Q. I am installing a wideband oxygen sensor and am curious about what A/F (air/fuel) ratios to aim for. Here is where I am stuck: I run a 20 percent blend of E85, and with the pump gas also with a 10 percent blend of ethanol, I am not sure what to look for on the wideband. I know running E85 with no tuning changes will cause a lean condition, so I have tuned for a slightly richer mixture, but now with a wideband I can hopefully remove the guesswork.

A. Assuming no detonation problems on available fuels with the present tune-up, at sustained cruise you generally want to be close to stoichiometric. WOT (wide-open-throttle) acceleration calls for around 10–15 percent richer than stoichiometric. But before I get into specific methodology to get you close to that, please remember that pump-dispensed retail fuels aren’t always what they’re claimed to be. As Rockett Racing Fuel’s Tim Wusz points out, they can, and often do, vary from their officially advertised composition. Out of the retail pump, so-called E85 may actually be E75 or even E95. Pure pump gas may be seasonally adjusted with “up to” 10 percent ethanol—or it may end up with an even higher composition, depending on how the particular refinery that made the brew is set up.

Innovate Motorsports LM-1 (recently superseded by the LM-2) portable wideband meters feature reasonable accuracy at a relatively affordable price. They read out in both Lambda values and air/fuel ratios, and can be calibrated for specific fuels. For a quick test, a portable tailpipe probe yields reasonably accurate results on mildly cammed motors as long as it extends at least 6–10 inches up from the end of the pipe.

Innovate Motorsports LM-1 (recently superseded by the LM-2) portable wideband meters feature reasonable accuracy at a relatively affordable price. They read out in both Lambda values and air/fuel ratios, and can be calibrated for specific fuels. For a quick test, a portable tailpipe probe yields reasonably accurate results on mildly cammed motors as long as it extends at least 6–10 inches up from the end of the pipe.

In theory, when predicting the effect of fuel blends on engine performance, jetting, and tuning, you need to take into account the fuel’s molecular weight and the atmospheric conditions encountered when mixing the fuel, not merely straight percentages. In the real world, this is significant when mixing heavy fuels like nitromethane (1.13 density) with lighter-density fuels such as methanol (0.797 density). When both fuels have similar light-density values—such as gasoline (approximately 0.73-0.74) or E85 (0.79)—ballpark results are obtainable with a simple mixing-ratio calculation, certainly within the margin of error induced by the variance in composition of pump-dispensed fuels.

For long-term use and/or to minimize exhaust gas dilution with cams over 230 degrees duration at 0.050, it’s best to install an oxygen sensor bung near the engine, in the header collector or near the end of a stock exhaust manifold. The added heat imparted to the sensor due to its proximity to the motor is also said to produce more consistent results.

For long-term use and/or to minimize exhaust gas dilution with cams over 230 degrees duration at 0.050, it’s best to install an oxygen sensor bung near the engine, in the header collector or near the end of a stock exhaust manifold. The added heat imparted to the sensor due to its proximity to the motor is also said to produce more consistent results.

The accompanying table lists typical A/F ratios for common fuels. To determine the A/F ratio with fuel blends, multiply the desired A/F ratio of each fuel in the blend by the percent of that fuel to the total mixture, then sum the products. For example, if you are running 20 percent E85, that means you are also running 80 percent gasoline (100% – 20% = 80%). If using straight gasoline (not mixed with 10 percent pure ethanol out of the pump), the equation for the blended stoichiometric A/F ratio would be:

Blend A/F ratio = (0.20 × E85 A/F Ratio) + (0.80 × Gasoline A/F Ratio) = (0.20 × 9.765) + (0.80 ×14.7) = 13.713

If you knew for sure the pump gas already contained 10 percent pure ethanol (E10 in the table), the same technique works, but substitute E10 for pure gasoline in the equation. The same basic technique works for any other blend or any number of additional fuel blends; just solve for all the additive elements and their corresponding ratios comprising the total fuel mix.

If tuning for full-power WOT, use the table’s full-power ratios instead of the stoichiometric ratios. For example, to calculate the max-power rich A/F ratio of your 20/80 E85/gasoline blend:

Blend A/F ratio = (0.20 × E85 Rich A/F Ratio) + (0.80 × Gas Rich A/F Ratio) = (0.20 × 6.975) + (0.80 ×12.5) = 11.395

Caution! What most A/F ratio devices actually measure is really the amount of residual oxygen (for lean mixtures) or unburned hydrocarbons (for rich mixtures) contained in the exhaust gas. Reflecting this, many consumer-level wideband sensors read out in Lambda (λ) values instead of the A/F ratio. Regardless of the fuel or fuel blend, the λ value at the correct stoichiometric A/F ratio for any fuel or fuel blend is always equal to 1.00—therefore with rich mixtures λ is less than 1.00; for lean mixtures λ is greater than 1.00. If tuning for a specific mixture ratio other than stoichiometric, the λ number would then be:

λ = (Desired A/F ratio) ÷ (Stoichiometric A/F Ratio)

So if you need to know what λ is for the 20/80 E85/gas blend at its max rich power A/F ratio:

λ = 11.395 ÷ 13.713 = 0.831

Conversely, if your meter reads out only in A/F ratios, it is probably calibrated just for pure gasoline. If running a different fuel or fuel blend, it will therefore report the A/F ratio inaccurately (since it is measuring residual exhaust oxygen or hydrocarbons, not the actual ratio). This calls for a meter-correction factor, and that’s where the λ number again comes into play. Using the previous equation, simply multiply the meter’s calibrated stoichiometric gasoline A/F ratio of 14.7 by the λ Value for your blend or different fuel’s real-world target A/F fuel ratio. Again, using the 20/80 E85/gas mix as an example, if tuning for the previously calculated max power rich 11.395:1 ratio:

Meter Correction = 14.7 × Target λ Value = 14.7 × 0.831 = 12.22

In other words, if your meter reads out only in A/F ratios and it’s calibrated for standard gasoline—in this example, when you tune for the true 11.385:1 A/F max-power-rich ratio for the blend under discussion—the meter would actually display 12.22:1.

If all this has left you totally confused, the hard-core Pontiac racers at Wallace Racing have a simplified interactive online Air/Fuel Ratio converter (see Contacts below).

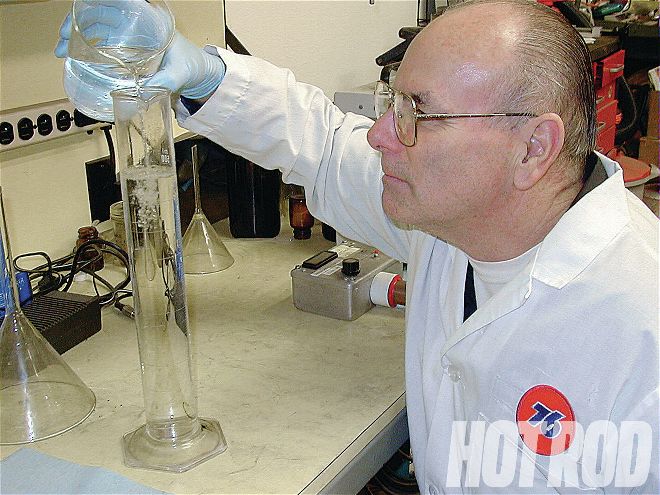

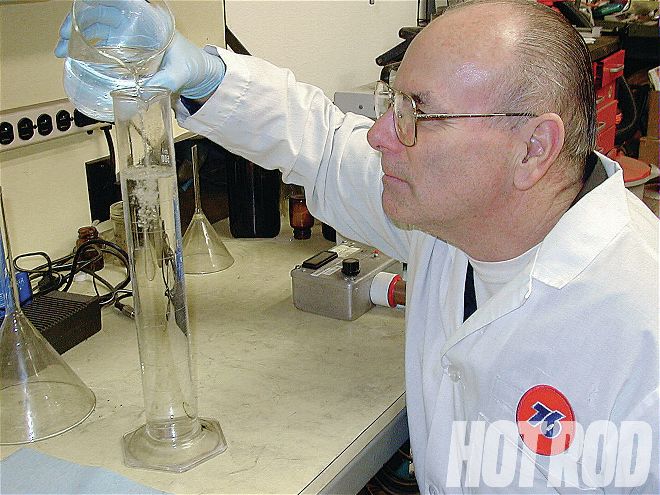

Hard-core chemists and Fuel racers will use a calibrated hydrometer to mix heavy fuel blends, but for street-based, lighter fuel blends, a simple ratio equation plus conversion factors yields reasonably accurate results.

Hard-core chemists and Fuel racers will use a calibrated hydrometer to mix heavy fuel blends, but for street-based, lighter fuel blends, a simple ratio equation plus conversion factors yields reasonably accurate results.

Fuel A/F Lambda (λ) Pure Gasoline Stoichiometric 14.7 1.000 Pure Gasoline Max Power Rich 12.5 0.8503 Pure Gasoline Max Power Lean 13.23 0.900 E10 Stoichiometric 14.08 1.000 E10 Max Power Rich 12.0 0.8523 E10 Max Power Lean 12.7008 0.9020 E15 Stoichiometric 13.79 1.000 E15 Max Power Rich 11.75 0.8521 E15 Max Power Lean 12.4362 0.9018 E85 Stoichiometric 9.765 1.000 E85 Max Power Rich 6.975 0.7143 E85 Max Power Lean 8.469 0.8673 Ethanol Stoichiometric 9.0078 1.000 Ethanol Max Power Rich 6.429 0.7137 Ethanol Max Power Lean 7.8 0.8659 Methanol Stoichiometric 6.45 1.000 Methanol Max Power Rich 4.0 0.620 Propane Stoichiometric 15.7 1.000 Propane Max Power Rich 13.18 0.8395

Source:

Wallace Racing Air/Fuel Ratio Value Converter; WallaceRacing.com/air-fuel-lambda.php

I have a very mild 454 in a 1977 K5 Blazer. I want to run a Quadrajet on it, but I have not been able to find much, if any, information on how to tune them, or where to get parts for them. Can you shed some light on this?

Bo Jangles

Via email

There are all sorts of Q-jet parts vendors, tuners, and restorers. Some of the more prominent include Cliff’s High Performance, QuadrajetParts.com, Jet Performance Products, Sean Murphy Induction, and The Carb Shop. A Google search will turn up even more. Many of these sites also offer online tuning advice and instructions, but I’ve also listed three good Q-jet books below. Prices are via Amazon.com as of January 2013.

I am planning on putting a 200-4R transmission in my 1940 Chevrolet. It has a TH350 right now. Can this trans be set up to run without electronics like the 700-R4 retrofit you covered in the Dec. 2012 Pit Stop column?

Al Aamodt

Horace, ND

Absolutely! All the parts mentioned in that column for running a “normal” 700-R4 without a computer—including the throttle-valve (TV) cable mounting bracket, TV cable, and torque-converter clutch (TCC) lockup wiring kits—also work for the 200-4R. FYI, the 200-4R can use your existing TH350 trans mount, but the mount location is located at approximately the same distance from the front of the case as the mount on a short-extension-housing TH400 transmission (26¾ for the TH400 versus 267⁄8 for the 200-4R).

TCI’s Universal TCC Lock-Up Kit (PN 376600) works on the 700-R4, 200-4R, and non-“E” 4L60 transmissions.

TCI’s Universal TCC Lock-Up Kit (PN 376600) works on the 700-R4, 200-4R, and non-“E” 4L60 transmissions.