In the hardcore wheeling world, maximum traction at any cost is the order of the day and lighter-duty options are often forgotten. The cost-effective answer for many on the low-adrenaline side of fourwheeling and work-truck environments is still the plain and simple limited-slip differential (LSD), and it's past time we shed light on the topic.

Traction is useful in all pursuits, even if it's not a hardcore wheeling environment.

Traction is useful in all pursuits, even if it's not a hardcore wheeling environment.

Open differential performance is only as good as the traction from the tire with the least grip. It all comes down to one basic rule: the average speed of both axles will always equal the speed of the ring gear. Going straight down the road, if the ring gear is turning 100 rpm, so is each axle ([100 + 100]/2 = 100). If you put one tire on ice and the other on dry, sticky pavement, torque takes the path of least resistance to the low-traction tire, which spins, and the high traction tire is stationary. If ring gear speed is 100 in that circumstance, then the spinning tire is turning 200 rpm if the stationary tire is 0 ([200 + 0]/2 = 100).

The same rule applies to a limited-slip, but it can shuttle some torque to the high-traction tire. The amount of torque that can be transferred from the low- to the high-traction side is commonly expressed as the torque bias ratio (see mini-glossary on page 68). The bias ratio is achieved by applying a "brake" or artificial torque/traction to the low-traction side. If you slow the spinning wheel down by any amount, the stationary wheel has to speed up by just as much.

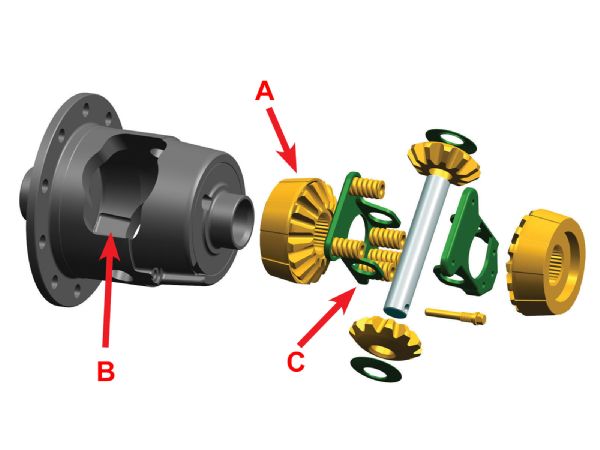

The exploded view of the Auburn LSD shows the gear/cone (A) that fits into the cone seat (B). The spring pack (C) applies a certain amount of preload to the cone clutches. The case is nodular (ductile) iron, and the cones are of a proprietary powdered metal construction. The metallurgical relationship between these two parts is very important so that they don't gall. If you ever have to pull the Auburn apart after it's been used, the cones need to stay with the bores that they are seated to.

The exploded view of the Auburn LSD shows the gear/cone (A) that fits into the cone seat (B). The spring pack (C) applies a certain amount of preload to the cone clutches. The case is nodular (ductile) iron, and the cones are of a proprietary powdered metal construction. The metallurgical relationship between these two parts is very important so that they don't gall. If you ever have to pull the Auburn apart after it's been used, the cones need to stay with the bores that they are seated to.

In general, there are two LSD types: clutch and gear. The clutch-type LSD comes with plates or cone clutches on each output (axle) side of the differential, behind the side gears. With a torque load on the axle, gear-separation forces between the side and spider gears force the side gears outboard, squeezing the clutches between them and the diff case. Increased resistance ("braking") is the result. Preloading the clutchpacks via springs adds to that resistance. If there is very little grip at the tire, the preloaded clutches are the torque ("artificial traction") that the differential needs to sense on the low-traction side before it can shuttle some of the torque. A gear-type LSD achieves the same braking via built-in rotational resistance in the gears.

For reference, many OEM LSDs are under a 2.0:1 bias ratio, and you will barely know they are there (on the street or the trail). The aftermarket units pick up from there and the more streetable ones will run to about 3.0:1. Around 2.5:1 is very common because it offers a noticeable improvement on the trail without bad manners on the street. In most rigs, bias ratios between 2:1 to 3:1 will be fairly transparent. A unit above 3:1 may be ill-mannered, depending on the weight and size of the vehicle. Gear-type limited slips can edge higher and stay more mannerly because they are typically not preloaded. If an aftermarket limited-slip is built for front axle use, it's usually no more than around 2:1.

The Auburn 542089 kit fits all Ford 10.25/10.5 axles from '83 onward, whether full- or semi-floating, with ABS or without. The kit comes boxed with two bottles of friction modifier for the oil. It has a 12-month material and workmanship warranty, as well as a low-cost exchange policy called D-Rex that's good for four years from purchase. If the unit wears out in that period, you can get a brand-new Auburn for about the cost of a rebuild kit for a plate-type unit.

The Auburn 542089 kit fits all Ford 10.25/10.5 axles from '83 onward, whether full- or semi-floating, with ABS or without. The kit comes boxed with two bottles of friction modifier for the oil. It has a 12-month material and workmanship warranty, as well as a low-cost exchange policy called D-Rex that's good for four years from purchase. If the unit wears out in that period, you can get a brand-new Auburn for about the cost of a rebuild kit for a plate-type unit.

The reason we have a differential in the axle is to allow turns without tire scuffing. In a turn, the outer tires travel a longer distance than the inners. Without differentiation, one tire scuffs. The LSD operates like an open diff, allowing one wheel to speed up and the other to slow down (always proportionally), but the clutches resist. Most LSDs have a certain amount of preload in the clutches, which means that the clutches are partially applied all the time. The question becomes: Will the clutches break loose before the tire does? Before the clutches can slip, a certain amount of "breakaway torque" is needed. In a high bias LSD, that torque may be more than the tire can support, so the tire scuffs (and barks). In a turn, weight transfer unloads the inner rear tire, so that's usually the barker. For this reason, a high bias LSD may be squirrelly on slippery roads due to tires skidding. If you live in a winter environment, you don't want a high bias LSD!

Auburn Gear has been in the traction business since the 1950s, supplying both the OE and the aftermarket with a variety of products. Their most enduring design is the cone-clutch limited slip. The side gears of the Auburn unit are combined with precisely machined cones that fit into conical seats in the diff case. Gear separation and preload force the cones outboard into the case to create the resistance needed for torque biasing.

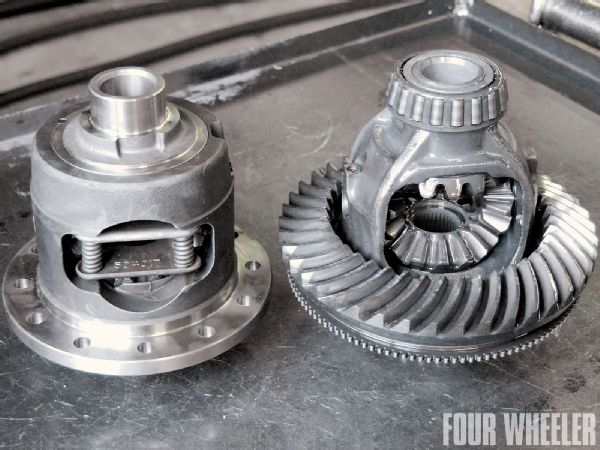

The obligatory new-versus-old shot. If you had the right tool and your carrier bearings were in good shape, you could remove and reuse the carrier bearings for the new LSD. In practice, it's much simpler (and advisable) to buy new bearings and install them onto the new diff.

The obligatory new-versus-old shot. If you had the right tool and your carrier bearings were in good shape, you could remove and reuse the carrier bearings for the new LSD. In practice, it's much simpler (and advisable) to buy new bearings and install them onto the new diff.

The cone clutch has some advantages over the plate-type, and a few disadvantages. On the upside, its working life is generally longer (at least twice as long as far as we can determine independently), and it's usually a bit smoother in operation and less prone to chattering. On the downside, it's not rebuildable when worn out, where you can get at least a couple of rebuilds out of a plate-type. Their smooth operation made the cone designs especially popular with the OE and in the car realm, but they can bias with the best if trail traction is needed.

The Auburn LSD comes in two guises, the High Performance Series (HPS) and the Pro Series (PS). The HPS is offered with a 2.5:1 bias ratio while the PS comes with a 3.5:1 bias. There is little difference between them other than the preload springs, but some applications are only offered in one form or the other. If you want to upgrade or downgrade the bias ratio, you can buy the preload springs to retune the unit.

Before you remove the original carrier from the axle, it's vital to check the ring gear backlash. That gives you the benchmark test measurement for reproducing the original gear pattern.

Before you remove the original carrier from the axle, it's vital to check the ring gear backlash. That gives you the benchmark test measurement for reproducing the original gear pattern.

We installed the HPS unit into the 10.25-inch semi-floating axle of our 2005 F-150HD. Auburn is one of the few companies to offer a LSD for this rare axle. The install was performed at Auburn's factory in (where else?) Auburn, Indiana, by product engineer Mike Ahlersmeyer and lab tech Phil Bryan. The installation is within the realm of the home wrencher with some experience and the ability to follow directions. A few special tools are needed, including a dial indicator, micrometer, and a torque wrench. Every axle comes apart a little differently, so consult your service manual for the exact procedures and necessary tools. The installation part of the story is covered in pictures, and we give you the important general instructions/tips that would apply to all axles.

Following the installation, the truck went from leaving one strip of black rubber on the pavement to leaving two! Since it's a farm truck, it seldom sees the trail, but getting into the woods for firewood cutting or across a muddy field are very important jobs. Slippery conditions had been stymieing the truck at various times around the farm, even in four-wheel drive. No more-the Auburn LSD is more than enough to give it the edge it needs to go through snow as deep as the front bumper. Best of all, the unit is practically transparent on dry roads. On icy roads you don't feel it much either, but instead of spinning one tire on a snowy road, as open-diff pickups are prone to do with even a light touch on the pedal, the truck now grips-and goes. The 2.5:1 bias ratio seems to be about a perfect dial-in for this truck on winter roads, because we're not experiencing much squirreliness at all.

The carrier caps must be returned to their original positions, so mark them before disassembly. The easy way is to use a punch: one mark for one side and two for the other.

The carrier caps must be returned to their original positions, so mark them before disassembly. The easy way is to use a punch: one mark for one side and two for the other.

Mini-glossary

Torque Bias Ratio: Also known as bias ratio (:1). The amount of total driveline input torque that can be sent from the low- to the high-traction tire. Using a 3:1 bias ratio as an example, if the low-traction side can support 100 lb-ft (a sum of available traction plus the braking action of the LSD), then 300 lb-ft can be transferred to the high-traction side.

Traction: The translation of wheel torque into forward movement.

Tire Grip: Also known as traction torque. The amount of torque the ground surface and tire can support before slipping.

Six Tips for Maximizing the LSD Experience

To minimize tire "barking" in turns, coast around corners or use minimal throttle. More throttle increases the gear separation force on the clutches and the amount of torque needed to slip the clutches for differentiation around a turn.

With wide differences in tire grip, side to side, and a heavy load, the LSD may be overcome and the low-traction tire will still spin. You can augment the braking power of the LSD clutches by applying the parking brake (if it operates on the rear wheels), or by brake pedal modulation (a gentle on/off of the brake pedal). The parking-brake trick is preferable because it does not increase rolling resistance by also braking the front tires.

When you pull the carrier, it's vital to keep the shims separated so you know which side they were on originally. Sometimes, depending on which type of axle you have, you can reuse the original shim packs, and sometimes not. No matter what, mark the original shims so you know the dimensions. In this case, we replaced the original one-piece shims with Randy's Ring & Pinion Super Shims. The kit comes with two hardened faces between which you stack smaller shims to make up the exact total thickness you need. That eliminates the need for lots of shims in stock.

When you pull the carrier, it's vital to keep the shims separated so you know which side they were on originally. Sometimes, depending on which type of axle you have, you can reuse the original shim packs, and sometimes not. No matter what, mark the original shims so you know the dimensions. In this case, we replaced the original one-piece shims with Randy's Ring & Pinion Super Shims. The kit comes with two hardened faces between which you stack smaller shims to make up the exact total thickness you need. That eliminates the need for lots of shims in stock.

If a bias ratio of 3.5:1 isn't enough (especially in a light rig), consider a locker. In most cases, an automatic locker is much more livable on the street than a very high bias-ratio LSD.

With any given bias ratio, a light vehicle will be more affected in the drivability department than a heavy one-and vice versa. On the other hand, the higher bias on the light vehicle will deliver better traction in the dirt than it will on the heavy one.

Low-bias LSDs are best for front axle use so as not to impede steering in tight quarters.

The LSD is a good choice for terrain where the difference in traction side to side is typically not huge-mud, snow, sand, etc. Very uneven rock with tire lifting is the worst venue for it (though it can be augmented via the techniques listed above). To improve lifted tire performance significantly requires a high-bias unit or a locker.

PhotosView Slideshow