We began this series by covering brake rotors in Part I. Now that you have a better idea of what you may want for your rotor design and why, it's time to discuss performance calipers, pads, and fluid. Once again, we've teamed up with some of the biggest names in the performance after-market and asked them to share their knowledge regarding what to consider when upgrading your brake system.

Manufacturers perform rigorous brake testing on brake dynamometers to find the limitations of their products. Photo: StopTech

Manufacturers perform rigorous brake testing on brake dynamometers to find the limitations of their products. Photo: StopTech

There is a stigma that factory brake systems are inadequate, and you have to go with something bigger and better. While this may be true in some cases, it's not for all. Many Pontiac owners with factory-disc brakes may have all the braking power they want, or they may desire a few subtle upgrades.

If you're simply after a better appearance, take the calipers off and paint them with specialized brake-caliper paint that will stand up to the heat and elements. If you're seeking improved stopping power, run a more aggressive pad. If you want more reliable operation, keep the fluid clean.

However, if you're looking to step up to the next level in braking, determine your budget and use the information in this series to your advantage to seek out a company that can provide the matched components you want.

Calipers

The caliper is the muscle behind the braking system; it sits over the rotor like a clamp. As hydraulic pressure is sent to the piston, it applies pressure to the pad, creating braking force. As more force is applied to the back of the pad, the caliper itself will want to expand. This expansion must be controlled and limited to maintain proper braking performance.

Here is a typical OEM-style floating caliper, as shown on our '05 GTO. Notice the discoloration of the red paint from the extreme temperatures the caliper was subjected to during our outing at Sebring International Raceway ("Open Track Packin'," Dec. '10).

Here is a typical OEM-style floating caliper, as shown on our '05 GTO. Notice the discoloration of the red paint from the extreme temperatures the caliper was subjected to during our outing at Sebring International Raceway ("Open Track Packin'," Dec. '10).

There are two kinds of calipers: floating and fixed. Both are designed to perform the same task, but which is right for you?

Floating calipers (also called sliding calipers): In a floating caliper, the caliper body is usually made of cast iron because it's subjected to forces that a fixed system is not. Cast iron is strong, cheap, and has known thermal properties. Floating calipers are the most common type of calipers and are used for most OE applications. In this system, one or more pistons mounted on the inboard side of the caliper push against the back of the brake pad. The caliper attaches to a bracket that allows it to "float" or slide freely so that when the brake pressure is applied, the caliper body actually moves, creating friction with both pads on both sides of the rotor.

A downside to floating calipers is that they tend to be heavier than fixed calipers (despite the fact that fixed calipers have more pistons) and can produce uneven pad wear. Since the caliper and its brackets are quite heavy, unsprung weight is increased.

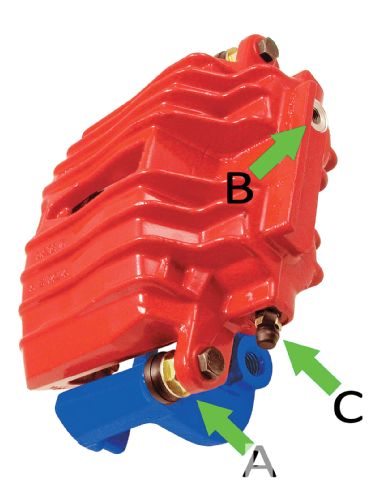

Here is a two-piston floating caliper. The red part is the actual caliper; the blue part is the caliper bracket. The caliper bracket is fixed and stays attached to the spindle. A: This is where the caliper bolt allows it to slide in and out of the bracket. B: This is where the brake line attaches to the caliper and supplies fluid to the piston, which is on the inboard side of the unit. C: This is the brake bleeder fitting. Photo: StopTech

Here is a two-piston floating caliper. The red part is the actual caliper; the blue part is the caliper bracket. The caliper bracket is fixed and stays attached to the spindle. A: This is where the caliper bolt allows it to slide in and out of the bracket. B: This is where the brake line attaches to the caliper and supplies fluid to the piston, which is on the inboard side of the unit. C: This is the brake bleeder fitting. Photo: StopTech

When cool air is drawn through the rotor "eye" of a ventilated disc, it exits from the openings on the outside of the rotor, blowing additional heat onto the caliper. If floating calipers are used regularly in racing conditions, they may begin to deform from the stress of applying brake pressure (the caliper tries to expand) while being softened from heat. This is easy to identify when you remove your pads because they will show irregular wear-less material at the top than at the bottom of the pad.

On the plus side, floating calipers can be very powerful and provide excellent stopping power on the street. Since these are probably what your Pontiac already has (both factory-disc-brake-equipped vintage Pontiacs and late-models use floating calipers), they become very attractive to the budget-minded aficionado. If you don't plan on aggressive braking, such as road racing or high-speed autocross, your floating calipers are probably up to the task of excellent braking, they just may not have the eye-catching appeal of a fixed caliper.

Fixed calipers: These are usually made from aluminum, which is a softer, lighter metal than cast iron. Manufacturers take extensive measures to ensure that these calipers don't expand under the stresses of braking and the heat that accompanies it.

Here we see a six-piston Brembo monoblock caliper on a work bench having the sequentially-sized pistons installed. Photo: Brembo

Here we see a six-piston Brembo monoblock caliper on a work bench having the sequentially-sized pistons installed. Photo: Brembo

Fixed calipers are finding their way onto more factory cars these days, but caliper-conscious consumers still consider them more of a performance novelty. This marvel of design is born out of function, as it is not constrained by having pistons only on one side. A fixed caliper can be made from lightweight aluminum and employ more pistons, yet still weigh less than a traditional floating caliper. The reduction in unsprung weight benefits performance across the board. Having brake pressure applied to both pads also helps the pads wear more evenly, even when multiple pistons are used.

The downside to fixed calipers is that they are more expensive and can be rather large, severely limiting wheel choices in some situations. Also important is that the more pistons added, the longer the caliper must be to support them. This imposes challenges to the structural integrity of the long aluminum body.

Manufacturers take different approaches to ensure caliper length doesn't negatively impact its performance. One approach is the monoblock caliper, which is formed from a single piece of aluminum and sculpted carefully so it's rigid in the areas that endure the brunt of the stress. Another approach is the multi-piece design, which uses a bridge to support the area across the top of the caliper and employs bolts to hold the unit together.

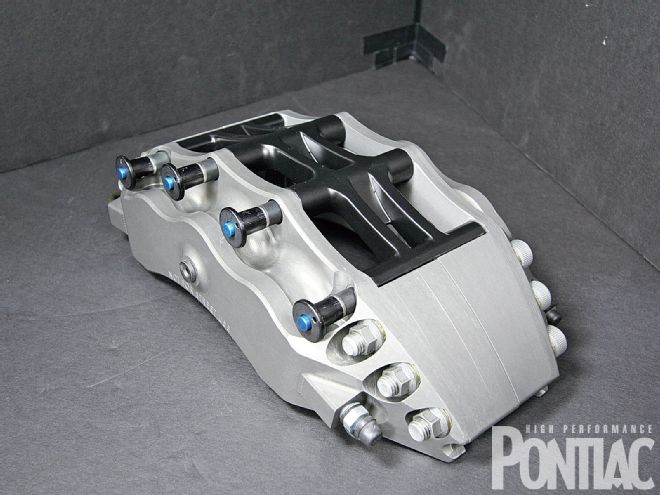

This is the back of the caliper looking down from the top. The large black structure in the middle is called the bridge, and like the caliper, it's made from aluminum. According to StopTech, the bridge is one of the most structurally important parts of its calipers. When heat and brake pressure is sent through the caliper, it will try to expand; the bridge reduces this flexing. The race-only caliper shown here features quick releases for the bridge, so a track-side pad change can't get any easier. Photo: StopTech

This is the back of the caliper looking down from the top. The large black structure in the middle is called the bridge, and like the caliper, it's made from aluminum. According to StopTech, the bridge is one of the most structurally important parts of its calipers. When heat and brake pressure is sent through the caliper, it will try to expand; the bridge reduces this flexing. The race-only caliper shown here features quick releases for the bridge, so a track-side pad change can't get any easier. Photo: StopTech

According to Brembo, the main differences between the two designs are in the manu-facturing processes-casting, machining, and assembly. Monoblocks (as the name implies) use less components than two-piece designs and are typically preferred for low-volume, performance-oriented manufacturing programs. However, they are more tailor-designed than the two-piece, and even small modifications to adapt them to new programs are not always feasible or convenient. This is why many high-volume caliper manufacturing programs use the two-piece calipers.

Companies such as Baer, Brembo, StopTech, and Wilwood control the braking forces across the back of the brake pad by using different size pistons. StopTech, with only a handful of caliper bodies, adjusts the balance of its brake kits by testing to find the piston sizes that work best on each individual application.

The design of a fixed caliper can be made stronger than a floating, which can translate into a more positive pedal feel. They are also designed to be more resistant to expansion under heavy braking, making them ideal for prolonged racing use. If you're planning on racing your Pontiac extensively, a good fixed-caliper kit should be on your wish list. They also look great and command attention at any car show, so there is the wow factor, too.

Note StopTech's abutment plate. This stainless-steel plate holds the pad in place inside the caliper. It also prevents the pad from rubbing and wearing the caliper's softer aluminum body. Photo: StopTech

Note StopTech's abutment plate. This stainless-steel plate holds the pad in place inside the caliper. It also prevents the pad from rubbing and wearing the caliper's softer aluminum body. Photo: StopTech

Brake Fluid

Brake fluid provides an incompressible medium to transmit the brake-pedal pressure you apply to the master cylinder; then through the lines to the caliper, the pistons, and the back of the pads, forcing them against the rotor. While never in direct contact with friction surfaces, brake fluid receives a great deal of thermal transfer, like every other component in the braking system. Having such an important role, it's easy to see why using the proper high-temperature fluid is key in any high-performance brake setup.

There are two different types of brake fluids: glycol- and silicone-based. These are classified by U.S. Government Department of Transporta-tion (DOT) specifications: DOT 3, DOT 4, and DOT 5. Glycol-based fluids, DOT 3 and DOT 4, are what you find in most cars today. DOT 4 is similar to DOT 3, but it contains borate esters to help increase the brake fluid's boiling point.

These glycol-based fluids absorb water and will degrade over time, needing to be flushed out eventually. The boiling point of water is 212 degrees Fahrenheit (or higher depending on the pressure in the system), and as Brembo explained to us, rotor temperatures can easily reach between 1,000 to 1,500 degrees at the end of a braking zone. The rotor will transfer anywhere between 400 to 600 degrees into the fluid, possibly more if there isn't adequate cooling.Consequently, water's presence in glycol-based brake fluid-even at 3 to 4 percent-is enough to effectively make it useless in severe braking.

Many manufacturers, like Wilwood, clearly mark their calipers for rotation because they are side-dependent. (Note the directional arrow on this caliper's outer face.) This is because manufacturers commonly use different size pistons across the backing plate of the pad to spread the pressure correctly. If not placed on the correct side of the car, the pressure is thrown off, resulting in irregular pad wear. Photo: Wilwood

Many manufacturers, like Wilwood, clearly mark their calipers for rotation because they are side-dependent. (Note the directional arrow on this caliper's outer face.) This is because manufacturers commonly use different size pistons across the backing plate of the pad to spread the pressure correctly. If not placed on the correct side of the car, the pressure is thrown off, resulting in irregular pad wear. Photo: Wilwood

DOT 5 does not absorb water because it's a silicone-based fluid. It also has a greater thermal stability. The downside to DOT 5 is that it's more compressible than the glycol-based fluids and can absorb air, forming pockets. Its chemistry allows air to live in the brake-fluid system in the form of microscopic bubbles that are invisible to the naked eye. These bubbles degrade braking performance and make the pedal feel like stepping on a big spring, according to StopTech. There is no denying DOT 5's thermal stability and high boiling points, but because of its other characteristics, it isn't a good choice for high-performance braking.

If you're looking for the best of both worlds, there is a solution, which the U.S. government has labeled DOT 5.1. It's a glycol-, ether-based fluid like DOT 4 and will still absorb water, but it features high boiling points like DOT 5, while retaining a stable viscosity. It can be mixed safely into DOT 3 and DOT 4 systems, making it a great choice, but is more expensive than its glycol-based brake-fluid siblings. (There are also higher-boiling point DOT 4 brake fluids available in today's market, referred to as DOT 4 Plus or Super DOT 4.)

Many car owners don't understand that they should check their brake fluid once a month and change it once per year-something most car owners do not do. (I check mine every few months, and make the extra effort to flush it out and replace it before every track day.)

As car manufacturers continue to push the performance envelope, fixed calipers have begun to find their way onto new cars. Brembo has worked closely with the OEMs to come up with high-performance brake packages from the factory. This can be seen on the '09 G8 GXP, which uses four-piston monoblock calipers. Photo: Brembo

As car manufacturers continue to push the performance envelope, fixed calipers have begun to find their way onto new cars. Brembo has worked closely with the OEMs to come up with high-performance brake packages from the factory. This can be seen on the '09 G8 GXP, which uses four-piston monoblock calipers. Photo: Brembo

Even in a sealed system, moisture can infil-trate brake fluid and degrade its effectiveness. That's why brake-fluid manufacturers com-monly advertise two boiling points: wet and dry. When brake fluid is wet, there is moisture in the braking system, which causes a lower boiling point. Once the fluid has passed the boiling point, you'll notice the pedal feel is no longer firm; the pedal may even stick to the floor. This is when the brakes become unresponsive.

Obviously, this isn't good. But, if you're running a high-performance fluid with a dry boiling point, close to 600 degrees or more, this should never happen. As a matter of fact, if you boil 600-degree fluid and there is no moisture, the problem isn't the fluid; it's something else in the brakes. You'll need to find a better way to cool the rotors, which in turn, will allow everything else to run cooler.

On the street, you probably won't come close to this temperature, but running a good fluid never hurts. Determine your budget for the fluid and buy the best you can afford. StopTech suggests its Motul RBF 600 brake fluid because it's a good bang for the buck.

"We've found that its 600-degree boiling point is hard to beat for the money," says Howard Hsia, StopTech sales manager. We run Amsoil Series 600 in our GTO, which also has nearly a 600-degree boiling point and a good price. Brembo and Wilwood offer its own mixtures for either street or the twisties.

Here you can clearly see the different size pistons on the GXP Brembo caliper, making them side-dependant. Photo: StopTech

Here you can clearly see the different size pistons on the GXP Brembo caliper, making them side-dependant. Photo: StopTech

Brake Pads

There are plenty of pad materials and compounds out there to choose from, but which one is best for you? You're simply never going to find a pad that will do everything ... well, at least for now. In a perfect world, an aggressive pad with low dust and quiet operation would be the ticket, but these attributes have not been combined into a single pad yet.

Brake pads have come a long way since the early days of disc brakes. In the beginning, pads were composed primarily of asbestos, which is a toxic material, and extremely dangerous if inhaled. In spite of asbestos' excellent thermal qualities, it is just too dangerous to use, so manufacturers have since moved on to organic, metallic, and ceramic brake pads.

Organic pads: These are usually quieter than their metallic or ceramic cousins, and aren't harmful to our health like the old asbestos pads. They are usually composed of glass, rubber, carbon, and sometimes Kevlar, as well as some resins. Organic pads work better when cold than metallic and ceramic pads, but they wear out faster and create more dust.

Brembo's High Performance brake pads offer a good balance for performance street cars. Photo: Brembo

Brembo's High Performance brake pads offer a good balance for performance street cars. Photo: Brembo

Semi-metallic pads: These are generally made of iron, copper, steel, and graphite bonded together. They offer a good balance of performance and comfort, and promise better braking at higher temperatures than organic pads, but are more aggressive on the rotor and need to heat up for optimal performance.

Ceramic pads: These wear better than the previous two choices, are lighter in weight, generally produce less dust, have a higher temperature range, and dissipate heat well to reduce fade over the course of repeated stops. This makes them a terrific choice for high-performance driving. However, they are higher priced and can create noise. Some companies, like Hawk Performance, make backing plates to help muffle the noise, and they do so fairly well.

Pads are considered the tunable component of the brakes because you can control brake torque output by the compound selection. The brake pads that came with your Pontiac were designed to stop quietly and competently at normal speeds and stop easily when still cold. This is why switching to performance pads can take your brakes to a whole new level.

It's understandable that spirited drivers want to increase brake bite but not dust and noise, or affect rotor life. Unfortunately, current brake-pad technology requires some give and take. There is more abrasive friction and there are bonds being broken from the adherant friction (when the pad leaves a thin layer of material on the rotors' surface). Inherently, the process generates heat, dust, and sometimes noise.

Hawk Performance's ceramic Dynamic Torque Control (DTC) line of brake pads have a high operating temperature to control fade during racing and offer aggressive-but-controllable initial bite. The DTC-70 is the top dog in Hawk's lineup, but there are over six different race compounds available to fine-tune your vehicle. Note: These race-only pads won't comply well with street use, and they wear excessively while creating a large amount of noise and dust. Photo: Hawk

Hawk Performance's ceramic Dynamic Torque Control (DTC) line of brake pads have a high operating temperature to control fade during racing and offer aggressive-but-controllable initial bite. The DTC-70 is the top dog in Hawk's lineup, but there are over six different race compounds available to fine-tune your vehicle. Note: These race-only pads won't comply well with street use, and they wear excessively while creating a large amount of noise and dust. Photo: Hawk

Remember, pads also have a limited operating temperature. Racing brake pads, like the Hawk DTC-70 pads we used on our GTO, have a very high operating temperature. In lower temperatures they feel aggressive, but when they heat up, the initial brake bite is tremendous. On the street, however, these pads will never reach their desired operating temperature, and excessive pad and/or rotor wear will result.

So how do you choose the right brake pad compound for your application? We suggest you review the characteristics of each of the three types of pad compounds and decide which one will work best for your style of driving. If you just want a better pad for street driving than the factory offering, Hawk Performance and other companies sell high-performance replacement pads for almost any Pontiac.

Conclusion

Now that we've given you the straight facts on brake calipers, pads, and fluid, check out HPP next month when we'll discuss the ancillary braking components that you should choose carefully when planning the remainder of your brake-system upgrade.

Watch your speed!

We spoke with Howard Hsia, StopTech's sales manager, about some of its products and how performance brakes migrate from the track surface to the street.

HPP: It appears StopTech doesn't manufacture a large variety of calipers but is able to fit them to quite a large range of applications. How is this possible?

Howard: We only make a handful of calipers, and the street calipers (ST-60 and STR-60) are variations on the race designs.We fine-tune each caliper for each application by altering the diameter of the pistons. This effectively controls the pressure on the brake-pad backing plate and minimizes pad taper.

It also tunes brake torque for each appli-cation because you don't want to hit the brakes and have them lock up instantly. StopTech was founded on the philosophy of balanced-brake upgrades, and this is something we research on every car, whether on the track or the road.

HPP: Please explain how you build an aftermarket big-brake kit for an OEM car. Do you test-fit it, then test it before it's released for purchase?

Howard: Once we receive the dimensions and mock up everything, (we fit it to) the actual vehicle. After this step, we begin fine-tuning and determine how much output each caliper needs to give proper brake balance. This is done through testing. The result is a kit made specifically for that vehicle, with the piston diameters carefully selected.

HPP: What are the differences between the ST and STR calipers?

Howard: The ST calipers are actually based on the STR racing calipers. Some race teams run the ST calipers without any issues. The only real difference is that the ST calipers have dust boots for the pistons and are painted, while the STR calipers don't have dust boots and are usually bare aluminum.

HPP: What do dust boots do?

Howard: Anytime the brakes are being used, they're susceptible to contact from various dirt and debris. Dust boots do an excellent job of keeping this junk away from the pistons, which could affect (the brake's) reliability. In a racing situation, (dust boots) will become extremely hot; since they're made of rubbers and silicones, they will melt or crack and fall away, putting debris in the piston area.

Race teams simply won't run them because they're going to be destroyed after only a few laps, so what's the point? These teams tear the cars down-especially the brakes-after every race. On the street, you want dust boots unless you want to clean out the caliper. That's why we came up with the higher-temperature boots-so that they can be enjoyed in mild racing conditions for street cars.