Hot rodding has always been a culture that richly rewards those with the creativity and acumen to build their own cars. Self-taught customizers—from Dean Jeffries out west to the Alexander Bros. in Detroit—are legends in our world. Today, fabricators are hailed as heroes on television. Painters are gawked at like demigods at car shows. Engine builders are the cool kids at the track. Hone any combination of these skills at home and you'll be the neighborhood kingpin, and save a ton of cash by doing things yourself. Better than fame or fortune, though, is the pride that comes from being able to say, "I built that."

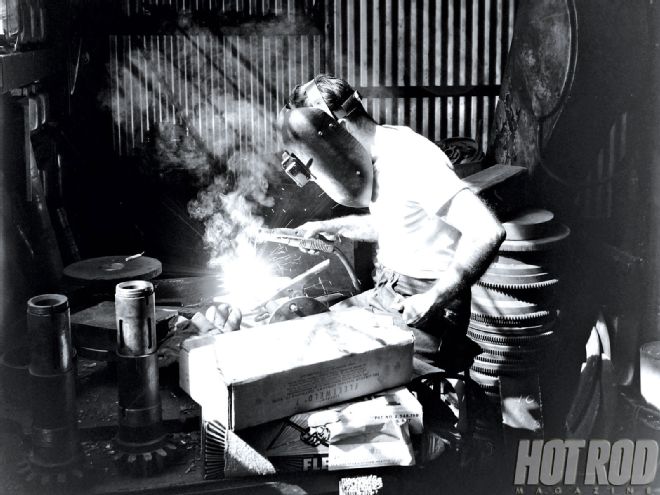

We know this guy is stick welding, but this 1958 photo by Eric Rickman from the HOT ROD archives is so cool we just had to run it.

We know this guy is stick welding, but this 1958 photo by Eric Rickman from the HOT ROD archives is so cool we just had to run it.

Learning to stick two pieces of metal together using electricity offers a sense of self-reliance that few skills can match, so we asked fans of the HOT ROD Facebook page (FaceBook.com/HotRodMagazine) what they wanted to know about buying their first wire-feed welder. The response was overwhelming. A cleanly executed weld of any type is a thing of beauty, and apparently it's a skill most hot rodders wish they had. The fact that you can buy a wire-feed welder for less than $200 at most chain auto parts and hardware stores makes it easy, and welding is useful, cool, and universal.

Although there are many different welding processes that can be used to build a hot rod, wire-feed is the easiest to master and the mostly widely used in our industry. A wire-feed welder works whether you are seated, standing, or lying on your back working upside down on the bottom of your hot rod. Whether connecting an exhaust system, installing a new quarter-panel, chopping a top, or grafting a new back half onto a chassis, a wire-feed welder can tackle the job neatly and quickly. Many of today's machines are portable and will run off the AC current found in most home garages, making them perfect for the home builder. In the hands of a master, a good welder will lay a sexy bead that will turn an ordinary car part into a show-quality mod.

Every welder consumes items like contact tips and wire. That’s an unavoidable expense. But, you won’t have to spring for the shielding gas and regulator if you’re on a tight budget—you can use flux-core wire, instead. Just know that the shielding gas will reduce weld splatter and make welding sheetmetal much easier.

Every welder consumes items like contact tips and wire. That’s an unavoidable expense. But, you won’t have to spring for the shielding gas and regulator if you’re on a tight budget—you can use flux-core wire, instead. Just know that the shielding gas will reduce weld splatter and make welding sheetmetal much easier.

Before mastering wire-feed welding and becoming the self-reliant hot rodder you always knew you could be, you'll need the right machine. The right machine is largely dependent on the type and size of material you'll weld on, the power available to run it, and your budget. Most automotive fabrication projects will involve mild steel varying in thickness from 24-gauge sheetmetal body panels to ¼-inch frame brackets like those found in aftermarket four-link suspensions. This article focuses on entry-level, 110-volt welders, most of them able to weld up to ¼-inch steel—if it's properly prepared and you are a competent welder. We have to point out that it's easier to weld thicker material with a higher-powered welder, such as a 220-volt model, but that's more expensive and requires a better power supply, so keep that in mind when shopping. There's no substitute for practice, experience, and skill when it comes to welding. A good fabricator can make safe welds no matter what kind of machine he is using.

220, 221: Whatever it Takes

There is some discrepancy between the common description of the available power supply in your home garage and the advertised specs for most welders. Welder manufacturers like to refer to their welders as 115-volt and 230-volt models instead of the 110-volt or 220-volt references we are accustomed to hearing. The thing to note here is that welders are designed to operate with a variance in input voltage, usually up to 10 percent. So don't worry if you have your heart set on a Lincoln 208 MIG welder if you have a 220-volt outlet in your garage. It will still work.

A 220-volt plug like this opens up your purchase options. If you have a clothes dryer plugged in to an outlet like this, you could have up to 30 amps of power ready for a high-powered welder.

A 220-volt plug like this opens up your purchase options. If you have a clothes dryer plugged in to an outlet like this, you could have up to 30 amps of power ready for a high-powered welder.

Now, it does you no good to run out and buy the biggest, baddest burner on the block if the only power outlet in your carport will barely keep a battery tender functioning properly. An assessment of your local electrical system is in order. Those of you with contractor friends can skip this part and just ask your buddy how much power you've got in the wall. The rest of you need to read on.

In general, you'll find two kinds of power outlets in most domestic residential garages. A 110-volt AC outlet looks exactly like the one inside your house that your DVD player is plugged in to. This type of outlet is normally rated at 15 to 20 amps. A quick look at the electrical panel in the wall of the garage will tell you how much your outlets are rated for. The circuit breakers will be clearly labeled. Most garages are only wired with one circuit to feed all the 110 outlets, so you'll probably need to turn off the other tools when your welder is in use.

If you've got a larger, round-shaped outlet in the wall then you're in luck, because that's a 220-volt outlet (usually rated at 40 amps or more), which means you can buy a more powerful welder if you choose. (Side note: If your washer and dryer are located in the garage and the dryer runs on electricity, then you may find a 220 outlet there as well. You can plug the welder in to it whenever you're not doing laundry. Just remember that most breaker switches for residential dryers are rated at 30 amps, and if you upgrade yours to a larger-capacity breaker switch for a high-powered welder, the dryer will no longer be protected properly. (The wiring is not likely rated for the additional amperage either.)

Facebook user Chad Stotz asked what kind of jobs a 110-volt welder worked on and what jobs a 220-volt machine was better suited for. Most of the 110-volt welders in this guide will weld up to 10-gauge steel in a single pass. Some will weld up to 1⁄4-inch if the material is prepared properly with beveled edges, the welder is set with the proper voltage output and wire speed, and the guy pulling the trigger has experience. If you’re worried about getting good weld penetration in thicker material such as the crossmember that’s being sunk into this ’37 Ford chassis, then we recommend either learning to weld from a pro before pulling the trigger or buying a higher-amperage, 220-volt model.

Facebook user Chad Stotz asked what kind of jobs a 110-volt welder worked on and what jobs a 220-volt machine was better suited for. Most of the 110-volt welders in this guide will weld up to 10-gauge steel in a single pass. Some will weld up to 1⁄4-inch if the material is prepared properly with beveled edges, the welder is set with the proper voltage output and wire speed, and the guy pulling the trigger has experience. If you’re worried about getting good weld penetration in thicker material such as the crossmember that’s being sunk into this ’37 Ford chassis, then we recommend either learning to weld from a pro before pulling the trigger or buying a higher-amperage, 220-volt model.

The power supply is an area you do not want to skimp on if you plan to weld thick material. When in doubt about your power supply, get an electrician to upgrade the wiring and outlets in your garage. A few hundred dollars spent now will at the least ensure that your new welder works properly, and it'll prevent your house from burning down due to overloaded circuits.

Got Gas?

Most of us refer to wire-feed welders as MIG welders, but MIG (metal inert gas) isn't a welder, it's a welding process that uses a solid-core welding wire surrounded by a shielding gas (usually a 75/25 percent mix of carbon dioxide and argon) that flows out of the gun or torch. It's the industry standard when it comes to building custom cars. But, many wire-feed welders will also work without shielding gas when you internally change the polarity from positive to negative and install flux-core wire in place of solid-core wire. The core of this wire shields the weld puddle as it burns and does not require any gas.

HOT ROD reader Tim Thompson wondered if a 220-volt welder is necessary for welding aluminum. The short answer is no. The key to welding aluminum with any wire-feed welder is the mechanism for feeding the wire. Aluminum wire is much softer than the wire used for welding steel and needs to be fed to the weld puddle at high speed. Because it’s so soft it tends to get bound up in a standard torch sleeve. The solution is a spool gun, like the one included in Eastwood’s MIG 175 outfit. It’s an add-on that contains its own spool of wire and motor drive. Work fast and you can make good welds on items like this alternator case. But, if you’re looking for sexy welds in aluminum that look like a roll of dimes, the best machines to use are more expensive TIG (tungsten inert gas) welders.

HOT ROD reader Tim Thompson wondered if a 220-volt welder is necessary for welding aluminum. The short answer is no. The key to welding aluminum with any wire-feed welder is the mechanism for feeding the wire. Aluminum wire is much softer than the wire used for welding steel and needs to be fed to the weld puddle at high speed. Because it’s so soft it tends to get bound up in a standard torch sleeve. The solution is a spool gun, like the one included in Eastwood’s MIG 175 outfit. It’s an add-on that contains its own spool of wire and motor drive. Work fast and you can make good welds on items like this alternator case. But, if you’re looking for sexy welds in aluminum that look like a roll of dimes, the best machines to use are more expensive TIG (tungsten inert gas) welders.

The benefit of welding without gas by using flux-core wire is that you can weld outdoors in windy conditions. Wind tends to disrupt the shielding gas, which makes it difficult to weld. The manner in which the flux-core wire is deposited into the weld also allows deeper penetration than the MIG process, which means the same welder can penetrate thicker mateiarial. The downside to flux-core welding is that it produces more weld splatter, smoke that you don't want to inhale, and heat, which makes it more difficult to cleanly weld thin material like sheetmetal without burning holes in it.

Welding with gas ups the initial cost of a new welder because of the required high-pressure bottle and regulator. And you'll have to refill the bottle later on, so there is an ongoing operating cost there as well. If you're welding indoors and care about the look of your project, and your welder will adequately penetrate the material using shield gas, then MIG welding is the way to go.

Consumables

Shielding gas is something that a wire-feed welder will use up as you weld. The same goes for wire, contact tips, and torch nozzles. Just like the family dog, your new welder will require care and feeding, so you'll want to factor in the cost and availability of these consumables before making a welder purchase. An Internet search for local welding supply stores such as Airgas and Praxair should be a vital part of the process, especially if you buy your welder online. You'll want to make sure that good-quality consumables for your particular welder are readily available nearby.

Switching from MIG welding to gasless flux core welding requires changing from solid-core wire to flux-core wire and changing the wire polarity inside the welder.

Switching from MIG welding to gasless flux core welding requires changing from solid-core wire to flux-core wire and changing the wire polarity inside the welder.

Duty Cycle

This is a specification that matters if you're going to be welding for long periods of time with the welder on its highest power setting. The higher the setting, the shorter the duty cycle, which is the amount of time you can continuously pull the trigger on the torch versus the time the welder needs to sit and cool off. It's usually expressed as a percentage, which can be misleading when comparing the duty cycle of one machine with another. The key here is to know the length of time used in the rating. Some manufacturers rate duty cycle over a 5-minute period, while others use a 10-minute period. For example, a 60 percent duty cycle over a 10-minute period means you can weld for 6 minutes and then the machine must cool off for the next 4 minutes before you can pull the trigger again. If that same rating is over a 5-minute period, then the welder is only good for 3 minutes of continuous work. Don't worry about buying the welder with the greatest duty cycle if you're primarily going to be spot-welding sheetmetal or working on smaller projects.

Extras

In case you didn't know, you can't stare at the torch of any welder at work without wearing appropriate eye protection. Otherwise, you'll spend the next few days feeling like you have sand in your eyeballs. A shield or helmet is a must, as are a few other safety items to protect your hands and body. These are items that don't always come with a new welder, and even if they do, you can always spend more for better gear. The cheapest gloves don't usually offer the best comfort or protection, and the more expensive helmets will be lighter and have helpful features such as an auto-darkening shield. Not all welders have wheels built into the case, and they usually don't come with a cart for rolling around the shop. These extra features add expense to your purchase but also enable you to make better welds in a more comfortable working environment.

Many welders come with a basic shield, which you flip down over your head to protect your eyes from the orb-scorching light and your face from weld splatter. If you have the extra cash, spring for an auto-darkening helmet like this one from Miller Electric. Instead of doing “the nod” to flip the helmet down when you’re ready to weld, which sometimes moves the torch out of position, an auto-darkening helmet allows you to see the work area in front of you and then it detects the weld spark and goes dark in 1/25,000 of a second so you don’t go blind.

Many welders come with a basic shield, which you flip down over your head to protect your eyes from the orb-scorching light and your face from weld splatter. If you have the extra cash, spring for an auto-darkening helmet like this one from Miller Electric. Instead of doing “the nod” to flip the helmet down when you’re ready to weld, which sometimes moves the torch out of position, an auto-darkening helmet allows you to see the work area in front of you and then it detects the weld spark and goes dark in 1/25,000 of a second so you don’t go blind.

The Intangibles

On the next page we've rounded up various types of entry level welders that will stick metal together. That's a given. The specs are important, but there are some attributes of any tool that can't be judged without firsthand experience. We can't vouch for how well each of these welders actually welds because we haven't tried them all. The higher-end models likely have upgraded internals for more stable voltage output and smoother wire feed. This will result in a smoother arc and better welds. That doesn't mean the less expensive units aren't right up your alley. Our best advice is to visit your local supply house and test out as many welders as you can before buying, especially if you are considering spending extra coin for a larger welder and upgrading the wiring in your garage to support it. Internet welding forums are bound to be discussing the welders you might be interested in, and several of the online stores we visited have buyer feedback you can check out.

Weld Anywhere

Almost every welder on the market either has a power cord that is too short to hit all the possible spots you need to tackle a project or it comes with no cord at all. An extension cord will be necessary to get the job done, unless you've got power outlets at every corner of the garage. When powering a welder, any old cord will not do. This chart gives the amperage rating for each gauge of wire found in extension cords up to 100 feet in length. The longer the cord, the lower the amperage rating. Conductivity overkill is perfect, so choose a wire gauge with an amperage rating that is higher than the current draw of your welder.

The Millermatic 211 will run on either 110 or 220 volts simply with a plug adapter inserted into the power cord. The unit will automatically adjust for the difference in input voltage.

Conductor Size AWGTypes SE, SEO, SJE, SJEO, SJT, SJTO,

The Millermatic 211 will run on either 110 or 220 volts simply with a plug adapter inserted into the power cord. The unit will automatically adjust for the difference in input voltage.

Conductor Size AWGTypes SE, SEO, SJE, SJEO, SJT, SJTO,What's in a Wire?

We've mentioned that it's important to choose a welder that's capable of feeding a range of wire sizes. Each wire diameter is manufactured to weld with a specific range of welder output power, measured in amps. Using too thick a wire on sheetmetal will require more welding power, and that produces more heat and increases the risk of warpage and/or burning through the metal. Conversely, welding with wire that's too thin means you won't get proper penetration into the base material. Wire in 0.024- to 0.030-inch sizes works great on thin sheetmetal. Thicker material such as 3⁄16-inch steel requires more penetration and heat, so you'll want to use a larger-diameter wire such as 0.035 to 0.045 inch.

Contact tips are available in multiple sizes for wires of different diameters. The ability to feed wire in several sizes is important because you’ll want to match the wire to the material you’re welding.

Contact tips are available in multiple sizes for wires of different diameters. The ability to feed wire in several sizes is important because you’ll want to match the wire to the material you’re welding.

Your new welder will likely have a chart built into the case that makes selecting the wire quick and easy. If not, simply convert the material thickness to a number with a decimal point (e.g., 1⁄8-inch sheetmetal equals 0.125 inch). In general, you'll need 1 amp of welding power for every one-hundredth inch of material thickness. In this case, you'll need 125 amps of power.

Now you can choose a wire according to its rated operating amperage range. The 0.045-inch MIG wire is designed for use with 75 to 250 amps of welding power, 0.035-inch wire works with 50 to 180 amps of power, 0.030-inch wire is good with 40 to 145 amps, and 0.023 wire can be welded with 30 to 90 amps.