For 2007, GM's pickups and SUVs feature highly refined ride and handling. When comparing GM's new suspension to the '99-'06 design it replaces, the design premise is basically the same, with the primary exception being that coilover shocks have replaced torsion bars. This raising of the bar, with front coilover shocks, challenges the aftermarket suspension companies to create lift systems that don't torpedo the OE seat-of-the-pants experience.

Superlift's series of '07 lift systems (they also offer 1.25- and 2.5-inch lifts) for 1/2-ton Silverado/Sierra pickups and Yukon/Tahoe, Yukon XL/Suburban, and Avalanche SUVs were designed by Mike Martin, who also created the 6-inch F.I.T. Series system for the '99-'06 GMs that was judged "Best Bang For Your Buck" and "Best Knuckle System" in a recent 4-Wheel & Off-Road Chevy suspension shootout.

Superlift used advanced computer modeling to address the various variables: four-wheel drive versus two-wheel drive (they share the same basic chassis platform), rear leaf springs in pickups, four-link and coils in SUVs; and GM's scad of factory shock options: standard shocks, Autoride, or Air-Ride computer-controlled units. Using SolidWorks CAD/CAM software, Superlift engineers start with factory chassis data provided by GM. This technology sharing allows Superlift to produce designs that beforehand took considerably more man hours, especially in fab-shop time. SolidWorks 3-D animation even allows operational clearances and geometry to be checked as the vehicle model goes through its suspension travel and steering cycles.

SolidWorks is also used in the design of welding and machining fixtures used by Superlift's manufacturing division. If the component is made from steel plate or tubing or involves machining processes, Superlift builds it in-house with an array of lasers, CNC presses, and machining centers.

Superlift offers two versions of the 6-inch lift, with the difference being front lift method. Replacement, lifetime-warranted monotube gas coilover bodies (left) are offered for 1/2-tons not equipped with the factory Autoride electronic shock option. The second version (right) is a coilover spacer system, which allows Autoride owners to keep this impressive option.

Superlift offers two versions of the 6-inch lift, with the difference being front lift method. Replacement, lifetime-warranted monotube gas coilover bodies (left) are offered for 1/2-tons not equipped with the factory Autoride electronic shock option. The second version (right) is a coilover spacer system, which allows Autoride owners to keep this impressive option.

Superlift recommends professional installation of this system-minor cutting and welding are required. Installation takes a pro six to eight hours, and is rated a "4" on Superlift's Difficulty Scale with "5" being the most difficult.

Knowing that most '07 Chevy/GMC trucks and SUVs will spend the majority of their lives on pavement, on-road ride was a design priority. Superlift chose to stiffen the front spring rate slightly to offset the additional leverage and loads generated by an increased vehicle track width, a byproduct of wider tires and wheels and aftermarket knuckles. This prevents "spongy" ride and handling characteristics. Superlift accomplishes this with stiffer-than-stock valving in its replacement front shock bodies or with preload rings for Autoride applications to boost the coil rate slightly.

The Tahoe's ride quality remains top-notch, as it should since the factory coilovers, rear springs, and impressive Autoride electronic shocks are retained. Ride quality on the pickup is impressive as well.

From a handling standpoint, both the pickup and the SUV felt more stable. The Tahoe realized the most improvement, with body roll and brake "dive" considerably reduced. Superlift attributes these improvements primarily to the increase in vehicle track width and the use of preload shims with the Tahoe's factory coilovers.

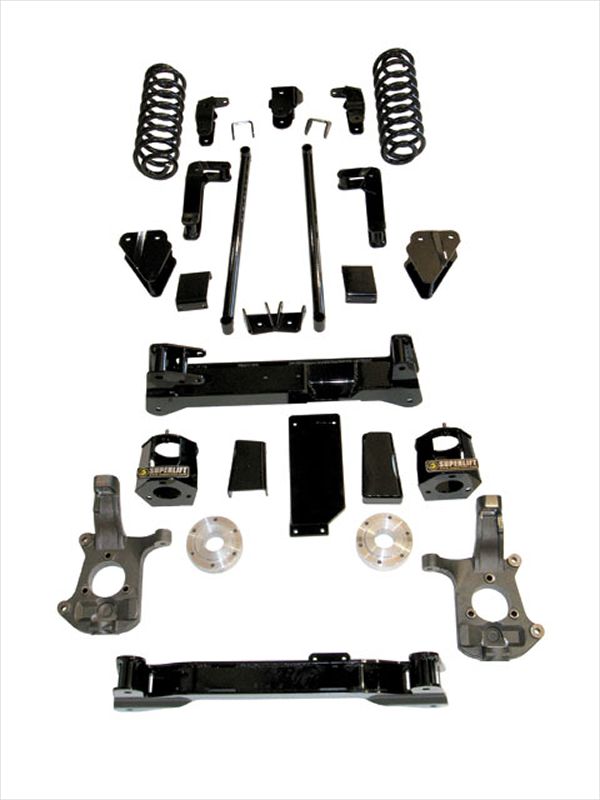

Front lift comes from replacement knuckles and one-piece lower control-arm crossmembers. Brackets lower the diff, billet CV axle spacers ensure proper axle engagement, and kicker braces add rigidity. Rear lift for SUVs (shown) consists of new coils and four-link relocation bracketry; pickups get either 5-inch blocks or replacement springs. Three different rear shock types are offered for pickups: Standard Superide, gas monotube (SS series), or gas with remote reservoir (SSR series).

Front lift comes from replacement knuckles and one-piece lower control-arm crossmembers. Brackets lower the diff, billet CV axle spacers ensure proper axle engagement, and kicker braces add rigidity. Rear lift for SUVs (shown) consists of new coils and four-link relocation bracketry; pickups get either 5-inch blocks or replacement springs. Three different rear shock types are offered for pickups: Standard Superide, gas monotube (SS series), or gas with remote reservoir (SSR series).

Overall extension and compression travel remained unchanged, which is borne-out by the before-and-after RTI numbers. Our crew-cab, short-wheelbase Z71 on a 20-degree ramp scored 450 lifted and 438 stock. Obviously, most 1/2-ton GM vehicles will spend the vast majority of their time on-road, and what minimal off-pavement action they see will not be the high-articulation demanding type. Increasing suspension travel while maintain factory driveability is possible-anything is, given enough time and money-although it's not worthwhile considering the 1/2-ton's intended use.

We expected rear axlewrap from the kit's rear lift blocks, yet none was evident in testing. Wrap-up may become an issue if modifications are made to restore some spunk, like gear ratio changes or engine performance mods. Superlift does offer replacement rear lift springs for those who would rather go that route.

The new GM's fender openings are ample at the top, but tight at the corners. Six inches of lift clears 33-inch-tall rubber without trimming; 35s will fit with the liberal application of a Sawzall. The fitment shown here is for 305/55-20 Toyo Open Country ATs (33.2-inch diameter, 12.4 inches wide) on 20x8.5 Velocity 101 Series wheels with 6 inches of backspacing (35mm offset).

Superlift 2007 GM 4WD/2WD 6-Inch Lift Systems

Maximum suggested tire diameter (in): 33s will fit with no trimming. Running 35s requires trimming the air dam/fascia and inner fenderwell. Tire/wheel width and wheel backspacing variances will affect fender/body clearance.

Maximum tire width (in): 12.5

Minimum wheel diameter (in): 17

Recommended wheel width (in): 8.5

Minimum wheel backspacing (in): 5.5

Maximum wheel backspacing (in): 6