Ali Mansour

Brand Manager, 4WD & Sport Utility

Photographers:

Troy Pittman

Ali Mansour

Brand Manager, 4WD & Sport Utility

Photographers:

Troy Pittman

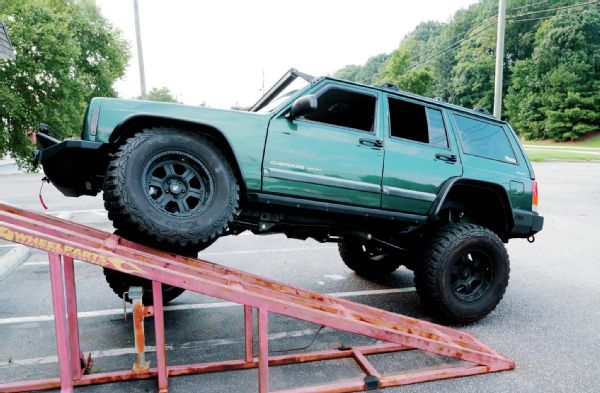

It’s no secret that we are fans of the ’84-’01 Jeep Cherokee XJ platform. They are inexpensive to own, easy to build, and if it wasn’t for that darn Unitbody, would be a nearly perfect blend of simplicity and rugged durability. However, there are areas where the XJ can be significantly approved upon, most notably the suspension.

Lifting an XJ past 31⁄2 inches puts the front control arms at an increased angle, which detracts from handling and upsets the geometry of an otherwise well-engineered suspension. The easy fix we’ve learned through the years is to install longer control arms. The rear is a different story.

Since the XJ is fit with leaf springs mounted on top of the axle, it’s more prone to suffer from axlewrap versus a linked suspension. Add a lift block and old springs to the equation and the effects can be even worse. Barring building an axlewrap device, which has its own set of drawbacks, the next best thing to do would be to convert the Cherokee from leaf springs to a multilink suspension. As you can imagine, building a multilink suspension from scratch is no easy task.

Luckily, Rock Krawler Suspension has solved an otherwise complex problem and packaged it in the form of the company’s X-Factor Plus suspension system. Offered in both 4.5-inch and 6.5-inch lift heights, the X-Factor Plus kit combines a long-arm front suspension with a rear coil conversion. While this kit does require a fair amount of welding, it is one of the easiest ways to ditch your leaf springs without having to be a master fabricator.

To check out the conversion firsthand, we stopped by our local 4Wheel Parts in Raleigh, North Carolina. There, we documented the highlights as the 4Wheel Parts team installed 4.5-inch version of the system on a ’01 Jeep Cherokee XJ.

Rock Krawler’s 4.5-inch X-Factor Plus long-arm suspension system with coil conversion includes nearly everything you need (minus rear coil springs). Up front, this system uses a single upper for a flexy three-link, along with a track bar to control the axle. Rock Krawler also offers kits with an additional upper control arm for those looking to add another front link to the equation.

Rock Krawler’s 4.5-inch X-Factor Plus long-arm suspension system with coil conversion includes nearly everything you need (minus rear coil springs). Up front, this system uses a single upper for a flexy three-link, along with a track bar to control the axle. Rock Krawler also offers kits with an additional upper control arm for those looking to add another front link to the equation.

For those of you installing the kit at home, you will be stoked to know that you can do it a little at a time since the rear axle truss doesn’t interfere with the leaf-spring mounts. This particular Cherokee was outfitted with a custom semi-float Dana 60 rear axle, so the owner opted for the Dana 60 truss from Rock Krawler. When ordering, be sure to note which rear axle your XJ is equipped with as the trusses are axle specific.

For those of you installing the kit at home, you will be stoked to know that you can do it a little at a time since the rear axle truss doesn’t interfere with the leaf-spring mounts. This particular Cherokee was outfitted with a custom semi-float Dana 60 rear axle, so the owner opted for the Dana 60 truss from Rock Krawler. When ordering, be sure to note which rear axle your XJ is equipped with as the trusses are axle specific.

With the rear link truss welded in place, the next major item is to notch out the rear portion of the Unitbody for the rear coil and shock mounts. A cut-off wheel was the tool of choice for this job. Rock Krawler sends the inset bracket already assembled, so it cuts down on fab time and guess work. Welding to the Unitbody isn’t the easiest task. It’s sheetmetal, which can melt quickly. The guys at 4Wheel Parts were well versed in welding to thin metal and didn’t have any trouble using a MIG welder to burn it in.

With the rear link truss welded in place, the next major item is to notch out the rear portion of the Unitbody for the rear coil and shock mounts. A cut-off wheel was the tool of choice for this job. Rock Krawler sends the inset bracket already assembled, so it cuts down on fab time and guess work. Welding to the Unitbody isn’t the easiest task. It’s sheetmetal, which can melt quickly. The guys at 4Wheel Parts were well versed in welding to thin metal and didn’t have any trouble using a MIG welder to burn it in.

This XJ was equipped with TnT Customs frame stiffeners, which meant the rear control-arm mounts had to be modified. The plus side is that the bolt-on bracket could be welded to the thicker steel of the chassis stiffener in addition to being bolted.

This XJ was equipped with TnT Customs frame stiffeners, which meant the rear control-arm mounts had to be modified. The plus side is that the bolt-on bracket could be welded to the thicker steel of the chassis stiffener in addition to being bolted.

This XJ was equipped with TnT Customs frame stiffeners, which meant the rear control-arm mounts had to be modified. The plus side is that the bolt-on bracket could be welded to the thicker steel of the chassis stiffener in addition to being bolted.

This XJ was equipped with TnT Customs frame stiffeners, which meant the rear control-arm mounts had to be modified. The plus side is that the bolt-on bracket could be welded to the thicker steel of the chassis stiffener in addition to being bolted.

On the axle side, new 3⁄16-steel lower control arm and shock mounts sandwich the leaf-spring perches. The upper guide plate makes it easy to get these in the correct location.

On the axle side, new 3⁄16-steel lower control arm and shock mounts sandwich the leaf-spring perches. The upper guide plate makes it easy to get these in the correct location.

Rock Krawler suggests using ’97-’06 Wrangler rear coil springs for the rear coil conversion. Since this XJ had a host of aftermarket armor, it was a bit heavier than an unarmored XJ. For this Jeep, Old Man Emu by ARB 2-inch Heavy-Duty rear TJ lift springs were selected and provided the Jeep with a level stance.

Rock Krawler suggests using ’97-’06 Wrangler rear coil springs for the rear coil conversion. Since this XJ had a host of aftermarket armor, it was a bit heavier than an unarmored XJ. For this Jeep, Old Man Emu by ARB 2-inch Heavy-Duty rear TJ lift springs were selected and provided the Jeep with a level stance.

To dampen the ride, Bilstein 5100-series shocks were installed front and rear. Shock lengths will vary depending on which springs you choose and how much wheel travel you are aiming for.

To dampen the ride, Bilstein 5100-series shocks were installed front and rear. Shock lengths will vary depending on which springs you choose and how much wheel travel you are aiming for.

Rock Krawler uses 2-inch, solid-steel lower control arms, which are formed for increased ground clearance. Each lower arm is built with a high-quality poly-blend bushing at the fixed end of the control arm and the company’s Krawler joint at the other. The Krawler joints feature forged chromoly housings and one-piece steel balls that are chrome plated.

Rock Krawler uses 2-inch, solid-steel lower control arms, which are formed for increased ground clearance. Each lower arm is built with a high-quality poly-blend bushing at the fixed end of the control arm and the company’s Krawler joint at the other. The Krawler joints feature forged chromoly housings and one-piece steel balls that are chrome plated.

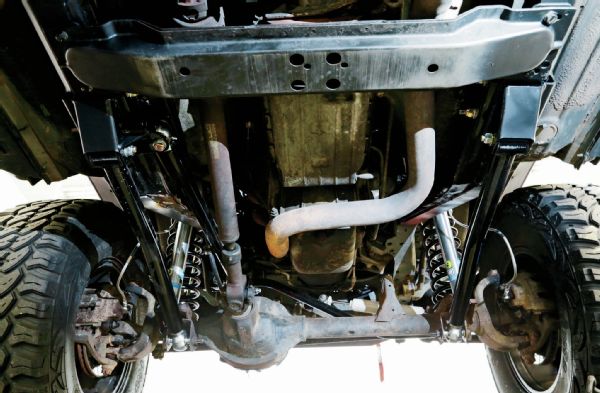

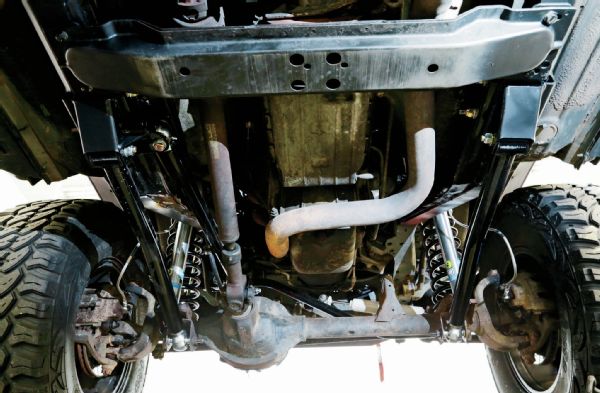

Two adjustable upper control arms fitted with Krawler joints attach to the rear 1⁄4-inch-thick steel axle truss. Since the arms are triangulated, there is no need for a rear track bar. You’ll need a new muffler and tail pipe with this kit as well. The crew at 4Wheel Parts found that the Banks Power PN52636 muffler is a great fit under the XJ and provides a nice tone that isn’t overly loud. Since this Jeep was already outfitted with a lift prior to the X-Factor Plus kit, it already had an aftermarket slip-yoke eliminator and CV driveline. If you’re Jeep does not, you will need to budget for the driveline upgrade as well.

Two adjustable upper control arms fitted with Krawler joints attach to the rear 1⁄4-inch-thick steel axle truss. Since the arms are triangulated, there is no need for a rear track bar. You’ll need a new muffler and tail pipe with this kit as well. The crew at 4Wheel Parts found that the Banks Power PN52636 muffler is a great fit under the XJ and provides a nice tone that isn’t overly loud. Since this Jeep was already outfitted with a lift prior to the X-Factor Plus kit, it already had an aftermarket slip-yoke eliminator and CV driveline. If you’re Jeep does not, you will need to budget for the driveline upgrade as well.

To adjust for the new front lift, a 1⁄4-inch-steel dual-sheer track bar bracket bolts in place of the stock mount at the Unitbody side. A drop pitman arm helps keep all of the geometry in check.

To adjust for the new front lift, a 1⁄4-inch-steel dual-sheer track bar bracket bolts in place of the stock mount at the Unitbody side. A drop pitman arm helps keep all of the geometry in check.

The solid-steel adjustable front track bar is formed for clearance around the stock Dana 30 front axle. Also included with the kit is a set of sway bar disconnects to allow you to get the full potential of the suspension system.

The solid-steel adjustable front track bar is formed for clearance around the stock Dana 30 front axle. Also included with the kit is a set of sway bar disconnects to allow you to get the full potential of the suspension system.

Since Rock Krawler uses a single upper link for its three-link version of the X-Factor Plus kit, you’ll need to remove the stock bushing from the driver side upper link mount. An air hammer will make this job much easier.

Since Rock Krawler uses a single upper link for its three-link version of the X-Factor Plus kit, you’ll need to remove the stock bushing from the driver side upper link mount. An air hammer will make this job much easier.

In place of the stock rubber bushing is a heavy-duty Krawler bushing that is designed to deal with the additional strain and load of the suspension. This joint is rebuildable, and if you’re wheeling your Jeep frequently, it’s something we would keep a spare of, just in case.

In place of the stock rubber bushing is a heavy-duty Krawler bushing that is designed to deal with the additional strain and load of the suspension. This joint is rebuildable, and if you’re wheeling your Jeep frequently, it’s something we would keep a spare of, just in case.

Rock Krawler’s front control-arm brackets fit between the stock crossmember and the Unitbody. In addition to using existing holes, you’ll need to drill a few other spots along the sheetmetal framerails for the brackets to tie into.

Rock Krawler’s front control-arm brackets fit between the stock crossmember and the Unitbody. In addition to using existing holes, you’ll need to drill a few other spots along the sheetmetal framerails for the brackets to tie into.

Post install, the entire Jeep’s suspension needed to be double-checked for alignment. The alignment equipment at 4Wheel Parts allows them to tune wheelbase evenly, along with getting the correct steering settings.

Post install, the entire Jeep’s suspension needed to be double-checked for alignment. The alignment equipment at 4Wheel Parts allows them to tune wheelbase evenly, along with getting the correct steering settings.

Where your bumpstops are located and how much sheetmetal you are willing to remove will make a big difference in tire sizing options. This XJ is fit with 315/70R17 Pro Comp Xtreme Mud Terrain II tires, mounted on 17x9 Pro Comp 7089 wheels.

Where your bumpstops are located and how much sheetmetal you are willing to remove will make a big difference in tire sizing options. This XJ is fit with 315/70R17 Pro Comp Xtreme Mud Terrain II tires, mounted on 17x9 Pro Comp 7089 wheels.