It’s nice to have project cars as a part of telling the story of race car technology. We have presented many how-tos using project cars that have rarely raced, at least not with our help and guidance. The Project Modified is different. We got our hands dirty on this one. And we applied all of the wisdom that we impart on you, the racer.

This started out as an engine build project with a motor that was being built by Koury Racing Engines in Deland, Florida, for Dick Anderson’s new Florida rules asphalt modified. Anderson wanted to return to driving a race car and decided on the modified division. He had been maintaining and setting up area modifieds for a few years already and the cars have done very well.

The Koury Engines race motor is nicely packaged into the hand-painted body and lefthander frame. Anderson spent a good six months putting this all together and didn’t spare any details.

The Koury Engines race motor is nicely packaged into the hand-painted body and lefthander frame. Anderson spent a good six months putting this all together and didn’t spare any details.

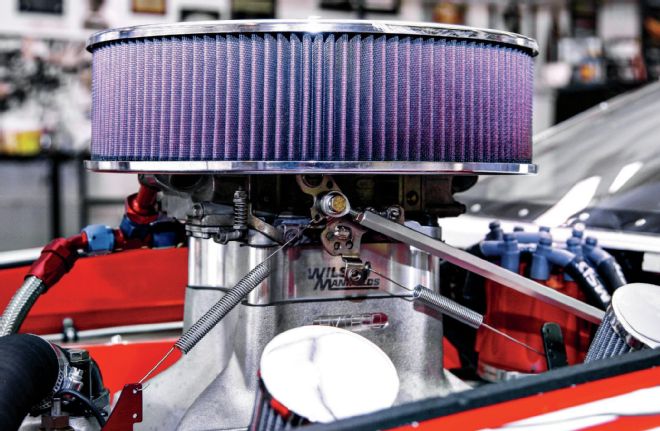

The Brodix intake manifold is topped by a Wilson Manifolds spacer. Note the dual return springs and large air cleaner.

The Brodix intake manifold is topped by a Wilson Manifolds spacer. Note the dual return springs and large air cleaner.

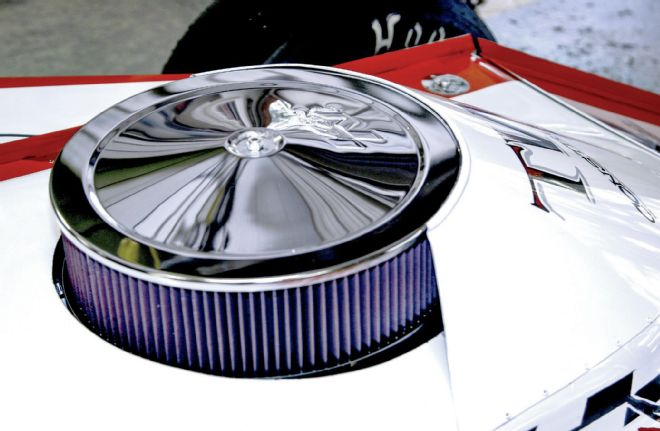

Note how the hood covers the front of the air cleaner. Anderson felt that allowing the air cleaner to be exposed to the oncoming air in flight would disturb the airflow into the carburetor. This configuration allows the air to flow more evenly into the engine.

Note how the hood covers the front of the air cleaner. Anderson felt that allowing the air cleaner to be exposed to the oncoming air in flight would disturb the airflow into the carburetor. This configuration allows the air to flow more evenly into the engine.

So, Anderson lost weight, worked out, and decided it was time to go racing once again. The car was completed, engine installed, setup run and installed, and we went testing at New Smyrna Speedway. This was in preparation for the annual Governors Cup races that draw a large number of participants from around the Southeast and Midwest.

The modified race was scheduled to be run on Saturday as a support race, and was listed as a 100-lap, $5,000 to win race that drew a good number of participants. So, Anderson decided that for him to return after a long layoff and run a serious race with top-notch contenders would be maybe a bit tough, so he enlisted Augie Grill to drive the car.

Our testing, with Anderson at the wheel, went very well and we quickly dialed the car in. Anderson said from the very first run that this was the best car he ever drove. “None of the late models that I have driven have ever been this good.” Our times were very good and about a tenth quicker than the previous modified race qualifying time, which was run just a few weeks prior.

This hinged door access panel helps the driver gain ingress and egress from the cockpit. It was simple to make but very effective. Even a driver with a smaller frame has difficulty accessing these cars. This makes it a whole lot easier and safer too.

This hinged door access panel helps the driver gain ingress and egress from the cockpit. It was simple to make but very effective. Even a driver with a smaller frame has difficulty accessing these cars. This makes it a whole lot easier and safer too.

There was no rule saying we couldn’t run an aluminum block in the modified class at New Smyrna, but once word got out, the tech officials felt they needed to even the playing field and said we needed to add 75 pounds to the front of the car in front of the flywheel. To get our front to rear percent the way we needed, we actually added 120 pounds to the front. So, we were well within the rules. The block made no more horsepower than a steel block and, some would argue, that it even makes less.

There was no rule saying we couldn’t run an aluminum block in the modified class at New Smyrna, but once word got out, the tech officials felt they needed to even the playing field and said we needed to add 75 pounds to the front of the car in front of the flywheel. To get our front to rear percent the way we needed, we actually added 120 pounds to the front. So, we were well within the rules. The block made no more horsepower than a steel block and, some would argue, that it even makes less.

We ran our Moment Center location on this car through a computer program. We found that the lower control arm angle was too much due to the spindle that was used for this chassis. So, we found a stock ball joint that gave us more length and that worked to take some angle out of the lowers. The upper arms were just what we needed and no alterations were made to those. We ran in the lower holes on both left and right upper links. That gave us about 16.5 degrees for the right upper angle and 25 degrees for the left upper angle. Our Moment Center, after dive and roll, was at minus 14.0 inches, or left of centerline.

We ran our Moment Center location on this car through a computer program. We found that the lower control arm angle was too much due to the spindle that was used for this chassis. So, we found a stock ball joint that gave us more length and that worked to take some angle out of the lowers. The upper arms were just what we needed and no alterations were made to those. We ran in the lower holes on both left and right upper links. That gave us about 16.5 degrees for the right upper angle and 25 degrees for the left upper angle. Our Moment Center, after dive and roll, was at minus 14.0 inches, or left of centerline.

There were still a few things to improve. Our brakes were out of balance with too much front brake. So, we switched the master cylinders for the test and ended up installing same-sized masters for the race. We ended up with 1.00-inch masters, which produced a 600-pound front pressure and 400-pound rear pressure on hard braking.

Anderson had gotten a little creative on the bodywork and once we arrived at the track for practice the day before the race, tech told us to tone it down and we had to trim some of the nice-looking, but outside the rules, bodywork. Anderson swears it didn’t help the car, only the appearance, but word had gotten around about our lap times in testing and all eyes were on this car from the get-go.

The draglink design for this car had a screw type of height adjustment on the right side and we spaced the link on the left side for zero bumpsteer. We also checked the front suspension for Ackermann and it had none with the stock spindles we were using.

The draglink design for this car had a screw type of height adjustment on the right side and we spaced the link on the left side for zero bumpsteer. We also checked the front suspension for Ackermann and it had none with the stock spindles we were using.

The stock brake calipers were painted by Anderson to reflect the paint scheme for the car. Where too much red would overpower the look, he chose a gray color for the springs and fuel cell. He really has an eye for a good-looking car.

The stock brake calipers were painted by Anderson to reflect the paint scheme for the car. Where too much red would overpower the look, he chose a gray color for the springs and fuel cell. He really has an eye for a good-looking car.

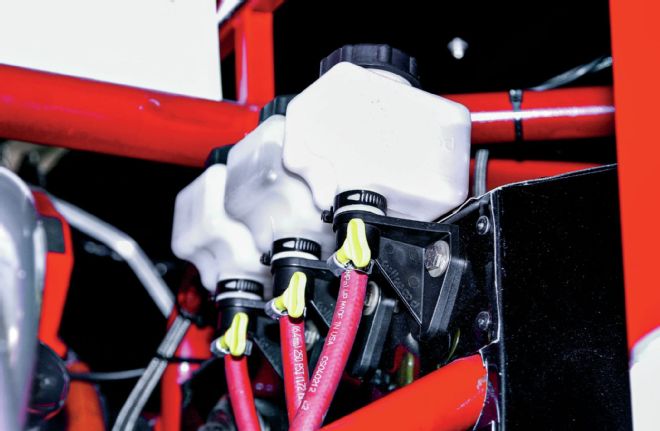

The brake master cylinders needed to be changed on this car because we were getting way too much front pressure. For our test, we switched the masters and that helped. For the race, we installed two 1-inch masters and the pressures worked out to be 600 psi on the front and 400 psi for the rear under heavy brake application.

The brake master cylinders needed to be changed on this car because we were getting way too much front pressure. For our test, we switched the masters and that helped. For the race, we installed two 1-inch masters and the pressures worked out to be 600 psi on the front and 400 psi for the rear under heavy brake application.

Then we had to find a driver once we arrived on Friday. Grill had been on a cruise with his family until Thursday and was still in Miami on Friday. So, Anderson made a tactical move and asked Jerry Symons if he would take the car out and test it. Symons is the current points leader in the modified class at NSS and one of the most experienced drivers for this class by far.

Both Anderson and I have known Symons and his crew for a lot of years and even though we would be competitors, the friendship cuts through all of the off-track drama. Symons took his own car out for the entire first practice. Then he came over to our pit and ran our car about 10 or so laps once he was confident of the brakes and how it steered.

The tires we had on were stickers during the test the week before and had about 30 or 40 laps on them. I’m not sure of Symons’ tires on his car, but when we timed him, he was about 21/2 tenths quicker with our car and he was well below the time he set for qualifying on the pole in the last race. There could have been a difference in tires that caused our car to be quicker, but it was what Symons told us after he got out of the car that was significant. He said, “This is the best car I’ve ever driven,” the very same comment we heard from Anderson a week earlier.

Anderson installed Penske steel non-adjustable shocks on the car by rule. The comment by Jerry Symons about how well this car drove could be attributed, at least in part, to the shock package.

Anderson installed Penske steel non-adjustable shocks on the car by rule. The comment by Jerry Symons about how well this car drove could be attributed, at least in part, to the shock package.

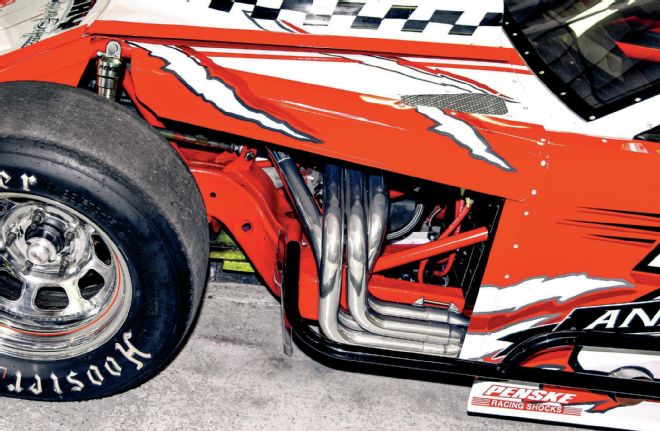

The Schoenfeld-coated headers improved the already great look of this car. Note the fancy graphics. The entire car was hand painted, as are all of Anderson’s cars. Even the CT logo at the rear was painted on and not one of our stickers.

The Schoenfeld-coated headers improved the already great look of this car. Note the fancy graphics. The entire car was hand painted, as are all of Anderson’s cars. Even the CT logo at the rear was painted on and not one of our stickers.

What I wanted to do here is present a photo essay and tell you how we built and set up this car. There are no tricks or special parts. The rear differential is a spool, very simple and cannot go wrong. The spindles and chassis parts are stock as they must be to meet the rules package. We built an aluminum block motor that we detailed in our motor build series over a three-month period. We didn’t save weight up front in the car because we had to add over 120 pounds to get our front to rear percentage right. The block only ran about 80 pounds lighter than a steel block.

Unfortunately, the weather did not cooperate and the race got rained out, to be rescheduled for a later date. We are still up in the air as to where we will race this car next, but we’ll be documenting that when it happens. Nonetheless, we were very pleased with the whole package, motor, setup, and driveability.

We insisted that if Anderson were to run our car as a CT project car, he had to wear a full face helmet and a head and neck restraint. After trying several brands, he chose the RaceQuip helmet because it fit his unusually shaped head much better. If you’ve ever met Anderson, you’ll understand. If your driver has a larger than average head with square temples, this might be the helmet for you.

We insisted that if Anderson were to run our car as a CT project car, he had to wear a full face helmet and a head and neck restraint. After trying several brands, he chose the RaceQuip helmet because it fit his unusually shaped head much better. If you’ve ever met Anderson, you’ll understand. If your driver has a larger than average head with square temples, this might be the helmet for you.

What we did was check our Ackermann and it was near zero without any changes, check our roll/Moment Center location, and install stock lower ball joints that were a bit longer than what was installed previously. We squared the rearend, set our trailing arms for near zero rear steer, and weighed the car.

Within these pages is a rundown of all of the parts and what we did to get this project car ready for competition. This is a lefthander modified chassis that was manufactured in 2004, but never raced or even built out. Anderson found the car and decided to make it his new car. And we decided to make it one of our project cars. While we figure out where this car is going to make its competitive debut, check out the finished product.

Once on the track, we had a chance to see what the setup would do. Our lap times were very good, a tenth or so faster than the previous pole time for New Smyrna, and Anderson could hold it down on the line through Turns 3 and 4. Our bite up off the corner was excellent and Anderson said it was the best car he’d ever driven.

Once on the track, we had a chance to see what the setup would do. Our lap times were very good, a tenth or so faster than the previous pole time for New Smyrna, and Anderson could hold it down on the line through Turns 3 and 4. Our bite up off the corner was excellent and Anderson said it was the best car he’d ever driven.