Building complete frames for '50s cars is nothing new to the team at Fatman Fabrications, and while they build frames for many cars ranging from the 1932 Ford and Tri-Five Chevy frames to things as obscure as a chassis for a Morris Minor there has been one glaring omission from the lineup. Fatman has been building a frame for the 1949-51 shoebox Ford for years and all this begs the question, why not a 1955-56 fullsize Ford chassis?

Well, it was just a matter of finding the time to produce the new chassis and we are pleased to announce that time is now and Brent VanDervort has just rolled production chassis number one under his very own 1956 Ford. While there is no denying the popularity and good looks of the Tri-Five Chevrolet, many people, this writer included, think the 1955-56 Ford is a better looking car and this new complete chassis will be a big help to hot rodders building these popular cars.

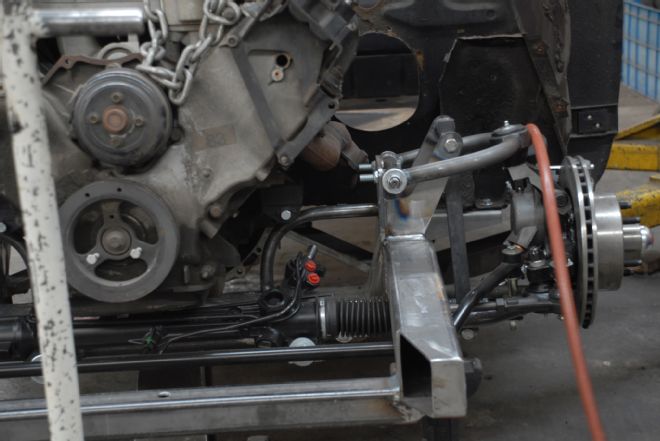

We have already introduced this new chassis detailing how VanDervort goes about prototyping a new chassis, along with the actual fabrication and components used. Like most Fatman frames this one rolls on fully independent front suspension that will employ Wilwood disc brakes and a power rack-and-pinion steering for a completely modern suspension system. Out back a new 9-inch rear from John's Industries will spin the rear wheels while RideTech coilover shocks are found on all four corners.

When it comes time to power a 1956 Ford it seems only right to select a modern motor with direct roots to Dearborn. In this case VanDervort opted for a 4.6L Ford motor coupled to a 4W70R automatic overdrive transmission. This will provide the perfect power for this mild custom cruiser.

With the new chassis complete it was time to remove the old body and test-fit it to the frame. Remember, this is chassis number one, actually a prototype, so some aspects of the production chassis may vary just a bit—after spending a couple hours under the 1956 wrestling with no less than 20 body mount bolts. Judging by the bracing in the outer floor of the 1956 Ford, the number of body bolts and the almost complete lack of chassis crossmembers Ford must have designed the floor of the car as a structural member of the chassis. Fast forward 60 years and we're thinking it would be better to have a chassis filled with real crossmembers rather than rely on vintage floorpans for strength. Team Fatman agrees with that thought and has constructed a chassis that is extremely strong and rigid.

Before removing the 1956 Fairlane Victoria body from the chassis a temporary inner structure was welded to ensure the hardtop-style body would not flex and twist when it was removed. With the inner structure complete and all the body bolts removed it was time to lift the body off the original frame. Now at home this would entail enlisting every hot rod buddy you know to lift the body up, but at Fatman's a lifting strap and fork truck made short work of the job. The body was actually lifted by the aforementioned inner structure and brought over to the automotive lift where it was positioned and raised in the air.

With the body in position the same fork truck brought the new Fatman Fabrications 1956 Ford chassis into the installation shop and it was promptly rolled under the car and placed on six jackstands. Then the body was slowly lowered in place.

Remember we are still working on a prototype project here, so as it came down everyone was carefully watching for any contact with the frame. The first thing to touch was the top side of the driveshaft loop. A small notch was cut in the floor to permit the loop to protrude inside the car. As it turns out the driveshaft loop protrudes through the floor under the rear seat. A simple hump in the floor will be fabricated and the stock rear seat goes back in place without modifications.

As the body came down lower the upper shock mounts contacted the forward corners of the trunk floor. Once again a notch was made with a cut-off wheel and then the body came to rest on the chassis. A check of all those body mounts showed that the front mounts needed to move rearward about 3/8-inch, beyond that every mount lined up perfectly, a real testament to VanDervort's skills on locating mounting points while prototyping a frame.

By the time the body was on the frame we took a quick lunch break and returned to place the motor and transmission in the new frame. Once again we would be checking for an interference with the floor or the firewall as the 4.6L Ford motor may be small in cubic inches (281 ci), it is not small in external dimensions. Once again the planning and design of the chassis was spot-on and with very minor adjustments to the frame adapters the 4.6L Ford motor slipped right onto the motor mounts and the 4W70R tranny bolted up the rear crossmember.

We were amazed at the complete lack of drama in placing a 60-year-old body on a new chassis for the first time. There were virtually no problems and the few minor adjustments made in this prototyping process are now part of the all-new 1955-56 Ford chassis from Fatman Fabrications, and Ford lovers, if you are wondering, yes, Fatman also produces a complete chassis for the very popular 1955-56 Ford Thunderbird, but we digress.

Take a look at the photos and we think you'll agree, swapping that old chassis for a new Fatman unit is one giant step forward when it comes to building the popular mid-'50s Fords.

The completed 1955-56 Ford chassis from Fatman Fabrications will soon be joined with Brent VanDervort's 1956 Fairlane Victoria.

After spending a few hours removing all the original body mount bolts and things like brake lines, E-brake cable, wiring, and steering column the body is ready for removal.

Prior to lifting the body off the frame a box tubing inner structure was welded in place from the door openings to ensure the body would not flex. Then a lift strap and a fork truck did the heavy lifting.

The original frame is in good condition for a 59-year-old piece, but note the almost complete lack of crossmember from the center of the frame rearward.

The new Fatman Fabrications frame incorporates outer 'rails formed from box tubing with a network of box-tubing crossmembers. This frame is superior to the original in every way.

The old Y-block served VanDervort well, but along with a new frame will be a new power source in the form of a 4.6L Ford engine. That Y-block leaked enough oil to keep the front portion of the frame rust free.

The Fatman frame is designed to accept a multitude of engines and they have mounts to accommodate the most popular engines. Once again, note the crossmember design in the frame.

The forklift transported the 1956 Ford body to the nearby lift in the Fatman Fabrications installation shop. This makes body swapping a breeze.

Next the chassis was brought over to slide under the body; once again the fork truck makes this easy.

With the new chassis situated under the body it was time to lift the chassis up so it rests on six jackstands. Then Pete D'Orta will lower the body down until the old body meets the new frame.

The body slipped down over the frame perfectly, but there was some contact between the driveshaft loop and the rear floor area. The front fit up perfectly.

The main point of contact was the driveshaft loop. A cut-off wheel made a quick slot, which will permit the body to come down. This loop is directly under the rear seat so a simple cover will be welded to the floor.

While cutting the driveshaft loop allowed the body to come down it didn't quite rest on the top of the framerails, as seen in this photo.

This time the culprit was the upper coilover shock mounts, they contacted the floor in the front corner of the trunk. The cut-off wheel provides clearances and a simple box will be welded to cover the opening. You may consider making this piece a bolt-on item for access to the top shock mount.

With those three clearance cuts the frame is now resting on the chassis and all body bolts are in place. The John's Industries 9-inch rearend clears the trunk floor nicely, and note the ample room for exhaust in the crossmembers.

The body mounts all align perfectly, and there are at least 20 bolts holding the 1956 Ford body in place.

Next up was installing the 4.6L Ford motor. During construction of the frame they measured the front and rear crankshaft center heights to determine where the new drivetrain should fit.

The Fatman Fabrications signature motor mounting system consists of a tube that connects from the framerails to the front crossmember. Here the 4.6L Ford motor is bolted to the motor mounts.

Meanwhile Mike "Bubba" Craig is underneath dealing with the transmission mount.

Here's the engine and transmission in place. Everything fit fine with just a minor reshaping of the transmission tunnel where it meets the toeboard. This is due the large bellhousing of the overdrive automatic transmission.