In 1993, Bill Reilly spent a bunch of time, effort, and money upgrading his 1969 Dodge Dart with bigger torsion bars, 1973-up disc brakes, and a healthy big-block. In his own words: "It was absolutely miserable to drive. It was all over the place. It was so hard to install the big-block—the headers and all that with the stock suspension—and then it drove like crap. It just really pissed me off. I still remember the exact piece of road I was on when I first thought that." A fabricator by trade, Reilly figured he would just fix it himself. It was second nature. "I'm going to rebuild this and make it better," Reilly told himself. Five years later, he was still reading through automotive engineering books trying to get it finished. By that point, he was simply obsessed with making a Mopar suspension work. "I was going to put a rack in the stock K-member, but to do that you end up with a bandage fix that doesn't quite work." One thing led to another, and it turned into a domino effect. There was only one way to do it: Make the whole thing from scratch.

Reilly's single-minded obsession to build a Mopar front suspension that worked well and packaged all the popular engine combinations culminated in what you see here: the AlterKtion K-member with coilover suspension. The fact is, all 40-plus-year-old suspensions have a lot to be desired, but far fewer of them have as many woes as the Mopar's. The concerns are divided into two major camps: powertrain/exhaust/oil pan packaging, and handling/steering.

If we face facts, most Mopar guys care more about power than handling—when they care about performance at all. Under that premise, it's difficult to make even basic upgrades like fitting a big-block engine with headers and a performance oil pan. There just isn't the space to fit pipes and pans around steering linkages, steering boxes, and the omnipresent torsion bars. It's so bad that Chrysler engineers had to move the engine centerline to the right side by as much as 3 inches on some cars. Loyalists who stand by the stock suspension end up either forgoing the horsepower, or resorting to fenderwell headers, cut sheetmetal, and origami-inspired oil pans. But hey, at least they've got the stock suspension, right?

In the other camp are guys who want a great handling Mopar. They are tired of the aimless wandering of a suspension with no caster, the seasickness of a high roll center, the sudden violent steering changes from a long scrub radius, and the dull response of a worn-out steering system with a slow-ratio box.

The thing about Reilly is that he fits into both camps: He wanted big power, he wanted great handling, and he wanted razor sharp steering. Oh, and he wanted it bad enough that he was willing to go to the ends of the earth for it. That's why he created the White Haven, Pennsylvania–based Reilly Motorsports (RMS). Since designing and marketing the AlterKtion, RMS has added the four-link Street Lynx rear suspension to its resume, and begun carrying other parts—such as brake kits and subframe connectors—that dovetail with their mission statement of Mopars without performance handicaps. Besides A-Body, RMS also offers front AlterKtion and rear four-link Street Lynx suspensions in versions for B-Body and E-Body, and for purposes as varied as drag racing and autocrossing. AlterKtion suspensions can also be ordered with a dizzying array of motor mounts, including 273/318, 340/360, 383/400/440 (all regular big-blocks), second-gen Hemi (426 style), third-gen Hemi (5.7/6.1/6.4), and even LS.

In the handling department, the AlterKtion has far better wheel behavior than stock. The roll center has been lowered from 8 inches above ground to a scant 1 inch, a change that manifests itself as a more glued-down feeling with all four tires sharing more of the grip. The caster angle of the AlterKtion improves the OEM spec of ¾-1 degree to 5 degrees or more, giving Mopars a more modern, confidence-inspiring track with improved self-centering instincts. By changing to a Mustang II/Pinto-style spindle, the AlterKtion introduces some much-needed steering inclination angle for better tracking and reduced scrub radius.

1. The RMS AlterKtion K-member for Mopars is transformative. Weight over the nose is reduced by 75-120 pounds, handling geometry is improved, and steering response is tightened with the included AGR rack-and-pinion conversion. RMS makes the AlterKtion for Mopar A-, B-, and E-Bodies, and for every Mopar engine family, including small-block LA/Magnum, R/RB big-block wedge, Gen II Hemi, and Gen III Hemi.

1. The RMS AlterKtion K-member for Mopars is transformative. Weight over the nose is reduced by 75-120 pounds, handling geometry is improved, and steering response is tightened with the included AGR rack-and-pinion conversion. RMS makes the AlterKtion for Mopar A-, B-, and E-Bodies, and for every Mopar engine family, including small-block LA/Magnum, R/RB big-block wedge, Gen II Hemi, and Gen III Hemi.

2. Before starting, Outlaw Motorsports dropped the stock K-member and engine/trans as an assembly. Four main bolts plus fluid lines, steering, and torsion bars and it’s out. Outlaw’s Aschtgen took the time to clean, sand, and shoot our engine bay with a dusting of the factory Sunfire Yellow before beginning the AlterKtion install.

2. Before starting, Outlaw Motorsports dropped the stock K-member and engine/trans as an assembly. Four main bolts plus fluid lines, steering, and torsion bars and it’s out. Outlaw’s Aschtgen took the time to clean, sand, and shoot our engine bay with a dusting of the factory Sunfire Yellow before beginning the AlterKtion install.

3. The first step is to remove the bumpstop brackets from the framerails. Four spot welds are drilled out along the side, two spot welds are drilled out from below, and a chisel is used to break the bracket free.

3. The first step is to remove the bumpstop brackets from the framerails. Four spot welds are drilled out along the side, two spot welds are drilled out from below, and a chisel is used to break the bracket free.

4. The RMS K-member bolts to the stock frame with the four stock k-member bolts. No cursing, no banging, no prying. It was a perfect fit on Project Valiant. The K-member is made from ⅛-inch-thick square mild steel tubing while the shock tower portion is ¼-inch-thick laser-cut plate steel. It’s about the same weight as the stock K-member; the huge weight savings comes from the rack-and-pinion, control arms, and spindles.

4. The RMS K-member bolts to the stock frame with the four stock k-member bolts. No cursing, no banging, no prying. It was a perfect fit on Project Valiant. The K-member is made from ⅛-inch-thick square mild steel tubing while the shock tower portion is ¼-inch-thick laser-cut plate steel. It’s about the same weight as the stock K-member; the huge weight savings comes from the rack-and-pinion, control arms, and spindles.

5. Two additional 7/16-inch bolts are added that go through the side of the AlterKtion shock tower support. Holes in the K-member will guide the drill through the framerails. This shot also shows how the suspension load is handled by the AlterKtion K-member—not the framerails or the unibody.

5. Two additional 7/16-inch bolts are added that go through the side of the AlterKtion shock tower support. Holes in the K-member will guide the drill through the framerails. This shot also shows how the suspension load is handled by the AlterKtion K-member—not the framerails or the unibody.

6. A shock tower backing plate bookends the framerail bolts from the inside, and after drilling through the first hole, it can be used to locate the drill for the second hole. Here Aschtgen tightens the framerail shock tower bolts.

6. A shock tower backing plate bookends the framerail bolts from the inside, and after drilling through the first hole, it can be used to locate the drill for the second hole. Here Aschtgen tightens the framerail shock tower bolts.

7. The left and right lower control arms are identical, except for the sway bar mounting hole, which faces the front. When putting them on, insert the bushings, aim the ball joint up, and insert the pivot shaft with the endcaps in place. A liberal coating of antiseize compound will keep them from squeaking. A small Allen set screw in the center of the pivot tube holds the pivot shaft in place to prevent galling and is a backup to the pivot bolt end nut.

7. The left and right lower control arms are identical, except for the sway bar mounting hole, which faces the front. When putting them on, insert the bushings, aim the ball joint up, and insert the pivot shaft with the endcaps in place. A liberal coating of antiseize compound will keep them from squeaking. A small Allen set screw in the center of the pivot tube holds the pivot shaft in place to prevent galling and is a backup to the pivot bolt end nut.

8. Our AlterKtion kit came with Viking Warrior double-adjustable coilover shocks. These lightweight twin-tube aluminum dampers have independent control of compression and rebound with 19 positions for each (361 combinations total). Each Warrior shock is dyno tested and serialized with a two-year warranty. Besides quality, performance, and adjustment range, RMS also likes Viking products for their larger 1.25-inch spherical bearings, which do not require special spacers and an extra assembly step. Viking Warrior springs are guaranteed to remain within 2 percent of their original free height over their lifetime and are silver powdercoated for great looks.

8. Our AlterKtion kit came with Viking Warrior double-adjustable coilover shocks. These lightweight twin-tube aluminum dampers have independent control of compression and rebound with 19 positions for each (361 combinations total). Each Warrior shock is dyno tested and serialized with a two-year warranty. Besides quality, performance, and adjustment range, RMS also likes Viking products for their larger 1.25-inch spherical bearings, which do not require special spacers and an extra assembly step. Viking Warrior springs are guaranteed to remain within 2 percent of their original free height over their lifetime and are silver powdercoated for great looks.

9. Unlike Mopar B-Bodies, A-Bodies have a small flange on the upper control arm mount that needs trimming in order for the AlterKtion upper control arm to swing through its full arc unimpeded. A quick cut with a reciprocating saw (already performed in this shot) solves the problem.

9. Unlike Mopar B-Bodies, A-Bodies have a small flange on the upper control arm mount that needs trimming in order for the AlterKtion upper control arm to swing through its full arc unimpeded. A quick cut with a reciprocating saw (already performed in this shot) solves the problem.

And while Mopar faithful might scoff at the use of a Ford part, consider this: The Mustang II/Pinto spindle not only is 8 pounds lighter per side than its Mopar counterpart, it is the most widely supported spindle in the industry when it comes to brake systems. The knockdown punch is the Ford spindle's much improved geometry. It could arguably be a little better like the more expensive C6 spindle, but it is cost-effective, it's well supported, and it's light-years ahead of stock spindles. Reilly put it best: "The spindle was designed by an engineer—a man. Only later did someone else come along and put a brand logo on it. Why punish yourself for that?"

Then there's the steering. While modest gains in the technology and feel of recirculating-ball steering boxes have made them viable choices, the rack-and-pinion design offers superior feel with fewer moving parts, fewer wear items, less mass, and a more compact package. It is de rigeur for modern production performance cars, and they are well supported in the aftermarket. In its AlterKtion systems, RMS uses a quick-ratio Mustang-style rack from AGR, a trusted leader in the steering market. Moreover, the rack-and-pinion design eliminates the massive factory steering linkage and opens up a world of engine choices and oil pan fitments.

At the heart of the AlterKtion is the use of adjustable Viking Warrior coilover shocks. These pieces are at the cutting edge of aftermarket shock design with a twin-tube aluminum body, deflective-disc technology, a PTFE/bronze piston seal, and a wide range of damper tuning via twin compression and rebound controls with 19 positions for each. They are paired with Viking Warrior springs that have a very attractive silver powdercoat look, which you won't mind showing off. As coilovers, they're also adjustable, meaning ride height and corner weight can easily be set. Additionally, RMS says it will swap out your springs at no charge should you want to make a change to your spring rate.

In the spectrum of Mopar handling stuff, you have everything from stock rebuild commodity parts, to bolt-on factory-style parts, to complete chassis that employ none of the benefits of the factory engineering (and yes, stock unibody construction does have its advantages). The AlterKtion is closer in cost to a bolt-on collection of parts consisting of control arms, shocks, springs, steering box, steering rebuild parts, sway bar, and bushings—yet it delivers performance closer to that of a full tube-frame chassis transplant. (At less than $4,500, the AlterKtion is less than a third of the cost of a starter chassis). Heck, after you eBay your old take-off K-member and parts, you might even come out ahead on the cost compared to a mash-up of stock-style aftermarket bolt-ons.

From an installation standpoint—there's no comparison. A chassis transplant can take months or even years as the DIY guy saves the cash, collects the tools, and learns the fabrication chops to pull it off. It took us just four hours to install the AlterKtion—less than the time it takes to swap out a box full of stock-style bolt-ons. It is the right suspension for the right price if you want to accomplish the most good, and you've got limited money and a modest skill set.

And lastly, there is the weight. Depending on your starting point, the AlterKtion front coilover suspension will shave the mass over the nose by anywhere from 75 to 120 pounds. That's a lot of peanut butter and banana sandwiches. We quickly realized we had to try one of these on Project Valiant, our 1968 Plymouth Valiant project car. We took the Valiant to our favorite shop, Outlaw Motorsports (Riverside, California), where proprietor Ron Aschtgen made short work of the AlterKtion on his first time ever seeing one. Just this year, Outlaw finished the two-year buildup of our '68 Nova project, and in that time on that Chevy we never experienced work progress at such a breakneck speed as the RMS AlterKtion. So well-engineered was the RMS K-member coilover system, it practically bolted itself together. See for yourself!

10. After threading the Heim joint rod ends into the upper control arms, insert the supplied spacers and install the upper control arms with the factory eccentric bolts, which are reused. The control arms are made of thick wall .156-inch DOM mild steel; the upper control arms are ⅞-inch thick while the lowers are 1-inch thick.

10. After threading the Heim joint rod ends into the upper control arms, insert the supplied spacers and install the upper control arms with the factory eccentric bolts, which are reused. The control arms are made of thick wall .156-inch DOM mild steel; the upper control arms are ⅞-inch thick while the lowers are 1-inch thick.

11. The AlterKtion suspension used a Mustang II/Pinto-style spindle, which attaches to new ball joints in the RMS control arms via castellated nuts.

11. The AlterKtion suspension used a Mustang II/Pinto-style spindle, which attaches to new ball joints in the RMS control arms via castellated nuts.

12. Install the supplied Energy Suspension urethane bushings in the AGR steering rack, then mount the rack to the backside of the K-member with the supplied fasteners.

12. Install the supplied Energy Suspension urethane bushings in the AGR steering rack, then mount the rack to the backside of the K-member with the supplied fasteners.

13. The tie-rod ends go on next with the bolt inserted from the bottom. Note that RMS modifies the forged Mustang II/Pinto spindle with its own steering arm that is designed specifically for the AlterKtion steering geometry.

13. The tie-rod ends go on next with the bolt inserted from the bottom. Note that RMS modifies the forged Mustang II/Pinto spindle with its own steering arm that is designed specifically for the AlterKtion steering geometry.

14. The AlterKtion front suspension includes a 11/16-inch diameter solid sway bar, which is as stiff as can be used without compromising the street feel. RMS does, however, offer an optional 1¼-inch diameter bar for all-out track use. Depending on your ride height setting and wheel choice, the sway bar can be mounted to the bottom of the control arms, or if reversed, to the top of the control arms. It does not matter.

14. The AlterKtion front suspension includes a 11/16-inch diameter solid sway bar, which is as stiff as can be used without compromising the street feel. RMS does, however, offer an optional 1¼-inch diameter bar for all-out track use. Depending on your ride height setting and wheel choice, the sway bar can be mounted to the bottom of the control arms, or if reversed, to the top of the control arms. It does not matter.

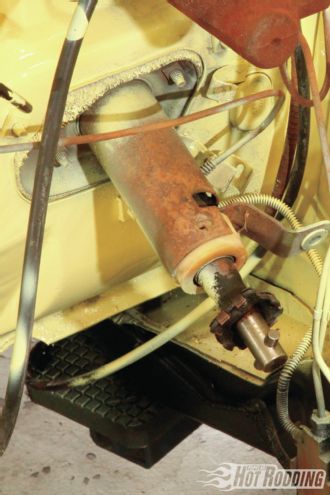

15. This is the stock unmodified steering column.

15. This is the stock unmodified steering column.

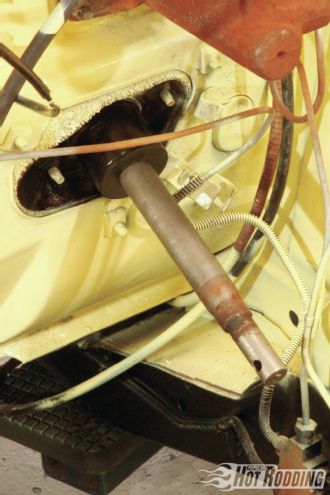

16. This is the same column after being shortened as described in the RMS instruction manual. The shortened column has a new column support bearing that is included in the RMS kit. Not all Mopars came with a support bearing, and on those that did, the bearing is often damaged or worn out. This column-shortening mod allows extra header clearance.

16. This is the same column after being shortened as described in the RMS instruction manual. The shortened column has a new column support bearing that is included in the RMS kit. Not all Mopars came with a support bearing, and on those that did, the bearing is often damaged or worn out. This column-shortening mod allows extra header clearance.

17. The last step is attaching the steering U-joints (reuse the factory roll pin for the upper, and new Allen screws and lock nuts for the lower). The intermediate shaft is included with the RMS kit (along with the U-joints) and will need to be measured and cut to fit. The shaft is then installed with the remaining Allen screws and locking nuts. A good thread-locking compound is recommended throughout.

17. The last step is attaching the steering U-joints (reuse the factory roll pin for the upper, and new Allen screws and lock nuts for the lower). The intermediate shaft is included with the RMS kit (along with the U-joints) and will need to be measured and cut to fit. The shaft is then installed with the remaining Allen screws and locking nuts. A good thread-locking compound is recommended throughout.

18. Installing the RMS AlterKtion coilover front suspension is the easiest, quickest major suspension swap we’ve ever done, clocking in at an astounding four hours. This view from up top shows just how much real estate has been reclaimed from the steering box, steering linkage, and torsion bars. We can now choose whatever engine, headers, and oil pan we want.

18. Installing the RMS AlterKtion coilover front suspension is the easiest, quickest major suspension swap we’ve ever done, clocking in at an astounding four hours. This view from up top shows just how much real estate has been reclaimed from the steering box, steering linkage, and torsion bars. We can now choose whatever engine, headers, and oil pan we want.