Jerrod Jones

Former Editor, Off Road

Jerrod Jones

Former Editor, Off Road

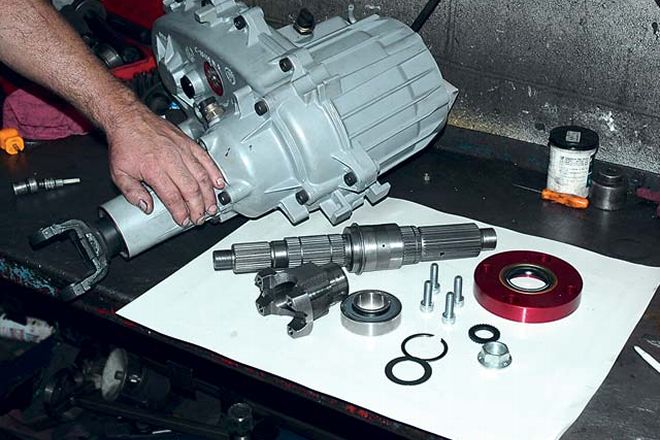

The best way to fix the slip-yoke on the back of your transfer case is to get rid of it. Period. There's really no advantage to having a slip-yoke on your NP231J, 231C, 231HD, 241C, 241D, or 243 with the exception of cheaper driveshafts and the fact that you already have one (if you do). And though a fixed-yoke conversion kit (aka slip-yoke eliminator or SYE) like this one from JB Conversions is a great thing to have, you must ask yourself if it is worth it. Slip-yoke tailends on transfer cases have absolutely nothing wrong with them under normal driving conditions, and are every bit as strong as the alternative. And besides the cost of the fixed-yoke kit (usually $200-$350, depending on what transfer case), you should also remember to include the cost of the new driveshaft with a slip-yoke (you must either have a slip-yoke on the driveshaft or transfer case to allow for suspension cycling and differentiating lengths as that occurs).

But even with the added cost, you want one, trust us. With a fixed yoke, you can damage your rear driveshaft, remove it, and still drive home in front-wheel drive. It also lets you run a longer driveshaft-or even a CV-joint-driveshaft for better driveshaft angles and less vibration. The major problem (and really the only one) with a slip-yoke on the back of a transfer case is that it will fall out of the back of the transfer case and you'll lose your gear oil if you pull the rear driveshaft.