Ali Mansour

Brand Manager, 4WD & Sport Utility

Photographers:

Steve Temple

Ali Mansour

Brand Manager, 4WD & Sport Utility

Photographers:

Steve Temple

We all know that the new breed of diesel trucks is fast, and with a little tuning you can pump out massive amounts of power. But how does all that newfound performance transmit through your stock transmission? In most cases the answer is, "Not very well." When the stock transmission was engineered there were specific tolerances set in place that limit the amount of power that the components can handle. From your torque converter to the output shaft, a certain intensity is reached where slippage occurs. Damage results from trying to inadequately control whatever power increase that you are attempting to send through the stock components.

Not all transmissions are built alike, and the upgrades needed on one type of transmission may not be true for another. When we started building our '06 Dodge Ram 2500 with the 5.9L Cummins, we knew that it wouldn't be long before all that newfound power ("Turbo 2 Go," "Power Atop Power," "Easy Diesel," Sept. '07) would start showing the telltale signs that our transmission was on its way out. Good indicators that your automatic transmission might be damaged are prolonged shift intervals; jerking when the truck is under load; slippage, which you can usually tell by increased rpm accompanied by only a slight increase in speed or movement; and transmission fluid that appears or smells burnt.

To prevent our daily driver/weekend hauler from leaving us stranded, we gave the transmission experts at North America Diesel Performance (NADP) a call and explained what the truck was primarily used for and the power levels we were hoping to achieve. They suggested replacing the stock unit with one of their Heavy Hauler series transmissions. This complete replacement transmission includes a triple-disc billet torque converter, heavy-duty input and output shafts, and a full array of billet internals to give our truck's transmission the ultimate balance of strength and reliability. With our truck sporting 35-inch tires and 4.10 gears we needed to make sure that the added rolling resistance wouldn't be a detriment to our new transmission. Luckily for us this is something NADP deals with regularly, and thus they built a transmission that would assure us of solid shifting and holding while towing heavy loads.

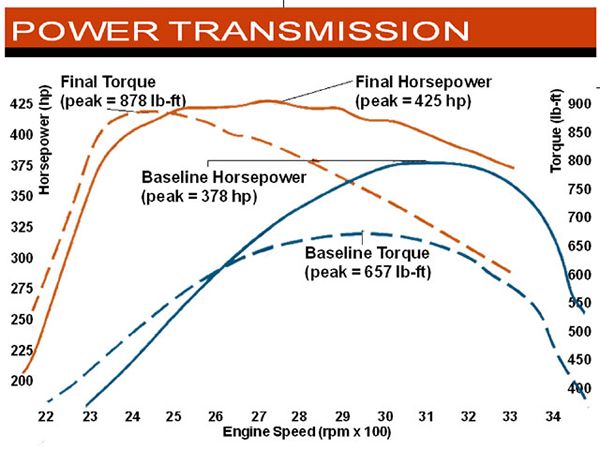

We put our transmission(s) through a series of tests including before and after dyno runs and towing tests to note overall shifting characteristics. We were amazed at how much of a difference a built transmission could make. No longer were we experiencing slippage or power loss as the 800+ lb-ft made our four-door diesel feel like a rocket, but it also didn't snap our neck every time it needed to shift. For the installation we drove over to Inglewood Transmission where Mike Lovrich and his team of knowledgeable transmission masters installed our new 48RE transmission and gave us a look into the damage that happens to a stock transmission when power levels are heavily increased over stock.

PhotosView Slideshow

PhotosView Slideshow