There are a lot of different ways to update the suspension on your muscle Mopar. If you're looking for a complete aftermarket for the front of your ride, there are a couple of choices available for you. For the sake of this article, we wanted to just focus on what can be done to improve handling, while retaining the stock suspension system. In other words, there'll be no mention of coilovers, airbags, or four-links--just the straight-up Mopar design. Lest you think that's boring, consider that there are some very fast Mopars out there running stock-style suspensions.

Torsion Bars

The torsion bars are as good of a place to start as any. The torsion bar is basically a cleverly designed spring that provides excellent performance from a compact assembly. People might curse torsion bars when trying to install headers, but on the up side, having the torsion bars located low in the chassis reduces the center of gravity, and the torsion bar is also unsprung weight. As a further benefit, the ride height is very simple to adjust with the Mopar torsion bar design.

Changing the bars is fairly easy, once you invest in a torsion bar removal tool. The surface of the torsion bar is highly stressed, so care must be taken to protect the bars while knocking them out, so using a pipe wrench or locking pliers is not a good idea. Replacement bars are available in a range of different spring rates, covering everything from drag racing to street use, to autocross and road racing. The spring rate of the bar is determined by the fourth power of the bar's diameter, so even a small change in size will make a large increase in its spring rate.

The factory offered several sizes of torsion bars for each body line, according to the intended use of the car. The softest bars were used in light duty cars (read Slant Six–powered commuters), while the biggest bars were offered as part of heavy-duty suspension packages, or with optional engines. It is still possible to find original/used torsion bars at swap meets, but since aftermarket bars are readily available, it is probably easier to just order new ones. For example, Performance Suspension Technologies (PST) offers torsion bars for A, B, and E-Body cars in sizes from .880 to 1.180-inch diameter. This might not seem like a huge difference in size, but the spring rate on the 1.180-inch bar is more than three times as great as the spring rate of the .880-inch bar. So be careful when you order torsion bars, as too much of a good thing can definitely spoil the ride.

Spring rates for torsion bars are measured at the lower ball joint, so they are representative of what the wheel sees. On cars with coil springs, the wheel rate is much less than the spring rate due to the geometry of the suspension. So don't try to compare a 200 lb/in torsion bar with a 200 lb/in coil spring, unless you know you are comparing wheel rates. A handy rule of thumb when picking a bar is to select one with a wheel rate that is 1?10 of the front-end weight of the car. For instance, a 3,600-pound car with 50 percent of the weight on the front end has a front end weight of 1,800 pounds. A good starting point for the wheel rate would be 1,800/10, or a 180 lb/in bar. If you're working on a B-Body, the closest bar available is the 1-inch bar with a wheel rate of 186 lb/in. For an A-Body, the .920-inch bar at 150 lb/in is probably the best choice. The next size up is the .990-inch bar at 200 lb/in, which is probably a tad too stiff for most folks. Remember, A-Body bars are shorter than B-Body bars, which makes them stiffer. A fairly common question people have is if they can use the drag race torsion bar on street-driven cars. Obviously, this low spring-rate bar is going to have difficulty controlling a heavy car while cornering, so you typically wouldn't want to use it for any type of daily driving. The real reason to avoid such a bar on the street has to do with the fact that this bar could be dangerously overloaded in such situations. Remember, the torsion bar is nothing more than a spring. And much like a valvespring that is overloaded, an overloaded torsion bar can fail. With a spring rate of only 92 lb/in of travel, the drag race bar has to be severely twisted to support the nose of a heavy car. Such a dramatic amount of twisting sends the internal stresses sky high. If the car hits a large bump and bottoms out, this overloaded bar could snap from the stress. Even if it doesn't snap right away, the life of such an overloaded spring is going to be fairly short.

Leaf Springs and Hangers

When it comes to handling, we need to take a look at the rear springs and the hangers as well. Chrysler engineering hit a home run when they designed the leaf springs for muscle-era Mopars. The biased design with an extra leaf on the passenger side helped control the axle on high-powered cars, as did the use of a shorter front segment (distance from the axle to the front hanger). These two design features made the Mopar rear suspension the best in the business for many years. Even today, a lot of cars are still racing every weekend with original style rear suspensions under them.

Mopar Performance offers a few different leaf spring packages including the XHD springs for street performance, Oval Track springs for track days, and Super Stock springs for drag racing. Various aftermarket vendors also offer different leaf spring packages for the A-, B-, and E-Body cars. The factory XHD leaf spring package is a good compromise for daily drivers. It has a reasonable spring rate that won't beat you up, but has enough strength to handle a healthy big-block engine. Drag racing puts a huge amount of stress on the rear suspension, which is why the factory designed the original Super Stock spring package. While the Super Stock springs work great on the dragstrip, their heavily biased design isn't recommended for cornering/handling, and the high spring rate can create a fairly harsh ride on the street. Some people have had success using these springs in road race applications by using two left side Super Stock springs, so that is an option for ambitious car crafters.

Torsion bars are available in a wide range of sizes. Factory bars were color coded for size, but paint markings are usually long gone, so carry calipers and a tape measure if buying used bars.

Torsion bars are available in a wide range of sizes. Factory bars were color coded for size, but paint markings are usually long gone, so carry calipers and a tape measure if buying used bars.

The use of different spring packages often requires the use of different spring hangers as well. There are a lot of different combinations available, so talk to the vendor to make sure that you have everything required to swap in the new parts. The installation of Super Stock springs can become fairly confusing on some cars due to the various spring lengths used by the factory. When in doubt, use your tape measure and study the specifications before you order the parts. For example, early B-Body cars are especially confusing due to their 21-inch front segment springs. In most cases, upgrading the rear springs on these early B-Body cars works best if you use A-Body springs in conjunction with special spring hangers. The Mopar Performance catalog isn't clear on this, so you need to do a little research before ordering parts. Mancini Racing can help you get the correct springs and spring hangers when looking for the Super Stock stuff.

Leaf springs come in several different varieties. There are monoleaf springs, (one plate of spring steel), and these are usually thick in the middle and get thinner toward the ends. Multi-leaf springs consist of several leaf springs of varying lengths, stacked on top of each other. The actual spring rate will set the tone for the rest of the suspension setup. This means how fast the car reacts to driver input (throttle, brake, turn in, etc). Spring rate dictates how stiff the car's ride is, and how much squat it will experience under hard acceleration.

If you're looking to dramatically improve the cornering performance, traction, and response of your Mopar, and want a bolt-in kit, Hotchkis Sport Suspension makes what they call a geometry correcting leaf spring. According to them, it is specifically designed to reduce roll steer. The kit features a bolt-in relocation bracket for the front of the spring, paired up with 160-lb/in leaf springs to improve handling performance and balance. Keep in mind that this spring is designed to lower the car approximately 1-inch. The lowered design reduces the vehicle's center of gravity.

A variety of leaf springs are available for A-, B-, and E-Body cars. These Oval Track springs from Mopar Performance have an odd 20-1/2-inch front segment, which moves the tire slightly rearward, so they require special hangers. XHD (Extra Heavy Duty) springs are a bolt in for most cars, while Super Stock springs usually require a longer spring hanger.

A variety of leaf springs are available for A-, B-, and E-Body cars. These Oval Track springs from Mopar Performance have an odd 20-1/2-inch front segment, which moves the tire slightly rearward, so they require special hangers. XHD (Extra Heavy Duty) springs are a bolt in for most cars, while Super Stock springs usually require a longer spring hanger.

Other than buying new rear springs, what can be done to improve the handling capabilities of a rear leaf-spring suspension? Controlling the lateral movement of the rear end under hard cornering can be accomplished by installing a Panhard rod or Watt's link. If you're not looking for something that extreme, you can also spend a lot less and get good results by swapping your OE bushings for better performing polyurethane pieces.

Adjusting the ride height is not nearly as simple with leaf springs as it is with the torsion bars. To help make it simple, you can get the Hotchkis leaf springs with their 1-inch drop, or Mancini Racing offers leaf spring hangers with a second eye bolt location to lower the car. Heating the springs to lower the car is not recommended. The use of a spacer placed between the leaf spring and the axle to lower the car is generally not a good idea on a race car, although a thin spacer might be OK on a street cruiser.

AntiSway Bars

Both front and rear antisway bars are currently available for the A-, B-, and E-Body cars. In some cases, such as the early B-Body cars, a newer design needs to be used since the original design is not reproduced, but that should not be a problem for most project cars. From the factory, Mopar only installed antisway bars as part of an option package, so not all cars were equipped with the proper mounting brackets. This can make upgrading an older car a little more challenging, but the aftermarket has developed brackets and mounts which can be retrofitted.

A variety of anti-sway bar designs were used over the years. Shown here is a '66-'69 B-Body style with aftermarket mounting hardware. Since many Mopars were delivered without a sway bar, this is a great alternative to searching for a used setup.

A variety of anti-sway bar designs were used over the years. Shown here is a '66-'69 B-Body style with aftermarket mounting hardware. Since many Mopars were delivered without a sway bar, this is a great alternative to searching for a used setup.

The original antisway bars installed by the factory were fairly small and had a limited effect on handling. As tire technology improved, so has the need for larger and stiffer antisway bars. The aftermarket has responded with a wide variety of types and sizes of bars, so virtually all of the bases are covered these days. Antisway bars work in the same manner as torsion bars, so once again, the stiffness of the bar is determined by the fourth power of the bar’s diameter. A small increase in diameter will change the stiffness of the bar significantly.

One fairly recent option is the use of hollow tubing for the construction of antisway bars. An antisway bar constructed from tubing can be both lighter and stiffer than a solid bar. Since the material in the center of the bar has only a limited effect on the stiffness of the antisway bar, removing the center of the bar reduces the weight significantly without reducing the stiffness very much.

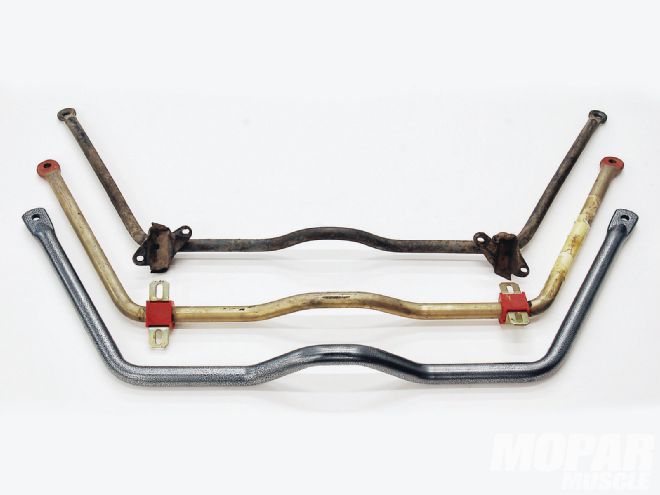

The original B-Body bar at the top is 15/16-inch in diameter. The gold bar is 1.125 inches in diameter and is twice as stiff as the stock bar. The bar at the bottom is a 1.375x.250-inch tube design from. The tube bar is 85-percent stiffer and three pounds lighter than the gold bar.

The original B-Body bar at the top is 15/16-inch in diameter. The gold bar is 1.125 inches in diameter and is twice as stiff as the stock bar. The bar at the bottom is a 1.375x.250-inch tube design from. The tube bar is 85-percent stiffer and three pounds lighter than the gold bar.

Rear antisway bars were rarely used by the factory engineers, except for police cars and special vehicles such as the 340-powered E-Bodies. If the rear bar is too stiff, the car will have an oversteering condition, which is generally regarded as unsafe. The relationship between the roll stiffness at the front of the car and at the rear is called the Roll Couple Distribution. Roll Couple Distribution is a controlling factor of understeer and oversteer. To control a car that is oversteering, you would increase the roll stiffness at the front end of the vehicle--install a stiffer antisway bar. The reverse is also true for an under-steering car. Roll couple is adjusted with spring and antisway bar rates. The stiffer end of a vehicle will lose traction first. So if a car’s front suspension is stiffer than the rear, the roll couple distribution will produce understeer because the front end is handling more weight transfer.

For a typical nose-heavy Mopar muscle car, the roll couple should be biased heavily towards the front. Usually something in the range of an 80/20 split works with the front suspension providing 80-percent of the roll resistance. If you have the ability to calculate your roll couple, then that is the best way to select the correct rear bar size. If you’re going to do it by feel, then start with a small-diameter bar, and work your way up.

Aftermarket rear sway bar kits are a good addition if your car already has a front sway bar. They typically come with all of the mounting hardware and brackets you'll need.

Aftermarket rear sway bar kits are a good addition if your car already has a front sway bar. They typically come with all of the mounting hardware and brackets you'll need.

Shock Absorbers

The shock absorber is an often un-appreciated part of the suspension. Some people buy the cheapest shocks available with their primary concern being the color, while others do understand their importance. If you spend any time talking with chassis guys at a racetrack you’ll quickly find out that they spend enormous amounts of time and money on their shock absorbers. Many race teams these days are equipped with shock dynos, which allows them to test and tune their shock absorbers. While it is possible to buy cheap replacement shocks at any discount auto store, it is also possible to purchase state-of-the-art, double adjustable mono-tube shocks that cost upwards of $700 each. In between those two extremes should be an option for every application and budget. PST carries the Bilstein line of shocks, and has a large range of shock absorbers for Mopar vehicles. Keep in mind, shock absorbers are actually vibration dampers; they don’t support the vehicle's weight. What they do, however, is convert kinetic energy into thermal energy through fluid friction. This involves the flow of oil being slowed down by the valve passages and shim plates inside the damper. The valve passages that the oil passes through are specifically designed to ensure that the vibrations transmitted by the spring are reduced right from the start. With adjustable shocks, there are either one or two one-way valves. The compression (Bump) meters how fast the oil or gas can be pushed out of one chamber to the other. Adjusting for more compression makes it harder for the fluid to be moved when the shock needs to compress. This condition can make you feel every bump in the road.

Although the principal of how a shock works is the same, there are several choices for shock absorbers. The shock at the top is a nonadjustable gas shock designed as a direct replacement. The red shock is a basic upgrade shock available from the aftermarket that is better than OE. The silver shock is adjustable, and the bottom one is a short design for cars with lower ride height. Getting what you need involves research and talking to the manufacturers.

Although the principal of how a shock works is the same, there are several choices for shock absorbers. The shock at the top is a nonadjustable gas shock designed as a direct replacement. The red shock is a basic upgrade shock available from the aftermarket that is better than OE. The silver shock is adjustable, and the bottom one is a short design for cars with lower ride height. Getting what you need involves research and talking to the manufacturers.

Rebound meters how fast the fluid is returned to the original reservoir, or how fast the tire can go to full or partial droop. If you have too much rebound pressure, the wheel doesn't go back down after the compression cycle. If it can't go back down quick enough, and you're hitting continuous bumps, the car actually lowers itself and can eventually bottom out the shocks.

Control Arms

The factory control arm design works pretty well as is, but there is always room for improvement. The original lower control arm design is an unboxed U shape, which can be twisted out of shape by a stiff antisway bar. We feel that boxing the lower control arm when using big antisway bars seems like a good idea. The upper control arms are a fairly simple design stamped out of steel. This design works OK for most applications, but one downfall is that the threads in the arm are easily damaged when replacing the upper ball joint, so most original control arms are worn out by now. Stamped replacement upper control arms are available in the aftermarket, but for serious performance it is probably best to go ahead and purchase a set of fabricated upper arms. The fabricated upper arms are designed to provide more caster and camber than is available from a stock arm, and the threaded sleeve used in most fabricated arms is much more robust than the stock design. If you are determined to keep the factory upper control arms, and need to get more camber, Moog makes an offset bushing to help. The offset bushing locates the center hole of the bushing off center to "move" the control arm farther, in order to gain more camber ability. Caster angle means that the pivot points of the steering (ball joints) are angled such that if a line is drawn through them, the upper ball joint is behind the lower one. The purpose of this is to provide a degree of self-centering for the steering--the wheel casters around so as to trail behind the axis of steering. This makes a car easier to drive and improves its directional stability (reducing its tendency to wander). Excessive caster angle will make the steering harder less responsive, but in racing, large caster angles are used to improve camber gain while cornering. Camber angles alter the handling qualities of a suspension. Negative camber will improve the grip of the tires when cornering. This is because it places the tire at a better angle to the road. Another reason for needing negative camber is that a tire tends to want to roll over itself while cornering. This effect is only true for the outside tire during the turn; the inside tire would benefit most from positive camber.

On the other hand, for maximum straight-line acceleration, the greatest traction will be achieved when the camber angle is zero and the tire's tread is flat on the road.

Some of the aftermarket control arms are adjustable to increase the available caster/camber angles, while others use relocated pivot points to change the front suspension geometry. There are a lot of options for upper control arms, so a little bit of Internet research is probably a good idea before you place the order.

Steering Linkage

There are a few tricks that can be used on the steering linkage to improve the feel and precision of the steering. If you have a manual steering box, you can change to a faster ratio box using either a 16:1 gear set or a 20:1 gear set. These quick ratio gear sets can be hard to find, so some searching might be required. The quick ratio steering box will increase the steering effort, so be careful if you have a nose-heavy car and wide tires.

Power steering boxes can be rebuilt and tuned up by the guys at Firm Feel to provide more road feedback. Quick ratio steering arms are also available if you want to duplicate the setup used on the AAR and T/A cars. The quick ratio arms are longer, which moves the steering linkage back, so check for sufficient exhaust clearance before ordering.

Using the larger 11/16-inch tie rod assemblies from a C-Body along with billet adjusters is an easy way to make the steering linkage stiffer.

Using the larger 11/16-inch tie rod assemblies from a C-Body along with billet adjusters is an easy way to make the steering linkage stiffer.

If you are planning on higher cornering speeds, then it is always a good idea to reinforce the steering box mounts on the K-frame. Any flex in this area reduces the responsiveness of the steering system. One last idea is to swap in the larger tie rod adjuster assembly from a C-Body car. The C-Body cars used larger 11/16-inch tie rod ends, which are twice as stiff as the original 9/16-inch units. This is a bolt-in swap, and as an added benefit, the C-Body tie rod assembly is often less expensive than the A-, B-, or E-Body part.

Wheels, Tires and Chassis

While the suspension is the primary focus of this article, the suspension does not act on its own. The tires connect the suspension to the road, while the chassis provides the mounting points for the suspension. Reducing the weight of the wheels will reduce the load on the shock absorbers, and make it easier to control wheel movement over rough sections of road. Tire width and aspect ratio will also have a dramatic effect on the car's handling. Mopar muscle cars were originally designed around tall, skinny, bias-ply tires. These tall tires were fairly soft and tended to roll over and distort while cornering. Replacing the original tires with wider, low-profile tires is one of the first steps towards improved performance.

The chassis also plays an important role in how well the suspension works. The Chrysler engineers designed the original unibody chassis to complement the OEM springs, shocks, and tires. Once the suspension is upgraded, the chassis will be unable to properly handle the loads placed on it. At some point, the springs and shocks become stiff enough to distort the chassis. Rather than compressing just the springs and shocks, the sheetmetal and frame will also start to deflect under the loads of heavy cornering. Photos of stock body NASCAR racers from back in the '70s will clearly show how much extra bracing was used to support the shock towers and K-frames. The guys who built those old race cars understood that they wanted the chassis to be rigid and the suspension to be compliant. That was good advice then, and it is still good advice today.

Summary

The Mopar torsion bar and leaf spring suspension was an excellent design. Even after more than 40 years, the original design is holding up well. A careful mix of replacement and aftermarket parts should allow any of the Mopar muscle cars to perform excellent on the street as well as at the track.

Rebound meters how fast the fluid is returned to the original reservoir, or how fast the tire can go to full or partial droop. If you have too much rebound pressure, the wheel doesn't go back down after the compression cycle. If it can't go back down quickly enough, and you're hitting continuous bumps, the car actually lowers itself and can eventually bottom out the shocks.

No matter what kind of racing you plan to do, having your car scaled so you know what each corner weighs is highly recommended. You need to know what the weight distribution is in order to pick the right parts.

No matter what kind of racing you plan to do, having your car scaled so you know what each corner weighs is highly recommended. You need to know what the weight distribution is in order to pick the right parts.