Stiffening the chassis of your LX Mopar just became a lot easier thanks to the subframe connector kit from Razors Edge Performance. Follow along as we show you how easy this kit is to install.

Stiffening the chassis of your LX Mopar just became a lot easier thanks to the subframe connector kit from Razors Edge Performance. Follow along as we show you how easy this kit is to install.

Modern technology has really made the new LX-platform cars from Chrysler fun to drive. Chargers, 300s, and Magnums all share this platform, which has proven to be quiet riding and comfortable, while not sacrificing handling and performance. The new Hemi engine has power to spare, and the drivetrain of these new Mopars is very refined when compared to the musclecars we normally feature in Mopar Muscle. Like most new cars, however, the LX Mopars are built as much for their luxury as their handling, so the true performance enthusiast may prefer a slightly stiffer, better handling suspension. Until recently, this meant the somewhat expensive SRT package needed to be ordered from the factory. Now, thanks to Razors Edge Performance, the handling characteristics of any LX Mopar can be improved by adding their subframe connectors and shock tower braces.

It has long been known that a rigid chassis in a car equates to better acceleration, braking, and handling performance. If you want proof, take a look at a purpose-built, full-chassis race car. In addition to the protective rollcage, there are bars and crossbars welded in place specifically to prevent chassis flex. This allows the suspension components like shocks, struts, springs, and sway bars to do their job, keeping the tires firmly planted to the pavement during all phases of driving. While the new LX cars are designed with some semblance of performance in mind, their unitbody construction makes them prone to chassis flex.

Knowing the LX's propensity for performance and its handling limitations, the engineers at Razors Edge Performance decided to do something to greatly improve the way these cars handle. What they came up with is a triangulated subframe kit that connects the front and rear subframes together, and shock tower braces for the front and rear.

In our two part series, we'll install the subframe connectors in this issue, and the shock tower supports in an upcoming issue.

Connecting the subframes together is nothing new in the automotive performance world. We've been stiffening our A-, B-, and E-body Mopars by connecting the front and rear subframes for many years. Though most musclecars were built for acceleration, and tying together the unibody certainly helps with that, a side benefit of adding frame connectors has always been improved handling, and to a lesser extent, improved braking performance. Although the LX unitbody is an engineering masterpiece when compared to the older Mopar unitbody designs, there is still room for improvement. Instead of simply building simple connectors for the front and rear subframes, the folks at Razors Edge went the extra step of designing their connectors to be right and left side specific, with multiple welding points for extra support. Once installed, these connectors tie the front and rear frames together and connect to the factory center chassis bar to support the frame side-to-side as well.

The best thing about this modification is the fact that handling is improved, while ride quality and comfort are not sacrificed as long as the rest of the suspension components are left alone. For the hard-core performance enthusiast, this alteration, along with the shock tower supports we'll install next month, is a great first step to accomplish prior to other modifications. By strengthening the chassis at these points, the frame will serve as a better platform for future improvements such as heavier springs, thicker sway bars, and stickier tires.

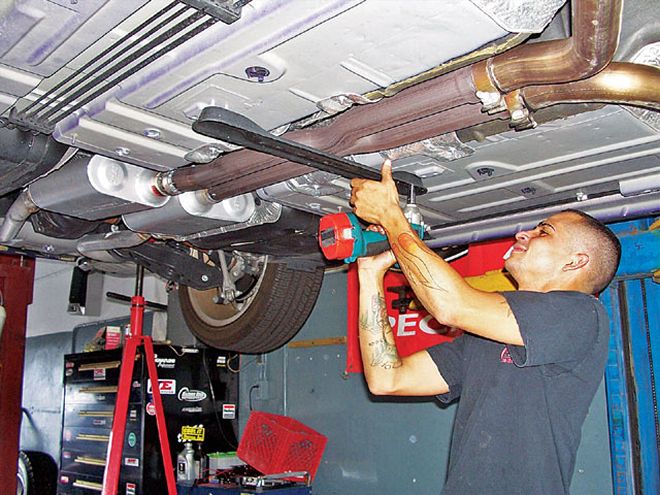

Follow along as we show you how these frame connectors can be easily installed in less than a day, and be sure to watch as we further improve the handling of our Dodge Charger by installing front and rear shock tower braces in a future issue.