Cryogenics, or deep freezing, has long been revered as a secret weapon for professional rock racers, Trophy Truck teams, and several other real-world professionals outside the four-wheeling community. In short, cryo treatment is a process by which metal is subjected to extremely cold temperatures as low as minus 301 degrees Fahrenheit. The process works on anything made of metal. The time it takes to treat a part relates directly to its mass. Most small parts, such as axles, gears and U-joints, can be treated in several hours' time. The results are, in the simplest of terms, stronger, more durable metal with a much higher yield strength. This begs the question: Why don't all manufacturers treat each and every axle, gear, bearing, or other drivetrain component before assembly? The answer lies in the cost of the process.

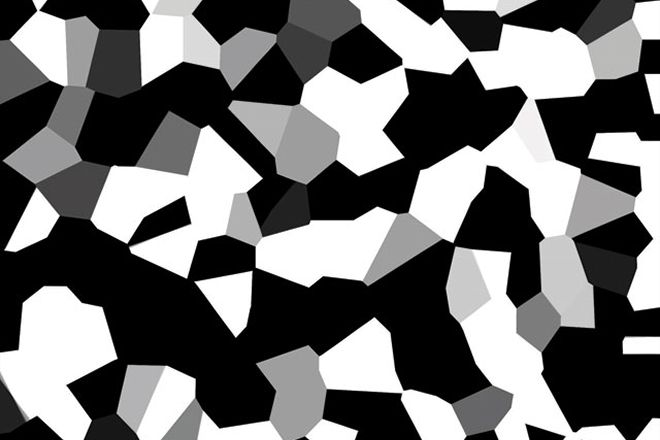

All metal parts have a specific grain structure to them. Think of it like this: Steel under a microscope has thousands of little divisions that interlock together, forming what appears to the naked eye as one uniform metallic part. Here is an example (Fig. A) of what untreated steel might look like under intense magnification.

Fig. A, Austenite

Notice the long disorganized lines revealing very little complexity in grain structure. This is referred to as austenite. Austenite is a solid solution of carbon and iron that is formed during the quenching phase of metal production. Austenite is weak because it contains few molecular interfaces to help hold the metal together. To demonstrate this, place both of your index fingers together so that the fingertips interlock. Note the amount of force or effort that is required to pull the two fingers apart. Now repeat the same process, but instead interlock all of your fingers together. It doesn't take a rocket scientist to understand that more interlocking surface equals greater strength. When metal is treated cryogenically, the austenite structure is transformed slowly into a highly organized grain structure called martensite. Here is an example (Fig. B) of what martensite would look like under a powerful microscope.

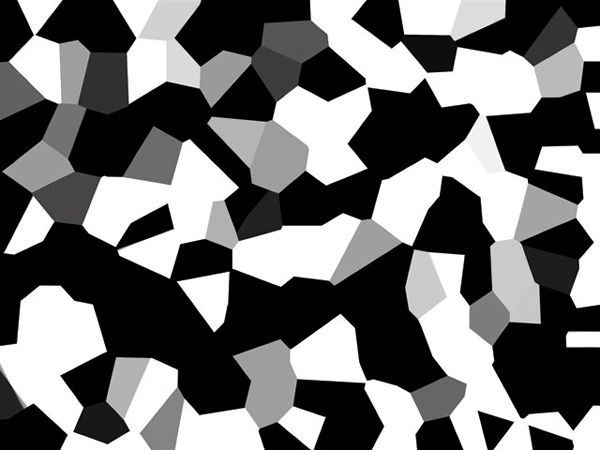

Fig. B, Martensite

Martensite is also formed during the quenching phase. However, its concentration in a given mass is a direct function of the lowest temperature encountered during the process. Typically, metal is formed at atmospheric temperature and pressure. Due in part to the techniques currently employed by large-scale metal manufacturing operations, mass-produced metal is quenched the least expensive way possible. This cost savings is good for consumers who don't rely on metal components to get them home after a long day on the trail. At any given temperature of quenching, there is always a certain amount of martensite present, but prior to cryo treatment, the ratio of strong martensite to weak austenite is less than favorable. This untransformed austenite is brittle and lacks dimensional stability, which allows the metal to break more easily under loads. To eliminate austenite, the quenching temperature has to be lowered. At very low temperatures, austenite is unstable and readily becomes martensite.

Improvement in durability (i.e., resistance to wear and fatigue) is around 100 percent (that's double). The typical increase in strength is 30 to 50 percent. As you might imagine, these results can dramatically reduce broken part expenditures. In fact, typical results are a doubling of the time between engine rebuilds, replacement of disc-brake rotors, and gears. Another advantage of cryogenic treatment is the increase in efficiency to dissipated heat. This means engines, transmissions, disc brakes, and gears run cooler.

Some of you may remember our Ultimate Unlimited buildup (Aug. '06). This Jeep LJ received a healthy dose of aftermarket parts including larger tires, high-strength axleshafts, and cryo-treated U-joints. While testing the rig out in Moab during Easter Jeep Safari last year, we experienced a rear ring-and-pinion failure. This didn't surprise us one bit as standard off-the-shelf gears were no match for the torque loads that Moab's slickrock trails combined with an aggressive right foot. Once back in California, we scored a new set of gears from Yukon and shipped them to our friends at Cryo Science of Oceanside, California.

* Once treated, disc-brake rotors and pads last up to three times longer.

* Ring-and-pinion gears last up to twice as long.

* Automatic transmissions run up to 50 degrees cooler.

* Engine internals, rings, and main and rod bearings last up to two times longer.

* Treatment can increase valve spring rates 1 to 3 percent.

* The yield strength of a U-joint can increase service life nearly two-fold.