Beading machines are one of the most versatile tools around, and are ideal for doing edging and detail work on sheetmetal panels. They are known by many names—bead rollers, beading machines, bench machines, rotary machines, Jennies, and swaging machines—but they all have one distinguishing feature: a pair of round dies that are used to roll distinct shapes into sheetmetal panels.

There is a broad range of machines available, both manual and power-operated, starting at less than $200, with prices topping $7,000 for some high-end machines. With such a broad range of offerings, how do you decide which machine is right for you? In this article, we'll take a look at several different machines, explore their features, and demonstrate a number of the processes these versatile machines excel at.

For many buyers, price is an important consideration. With a minimal investment, you can get started with a machine that will make beads and steps, which are the two features these machines are used for most often. Be sure that you get a machine that works with the metal thickness you will be using, and check that the throat depth of the machine is adequate for your application. A machine with a 24-inch throat will reach the center of a 48-inch piece of metal, which will allow you to make fullsized floorboards, and should be large enough for nearly any automotive project. If you don't plan to make such large panels, a machine with a smaller throat may fit your needs nicely.

Having a machine powered by an electric motor offers some important benefits. It lessens the effort of hand cranking the machine, but more importantly, it allows you to keep both hands on the work, which is extremely important for delicate work. Store-bought machines with an electric motor usually cost over $1,000, but a clever builder could easily adapt a motor to an existing machine. It's highly desirable to have a speed control for the motor. Some machines have a dial to control the speed, but it's even better to have a foot pedal that can adjust the speed “on the fly”, so you don't have to take your hands off the work.

If you have access to a lathe, you can make your own dies, but of course it's a lot more convenient to purchase ready-made dies. For that reason, you should carefully evaluate the dies available for any machine you are considering. Most dies are made of steel, but for some operations plastic dies may be preferable. One example is when working with soft metals, like aluminum. Plastic dies are far less likely to mark aluminum panels, so keep that in mind as you are shopping. A recent development in beading machine operation makes use of a flat, soft urethane die (like a skateboard wheel), which is ideal for certain uses, such as embossing.

The beading machine is a key piece of equipment in many street rod shops, and I'm amazed at the ways clever builders develop new designs of bead-rolled patterns, and their discovery of new processes and tooling. You'll see a few types of unusual tooling in this article, such as a simple fixture that allows you to roll rings from tubing or sheetmetal shapes.

While function drives many of the applications of the beading machine, very often you can incorporate a distinctive design element in the work you do, and a few free-thinking individuals are doing amazing artwork with these versatile machines. Let your imagination soar as you plan future projects for the beading machine, and I'd love to see any innovations that you develop.

Beading machines come in many sizes and styles. They utilize round upper and lower dies, which enable them to form strong, beautiful details on panels.

Beading machines come in many sizes and styles. They utilize round upper and lower dies, which enable them to form strong, beautiful details on panels.

This is the Eastwood beading machine. It comes with three beading dies and three step dies, making it quite versatile—and it’s very affordable! It’s designed to be held in a vise, or you can build a simple stand for it.

This is the Eastwood beading machine. It comes with three beading dies and three step dies, making it quite versatile—and it’s very affordable! It’s designed to be held in a vise, or you can build a simple stand for it.

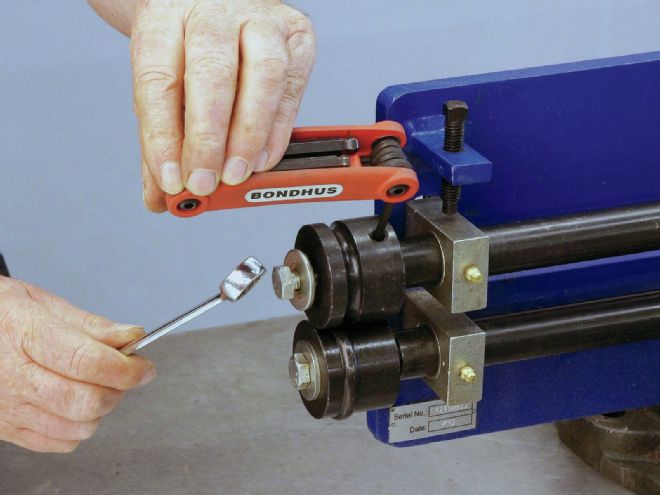

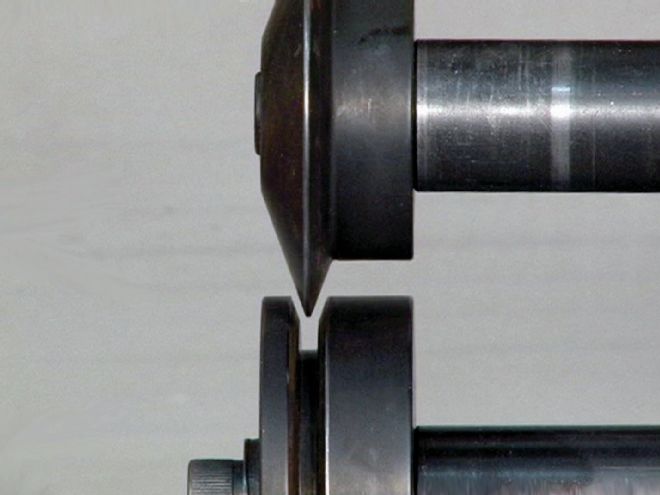

The dies are held tightly to the machine’s shafts with a bolt and a set screw. This holds them securely, and makes it easy to make die changes.

The dies are held tightly to the machine’s shafts with a bolt and a set screw. This holds them securely, and makes it easy to make die changes.

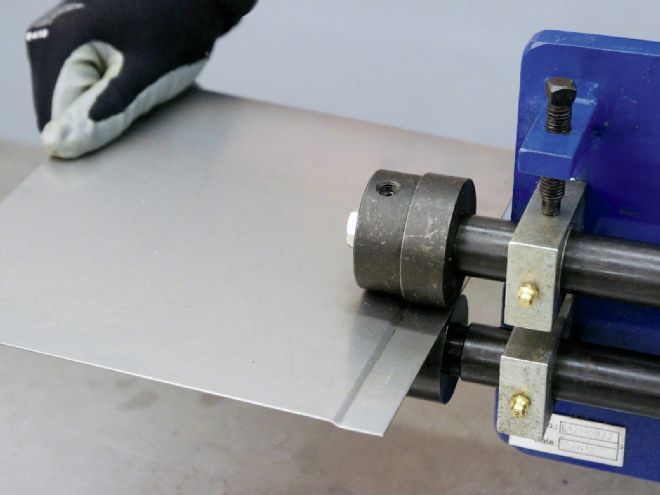

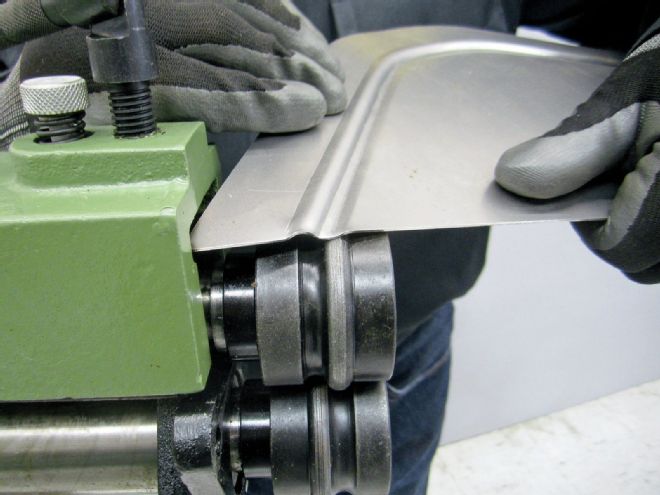

The 1/16-inch step die is being used here. This is ideal for stepping the edge of patch panels, allowing them to fit flush, and easing the fitting for welding.

The 1/16-inch step die is being used here. This is ideal for stepping the edge of patch panels, allowing them to fit flush, and easing the fitting for welding.

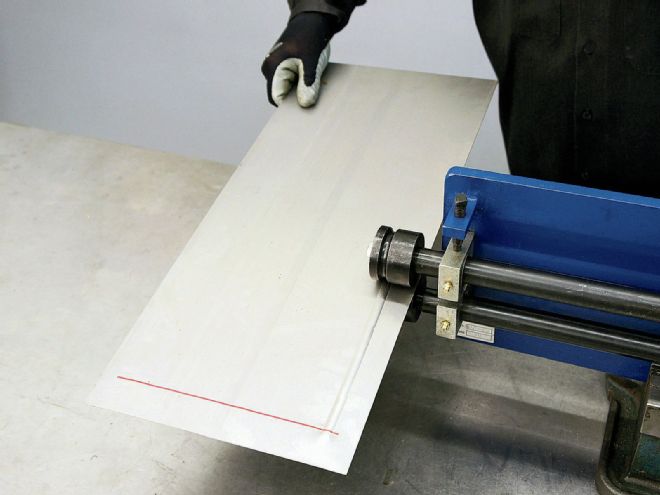

A larger step die can be used for strengthening panels, or for matching a stepped detail on a replacement panel.

A larger step die can be used for strengthening panels, or for matching a stepped detail on a replacement panel.

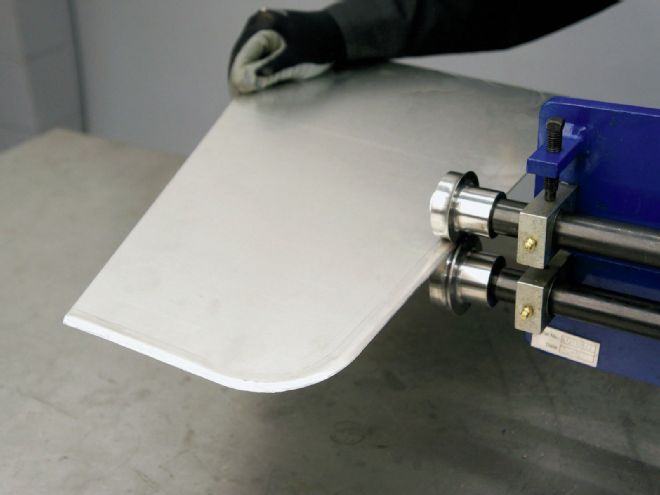

Beading dies are commonly used for strengthening panels, such as floorboards and firewalls. They can also add an interesting design element to panels that will be exposed.

Beading dies are commonly used for strengthening panels, such as floorboards and firewalls. They can also add an interesting design element to panels that will be exposed.

An edge guide makes it easy to position steps or beads with accuracy. These work well on straightedges and outside curves.

An edge guide makes it easy to position steps or beads with accuracy. These work well on straightedges and outside curves.

Different dies can be adapted to the Eastwood machine by using a sleeve on the shaft, as long as they have bore larger than the shaft.

Different dies can be adapted to the Eastwood machine by using a sleeve on the shaft, as long as they have bore larger than the shaft.

This is an accessory “rounding-over” die that puts a radius on the edge of a panel. This is a great way to give a finished look to the edge of panels.

This is an accessory “rounding-over” die that puts a radius on the edge of a panel. This is a great way to give a finished look to the edge of panels.

This is an imported beading machine with a cast-iron body. While the throat depth is limited, the cast-iron construction makes it a very stiff and versatile machine.

This is an imported beading machine with a cast-iron body. While the throat depth is limited, the cast-iron construction makes it a very stiff and versatile machine.

Here, a 1/2-inch radius rounding-over die has been fitted to the machine in preparation for making the end cap for a tank with rounded edges.

Here, a 1/2-inch radius rounding-over die has been fitted to the machine in preparation for making the end cap for a tank with rounded edges.

The rounding-over dies have a stop on the lower die that acts as a guide for the metal edge. This allows it to accurately follow edges with any shape, even inside curves.

The rounding-over dies have a stop on the lower die that acts as a guide for the metal edge. This allows it to accurately follow edges with any shape, even inside curves.

All four edges of this tank cap have been curled, and I’m laying out the location of the beads for the center of the panel. A roll of tape makes a handy radius template for the corners.

All four edges of this tank cap have been curled, and I’m laying out the location of the beads for the center of the panel. A roll of tape makes a handy radius template for the corners.

I’m using a 5/16-inch bead on this panel. An edge guide is used for the straight sections, and the rounded corners are done freehand.

I’m using a 5/16-inch bead on this panel. An edge guide is used for the straight sections, and the rounded corners are done freehand.

This is the finished tank, with the end cap welded into place and sanded smooth. This is a great way to make a very professional-looking part!

This is the finished tank, with the end cap welded into place and sanded smooth. This is a great way to make a very professional-looking part!

Beads are often used for stiffening panels. This is an “ogee” die, which essentially forms one bead up and one bead down, strengthening a panel much more than a single bead.

Beads are often used for stiffening panels. This is an “ogee” die, which essentially forms one bead up and one bead down, strengthening a panel much more than a single bead.

This is a vintage Pexto brand machine, an old standby for metal fabricators.

This is a vintage Pexto brand machine, an old standby for metal fabricators.

A 5/8-inch beading die has been fitted to the machine, and it’s being used to make a bead on 18-gauge steel. This is slightly over the capacity for this machine, so it will take several passes to reach full depth.

A 5/8-inch beading die has been fitted to the machine, and it’s being used to make a bead on 18-gauge steel. This is slightly over the capacity for this machine, so it will take several passes to reach full depth.

I’m making a cycle-style fender here, and I’m checking the fit of the fender side panel against the curved center strip.

I’m making a cycle-style fender here, and I’m checking the fit of the fender side panel against the curved center strip.

One-and-a-half-inch radius rounding-over dies have been fitted to the machine, and the edges of the fender center and side panels are run through the machine.

One-and-a-half-inch radius rounding-over dies have been fitted to the machine, and the edges of the fender center and side panels are run through the machine.

After being curled, the edges of the panels are worked with a shrinking machine to pull them into the proper shape.

After being curled, the edges of the panels are worked with a shrinking machine to pull them into the proper shape.

The parts are carefully fitted with a butt joint, and tack welded together.

The parts are carefully fitted with a butt joint, and tack welded together.

The panels have been finish welded and metal finished. The rounding-over dies are great for this type of work.

The panels have been finish welded and metal finished. The rounding-over dies are great for this type of work.

Here, the edges of the fender have been trimmed and folded over to create a hemmed edge for strength and safety. Fenders of this style can be used on street rods, too!

Here, the edges of the fender have been trimmed and folded over to create a hemmed edge for strength and safety. Fenders of this style can be used on street rods, too!

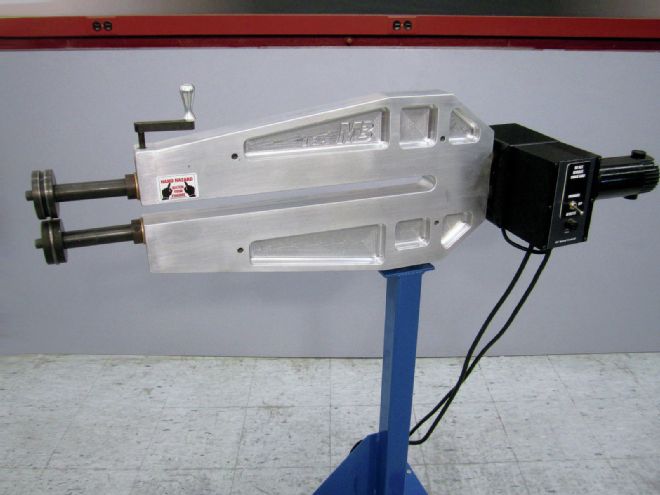

This is a beading machine from Mittler Brothers. They are made in various sizes and styles. This is a 24-inch throat machine, which has a billet aluminum frame and an electric motor drive.

This is a beading machine from Mittler Brothers. They are made in various sizes and styles. This is a 24-inch throat machine, which has a billet aluminum frame and an electric motor drive.

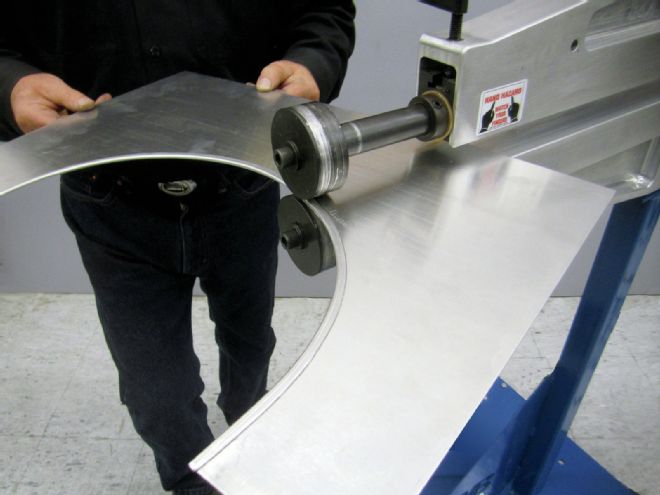

Here I’m using a 3/16-inch beading die to make an oval number plate. Having a power drive allows me to keep both hands on the work, which is extremely beneficial for making accurate beads.

Here I’m using a 3/16-inch beading die to make an oval number plate. Having a power drive allows me to keep both hands on the work, which is extremely beneficial for making accurate beads.

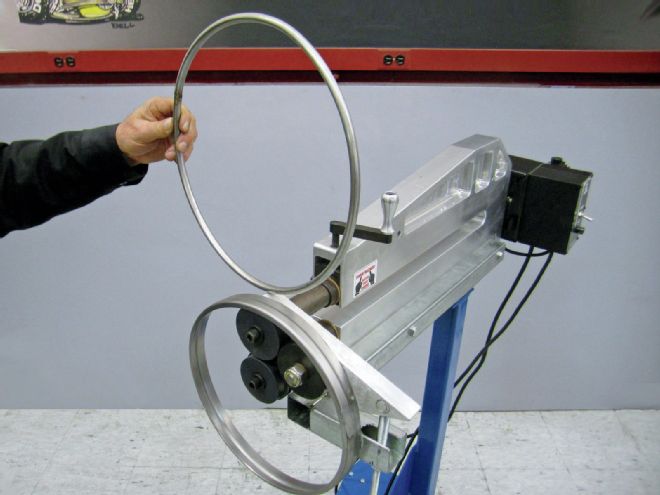

Here’s a way to use a machine to make arcs or rings from tubing or sheetmetal. Two idler dies have been mounted to the upper shaft, and the lower die rolls the work between them, creating an accurate curve.

Here’s a way to use a machine to make arcs or rings from tubing or sheetmetal. Two idler dies have been mounted to the upper shaft, and the lower die rolls the work between them, creating an accurate curve.

Here is a piece of tubing and a flanged strip of sheetmetal that have been rolled into accurate rings with this shop-built tooling for the beading machine.

Here is a piece of tubing and a flanged strip of sheetmetal that have been rolled into accurate rings with this shop-built tooling for the beading machine.

Mittler Brothers offers a nice three-stage set of dies that makes it quick and easy to form a hem. The first die set forms a 90-degree flange.

Mittler Brothers offers a nice three-stage set of dies that makes it quick and easy to form a hem. The first die set forms a 90-degree flange.

Here I’m forming a 90-degree flange around an edge with an inside curve. The lower die has a step that the edge of the metal is guided against, making it easy to get a consistent flange width.

Here I’m forming a 90-degree flange around an edge with an inside curve. The lower die has a step that the edge of the metal is guided against, making it easy to get a consistent flange width.

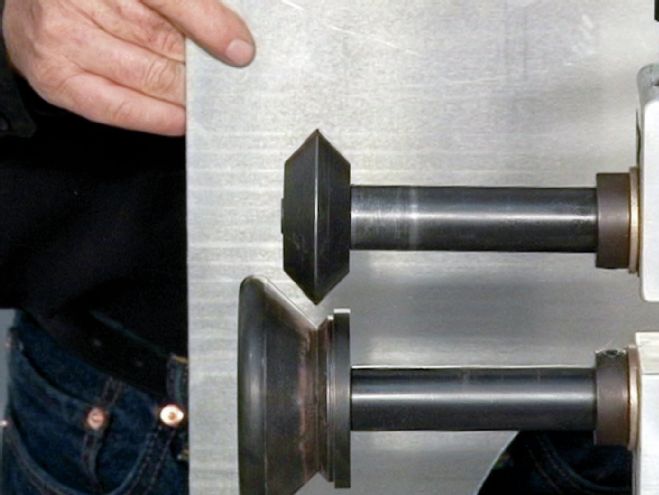

The next die set takes the 90-degree flange and forms it to an acute angle. The peaked edge of the top die is guided along the root of the previously formed flange, making it sharper.

The next die set takes the 90-degree flange and forms it to an acute angle. The peaked edge of the top die is guided along the root of the previously formed flange, making it sharper.

Flat dies are used to flatten the hem, making a nice, neat, strong edge with a beautifully finished appearance.

Flat dies are used to flatten the hem, making a nice, neat, strong edge with a beautifully finished appearance.

This is the very versatile Lazze machine with about 40 different die sets available.

This is the very versatile Lazze machine with about 40 different die sets available.

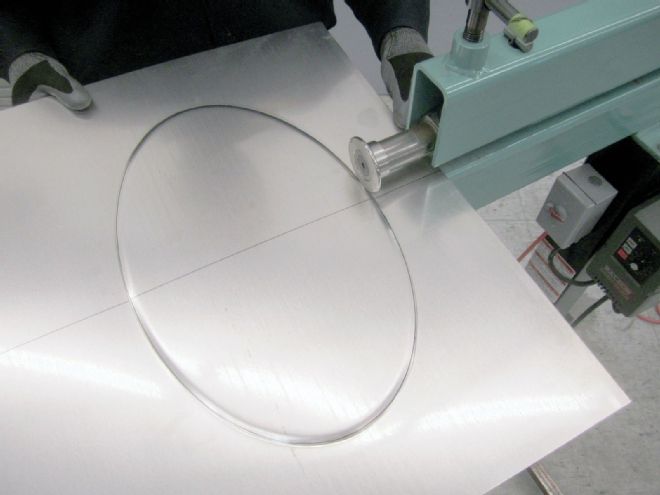

I’m using small rounded dies on both the top and bottom shaft to make an oval recess for a door panel.

I’m using small rounded dies on both the top and bottom shaft to make an oval recess for a door panel.

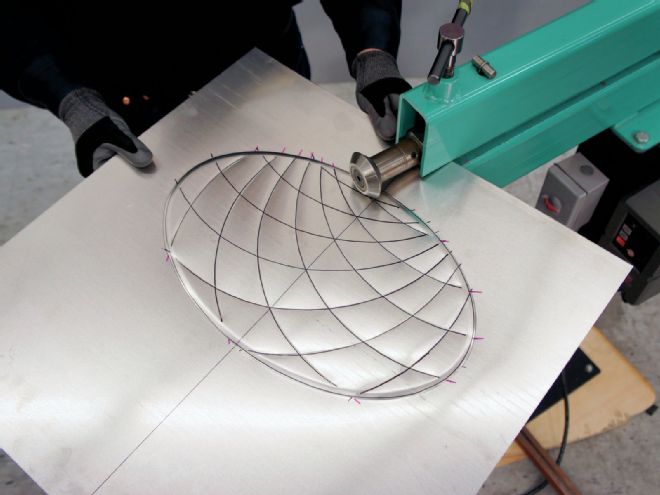

Using a peaked top die, and working against a soft urethane bottom die, I’m making embossed character lines in the recessed oval portion of the door panel.

Using a peaked top die, and working against a soft urethane bottom die, I’m making embossed character lines in the recessed oval portion of the door panel.

Using a 5/16-inch beading die, I’m putting more beads on the panel for the finishing touch.

Using a 5/16-inch beading die, I’m putting more beads on the panel for the finishing touch.

Here’s the completed door panel, made with fairly simple tooling. The design possibilities are unlimited for this type of work.

Here’s the completed door panel, made with fairly simple tooling. The design possibilities are unlimited for this type of work.

This is a beautiful custom seat made by Jamey Jordan, of the Handmade Seat Company, who created the steps and quilted pattern using his signature dies on the Mittler Brothers machine.

This is a beautiful custom seat made by Jamey Jordan, of the Handmade Seat Company, who created the steps and quilted pattern using his signature dies on the Mittler Brothers machine.

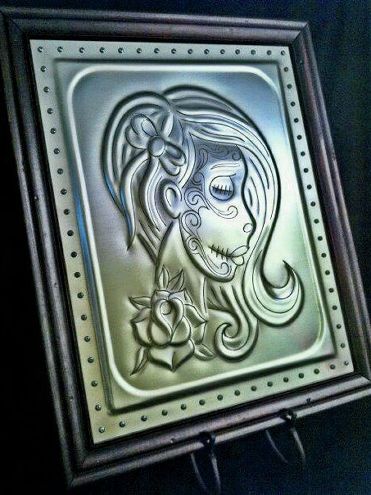

Jordan uses the beading machine to create true art pieces. This beautifully crafted example is designed to be hung on a wall. Your imagination is the only limit to what can be done with beading machines!

Jordan uses the beading machine to create true art pieces. This beautifully crafted example is designed to be hung on a wall. Your imagination is the only limit to what can be done with beading machines!

Ron Covell has made a 97-minute DVD on beading machines, which shows six different machines in action, and details a broad spectrum of the processes these versatile tools can be used for.

Ron Covell has made a 97-minute DVD on beading machines, which shows six different machines in action, and details a broad spectrum of the processes these versatile tools can be used for.