When the time comes to elevate the nose of your '99-'02 Ford F-350 dually, you may discover that options are very limited. It may simply be a case of some manufacturers skipping over certain applications that would be considered low-volume, or perhaps it is the lack of available wheel and tire fitments for dually trucks that makes lifting one harder to justify. Whatever the case, the scenario creates a real dilemma for the dually owner.

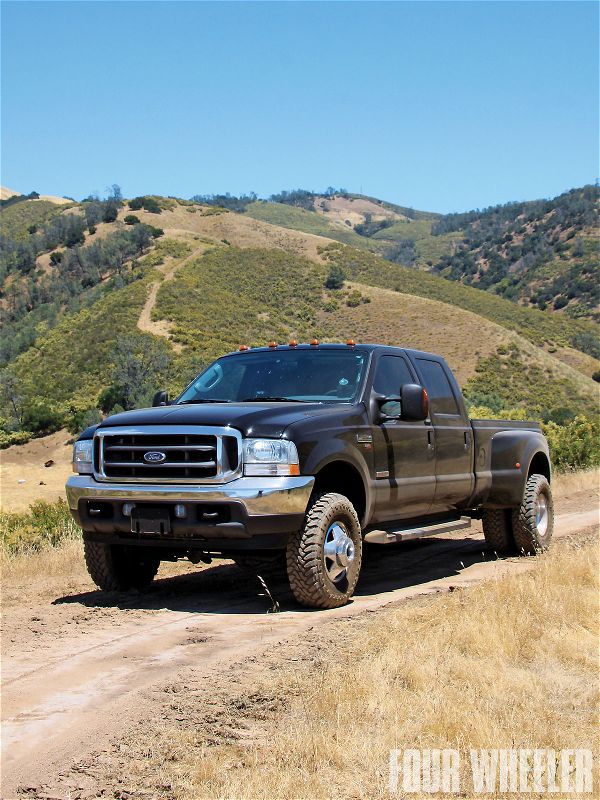

Recently a friend of ours asked us why he couldn't find a kit that would allow him to level the front of his '01 F-350 dually. At the time, we did not have a good answer for him, so we did a little investigation on the matter. Much to our surprise, we found a lot of dead ends. Some companies offered kits for 1-ton single-rear-wheel vehicles, but few actually had part numbers for dual-rear-wheel applications. Fortunately, the folks at Full-Traction Suspension had what our friend was looking for. Full-Traction has been in business for more than 20 years, and they specialize in suspension systems for fullsize pickups, including a leveling system for late-model 1-ton Ford dually pickups. The setup allows all '99-'02 Ford dually owners the ability to install a set of 255/85R16 (33-inch) tires without fender trimming.

However, as we found with this project, fitting larger tires to a factory dually wheel requires more than just a leveling kit. The scenario also requires a pair of wheel spacers to maintain some very critical tire spacing in order to sustain the appropriate load-carrying capacities. When it comes to wheel spacers and dually pickups, it is essential to maintain the factory's hub-centric wheel mounting method, rather than the lug-centric style that other light-duty applications employ. You may have noticed that dually lug nuts are very different than those found on most other vehicles. Instead of having an acorn taper to help center the wheel, dually lug nuts have a flat surface where the wheel and the lug nut come together. This purposeful arrangement, together with a tighter hub-to-wheel fitment, ensures steady contact between the center opening of the wheel and the outside diameter of the full floating hub. On this setup, all that the lug studs and nuts are required to do is hold the wheel to the axle hub-no lateral forces and no need to center the wheel.

Buyer beware, some dually spacers do not address this critical matter. Without hub-centricity, a dually wheel must rely on the lug studs and the lug nut's ability to clamp the wheel to the axle hub. This setup typically leads to vibrations as the tolerances of the eight wheel lug holes were never intended to center or locate the dually wheel, let alone carry the weight of the truck. These vibrations are usually followed by stud or wheel damage as the wheel tries to move slightly around the outer bore of the hub-not good. So, for this installation we took our project to the experts at Off Road Unlimited in Burbank, California-ORU has a reputation for building lifted dually trucks. Read on as we showcase our results and highlight a few crucial steps of the installation process.

PhotosView Slideshow