower, but consider one with at least 200 horsepower. Used forklifts can come surprisingly cheap--as little as $500. And what's left of your 15,000 lb forklift will bring about $750 if sold for scrap at $0.05 a pound.

Remove the car's engine. Build a custom steel adapter to fit the electric motor to the transmission bellhousing, and a custom coupler to join its output shaft to the transmission input shaft. Inexperienced fabricators may wish to enlist the services of a machine shop here, but to those with the tools and skill to do this procedure will be fairly self-explanatory.

Replace your car's gas tank with car deep-cycle, 24-volt batteries. The exact number and configuration is up to you, but wire them in accordance to the motor's needs. If your forklift motor runs off of 48 volts, wire your 24-volt batteries in series of two, then run the circuits parallel into your forklift's motor controller.

Connect your batteries to your batteries a motor controller unit. You can use the silicone-resistance-type motor controller that came with the forklift, but remember that it was designed for use with the forklift's massive battery pack. Consider purchasing a more efficient mosfet-based motor controller from Curtis or Altrex. The older controller will work, but will be harder on your batteries and may reduce their lifespan.

Transfer the electrical harnesses, throttle and fuse assembly from the forklift to your car. This is obviously an oversimplification of the wiring procedure, but thinking of it this way will help ensure proper operation on the road.