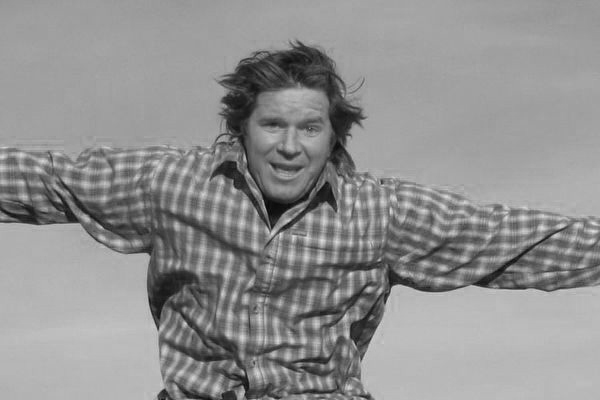

Fred Williams

Brand Manager, Petersen’s 4Wheel & Off Road

Fred Williams

Brand Manager, Petersen’s 4Wheel & Off Road

We've been wrenching, welding, and improvising on our IFS Chevy and this month we'll show you some of the custom upgrades that we've done to try and make it stay alive for another 30 days or more.

We found that the Tuff Country suspension was holding up just fine, but all the stock components like axle halfshafts, steering, and even the driveshafts can't take the abuse of even moderate off roading.

So this is the point where we left the normal path of upgrades and started working with different folks to find new options. The ultimate plan here is to try and determine if IFS can be built to be as strong as a solid front axle, and just how expensive that goal is.

Some of these parts are available now, and others are prototypes for possible future parts depending on demand. Either way, in an upcoming issue (probably September or October 2006) we will wrap up the IFS episode and let you know if it's worth all the effort to keep it alive or if going to a solid-axle swap makes more sense.